büchiglasuster

Videos

Loading the player ...

- Offer Profile

- Büchi is a globally leading

manufacturer of reactor systems, pilot plants and related services in the

field of demanding process requirements in terms of:

• Corrosion resistance

• Pressure resistance

• Regulatory, operational and other process related requirements

We are a global partner for companies operating in the chemical and pharmaceutical industries as well as for research organizations.

Product Portfolio

Glass Reactors & Plants / Pilot Plant equipment

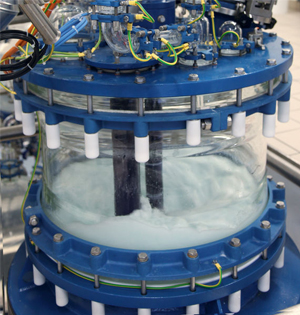

- Buchi reactors and chemical glass plants have passed the test of time with outstanding performance, robustness and versatility in daily operation. Reactor systems, nutsch filters, mixing vessels and scrubbers are used for cGMP production of APIs and chemicals in pilot plants and production sites. Buchi process equipment is built with solid glass based on unique flexible joints and glass lined steel components.

Reactor systems 5 - 250 liter

miniPilot

-

Glass reactor: 5, 10, 15 liter

Pressure: -1.0 (FV) to +1.0 bar

Temperature: -60 °C (-90 °C) to +200 °C

Material: Borosilicate glass 3.3, PTFE, PFA, PEEK

Standard package- 5, 10, 15 liters jacketed glass reactor, interchangeable

- Baffle with Pt100 temperature sensor

- Continuous adjustable agitator speed, 0-600 rpm

- Dry running mechanical seal

- Compact stainless steel frame, table or floor model, mobile

- ATEX Zone 1 (0) / CE / cGMP

- CIP capable

- FDA conform, highly corrosion resistant

- Complete documentation

Standard options- Reactor lift for easy reactor opening, cleaning, stirrer exchange

- 3-wall reactor vessel for -90 °C chemistry

- Glass distillation overhead

- Sampling system

- Probes for pH, others

- CiP spray nozzle

- IQ / OQ / PQ

midiPilot

-

Glass reactor: 20, 30 liter

Pressure: -1.0 (FV) to +1.0 bar

Temperature: -60 °C (-90 °C) to +200 °C

Material: Borosilicate glass 3.3, PTFE, PFA, PEEK

Standard package- 20 , 30 liters jacketed glass reactor, interchangeable

- Baffle with Pt100 temperature sensor

- Continuous adjustable agitator speed, 0-600 rpm

- Dry running mechanical seal

- Compact stainless steel frame, table or floor model, mobile

- ATEX Zone 1 (0) / CE / cGMP

- CIP capable

- FDA conform, highly corrosion resistant

- Complete documentation

Standard options- Reactor lift for easy reactor opening, cleaning, stirrer exchange

- 3-wall reactor vessel for -90 °C chemistry

- Glass distillation overhead

- Sampling system

- Probes for pH, others

- CiP spray nozzle

- IQ / OQ / PQ

chemReactor CR

-

Glass-, glass lined steel reactor: 15, 30, 60, 100, 160, 250 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90°C) to +200 °C

Material: Borosilicate glass 3.3, glass lined steel, PTFE, PFA, Tantalum

Standard package- Jacketed full glass / glass lined steel reactor

- Multipurpose glass distillation overhead

- Stainless steel frame, supporting flexible glass superstructure

- ATEX Zone 1 (0) / CE / cGMP

- CIP capable

- FDA conform, highly corrosion resistant

- Complete documentation

Standard options- Reactor lift for easy opening (vessel cleaning)

- Sampling device

- pH monitoring and control

- Gas introduction (Nitrogen purging and active gas)

- Vacuum / exhaust piping

- Additional feeders / receivers

- Solid feeding

- Cryogenic vessel for low temperature chemistry (-90°C)

- in special glass lining or Hastelloy C22

- mixed systems with pressure reactor and vacuum distillation

- IQ / OQ / PQ

chemReactor BR

-

Glass reactor: 15, 30, 60 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90°C) to +200 °C

Material: Borosilicate glass 3.3 / glass lined steel / PTFE / PFA / Tantalum

Standard package- Jacketed full glass reactor

- Multipurpose glass distillation overhead

- Stainless steel frame, supporting flexible glass superstructure

- ATEX Zone 1 (0) / CE / cGMP

- CIP capable

- FDA conform, highly corrosion resistant

- Complete documentation

Standard options- chemReactor CR type Distillation glass overhead

- Reactor lift for easy opening (vessel cleaning)

