- Offer Profile

Many of our competitors´ production plants regard outsourcing as a good idea. Not us. Right from the beginning, our aim has always been to manufacture all the most important components of our products ourselves.

This approach and way of working have also ensured that innovative ideas and further developments have arisen time and again, and these have in turn made a significant contribution towards giving us a technological edge in both design and production.

In all phases of cooperation, from first consulting to after-sales service, you will benefit from their extensive specialist knowledge which is due to the fact that they know our products down to the smallest detail.

Magnetic Centrifugal Pumps

Magnetic Centrifugal Pumps RM

-

- Hmax: 2 mWS

- Qmax: 20 l/min

Motor output: 60 W bis 90 W

Single-phase/three-phase alternating current.

Materials:

- PP black, gray or natural (available with or without additional fillers)

- PVDF black and natural (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(3/30, 5/35, 7/30*) - Hmax: 2 mWS

-

- Hmax: 5 mWS

- Qmax: 60 l/min

Motor output: 120 W bis 180 W

Single-phase/three-phase alternating current.

Materials:

- PP black, gray or natural (available with or without additional fillers)

- PVDF black and natural (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(7/55, 10/80*)

RM 2 type 5/50

-

- Hmax: 4,5 mWS

- Qmax: 75 l/min

Motor output: 125W - 180W

Materials:

- PP black, gray or natural (available with or without additional fillers)

- PVDF black and natural (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(8/60, 10/110, 12/130*)

RM 2D type 16/60

-

- Hmax: 16 mWS

- Qmax: 60 l/min

Materials:

- PP grey

- PVDF natural

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

RM 2U type 5/50

-

- Hmax: 4,5 mWS

- Qmax: 75 l/min

Single-phase/three-phase alternating current.

Materials:

- PP black, gray or natural (available with or without additional fillers)

- PVDF black and natural (without additional fillers)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(7/40, 8/60, 10/100)

RM 3 type 6/140*

-

- Hmax: 6 mWS

- Qmax: 170 l/min

Motor output: 0,37kW 4-pol.

Materials:

- PP black, gray or natural (available with or without additional fillers)

- PVDF black and natural (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(10/120, 12/150, 14/180, 13/300, 16/200, 20/200, 23/200, 28/230*)

RM 4 type 7/220*

-

- Hmax: 7 mWS

- Qmax: 220 l/min

Motor output: 0,55kW 4-pol.

Materials:

- PP schwarz, grau oder natur (mit und ohne zusätzliche Füllstoffe lieferbar)

- PVDF (ohne zusätzliche Füllstoffe)

- Edelstahl

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(9/350**, 35/200, 18/240, 20/300, 24/340, 27/400, 30/400)

RM 4.5 type 10/550**

-

- Hmax: 9 mWS

- Qmax: 800 l/min

Motor output: 2,2kW u. 3,0kW IE2 4-pol.

Materials:

- PP schwarz, grau oder natur (mit und ohne zusätzliche Füllstoffe lieferbar)

- PVDF (ohne zusätzliche Füllstoffe)

- Edelstahl

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(35/800*, 18/550, 23/650, 27/750, 3/850)

RM 5 type 13/1000**

-

- Hmax: 13 mWS

- Qmax: 1200 l/min

Motor output: 4,0kW IE2 + IE3 (4-pol.)

Materials:

- PP gray, black or natural (available with and without additional fillers)

- PVDF (without additional fillers)

Other Features:- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(45/1000, 22/500**, 25/1700, 35/1200)

RM 5 type 40/300

-

- Hmax: 40 mWS

- Qmax: 400 l/min

Motor output: 4,0kW – 5,5kW IE2 (4,0kW – IE3)

Materials:

- PP gray, black or natural (available with and without additional fillers)

- PVDF (without additional fillers)

Other Features:- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(45/400)

Magnetic Centrifugal Pumps RM-KM

RM-KM type 18/240

-

- Hmax: 18 mWS

- Qmax: 320 l/min

Materials:

- PP gray

- PVDF natural

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(20/300, 24/340)

Magnetic Centrifugal Pumps RM-MF

RM-MF 3 type 10/120

-

- Hmax: 14 mWS

- Qmax: 180 l/min

Motor output: 0,55kW MF

Materials:

