- Offer Profile

- LLA Instruments GmbH & Co. KG

(LLA) develops and manufactures analytical spectral imaging process

technology, hyperspectral cameras and optical spectrometer for R&D. The

company is established as a reliable partner for sensor-based sorting

technology especially for the evaluation of material in production.

LLA is market leading in the area of hyperspectral imaging for industrial usage.

Analytical process equipment and user-friendly control software are developed and manufactured at a technologically advanced level. A qualified and highly motivated team is permanently working for high product standards. NIR spectrometer and LIBS technology are available inhouse for test measurements. In the LLA technicum; samples can be investigated by NIR process technology on semi-automatic conveyor belts.

SPECTROMETER & CAMERAS

-

LLA Instruments GmbH & Co. KG (LLA) is a world wide

manufacturer of process analytical technology for the recycling industry,

R&D and laboratory applications. The product portfolio includes NIR

hyperspectral imaging camera technology as well as UV-VIS hyperspectral

imaging camera, multiplexed NIR spectrometer and Echelle spectrograph for

LIBS applications.

LLA' s NIR technology is made for high-speed identification and analysis in processes or single measurements in laboratory. Hyperspectral Camera

-

High-speed material identification by hyperspectral

imaging cameras. Process analytical technology (PAT) and chemical imaging by

NIR & UV-VIS.

LLA Instruments GmbH provides high-speed analysis technology for sorting processes in plants as well as quality control applications in laboratory, science and R&D.

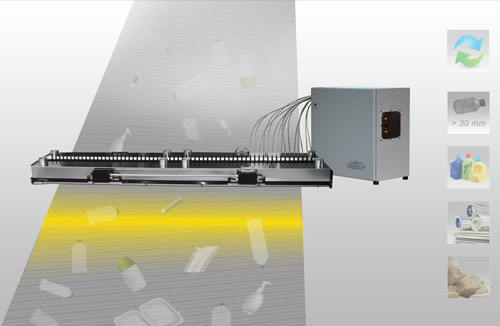

KUSTAx.xMSI - NIR hyperspectral imaging cameras for recycling

- High-speed identification and analytical imaging in

sorting processes

The hyperspectral cameras KUSTA1.7MSI, KUSTA1.9MSI and KUSTA2.2MSIsens (KUSTAx.xMSI) are designed for the identification and the subsequent sorting of materials from waste collections (recycling).

KUSTA1.7MSI and KUSTA2.2MSIsens are particularly suitable for the identification of fine grained materials (flakes, agglomerates, granulates) of a few mm in diameter on fast moving conveyor belts. Whether the hyperspectral camera KUSTA1.7MSI or KUSTA2.2MSIsens is proposed depends on the NIR absorption characteristics of the material to be analysed.

The high sensitivity of the hyperspectral camera KUSTA1.9MSI permits applications like:- PVC elimination of PET-flakes

- Identification of thin foils in mixed plastics

- Detection of additives in plastics

- Paper analysis

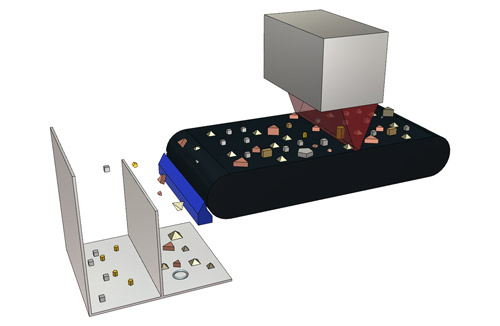

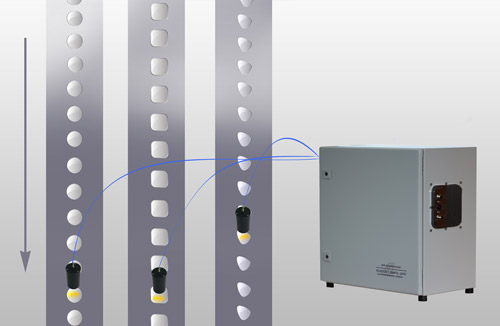

Schematic illustration of a sorting plant

The sorting material is moving on a conveyor belt with a speed of up to 2.5 m/s towards the hyperspectral camera KUSTAx.xMSI. The material is analysed passing below illumination unit and hyperspectral camera. The analysis result is forwarded to process control which controls the nozzles located at the end of the conveyor belt. Depending on the identification result, the material is passed through or ejected by the nozzles.

uniSPECx.xHSI - NIR hyperspectral imaging cameras for science & industry

- High-speed real time analysis and chemical imaging

The high performance hyperspectral cameras uniSPEC1.7HSI, uniSPEC1.9HSI and uniSPEC2.2HSIsens are predominantly used in industrial applications for quality control.