- Triple wall reactor vessel

- Sampling device

- pH monitoring and control

- Gas introduction (Nitrogen purging and active gas)

- Vacuum / exhaust piping

- Additional feeders / receivers

- Solid feeding

- IQ / OQ / PQ

chemReactor GR

-

Glass reactor: 15, 30, 60 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90°C) to +200 °C

Material: Borosilicate glass 3.3 / glass lined steel / PTFE / PFA / Tantalum

Standard package- Jacketed full glass reactor

- Multipurpose glass distillation overhead

- Stainless steel frame, supporting flexible glass superstructure

- ATEX Zone 1 (0) / CE / cGMP

- CIP capable

- FDA conform, highly corrosion resistant

- Complete documentation

Standard options- chemReactor BR type Distillation glass overhead

- Reactor lift for easy opening (vessel cleaning)

- Triple wall reactor vessel

- Sampling device

- pH monitoring and control

- Gas introduction (Nitrogen purging and active gas)

- Vacuum / exhaust piping

- Additional feeders / receivers

- Solid feeding

- IQ / OQ / PQ

Process equipment > 250 liter

Production scale Reactors systems & Plants

-

Glass lined reactor: 250 - 10000 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60°C to +200°C

Material: Borosilicate glass 3.3 / glass lined steel / PTFE / PFA / Tantalum

Nutsch Filter 10 - 300 liter

Nutsch Filter

-

Glass vessel: 10, 30, 50, 100, 140, 300 liters

Pressure: -1.0 (FV) to +1.0 bar

Temperature: -60 °C to +200 °C

Filter cloth: Mesh size 8 - 115 micron

Material: Borosilicate glass 3.3, PTFE, PFA, ETFE

Standard package- Glass filter vessel

- ETFE coated cover plate with ports for slurry feed, nitrogen, etc.

- PTFE bottom plate with filter cloth

- Mobile stainless steel frame with lifting device

- Highly corrosion resistant

- FDA conform

- cGMP

- Complete documentation

Standard options- Manual stirrer in stainless steel, Hastelloy or with inert coating

- ATEX stirrer drive with adjustable stirrer speed

- CIP capability

- Heating jacket (drying)

- IQ / OQ / PQ

High containment filter

-

Glass vessel: 30 liter

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60°C to +200°C

Material: Glove made of EPDM

Stirred Nutsch Filters (also SPPS)

-

Glass vessel: 10 - 300 liters

Pressure: -1.0 (FV) to +1.0 bar

Temperature: -60 °C to +200 °C

Filter cloth: Mesh size 8 - 115 micron

Material: Borosilicate glass 3.3, PTFE, PFA, ETFE, glass lined steel

Pressure filters

-

Metal vessel: 5, 10, 20 liter

Pressure: -1.0 (FV) to +6.0 bar

Temperature: -60°C to +250°C

Filter: sintered 8 - 115 micron

Material: stainless steel, Hastelloy C22

These filters are designed for filtration, pressurizing the vessel with up to 6bar pressure. The filter vessel is jacketed and can be temperature controlled by a circulator. Process connections are standard Tri clamp configuration.

Mixing vessel, Glass Reactors, Tanks 5 - 400 liters

Mobile Pilot Plant units, stationary Glass Tanks

-

Jacketed glass reactor: 30, 50, 100 liter

Mixing vessel: 30, 50, 100, 200 liter

Glass tanks: 30 - 400 liters

Pressure: -1.0 (FV) to +0.5 bar

Temperature: -60 °C (-90°C) to +150 °C (200 °C)

Material: Borosilicate glass 3.3, PTFE, PFA, ETFE

Standard package- Full glass vessel with bottom valve

- Glass dome with ports for inlet, solid feed, vacuum, etc.

- ETFE coated stirrer, dry-running mechanical seal

- ATEX stirrer drive, adjustable speed

- Mobile stainless-steel frame

- ATEX / CE / cGMP

- Complete documentation

Standard options- Stirrers in different shapes /e.g. multi-stage, etc.)