- PP black, gray or natural (available with and without additional fillers)

- PVDF (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(16/200, 23/200)

RM-MF 4 type 18/240

-

- Hmax: 24 mWS

- Qmax: 350 l/min

Materials:

- PP black, gray or natural (available with and without additional fillers)

- PVDF (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(22/300, 27/400, 30/400, 38/400)

RM-MF 4.5 type 18/550

-

- Hmax: 22 mWS

- Qmax: 750 l/min

Materials:

- PP black, gray or natural (available with and without additional fillers)

- PVDF (without additional fillers)

- Stainless steel

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(27/750, 35/800, 23/650)

Magnetic Centrifugal Pumps RM-MS

RM-MS type 28/200

-

- Hmax: 28 mWS

- Qmax: 300 l/min

Motor output: 1,5kW – 3,0kW IE2 + IE3 2-pol. 1-stufig

Materials:

- PP gray or natural

- PVDF natural

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(65/200, 62/200*, 32/220, 32/300*, 40/300*, 47/200)

Magnetic Centrifugal Pumps RM-TS “safe-to-run-dry”

RM-TS 2 type 5/50

-

- Hmax: 4 mWS

- Qmax: 75 l/min

Motor output: 125W - 180W

Materials:

- PP black (PPS®, PEEK, SIC, PTFE)

- PVDF natural (PPS®, PEEK, SIC, PTFE)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(8/60, 10/110)

RM-TS 3 type 10/120

-

- Hmax: 9 mWS

- Qmax: 130 l/min

Motor output: 0,25kW - 0,55kW 2-pol.

Materials:

- PP black (PPS®, PEEK, SIC, PTFE)

- PVDF natural (PPS®, PEEK, SIC, PTFE)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(12/150, 14/180, 16/200, 20/200)

RM-TS 4 type 18/240

-

- Hmax: 18 mWS

- Qmax: 320 l/min

Motor output: 1,1kW + 1,5kW + 2,2kW IE2

Materials:

- PP black (PPS Ryton®, PEEK, SIC, PTFE)

- PVDF (PPS Ryton®, PEEK, SIC, PTFE)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(24/340, 27/400, 30/400)

Magnetic Centrifugal Pumps RMB and RMS

RMB 3.1 type 12/175

-

- Hmax: 13 mWS

- Qmax: 180 l/min

Motor output: 0,55kW - 0,5kW IE2 (Werkstoff PP)

Materials:

- PP gray

- PVDF natural

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(15/225)

RMS 2.1 type 9/8

-

- Hmax: 8 mWS

- Qmax: 10 l/min

Motor output: 0,37kW

Materials:

- PPS (Ryton®)

- PVDF (without additional fillers)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Different variants available.

(15/10, 35/17, 55/23)

RSPM Pumps

RSPM 1.5 type 15/80

-

- Hmax: 15 mWS

- Qmax: 80 l/min

Materials:

- PVDF (without additional fillers)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

- “speed-controlled”

RSPM 40 canned motor 50/500

-

- Hmax: 50 mWS

- Qmax: 500 l/min

Materials:

- PP black, gray or natural (available with and without additional fillers)

- PVDF (without additional fillers)

Other Features:

- Corrosion-free plastic pumps

- Energy efficient thanks to high overall efficacy of the system (pump / motor)

- Reliable power transmission due to powerful magnetic couplings

Vertical Centrifugal Immersion Pumps

Vertical Centrifugal Immersion Pumps RT

RT-VC 100 type 4/22

-

- Hmax: 4 mWS

- Qmax: 28 l/min

Motor output: 60 W – 90 W

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

- Stainless steel

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(5/45, 7/80, 12/95*)

RT 1.5 type 5/45

-

- Hmax: 5 mWS

- Qmax: 60 l/min

Motor output: 120 W – 180 W

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(10/80*, 7/55)

RT 2 type 5/50

-

- Hmax: 5 mWS

- Qmax: 60 l/min

Motor output: 120 W – 440 W

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

- Stainless steel

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(8/60, 10/110, 12/130*)

RT 3 type 4/100**

-

- Hmax: 4 mWS

- Qmax: 110 l/min

Motor output: 0.25 kW – 1.5 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

