KROMA

Videos

Loading the player ...

- Offer Profile

- Kroma Ltd was founded in 1994 as a privately owned business for manufacturing and trading. The focus of our activities has always been on development and production of sealing systems for rotary equipment, such as pumps, compressors and mixers.The technological process of production is completely "in-house". Starting from the design of new products, production and testing as well as control and monitoring of exploitation at end users.

Product Portfolio

Kroma Ltd

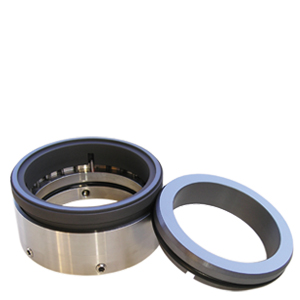

Mechanical seals

-

Whether it is refinery, chemical process pump, mixer, boiler feed pump, pump in brewery or food industry, mechanical seal is very important in safety and efficiency, and because of that, designing of mechanical seal doesn’t allow mistakes.

All mechanical seal components must be selected and applied properly, but most important are seal faces.

The function of a mechanical seal is to prevent the loss of media and to:- protect environment

- protect the expensive equipment

- stop lose the expensive media

- Therefore, designing of mechanical seal doesn’t allow mistakes.

Seals with conical spring

NS-1

-

- Simple mechanical seal for water pumps.

- Single spring configuration.

- Unbalanced.

- Dependant on shaft rotation direction.

Working conditions

Face materials:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 10 bar

- t= -20 to 180 °C

- v = 10 m/s

NT-2

-

Mechanical seal type NT-2 is mainly used in submerged pumps, sewage pumps and water pumps; very rugged and reliable. Combination of seal faces materials is designed for working condition and pumping media.

Secondary sealing: O-ring.

Other construction parts Cr-Ni steel.

Working conditions- Face material:

- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 10 bar

- t= -20 to 180 °C

- v = 10 m/s

Seals with springs in metal case

NV-1

-

Multiple springs mechanical seal type NV-1 is mainly used in petrochemical, oil refining and process industries.

Secondary sealing on a shaft with PTFE wedge or O-ring.

Seal arrangement allows fast and cheap reparation.

Mechanical seal type NV-1 is bi rotational.

Working conditions

Face materials:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 16 bar

- t= -40 to 220 °C

- v = 20 m/s

NV-2

-

Mechanical seal type NV - 2 is very similar to seal type NV - 1. The main difference is single spring instead of multiple springs. Reason is usage in high viscous media or media containing solids. Mechanical seal design with single spring prevents sticking and blocking of small multiple springs. Seal is very easy and cheap to repair.

Working conditions

Face materials:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 16 bar

- t= -40 to 220 °C

- v = 20 m/s

NV-3

-

Wave spring mechanical seal type NV - 3 is very similar to seal types NV - 1 and NV - 2. Main difference is the wave spring instead of multiple springs or single spring. Reason is usage in high viscosity media or media containing solids. Mechanical seal design with wave spring prevents sticking and blocking of small multiple springs. Another advantage of wave springs is more uniform force on the seal face. A steep characteristics curve makes wave springs more sensitive and allow small axial space requirements.

Working conditions

Face materials:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 16 bar

- t= -40 to 220 °C

- v = 20 m/s

Elastomer bellows seals

NM-1

-

Design with elastomer bellows is frequent and among most commonly used NM-1 type has got very good secondary sealing on a shaft with elastomer bellows. This type is highly recommended for sealing media with possibility of crystallization or containing solids in waste water or sewage application. Constructions allow fast and cheap reparation because there is no boned joints. NM-1 seals don’t depend on the direction of shaft rotation. All other metal parts are made of stainless steel.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 12 bar

- t= -20 to 120 °C

- v = 10 m/s

NM-AD

-

Design with elastomer bellows is frequent and among most commonly used. Short length allows wide range of application. This type is highly recommended for sealing media with possibility of crystallization or containing solids in waste water or sewage application. Ideal for domestic and garden pumps, whirlpool and swimming pool pumps, dishwasher pumps, submersible and water pumps.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 6 bar