The cameras are characterised by their high analytical precision and can therefore be used for a variety of demanding identifications like analytical tasks of small grained materials (> 2 mm) or chemical imaging of objects with structured material composition. Semi-quantitative analysis in minerals industry, quality control of food and monitoring of coating processes are further applications of LLA high performance hyperspectral cameras.

Further, scientific applications are possible, i.e. uniSPECx.xHSI may be used in R&D.

uniSPEC0.9HSI - Ultraviolet-visible hyperspectral camera for analytical imaging

- The ultraviolet-visible (UV-VIS) hyperspectral camera

uniSPEC0.9HSI is the latest member of LLA´s product line of hyperspectral

camera systems uniSPECx.xHSI, especially designed for applications in the

ultraviolet and visible spectral ranges.

Using this new CMOS-based technology, it is now possible to perform analysis in a wavelength range from 350 nm to 950 nm. The camera was developed for a multiplicity of applications, ranging from industry to scientific laboratory experiments, such as:- Analytical measurements (color-analysis, process and quality control),

- Identification of minerals,

- Food inspection and sorting,

- Life Science (fluorescence, screening, ...)

The UV-VIS hyperspectral camera uniSPEC0.9HSI is equipped with a configurable CMOS sensor and can be operated in several different measurement modes, hence matching the camera´s spatial and spectral resolutions to the requirements of any application.

Furthermore, the UV-VIS hyperspectral camera uniSPEC0.9HSI is available in two versions an enhanced spectral resolution version (uniSPEC0.9HSI_w) and high spatial resolution version (uniSPEC0.9HSI_s).

The UV-VIS hyperspectral camera uniSPEC0.9HSI can be combined with the NIR-hyperspectral cameras uniSPECx.xHSI, providing coverage of the full wavelength range from UV to NIR. The data format and user interface are similar to those already used in LLA Instruments´ NIR hyperspectral cameras; hence, the new UV-VIS hyperspectral camera uniSPEC09.HSI can easily be integrated in pre-existing systems.

uniSPECx.xFOM - Fiberoptic NIR hyperspectral cameras

- Multi

point measurement for analytical quality control

The NIR hyperspectral cameras uniSPEC1.7FOM, uniSPEC1.9FOM and uniSPEC2.2FOM (uniSPECx.xFOM) combine LLA Instruments’ NIR hyperspectral imaging technology (e.g. uniSPECx.xHSI) and fibre optics instead of an objective as optical element.

The fibre optical hyperspectral camera is advantageous in case small installation heights are requested for large conveyor belt widths. The flexibility of the fibre cables enables e.g. online quality control of finished products on various conveyor belts which may even be many meters apart from each other. Generally, uniSPECx.xFOM and uniSPECx.xHSI are suitable for the same application fields.

The uniSPECx.xFOM can be equipped with up to 64 optical fibre cables. The optical fibre cables consist of low-OH quartz material, enabling a high speed transmission of NIR radiation to the spectrometer. The high frame rates of the uniSPECx.xFOM (270 Hz for uniSPEC1.7FOM and uniSPEC2.2FOM; 795 Hz for uniSPEC1.9FOM) ensure a better performance at high conveyor belt speeds compared to the multiplexed NIR spectrometer uniSPECx.xMPL-24V.

The uniSPECx.xFOM is integrated into a control cabinet including optical fibre cables, splice box and an industrial PC for camera control. The industrial PC includes camera control software and pre-configured application software, depending on analysis (sorting) task. The control cabinet has a degree of protection level of IP54 (camera itself IP 65).