- Stainless steel

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(28/220, 14/140, 7/140*, 10/160, 12/150, 14/180, 16/200, 20/200, 25/280*)

RT 4 type 8/350

-

- Hmax: 8 mWS

- Qmax: 300 l/min

Motor output: 1,1 kW – 4,0 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

- Stainless steel

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(18/300, 22/400, 26/400, 32/400)

RT 5 type 9/500**

-

- Hmax: 9 mWS

- Qmax: 650 l/min

Motor output: 1,5 kW – 7,5 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

- Stainless steel

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(28/700, 36/600, 28/1000, 38/800(Tauchkreiselpumpe), 40/600*)

RT 6 type 12/870

-

- Hmax: 12 mWS

- Qmax: 900 l/min

Motor output: 2,2 kW – 22,0 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(9/1000**, 18/1500**, 28/1450, 30/3000, 43/800)

Vertical Centrifugal Immersion Pumps RTM

RTM 3 type 12/150

-

- Hmax: 12 mWS

- Qmax: 200 l/min

Motor output: 0,37 kW – 0,75 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(14/140)

RTM 4 type 24/340

-

- Hmax: 24 mWS

- Qmax: 400 l/min

Motor output: 1,5 kW – 4,0 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(30/340)

Vertical Centrifugal Immersion Pumps RTZ

RTZ type 3 12/150

-

- Hmax: 12 mWS

- Qmax: 200 l/min

Motor output: 0,75 kW bis 1,5 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

Different variants available.

(20/200)

RTZ 4 type 27/400

-

- Hmax: 24 mWS

- Qmax: 400 l/min

Motor output: 1,5 kW – 4,0 kW

All RENNER vertical pumps RT are available with an integrated variable speed drive and with high efficiency motors (IE2 + IE3 + IE4)

Materials:

- PP gray

- PVDF natural

Other features:

- Corrosion-free plastic pumps

- Alternatively also pumps made of stainless steel or titanium

- Energy efficient thanks to high overall efficacy of the system (pump / motor) Vertical centrifugal pumps overview

RENNER Filter Housings

Universal Filter Housings FI

RFI 32 series

-

The RFI 32 filter housings are designed for use with cartridge inserts.

The RENNER universal filter housings are used to remove organic and inorganic impurities through deep and surface filtration of aggressive and neutral liquids and gases.

All universal filter housings are engineered to also accomodate wound cartridges, activated carbon, filter bags and filter plates

- Qmax = 70.000 l/h

Filter surfaces:- 0,02 m2 bis 5,0 m2

Volume:

- 0,02 m2 bis 5,0 m2

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Easy operating thanks to the quick fastening

- Combination possible with the complete range of products

- Low pressure drop

RFI 15 series

-

The RFI 15 universal filter housings are suitable for cartridge and plate inserts.

The RENNER universal filter housings are used to remove organic and inorganic impurities through deep and surface filtration of aggressive and neutral liquids and gases.

All universal filter housings are engineered to also accomodate wound cartridges, activated carbon, filter bags and filter plates

- Qmax = 70.000 l/h

Filter surfaces:- 0,02 m2 bis 5,0 m2

Volume:

- 0,02 m2 bis 5,0 m2

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Easy operating thanks to the quick fastening

- Combination possible with the complete range of products

- Low pressure drop

Different variants available.

RFI 1 series

-

The RFI 1 universal filter housings are suitable for cartridge, plate, bag and activated carbon inserts.

The RENNER universal filter housings are used to remove organic and inorganic impurities through deep and surface filtration of aggressive and neutral liquids and gases.

All universal filter housings are engineered to also accomodate wound cartridges, activated carbon, filter bags and filter plates

- Qmax = 70.000 l/h

Filter surfaces:

- 0,02 m2 bis 5,0 m2

Volume:

- 0,02 m2 bis 5,0 m2

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Easy operating thanks to the quick fastening

- Combination possible with the complete range of products

- Low pressure drop

RFI 4 series

-

The RFI 4 universal filter housings are suitable for cartridge, plate, bag and activated carbon inserts.

The RENNER universal filter housings are used to remove organic and inorganic impurities through deep and surface filtration of aggressive and neutral liquids and gases.