- t= -20 to 140 °C

- v = 10 m/s

Metal bellows mechanical seal

NMM-1

-

Metal bellows mechanical seal has a very wide field of application, but because of high price we use it for extreme conditions, like very high temperature, aggressive and dirty media. Main advantage is that there is no dynamic O-ring or elastomer part. All elastomer parts have a high temperature usage limit, and when it is passed, mechanical seal failed. Metal bellow mechanical seals work in high temperature, high aggressive and high viscosity media without fail. Because of metal bellows design, seal could work with media containing solids. Independent of direction of rotation.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 16 bar

- t= -40 to 220 °C

- v = 20 m/s

NMM-2

-

Balanced seal. Independent of direction of rotation. Metal roller bellows. Roller bellows seals type NMM-2 have wide range of application. Ideal for waste water pumps, chemical industry, refineries and food industry. Due to roller metal bellows seals of this type are insensitive to solids in the medium.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 16 bar

- t= -40 to 220 °C

- v = 20 m/s

Seals for aggressive media

CHEM NM-3

-

Mechanical seal metal part incompatibility to media is common problem when sealing aggressive, corrosive media. Mechanical seal type CHEM NM-3 with no metal parts in contact with media is strongly recommended and common choice in chemical industry. Poor resistance of elastomers to acids is avoided by application of PTFE bellow.

Independent on direction of shaft rotation. Seal arrangement and choice of seal faces material make mechanical seal typeCHEMNM-3 best choice for sealing aggressive corrosive media.

Working conditions

Face materials:- Stationary seat:

- carbon-graphite

- silicone carbide

- ceramics

Rotating seal:- PTFE glass impregnated

- PTFE carbon impregnated

- silicon carbide

Operating limits:- p= 10 bar

- t= -40 to 220 °C

- v = 16 m/s

CHEM NM-4

-

Mechancial seal type CHEM NM-4 is mostly used in processing aggressive media. Mechanical seal is independent of direction of rotation. Secondary seal depend on processing media.

Working conditions

Face materials:- Stationary seat:

- carbon-graphite

- silicone carbide

- ceramics

Rotating seal:- PTFE glass impregnated

- PTFE carbon impregnated

- silicon carbide

Operating limits:- p= 10 bar

- t= -40 to 220 °C

- v = 16 m/s

Balanced mechanical seals

BT-1

-

When we are designing the mechanical seal with sleeve on a shaft or making a stepped shaft, we balance the forces which are acting on the sliding surfaces. By that we could arrange higher P-v values. We call this the "balanced mechanical seal" BT-1 type is mostly used in water pumps and central heating pumps and it’s very rugged and reliable. Combination of seal face materials is designed for working condition and pumping media. Secondary sealing by O-ring. Other construction parts are made of stainless steel.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 25 bar

- t= -20 to 180 °C

- v = 15 m/s

BT-TNG

-

Design with sleeve on a shaft enables seal applications with higher P-v values. BT-TNG type can be used in all standard applications and it is reccommended for fluids containing solid particles and/or higghly viscous liquids. This seal type is first choice for sealing LPG. Combination of seal face materials is designed for working condition and pumping media. Secondary sealing by O-ring. Other construction parts are made of stainless steel.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 25 bar

- t= -20 to 180 °C

- v = 15 m/s

BV-1

-

BV-1 type is mostly used for pumps and compressors in oil refining and petrochemical industry. It has got secondary shaft sealing with wedge or O-ring. All other metal parts are made of stainlees steel. BV-1 type is birotational and easy for reparation.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 25 bar

- t= -40 to 220 °C

- v = 20 m/s

BV-2

-

In BV-2 seal design springs are not emerged in operating fluid. In that manner spring blocking and material incompatibility problems are eliminated. In BV-2 seal design rotating part O-ring is in static state all the time, even during operation. Seal face wear is compensated by springs, therefore O-ring is never under dynamical load. Mechanical seal type BV-2 can be applied in conditions of pressure up to 40 bar due to shaped seal face cross-section. Standardized seal face dimensions allowe simple application of wide range of seal face materials and easy component replacement

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 42 bar

- t= -40 to 220 °C

- v = 20 m/s

BV-3

-

Balanced mechanical seal with wave spring.