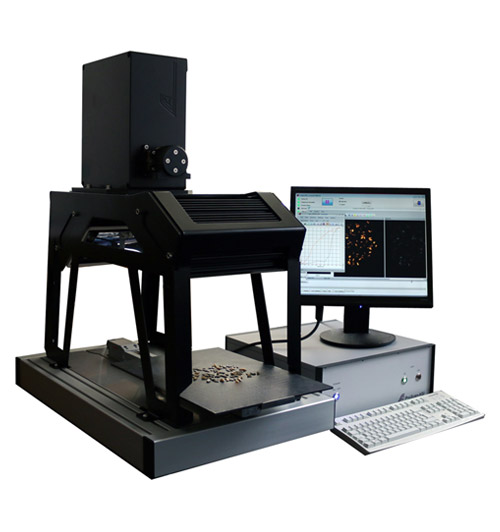

Compact Hyperspectral Scanner - ProScan-HSI

-

Solution for high-resolution Hyperspectral Imaging

ProScan-HSI is the newest process-dedicated system developed by LLA Instruments GmbH & Co. KG (LLA).

Based on the combination of LLA´s high performance hyperspectral imagers, a rapid scanning table and an optimised line-illumination system, ProScan-HSI is the perfect solution for laboratory users or process developers who want to perform rapid chemical imaging analysis of small to medium-sized samples, at high spectral and spatial resolution.

The transportable scanner unit is fully compatible with any of the hyperspectral cameras in LLA´s portfolio, hence allowing to work on various wavelength ranges from 400 nm until 2.2 µm, depending on the application. ProScan-HSI can also be equipped with two different optics, giving either access to a wide field of view (320 mm), or to a

higher spatial resolution (down to 50 µm/pixel).

The system was developed to offer the highest level of modularity in terms of spectral bandwidth and resolution, along with user-friendliness:- Position the sample on the scanning table,

- Start the scan and

- Within seconds the results of the analysis are available.

Of course, ProScan-HSI is fully compatible with the data-processing software suite developed by LLA, and can also be delivered with the Prediktera´s software EVINCE for quick and easy visualisation.

LLA offers a variety of pre-configured applications for different industries. Customised application design is available upon request.

Scope of Delivery- Hyperspectral camera,

- Imaging optics,

- Scanning table, housing, side cover

- Double-sided halogen illumination unit,

- Control computer,

- White calibration standard,

- LLA´s control software KustaMSI,

- LLA´s spectral analysis software KustaSpec,

- LLA´s visualisation software KustaBelt,

- Optional: Prediktera´s hyperspectral analysis software EVINCE

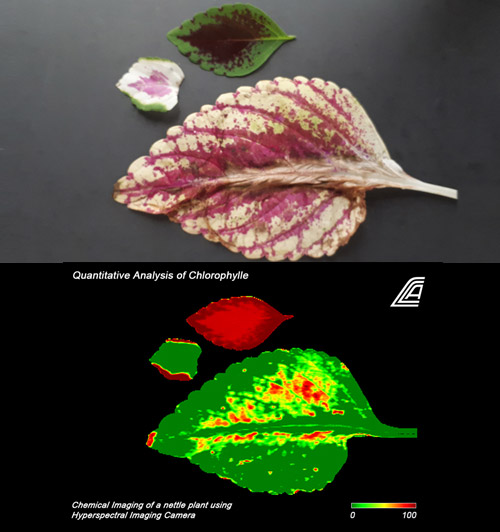

ProScan-HSI - Compact Hyperspectral Scanner

Application Example of qualitative and quantitative Analysis of Poultry

Application Example of quantitative Analysis

Multiplexed NIR spectrometer technology

-

NIR identification in sorting processes

Multiplexed NIR spectrometer are widly used for the identification of plastic material in recycling plants. Waste collections from e.g. household waste are identified and analysed by an optical spectrometer and can therefore be sorted out.

KUSTA1.9MPL-24V - Multiplexed NIR spectrometer for recycling

- Material identification in sorting plants

Multiplexed NIR spectrometer KUSTA1.9MPL-24V (formerly KUSTA1.9MPL) is a fast scanning near-infrared sensor, which is used for the identification of bulk solids in sorting plants. On a conveyor belt the singulated material is passed by under the illumination unit and the reflected radiation is transferred to the optical multiplexer via fiber cables. The multiplexed spectrometer scans the 64 measuring tracks at frequencies of up to 70 Hz and sends the identification results to the process control via an ethernet protocol.

KUSTA1.9MPL-24V is mainly used in plastic- and waste paper recycling. Depending on the application certain standard identification routines are included, which enable to reject several material types referring to freely selectable criteria.