All universal filter housings are engineered to also accomodate wound cartridges, activated carbon, filter bags and filter plates

- Qmax = 70.000 l/h

Filter surfaces:

- 0,02 m2 bis 5,0 m2

Volume:

- 0,02 m2 bis 5,0 m2

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Easy operating thanks to the quick fastening

- Combination possible with the complete range of products

- Low pressure drop

Different variants available.

HR-RF series

-

The HE-RF filter series is characterized by its novel flow concept, which was developed using detailed CFD simulations. The result is significantly higher separation rates with a smaller filer housing. The filter input and output are directed vertically downwards for direct flow to a pump. An integrated handle makes it easier to open the filter cover. The filter cartridges can be changed quickly and without any tools.

- Qmax = 70.000 l/h

Filter surfaces:

- 0,02 m2 bis 5,0 m2

Volume:

- 0,02 m2 bis 5,0 m2

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Easy operating thanks to the quick fastening

- Combination possible with the complete range of products

- Low pressure drop

Quick change Filter Housings SF

RSF 3 series

-

The line of products SF has proofed to be extremely reliable for use in chemical plants. These filters are characterised by compact design as well as easy and quick handling thanks to the quick fastenings, which notably reduce time for maintenance. All quick change filters are supplied with two safety switches, which prevent the filters from working without or with an open cover.

- Qmax = 24.000 l/h

Filter surfaces:

- 0,05 m2 – 0,2 m2

Volume:

- 2,0 dm3 – 13,5 dm3

Lengths:

- 10 “

- 20“

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

Other features:

- Solid plastic version

- Easy operating thanks to the quick fastening

- Reduced time for maintenance

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

RSF 1 series

-

The line of products SF has proofed to be extremely reliable for use in chemical plants. These filters are characterised by compact design as well as easy and quick handling thanks to the quick fastenings, which notably reduce time for maintenance. All quick change filters are supplied with two safety switches, which prevent the filters from working without or with an open cover.

- Qmax = 24.000 l/h

Filter surfaces:

- 0,05 m2 – 0,2 m2

Volume:

- 2,0 dm3 – 13,5 dm3

Lengths:

- 10 “

- 20“

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

Other features:

- Solid plastic version

- Easy operating thanks to the quick fastening

- Reduced time for maintenance

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

RENNER Filter Systems

Universal Filter Systems

Unit 1 series (Example)

-

In close cooperation with our customers, individual requirements are taken into account during project planning, interfaces are defined and desired specificities are developed constructively. The customer receives his individual, ready-to-install function module.

- Qmax = 70.000 l/h

Volume:

- 1 dm³ bis 185 dm³

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Customized package solution

- Supports use of different filter elements

- Extensive performance range

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

Unit 2 (Example)

-

In close cooperation with our customers, individual requirements are taken into account during project planning, interfaces are defined and desired specificities are developed constructively. The customer receives his individual, ready-to-install function module.

- Qmax = 70.000 l/h

Volume:

- 1 dm³ bis 185 dm³

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Customized package solution

- Supports use of different filter elements

- Extensive performance range

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

Unit 3 (Example)

-

In close cooperation with our customers, individual requirements are taken into account during project planning, interfaces are defined and desired specificities are developed constructively. The customer receives his individual, ready-to-install function module.

- Qmax = 70.000 l/h

Volume:

- 1 dm³ bis 185 dm³

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Customized package solution

- Supports use of different filter elements

- Extensive performance range

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

Unit 4 (Example)

-

In close cooperation with our customers, individual requirements are taken into account during project planning, interfaces are defined and desired specificities are developed constructively. The customer receives his individual, ready-to-install function module.

- Qmax = 70.000 l/h

Volume:

- 1 dm³ bis 185 dm³

Lengths:- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Customized package solution

- Supports use of different filter elements

- Extensive performance range

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

Unit 3 (Example)

-

In close cooperation with our customers, individual requirements are taken into account during project planning, interfaces are defined and desired specificities are developed constructively. The customer receives his individual, ready-to-install function module.