Independent of direction of rotation.

Secondary shaft sealing with wedge or O-ring.

All other metal parts are made of stainlees steel.

Easy reparation.

Working conditions

Face material:- carbon-graphite

- Cr-steel

- Cr-Ni steel

- tungsten carbide

- silicon carbide

- alumina

Operating limits:- p= 25 bar

- t= -40 to 220 °C

- v = 20 m/s

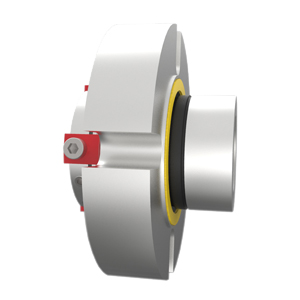

Cartridge seals

-

On average, only 10% of the mechanical seals reach their full life. For the remaining 90% there is a premature failure, mainly because of wrong exploitation, assembly or selection. Much better performances are achieved with the cartridge type mechanical seals. The cartridge is a compact unit which allows easy interchangeability and eliminates the potential for error in assembly. The construction of the cartridge is such that large axially movements allowed, and pressure is made possible with the use of hydraulic balancing at higher operating rates.

Construction:- Stationary springs enable higher speed of rotation.

- The dynamic secondary seals are placed in the atmospheres of the seal, thus preventing the blockade in the deposition of the working fluid.

- The design of the seal with multiple springs allows a uniform distribution of the load on the seal face.

- The springs are not in contact with the working fluid, thereby avoiding the possibility of the blockade of the spring and the reliable performance is made possible.

- Seal faces are double balanced.

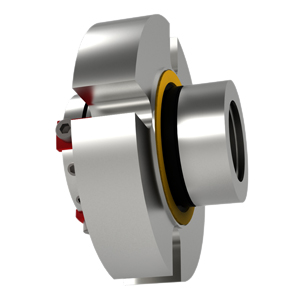

Type UCA

-

Characteristics:

- Single spring

- Hydraulically balanced

- Rotation direction independent

Application:- media with low viscosity

- media without solids

- media without pollutants

- media with sedimentation tendency (type UCB)

Materials:- Sealing faces:

- carbon graphite

- tungsten carbide

- silicon carbide

Secondary seals:- NBR

- EPDM

- Viton

- PTFE

Springs:- X12CrNi17.7

Other metal parts:- stainless steel

Working conditions

Operating limits:

Pressure:- p = 25 bar

Temperature:- t = - 40 ... 120 °C (NBR)

- t = - 50 ... 150 °C (EPDM)

- t = - 40 ... 250 °C (Viton)

Velocity:- v = 25 m/s

Type UCB

-

Characteristics:

- Single seal

- Hydraulically balanced

- Rotation direction independent

- Cover with auxiliary connection for flushing

Application:- media with low viscosity

- media without solids

- media without pollutants

- media with sedimentation tendency (type UCB)

Materials:

Sealing faces:- carbon graphite

- tungsten carbide

- silicon carbide

Secondary seals:- NBR

- EPDM

- Viton

- PTFE

Springs:- X12CrNi17.7

Other metal parts:- stainless steel

Working conditions- Operating limits:

Pressure:- p = 25 bar

Temperature:- t = - 40 ... 120 °C (NBR)

- t = - 50 ... 150 °C (EPDM)

- t = - 40 ... 250 °C (Viton)

Velocity:- v = 25 m/s

Type UCC

-

Characteristics:

- Single seal

- Hydraulically balanced

- Rotation direction independent

- Assumed quench fluid application

Application:- media with poor lubrication properties

- media which react with oxygen

- media with sedimentation tendency (type UCC)

- chemically aggressive media (typeUCD).