In the version “-24V”, which is available from January 2016, the optical multiplexer, the spectrometer and the RGB sensor come in a separate housing of protection degree IP65, which can be mounted directly at the probe. Due to the high scan rate, materials on even 2 to 3 m wide conveyor belts can be identified at speeds of up to 3 m/s. For the detection of smaller particles (< 30 mm in diameter) hyperspectral imaging cameras KUSTAx.xMSI are recommended.

uniSPEC1.9MPL-24V - Multiplexed NIR spectrometer for science

- NIR technology for quality control

Multiplexed NIR spectrometer uniSPEC1.9MPL-24V (former uniSPEC1.9MPL) was developed for analytical evaluation of material in the production process. Due to the high spectral resolution, these NIR spectrometers are ideal tools for scientific applications. Additionally, a high luminous intensity and a large sensitivity of the spectrometers are perfect properties for the use in quantitative- and rapid analysis applications of material streams.

The spectrometer are widely used as online analytics in food industries, plastics- and paper industry, for thickness measurement in control of coatings, the quality control in mineral industry and many more. Depending on the application, uniSPEC1.9MPL-24V is utilised. LLA advises the best fitting device for the customised application.

For each application, customised analysis modules are developed. Additional control software for the NIR spectrometer is custom-built and scope of delivery. The user interface can be designed and customised. The software can be used to store measured information for a future analysis or to change parameters in working processes.

The multiplexed NIR spectrometer can be connected to probe lines (64 measurement tracks) via fiber cables. Thereby a spatially resolved recording of material streams is generated.

In real time, analytical results will be automatically forwarded to a subsequent control system (e.g. nozzle control system) by a standardised interface (e.g. Profibus, Ethernet). This ensures a reliable identification and ejection of defective material (impurities, rejects, extraneous material).

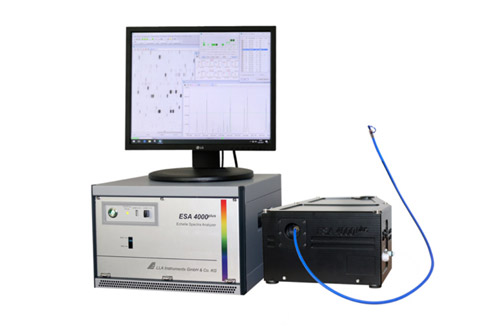

Echelle Spectrometer - ESA 4000plus

-

The Echelle spectrometer / Echelle spectrograph ESA 4000plus is a

compact device based on an ICCD camera for UV/VIS measurements. The device

can be coupled with different radiation sources (e.g. lasers) for atomic

spectroscopy applications.

A spectral resolution in the pm range is achieved within the spectral range from 200 nm to 780 nm or 191 nm to 420 nm. The ESA 4000plus is the successor of the Echelle spectrographs ESA 3000 and ESA 4000, now including an updated electronic unit for controlling any kind of external excitation sources.

Furthermore, the camera board has been re-designed to reduce the readout noise significantly.

ESA 4000plus is widely used for research and development as well as quality control purposes.

Echelle Spectrometer ESA4000plus with electronic control unit (Industrial PC, fast pulse generator and cooling unit) available as LAB and OEM model:- ESA 4000plus – LAB Basic device, tabletop unit for use in and outside laboratory

- ESA 4000plus – OEM 19” rack configuration for industrial process integration

LIBS-analysis of material composition of technical glasses or micro analytical evaluation of tool steel.

ESA 4000plus – LAB

ESA 4000plus – OEM 19”

RGB line scan camera - uniScanRGB

-

The RGB line scan camera uniScanRGB is suitable for color machine vision

applications. The camera is based on newest CMOS chip technology. The high

sensitivity CMOS sensor is characterised by:

- Minimised noise level

- High image contrast

- Low power consumption

The high effective resolution of 2048 tracks combined with a digital resolution of 12 bit and a full frame rate of 260 Hz to 850 Hz provide an outstanding performance of uniScanRGB. Even smallest objects are scanned in detail at high frame rates, enabling the usage of uniScanRGB in sorting and screening applications requiring both: high resolution and high speed. The RGB line scan camera is equipped with an industrial proof RGB objective lens and integrated into an IP 65 rated housing, enabling maintenance-free 24h/7d operation. Several binning modes for the combination of the RGB line scan camera with hyperspectral cameras KUSTAx.xMSI or uniSPECx.xHSI are available. The dynamic range is then increased to 16 bit, enabling a better performance at unfavourable lighting conditions.