- Qmax = 70.000 l/h

Volume:

- 1 dm³ bis 185 dm³

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Vast range of products

- Solid plastic version

- Customized package solution

- Supports use of different filter elements

- Extensive performance range

- Cleaning of electrolytic baths by means of activated carbon

- Removal of external metal from electrolytic baths

- Recycling of precious metals from flush water

RENNER Filter Pumps

Horizontal and Vertical Filter Pumps

RFI/RMI 32 series

-

Renner magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

RFI/RMI 15 series

-

Renner magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

Different variants available.

RFI/RMI 1 series

-

Renner magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

RFI/RMI 4 series

-

Renner magnetic filter pumps consist of a combination of magnetically coupled centrifugal pumps RM and filter housings FI. The units are individually tailored to your application and delivered ready to use. Thanks to our efficient organizational structure, we develop these particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

Other variants available.

SF 3 + RT 5

-

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

Different variants available.

SF 1 + RT 5

-

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

Different variants available.

SF 1 + RT 3

-

RENNER vertical filter pumps are made up of RT vertical centrifugal pumps and RFI or RSF filter housing. They com ready for operation mounted on flange ready for installation directly into process tanks. When compared to filter pumps installed outside of the tank, there is a significant savings on both space an piping. Thanks to our efficient organizational structure, we develop theses particularly economically.

- Qmax = 70.000 l/h

Volume:

- 2,37 m3 – 13,5 m3

Lengths:

- 4″

- 10″

- 20″

- 30″

- 40″

Materials:

- PP gray or natural (available with or without fiber glass)

- PVDF natural (no fiber glass)

- ECTFE

- Plexiglas®

- Jenaer Glas®

- Stainless steel (1.4305, 1.4571)

- Titanium

Other features:

- Density:

up to max. 2.0 kg/dm3 - Viscosity:

up to max. approx. 160 mPas (cP) - Acid and alkaline solutions, mixtures

- Solvents

Filter Elements

Filter Cartridges

Activated carbon filter cartridges

-

Activated carbon filter cartridges are equipped with steam-activated hard coal pellets and are especially designed for heavily contaminated liquids. Due to the bulk form, no blocking of the activated carbon surface by coarse dirt is possible and the period of use is extremely long.

Filter micron rating:

- 1 µm – 1.000 µm (Standard)

Diameter:

- inside diameter: ca. 27 mm

- outside diameter: 64,5 mm at DOE

Lengths:

- 250 mm

- 500 mm

- 750 mm

- 1.000mm

Materials:

- Medium: cylindrically shaped hard coal (pellets)

- Backing/Center: polypropylene

- Casing pipes: polyethylene, sintered

Application:

- Water

- Odour and taste neutralisation

- Dechlorination

- Electroplating

- Hot liquids

- Solvent

- Viscose liquid

- Superheated steam

- Oxidant (z.B. potassium permanganate, hydrogen peroxide, nitric acid etc.)

EPDM sealing (flat seal for DOE)

Metal mesh filter cartridges

-

Metal mesh filter cartridges are special cartridge filters made of stainless steel. they are used when plastic filter cartridges are unsuitable, e.g. at high operating temperatures or in connection with certain chemicals as well as in proceses that take place at high pressures. They are also known as surface filters.

Filter micron rating:

- 1 µm – 1.000 µm (Standard)

Diameter:

- inside diameter: ca. 27 mm

- outside diameter: 64 mm at

Mesh surface:

- Standard:

ca. 500 cm2 - Pleated:

ca. 1.500 cm2

Material:

- Mesh, center, end caps: stainless steel1.4301

Max temperature:

- up to 200 °C for water und static conditions (limited by sealing material)

Application:

- Hot liquid

- Solvent

- Viscose liquid

- Superheated steam

- Oxidant (z.B. posassium permanganate, hydrogen peroxide, nitric acid, etc.)

Polypropylene mesh filter cartridges

-

The polypropylene mesh filter cartridges is a cersatile reusable filter element made of polypropylene fabric.

It is easy to clean and can be quickly voncerted to other lenghs and/or finenesses using the modular principle with a few components and little effort.