- Flush mounted drain valve (zero dead volume)

- Full glass reactor with heating / cooling jacket

- CIP capability

- Glass reflux condenser

- Camlock fittings for flexible hose connection

- IQ / OQ / PQ

Gas scrubber 10 - 100 liter, Columns

Gas scrubber

-

Mobile gas scrubber: 10, 20, 50, 100 liter

Glass column: DN 50, 70, 100, 150, 200 (up to DN600)

Pressure: -1.0 (FV) to +0.5 bar

Temperature exhaust gas: -60 °C to +200 °C

Temperature scrubbing liquid: 0 °C to +80 °C

Material: Borosilicate glass 3.3 / PTFE / ETFE

Standard package- Round glass flask

- Absorption column, packed with raschig rings

- Glass spiral cooler

- ATEX circulation pump

- Mobile stainless steel frame

- Highly corrosion resistant

- ATEX / CE

- Complete documentation

Standard options- Different column packing

- Scrubbing columns for production scale

- pH monitoring of scrubbing liquid

- IQ / OQ / PQ

Accessories / Buchiflex components

Buchiflex Glass components

-

buchiflex - the modular glass component system

flexibility under operation condition

DN15 – DN600

Heat exchangers / condensers

-

Heat exchangers are mainly used in vacuum distillation systems for cooling and condensation in the absorption and rectification processes in chemical plants. Glass heat exchangers enable visual process control during scale-up and production and processing of multiple (acidic) chemical substances. We offer glass spiral type heat exchangers and shell & tube type heat exchangers. These are often operated in combination with a secondary condenser for additional vapor condensation.

The glass spiral heat exchangers can be operated in parallel to form large heat exchange areas for higher condensation performances and larger reactors systems in pilot plants. They feature easy cleaning and operation of cooling media at up to 3 bar pressure.

Shell and tube type heat exchangers are used in combination with packed rectification columns as reflux condenser on larger systems. Buchi offers full glass and glass / silicon carbide (SiC) type heat exchangers with a 0.6 to 23m2 heat exchange area. SiC heat exchangers feature excellent thermal transfer, thus reducing the requested heat exchange area compared to full glass types which can reduce the requested space for the complete system. The optional safety chamber enables easy leakage examination and increases the operation pressures of the cooling media to 6 bar

Distillation / Rectification

-

Glass overheads are typically built (in our standard chemreactor and production plant setups) for multipurpose and semi – batch operation mode under full vacuum. They mostly consist of feeder vessel, a distillation column, condenser and secondary condenser, phase separator, receiver, including valves and pressure equalization piping and a rupture disc as safety device.

For rectification, packed distillation glass columns up to DN600 are used with reflux condenser, a reflux splitter with a reflux controller to set the reflux ratio. In Buchi chemreactors, both systems can be combined.

Distillation columns / Packing

-

Glass columns up to DN 600 are packed with random packing such as Raschig rings, ceramic saddles, PFA packing elements or structured packing dependent on the required separation performance and process media.

Each packing type shows different separation performance, indicated by their number of theoretical stages. In combination with glass process equipment, highly corrosion resistant packing material is used for packed glass distillation columns.

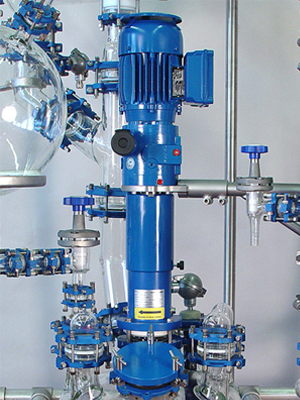

Ex stirrer drives, stirrer shaft seal

-

A stirrer drive consists of:

Ex motor with ex proof speed reducer for manual speed adjustment or with a frequency converter for electrical speed adjustment and measuring of the stirrer speed and torque

Ex proof stirrer shaft seal keeping the reactor tight against the atmosphere and dry running to avoid any contamination of the chemical process and product

stirrers for best heat transfer into the product and efficient mixing of the chemical components

Stirrer drive with dry running mechanical sealing

The stirrer shaft seal is a key component of chemical reactors. It stands for leakage free operation of the rotating stirrer shaft. A mechanical seal shall be dry running, avoiding any contamination of the chemistry by a lubricant. Stirrers or agitators are important for mixing and heat-transfer so design and dimensions are crucial. Impellers are used for universal tasks

Mechanical sealing is designed for vacuum and low pressure and stirrer speed operations for larger glass lined steel stirrer shafts. These shafts are offered in corrosion resistant metal and ceramic for very high pressures and viscosities – see also our magnetic couplings below

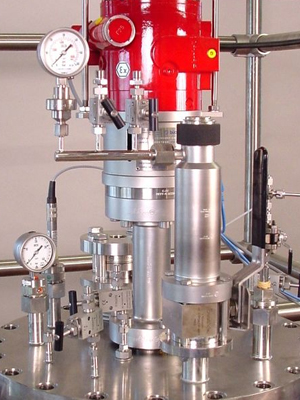

Stirrer drives with dry running magnetic coupling

Dry running mechanical stirrer shaft sealing including stirrer, motor and control used for high vacuum to high pressure and high viscosities are equipped with magnetic couplings as a static sealing element. These stirrer drives for chemical pressure reactors are designed for extreme operating conditions regarding temperature, pressure, low and high torque mixing, high stirrer rotation speed. The wetted parts are made in corrosion resistant metals and ceramic.