Included in delivery is a preconfigured industrial PC with camera control and analysis software. The analysis software can be customised for specific tasks including sorting and monitoring applications. Prior to data evaluation, the software transfers the RGB data automatically into the user-friendly HSV-colour model. The analysis result is sent to an external process control unit (e.g. SPS control) via standard Gigabit Ethernet interface in real-time. In addition to the type code, the HSV information is available as well.

Possible Applications:- Color sorting of material streams,

- Surface inspection of natural materials,

- Monitoring,

- Scanning

The RGB line scan camera uniScanRGB can be additionally equipped with:- Illumination unit PMAmsi,

- Installation bridge,

- Automatic calibration unit CUa

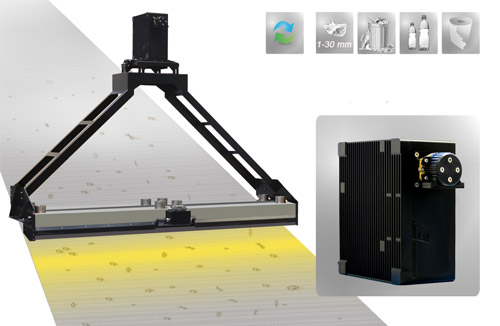

On-line XRF Analyser Line

-

The on-line XRF analyser line XRFline is suitable for detection of all

elements with an atomic number higher than Potassium (in special cases maybe

even below). The system uses state-of-the-art X-Ray detector technology. The

performance of the KETEK Silicon Drift Detector (SDD) is characterised by:

- High count rate capability (>1 Mcps)

- Excellent peak-to-background ratio

- Good energy resolution (~130 eV)

- Wide energy range (0.2 keV to 30 keV)

Paired with water cooled high power X-Ray tubes the full potential of the SDD´s can be exploited. Therefore the sensitivity of the system is high enough to distinguish between different alloys of stainless steel, bronze, brass and more.

The resolution across the belt can be selected basically free (the smallest possible width is 25 mm) and will be adjusted for each system according to the size of the analysed material stream. The resolution along the conveyor belt depends strongly on the belt velocity. The minimum resolution is about 1/100 of the belt velocity (e.g. 25 mm at 2.5 m/s). Hence it results for high throughput a smallest pixel size of about 25 mm x 25 mm. Bigger objects will be detected in several pixel and identified as one object, while smaller objects are detected as single objects as long as they are sufficiently separated.

By reducing the belt velocity and increasing the acquisition time per pixel a higher elemental sensitivity can be achieved to detect elements in low concentrations or small amounts (alloys, REE, PGM,…)

The housing of the XRFline fulfils the radiation safety requirements according to the Radiation Protection Ordinance of Germany. The radiation protection at and around the conveyor belt has to be provided by the manufacturer according to the effective Radiation Protection Ordinance at the place of operation. Furthermore the XRF line camera is integrated into a IP 65 rated housing, enabling maintenance-free 24h/7d operation.

Included in delivery is a preconfigured industrial PC with sensor control and analysis software. Due to the huge material variety the analysis software has to be customized for specific applications. The analysis result is sent to an external process control unit (e.g. SPS control) via standard Gigabit Ethernet interface in real-time.

Possible Applications:- Rejecting unwanted substances from material streams (e.g. meatballs, lead glass)

- Sorting material streams by alloys (e.g. steel, brass, bronze)

- Monitoring and/or analysis of output streams (e.g. shredder, mining)

- Monitoring and/or analysis of input streams (e.g. steel mill)

Schematic illustration of on-line XRF analyser line

SOFTWARE

- LLA Instruments‘ software is developed in-house and included in delivery of the spectrometer and cameras. LLA provides an extensive software portfolio for device control. For standard applications such as plastic identification and paper sorting, ready-to-use application routines are available. An extensive software package for chemometrics is available for application development purposes.

Device control software

- In addition to high performance NIR spectrometer & cameras, LLA develops the control software for these devices.

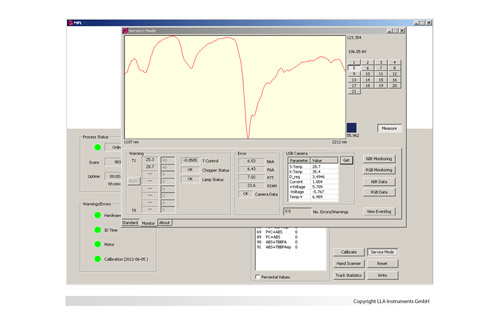

KustaMPL

- The software KustaMPL is utilised for the control of the

multiplexed NIR spectrometer uniSPECx.xMPL-24V and KUSTAx.xMPL-24V. The

software is included in delivery of the multiplexed NIR spectrometer.