Filter micron rating:

- 15 µm – 300 µm (Standard)

Volume:

- 2,37 m3 – 13,5 m3

Lengths:- 10“

- 20“

- and desired length on request

Material:

- Fabric, center and end caps: polypropylene

Application:

- PCB production

FKM and EPDM sealing

Membrane filter cartridges

-

Membrane filter cartridges use a polyethersulfone membrane and can therefore filter ultra-fine particles down to bacteria.

They have special adsorption properties and are produced under strictly controlled maufacturing conditions in a clean room.

Filter micron rating:

- 0,2 µm – 0,45 µm (Standard)

Diameter:

- inside diameter: ca. 28 mm

- outside diameter: 69 – 71 mm

Lengths:

- 9 ¾“

- 10“

- 20“

- 30“

- 40“

Max Temperature:

- up to 70 °C for water under static conditions

Materials:

- Membrane: polyethersulfone

- Center und Drainage: polypropylene

Application:

- Ultra pure water

- Sterile filtration

- Cosmetics

- Microelectronics

- Ultra pure chemicals

- Drinks industrie

- Food

- Solvent

Pleated depth filter cartridges

-

The microfibres used in the pleated depth filter cartridges are particularly uniform and are thermally bonded to from a homogeneous filter layer.

The resulting micropolypropylene filter matrix is considered to be the most effective deep cartridge filter and has the highest efficiency for very difficult to filter fine particles.Filter micron rating:

- 0,2 µm – 75 µm (Standard)

Diameter:- inside diameter: ca. 28 mm

- outside diameter: 69 – 71 mm

Lengths:

- 9 ¾“

- 10“

- 20“

- 30“

- 40“

Max temperature:

- up to 82 °C for water under static conditions in long-term operation

Material:

- Polypropylene

Application:

- Ultrapure water

- Drinks industry

- Fine chemistry

- Semiconductor industry

- Cosmetics

- High purity chemicals

Depth filter cartridges Type R-CX (absolute filter)

-

The R-CX depth filter cartridge is the premium product among the “melt-blown filter cartridges”. Only precisely defined microfibers from a special recipe of bi-components are used in the melt-blown process for the production of these 3D-absolute filters.

Filter micron rating:

- 0,5 µm – 100 µm (Standard)

Diameter:

- indside diameter: ca. 30 mm

- outside diameter: 66 mm

Lengths:

- 250 mm

- 500 mm

- 750 mm

- 1.000 mm

Max temperature:

- up to 80 °C for water under static conditions

Material:

- Bi-components of polypropylene und polyethylene

Application:

- Food and beverage industry

- PCB industry

- Paint and varnish manufacturers

Depth Filter cartridges Type R-HP

-

These depth filter cartridges are known for their particularly long service life. Due to its thermally bonded microfibers, the depth filter cartridge is known as a unique quality product that cannot release fibers into the filtrate and also has extremely long service life.

Filter micron rating:

- 1 µm – 75 µm (Standard)

Diameter:

- inside diameter: ca. 28,5 mm

- outside diameter: 63 mm

Lengths:

- 9 ¾“

- 10“

- 19,5“

- 20“

- 29 ¼“

- 30“

- 39“

- 40“

Max temperature:- up to 70 °C for water under static conditions

Material:

- Polypropylene

Application:

- Food and beverage industry

- Electroplating

- Water

Wounded filter cartridges

-

The microscopic structure of the filter medium is one of the decisice factors for the separation efficiency and filter life of wound cartridges.

Filter micron rating:

- 1 µm – 600 µm (Standard)

Diameter:

- inside diameter: ca. 27,2 mm

- outside diameter: 64 mm

Lengths:- 4“

- 10“

- 20“

- 30“

- 40“

Materials:

- Thread:

wahsed polypropylene, high pressure washed polypropylene, cotton / viscose, fiberglass, polyester, Nylon®

- Centre:

Polypropylene oder stainless steel

Application:

- Galvanic bath

- Food and beverage industry

- Coolant

- Chemistry

Filter Bags and Papers by RENNER

Filter bags by RENNER

-

Filter bags are a widespread alternative to filter cartridges and particularly easy to handle. Because the debris remains inside the filters and when changing the bag the dirt is also eliminated – the bag filter housing remains clean on the filtrate side. Key applications include paints and coatings, chemicals and the food processing industry.