Sealing faces:- carbon graphite

- tungsten carbide

- silicon carbide

Secondary seals:- NBR

- EPDM

- Viton

- PTFE

Springs:- X12CrNi17.7

Other metal parts:- stainless steelWorking conditions

Operating limits:

Pressure:- p = 25 bar

Temperature:- t = - 40 ... 120 °C (NBR)

- t = - 50 ... 150 °C (EPDM)

- t = - 40 ... 250 °C (Viton)

Velocity:- v = 25 m/s

Type UCD

-

Characteristics:

- Double seal

- Hydraulically balanced

- Rotation direction independent

- Assumed quench fluid application

Application:- media with poor lubrication properties

- media which eact with oxygen

- media with sedimentation tendency (type UCC)

- chemically aggressive media (typeUCD).

Sealing faces:- carbon graphite

- tungsten carbide

- silicon carbide

Secondary seals:- NBR

- EPDM

- Viton

- PTFE

Springs:- X12CrNi17.7

Other metal parts:- stainless steel

Working conditions

Operating limits:

Pressure:- p = 25 bar

Temperature:- t = - 40 ... 120 °C (NBR)

- t = - 50 ... 150 °C (EPDM)

- t = - 40 ... 250 °C (Viton)

Velocity:- v = 25 m/s

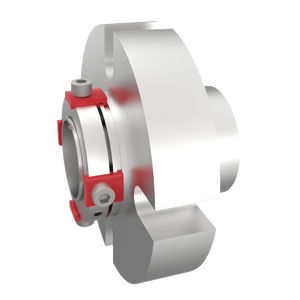

API Cartridge seals

-

Cartridge mechanical seals manufactured to meet API 682 (ISO21049) are meant for use in the petroleum, natural gas and chemical industries.

During processing of crude oil various chemical compounds are being released, and designers should count on sealing fluids which could be:- under the very high pressure

- under very high or very low temperatures

- on very high or low pH value

- very high or very low viscosity

- abrasive

- harmful, polluting and potentially explosive

API 682 (ISO21049) specifies requirements and gives recommendations for sealing systems with aim to secure that the fluids with characteristics above could be transported:- with minimum waste

- with maximum environmental protection

- with minimum mechanical failure

- with best price-quality ratio

RCS-S

-

Characteristics:

- Single mechanical seal

- Compact – cartridge design

- Pressure double balanced monolithic seal faces

- Stationary multiple springs

- Suits API682 requirements

- Pipe connections enables quench/drain application

- Low heat generation

- Independent on rotation direction

- Easy to retrofit

Application:- RCS-S refinery cartridge seal for oil and gas industry

- LPG plants

- Petrochemical industry

- Power plants

- Chemical industry

Materials:- Seal faces: Carbon (resin or metal grade impregnated), RbSiC (Q2), SSiC (Q1), tungsten carbide grades (Cobalt or Nickel bounded)

- Secondary seal: EPDM (E), FKM (V), FFKM (K), FEP coated

- Spring: X12CrNi17.7, Hastelloy C-276

- Metal parts: 316 SS

Working conditions

Operating parameters:- p = vacuum to 35 bar

- Temperature limits (elastomer)

- 150°C EPDM

- 205°C FKM , FEP

- 260°C FFKM

- Speed 25 m/sec

- *For higher values of working parameters please consult our engineers.

RCS-D

Special applications

MixSeal Single

-

- Single seal

- Balanced

- Independent of rotation direction

- Top entry

- Dry running

- Outboard

- Multiple springs

- Atex certificate on request

Working conditions

MixSeal Double

-

- Double seal

- Balanced seal faces

- Cartridge design

- Independent of rotation direction

- Pressure tested

- Pressure reversals allowed

- Possible integrated floating bearing

- Possible customized construction for different torque transmissions

- ATEX certificate available on request

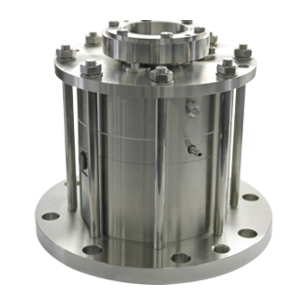

Rotary pressure joints

-

Rotary pressure joint is an assembly which secures sealing between inlet pipe and rotational cylinder thus providing heat transfer by media in or from the equipment's rotational element. Fluids that are commonly used for heat transfer are water, thermal oils, hydraulic oils, cooling fluids and vapor.