Several standardised interfaces are implemented in KustaMPL for data

transfer to an external process control device. The results of the active

application routine are transferred in real time.

In process mode, status information of the device as well as analysis statistics are available. In service mode, settings for device parameters such as integration time are accessible. Important device parameters are password protected and therefore changeable by service personnel only.

In addition, the application routine can be changed in service mode, enabling an easy adaption of the multiplexed NIR spectrometer to different sorting tasks. KustaMPL provides extensive options for NIR-data acquisition and data recording.

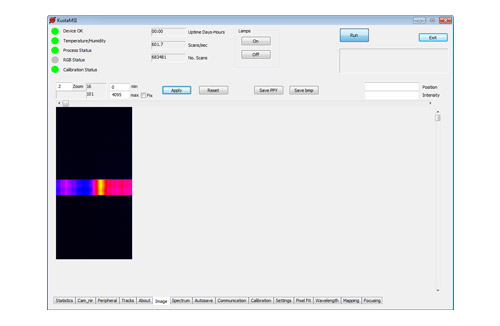

KustaMSI

- The software KustaMSI is utilised for the control of the

2D-hyperspectral cameras KUSTAx.xMSI and uniSPECx.xHSI. The software is

included in delivery of the cameras. In addition to the camera control

options, several standardised interfaces are implemented in KustaMSI for

data transfer to an external process control device.

The graphic user interface is composed of the permanent main window and additional tabs. The main window shows the hardware status, the tabs are utilized for the settings of the camera parameters. In addition, a statistical analysis is available.

Important device parameters are password protected and therefore changeable by service personnel only. In addition, the application routine can be changed in service mode, enabling an easy adaption of the hyperspectral NIR cameras to different sorting tasks. KustaMSI provides extensive options for NIR-data acquisition and data recording.

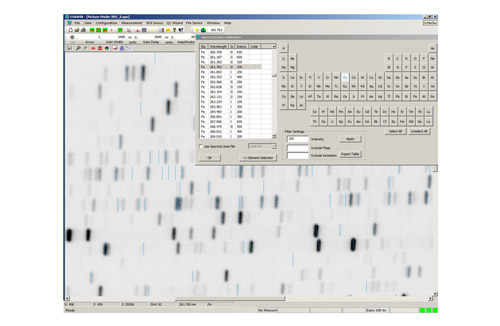

ESAWIN

- ESAWIN is an online data acquisition software for the

Echelle spectrometer ESA 4000. The software is included in delivery of the

Echelle spectrometer / Echelle spectrograph. Atom emission spectra generated

by LIBS or other excitation sources are detected.

Spectral display and spectral analysis are implemented in the software. In addition, the software can be operated in offline mode with deactivated acquisition options.

The following options are implemented:- Spectrometer control (online only)

- Spectra display

- Camera picture display

- ROI (Region of Interest) display

- Data conversion

- Automatic qualitative spectra analysis (all elements)

- Generation of quantitative calibrations

- Quantitative analysis (regarding calibration)

- Statistic and protocol functions for quantitative analysis

Chemometric software

- ILLA Instruments’ device software is complemented by software kits for chemometric application development.

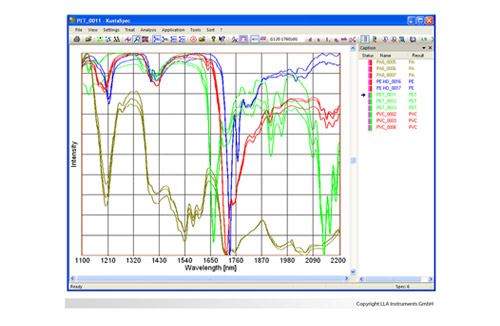

KustaSpec

- KustaSpec is an off-line software tool for chemometric

application development. The applications developed by KustaSpec are

compatible to device software KustaWIN, KustaMPL and KustaMSI. KustaSpec

supports the spectral data format of the device software as well as standard

ascii data.

KustaSpec includes:- Spectra visualisation

- Spectra processing

- Data conversion

- Development of single- and multi step analysis models, test and optimisation thereof

Development and modification of analysis models require the handling and visualization of large data sets. For this purpose, KustaSpec permits simultaneous loading, grouping and colouring of thousands of NIR-spectra.