Filter micron rating:

- 1 µm

- 5 µm

- 10 µm

- 25 µm

- 50 µm

- 100 µm

Lengths:

- 20“ (Standard)

Material:

- Polypropylene

Application:

- Water filtration

- Food and beverage industry

- Paints and Coatings Industry

- Chemical industry

- Coolants

- Solvents

- Pickling baths

- Degreasers

- Sewage

Filter paper 550 g/m²

-

Filter paper is a widely used filter medium, especially in the galvanic industry, and is available in thin or thick as well as in an activated carbon version. Our filter papers are available in all common sizes – please specify your desired dimensions when requesting.

Weights:

- 90 g/m2 (thin)

- 390 g/m2 (thick)

- 550 g/m2 (activated carbon)

Sizes:- All standard sizes are available

Materials:

- Cellulose

- Cellulose impregnated with activated carbon

Application:

- Galvanic baths

Different variants available.

Absorption Media for Filters by RENNER

Absorption media

-

dsorption media are a kind of pre-filters based on polypropylene, which are integrated in the actual filtering process. RENNER differentiates “Spaghetti filters” of microfiber and “Angel hair” comprising fiber flakes.

Design:

- Spaghetti as microfiber strips

- Angel hair as individual microfibers in flakes

Materials:- Polypropylene

Application:- Degreasing and phosphating

- Oil emulsion

- Pickling preparation

- Suspensions with Sn (+II / + IV)

- Acid baths

Electronic Process Protection

RPR-Control 100-1

-

Features:

- For switching cabinet installation (DIN rail mounting)

- Without programming unit

RPR-Control 100-2

-

Features:

- For switching cabinet installation (DIN rail mounting)

- With integrated programming unit

RPR-Control 100-3

-

Features:

- Field unit with power unit up to 4.0 kW (optional 7.5 kW)

- Installation in IP65 housing directly on the equipment (e.g. on the filter unit)

- Complete with signal lamps and pusbuttons

- Without programming unit

Seperate programming unit

-

Features:

- As a hand-held device with cable and plug

- For RPR-Control 100-1 and 100-3

- For programing the switching values

Accessories by RENNER

Accessories for Pumps and Filters

Motion automation

-

Features:

Continuous forward and backward movement of objects with a push rod. The drive is carried out via a motor with a protective low voltage of 24 V, and on request also with infinitely variable speed.Material:

- Polypropylene

Application:

- Moving parts in a small electroplating shop

- Polypropylene

Flow control

-

Features:

The device is used to monitor the flow in pipelines and thus prevent pumps from running dry. The instalation is carried out directly in the pipelne. A float triggers a signal when the pressure line has flowed through.

Fitting:- DN25

- DN32

- DN40

Materials:

- PP

- PVDF

Application:

- Monitoring device for magnetically coupled centrifugal pumps to protect against dry running.

Differential pressure switch

-

Features:

The device monitors a limit value for the pressure difference between the input and the output. the level of which can be adjusted in a wide range.

Application:

- Monitoring of the differential pressure in closed systems. Especially for pump and filter monitoring as protection against overheating and / or indicator of filter contamination.

Paper support plate

-

Paper support plate for filter paper.

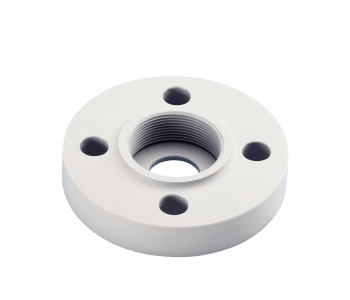

Flange for suction and pressure side

-

Connections:

Connection dimenstions DIN 2501 / ANSI B16.5:

- DN20

- DN25

- DN32

- DN40

- DN50

- DN65

- DN80

- DN90

- DN100

Angular hose coupling

-

Diameter:

Outside-Ø:

- 13 mm

- 18 mm

- 21 mm

- 26 mm

- 32 mm

- 40 mm

- 50 mm

Hose coupling straight

-

Diameter:

Outside-Ø:

- 13 mm

- 18 mm

- 21 mm

- 26 mm

- 32 mm

- 40 mm

- 50 mm

Holding screw

-

Thread/SW:

- G 3/4”