When it comes to rotary pressure joints, sealing of work fluids is done by the use of mechanical seal. The mechanical seals spring provides contact between sealing faces before the machine starts it's work, while during work, the contact is secured by the act of hydraulic pressure, except in cases of low operating pressures or vacuum.

The right choice of mechanical seal is of major importance in order to reach the work of rotary pressure joint efficient , because in cases of mechanical seal malfunction, leakage occurs which reduces efficiency of entire cooling or warming process.

“ Kroma Ltd” delivers rotary pressure joints adjustable for single, as well as for dual flow.

Type UOPM

-

Rotary pressure joints type UOPM are used in cases were we have a fluid entering on one end of the cylinder, and exiting on the other. In this instance we have a single flow through the rotary pressure joint. Systems such as these use two rotary pressure joints, one in the entry point in the system, and one in the exit point.

Working conditions- p=40 bar

- t=120°C

- Depending on the thread up to 3500 RPM.

Type UOPD

-

Rotary pressure joints type UOPD are joints with dual flow technology. This type implies that a fluid passes through the same rotary pressure joint when entering and exiting the system. The design of the rotary pressure joint prevents mixing of the entering and exiting fluid, as well as fluid exiting to the atmosphere. Rotary pressure joint type UOPD is used the intake pipe is stationary. The connection between the intake pipe and rotary pressure joint housing is possible with thread connection.

Working conditions- p=40 bar

- t=120°C

- Depending on the thread up to 3500 RPM.

Type UOPB

-

Rotary pressure joint type UOPB is used when syphon internal pipe is rotational. Internal pipe rotates in the slide bearing of the casing.

Working conditions- p=40 bar

- t=120°C

- Depending on the thread up to 2000 RPM.

Type HTOPM

-

Rotary pressure joint type HTOPM is a assembly that enables the supply of fluid form intake pipe to rotational equipment. The H sign stands for "hot", so these rotary pressure joints are suitable for sealing steam, hot water or oil etc. The assembly does not require additional lubrication or sealing, it's easily mounted and can be replaced as a separate unit. HTOPM is designed to compensate misalignments caused by overheating.

Working conditions- p=15 bar

- t=300°C

- Depending on the thread up to 750 RPM.

Type HTOPD

-

Rotary pressure joint type HTOPD is a assembly that enables the supply of fluid form intake pipe to rotational equipment. The H sign stands for "hot", so these rotary pressure joints are suitable for sealing steam, hot water or oil etc. The assembly does not require additional lubrication or sealing, it's easily mounted and can be replaced as a separate unit. HTOPD is designed to compensate misalignments caused by overheating.

Working conditions- p=15 bar

- t=300°C

- Depending on the thread up to 750 RPM.

Graphite products

-

Carbon graphite, as a material is used to manufacture:

- Graphite slide bearings

- Carbon vanes

- Segment radial sealing rings

Characteristics of the material include:- Self-lubricant

- Can be used in high temperatures

- Chemical composition that ensures usage in chemical and pharmaceutical industry

- Good mechanical properties

Segmental radial sealing rings

- Segmental radial sealing rings are mostly used for shaft sealing on water turbines (Francis of Kaplan), steam turbines, compressors and fans. Each ring consists of certain number of segments surrounded by spring. Number of segments depend on shaft diameter. During the application medium pressure is equally distributed on outer ring diameter, thus the purpose of spring is to hold segments together until sufficient pressure of medium is achieved. Number of rings depends on working pressure. Very similar shape but different in application are piston rod seals and piston guide rings. They also consist of several segments, but moving of piston rod or piston is axial. Most common applications include steam turbines, water turbines, compressors, fans etc.