A comprehensive range of mathematical operations e.g. derivations are available for spectral processing. Statistical data evaluation as well as graphical analysis tools e.g. scores plot and vector plots are implemented for the validation of new applications by NIR test sets. The NIR test sets and learnsets (NIR reference spectral dataset for application development) can be generated and modified by KustaSpec as well.

Evince

- The data acquired with the hyperspectral cameras KUSTAx.xMSI can also be

easily processed using the commercial software Evince.

Evince Image is a modern software for exploration of hyperspectral image data. It has a graphical user interface, which allows import of most common image formats. With powerful analysis techniques, the user can efficiently extract relevant information from the image. A wide range of visualisations are available, both for raw and processed data. A visible interaction between data and graphics makes the exploration fast and effective! Evince runs on Mac, Linux and Windows® operating systems.

Applications

Evince Image can be used in a wide field of applications for research and laboratory routine analysis:- Prediction of moisture distribution in bread,

- Quality control of cheese,

- Moisture prediction of incoming timber,

- Multivariate calibration,

- Freshness control of fruits and berries,

- Classification of nuts,

- Assessment of glue hardening or

- Discovery of adulteration in spices

Tools

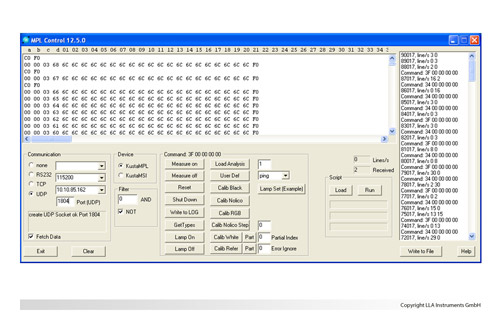

Kusta Control

- Kusta Control permits emulation of the complete communication with the Host PC of KUSTAx.xMPL-24V or KUSTAx.xMSI. Extensive testing of interfaces and control commands as well as long-term error analysis options are implemented in Kusta Control.

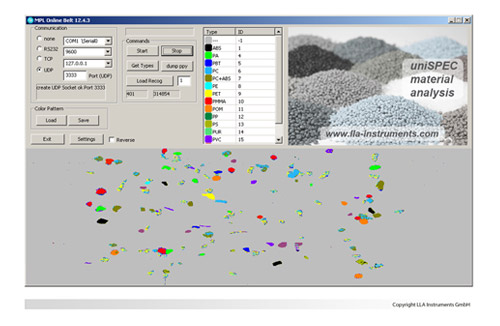

Kusta Online Belt

- Kusta Online Belt is visualization software specialized on large data sets. In combination with process equipment KUSTAx.xMPL-24V / uniSPECx.xMPL-24V, material streams can be visualized in real-time. The distinct material types in an application are visualized by false colour representation. The graphical representation can be particularly useful for a fast assessment of information regarding material composition and material distribution on a conveyor belt.

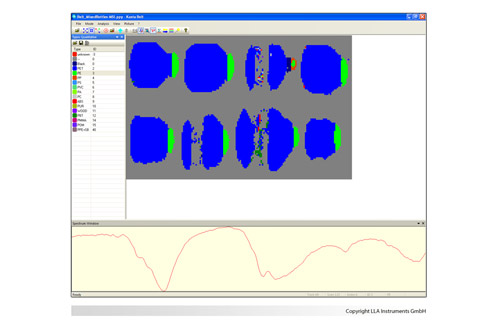

Kusta Belt

- Kusta Belt is an off-line data evaluation software tool

for 2D datasets (belt recordings) recorded by the NIR spectrometer and

cameras KUSTAx.xMSI / uniSPECx.xHSI or KUSTAx.xMPL-24V / uniSPECx.xMPL-24V.

Kusta Belt enables a graphical display of analysis results for previous belt recordings of material streams. In addition, a survey of the impact of modified applications on the identification task is feasible. Especially for off-line tests of new object related identification routines, Kusta Belt is a useful addition to the chemometric software package KustaSpec.

Applications

-

Spectral characterisation of materials and chemical imaging

LLA Instruments GmbH & Co. KG (LLA) spectrometer and cameras are utilised in a wide field of applications. For most application fields shown on the left side, ready-to-use identification routines are available. The identification routines can be selected easily in the device software, enabling an easy way to change the sorting task of the device.