- SW 28

Materials:

- PP

- PVDF

Staining screw

-

Thread/SW:

- M 8 x L: Lmin. = 20 mm

- M 10 x L: Lmax. = variable

Materials:

- Screw: A2, A4, Titanium

- Grip: PP

Plastic screw

-

Thread/SW:

- M 6 up to M 12

- Different thread lengths available

Materiasl:

- PP

- PVDF

Tension nut

-

Threat/SW:

- M8

- M10

Materials:

- Nut : A2, A4, Titanium

- Grip: PP

Cap nut

-

Features:

Nut overmoulded with plastic according to DIN EN 24 032Threat/SW:

- M 6 / SW 14

- M 8 / SW 19

Materials:

- PP/A4

- PP/Titanium

- PVDF/A4

- PVDF/Titanium

Industry Sectors

Renewable energies

-

RENNER pumps for renewable energies, solar cell production and energy storage systems

Energy storage systems are an important element in the transition to power supply of renewable energy. Our pumps play a valuable role in the production of solar cells in wet processes as well as in the circulation of electrolytes in energy storage systems.

PCB industry

-

RENNER pumps for PCB industry

Our corrosion-resistant pumps and filters have a proven record of delivering and discharging solutions for numerous companies around the globe.

Regardless of whether developing, etching, stripping or purging – RENNER pumps always ensure the necessary pressure in spray processes and sufficient volume of flow during flooding or circulating processes. Undesirable dirt particles are captured by Renner filters to protect the PCB. For filter replacement without extended interruption in production, we have developed special locking mechanisms to help significantly increase your plant‘s productivity.

Electroplating and surface finishing

-

RENNER pumps for electro-plating and surface finishing

Our pumps and filters enable processes for surface finishing. They are used in rack as well as in drum processing. Depending on purpose, they are manufactured in a variety of materials. Transfer of aggressive or toxic liquids is never a problem.

Water treatment and environmental engineering

-

RENNER pumps for renewable energies, solar cell production and energy storage systems

A wide range of different filtering techniques enable the transfer of highly contaminated water polluted with suspended solids. Examples include specially designed pumps for gas and exhaust air scrubbers. Our products and solutions are used worldwide in wastewater treatment, landfill drainage, water supply and in distance heating

Chemical and lab technology

-

RENNER pumps for chemical industry and lab technology

Many processes require reliable transfer of aggressive media (acids, bases, solvents). Our pumps are corrosion resistant and chemical-resistant due to the use of different materials. They are therefore suitable for tanker flushes as well as for filling and supplying of chemicals from storage tanks.

Agriculture

-

Agriculture

Reliable pump performance under severe operating conditions – this is what RENNER pumps are for. Our maintenance free pumps ensure a smooth transfer of pesticides and fertilizers as well as for livestock irrigation systems.

Food and beverage industry

-

RENNER pumps for food and beverage industry

Breweries and dairies rely on RENNER solutions for cleaning their extensive piping systems. Our pumps are serving in a host of other process applications such as in large bakeries for applying lye to pretzels.

Pharmaceutical industry

-

RENNER pumps for pharmaceutical industry

In the strictly controlled pharmaceutical industry, purity of all products must be guaranteed. Our hermetically sealed pumps do their part to ensure that there is no entry of air during transfer.

Refrigeration and heat exchangers

-

RENNER pumps for refrigeration, heat exchangers and thermal power stations

Whether coolants or water with additives – our pumps are well suited for all requirements in cold and heat applications.

Nuclear technology

-

RENNER pumps for nuclear technology

Nuclear technical processes depend on 100 % safe cooling circuits. Our maintenance free pumps guarantee the required reliability in this critical area.

Semi-conductor industry

-

RENNER pumps for semi-conductor industry

In clean-room environments, high demands are placed on pumping systems. Hermetically sealed pumps from Renner provide the best conditions for these applications; for example, wafer manufacturing or in the treatment of silicon by means of spraying or dip etching.

Mobile applications

-

RENNER pumps for mobile applications

RENNER solutions for mobile applications are tried and tested every day, for example, on ships for waste water treatment or in cooling systems. In the aerospace industry we supply, among other things, accessories for engine cleaning systems.