Carbon vanes

- Carbon and graphite are very high temperature and corrosive resistant materials, which are the most important characteristics for vanes material. The most common applications of vanes made from carbon-graphite are in vacuum pumps, rotary compressors and fuel tanks. Beside that we could find application in food processing equipment, spray paint and printing machinery, petrol pumps and packing machinery. Carbon vanes are suitable for wet and dry running, they are chemically inert and they cannot contaminate pumping media. Because of good self-lubricating properties they are very good for handling liquids with poor lubricating properties like petrol. Depending on working conditions and pumping media vanes could be made of carbon-graphite, metal impregnated carbon graphite or resin bonded graphite.

Carbon slide bearings

-

Our range of bearings are available in carbon and graphite as well as silicon carbide. These materials are traditionally used as a bearing material. Carbon is self lubricating and has low coefficient of friction at high and low temperatures. Its use as a bearing material is extensive when conventional lubricants is not possible and also where the performance of other lubrication is poor. There are other properties which give it unique and distinctive advantages for bearings. These include:

- Low wear rate

- Mechanically strong in compression

- High strength-wight ratio

- Electrically conductive

- Relatively low density (2 gm per square meter)

- High thermal conductivity

- Is non oxidising to 500oC (depending on grade)

- High resistance to thermal shock

- Chemically inert

- Easily machined to close tolerances

- Dimensionally stable (deos not swell in water)

Industries

Power plant technology

-

Mechanical seals are key components in all types of power plants. They can be found in various different positions and often in critical places in the system. To achieve a long term and reliable exploitation of the mechanical seal choosing the correct type of seal is a key decision.

Kroma Ltd has been delivering mechanical seals to the energetic industry sector for a long period of time. Weather we are talking about hydro power plants, thermal power plants we have the products to satisfy all operating conditions required.

Kroma Ltd can provide ATEX certificate for all our products, when the seal is used in explosive environment.

Water treatment industry

-

Water is the most commonly transported fluid thus the most sealed one as well. Sealing water is found in various industries, such as civil engineering , water treatment, thermal water transportation etc. All this implies that the selection of the correct seal is not only difficult but also determines the operating lifetime. The differences in the water characteristics are important for seal selection, we consider temperature, chemical composition (various chemicals present), viscosity, presence of hard particals etc.

Kroma Ltd can offer a wide range of standard seals to meet most requirements. In the cases where our standard products can't meet the demands of operating conditions, we can offer a specifically designed products, for specific purpose. This is what we refer to as "engineered seals", and we approach this as project jobs.

Oil, gas and petrochemical industry

-

Rotational equipment in refineries, such as pumps, mixers and compressors have to be adequately sealed. Reliability and high quality are paramount for seals used in refineries and petrochemical plants. Mechanical seals according to API 682 standard can be found in our product portfolio and present the best choice for these demanding applications.

In cases were standard and API cartridge seals can't meet the requirements of exploitation we can offer our services and solutions by designing a completely new seal. These seals are "one-off" seal designed for specific use. Our engineers design the seal, monitor the production, testing and packing. This way our clients receive a seal fit to meet their specific demands.

Pulp and paper industry

-

Pulp and paper industry

The pulp and paper industry is a very demanding industry for sealing and mechanical seals. Since Kroma Ltd started delivering seals to companies from this industry sector we have always strived to deliver products with better performances. We have used our knowledge to innovate our products to do so.

Today Kroma Ltd can offer a complete range of products and solutions standard and non standard for various sealing positions in the pulp and paper industry sector. Whether we are talking about seals used in pumps and compressors or sealing on rotational equipment using rotary pressure joints we can answer to all demands of our customers.

Food and beverage industry

- Food and beverage industry requires some industry standards to be meet when manufacturing a seal. This specifics imply specific designs that have little to no cavities in which matter can get stuck and contaminate the environment. Also surface have to be electropolished stainless steel because of the same reason. Mechanical seals that don't require disassembly are often used in food and beverage industry. All our products offered to the food and beverage industry sector are in compliance with CIP requirements.