Sampling, pH probes

-

Buchi offers a wide range of accessories to glass -, glass lined steel reactor systems. Due to the high number of nozzles on the reactor head, several accessories can be installed simultaneously. Temperature sensors and other electronic / electric components are intrinsic safe and Ex proofed for equipment installed in Ex - Zone 0 - 0, see also ATEX Directive 94/9 EC. We offer systems for:

- sampling

- solid feed

- pH probes, probes for different process parameters

- gas inlet tubes to introduce gas in gas - or liquid phase

- solid feed

- integration of high containment solid charge systems

- etc.

Measure & Control

-

Our glass process equipment is mainly installed in Ex Zones and therefore requires intrinsically safe ex proofed sensors and ex displays (field displays) in most cases. All electrical and electronic equipment installed in hazardous area must comply with Atex (Europe) or local fire - protection safety regulations and guidelines. Buchi Ex proofed components are:

- ex control panels

- ex control and displays, example pH

- pneumatically driven valves with actuator

- reflux controller

- others

- Ex free or non ex zone

- installed outside Ex Zones but with connection to probes in the Ex zone

Safety options / accessories

-

Buchi glass reactors and plants are designed and supplied with integrated safety components, see also safety with chemical glass equipment. Standard and optional safety devices are:

- rupture disc, safety relief valve

- glass components, assemblies with electrostatic discharge concept (ATEX), see buchiflex - flexible joint and buchiflex glass catalog, chapter 2

- protection of the glass itself by coating with Glassprotect or building it into an isolator

- others

Auxiliary equipment

-

Temperature control systems, vacuum pumps, others

Utilities such as temperature control systems, TCU’s, circulators, chillers, vacuum pumps and others are required to run chemical reactors. Buchi and local Buchi representatives support customers worldwide on the supply of complete chemical process systems with the expertise on reactors and auxiliary equipment.

Buchi Glass Plants - General Info

Performing Reactors

-

Glass / glass lined steel equipment - designed for reliable day to day operation

For chemical research, glassware and reactors in glass are standard Lab equipment worldwide due to several reasons:- excellent chemical resistance

- transparency for better understanding during process development

- visual control compared to expensive Ex-proof control systems

- easy an efficient cleaning

- inexpensive raw material

Buchiflex - unique glass joint

-

Modular assembly system

- High modularity: DN 15 - 600

- Wide choice of Büchi standard components increases

- efficiency of design, construction and delivery

- Efficient planning to meet customer needs

- Reliable supply of spare parts

- Enables fast modifications of the existing setup

- Self-emptying piping

Flexibility- Safety, preventing the glass from mechanical stress

- Self-aligning, since spherical

- Fast and easy installation

- Short service interventions

Flame - polished glass joint

- No residues

- Efficient cleaning

Metal flanges- Electrical conducting blue colored coating

- Proper earthing of system (ATEX)

- Spring-loaded flexible connection

Approvals- ATEX

- PED

- TA Luft

Stirred lab Autoclaves / Pressure Reactors

- Buchi laboratory autoclaves and pressure reactor systems are used for reactions under pressure such as hydrogenation, polymerization, catalyst research and materials research in chemical laboratories. They are also used for small-scale production. The autoclave reactor can be operated with various interchangeable glass reactors made of borosilicate glass 3.3 or high pressure-, high temperature reactors made of metal. Corrosion-resistant metals such as stainless steel, hastelloy, tantalum, titanium, zirconium etc. are used, see corrosion resistant materials. Powerful agitator drives with magnetic couplings ensure efficient stirring and mixing even at high viscosities.

Lab – Pilot scale 0.25 – 500 liters

ecoclave

-

Reactor volume: 0.25 - 5.0 liter

Pressure: -1 (FV) to +60 / 200 bar

Temperature: - 20 °C to +250 °C

Material: Borosilicate glass 3.3, stainless steel, Hastelloy®

Standard package- Safety housing with polycarbonate sliding door for safe operation of glass pressure vessels

- Pressure vessel in glass, steel / Hastelloy with suitable stirrer shaft, stirrer, baffle, Pt-100, bottom valve depending on vessel type

- Cover plate with 7 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive «cyclone 075» with integrated high torque magnetic coupling, incl. controller «cc075»

- Tools and spare parts

Standard options- cyclone 300 stirrer drive

- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

- 200 bar version

polyclave

-

Reactor volume: 0.25 - 5.0 liter

Pressure: -1 (FV) to +60 / 200 bar

Temperature: -20 °C to +250 °C

Material: Borosilicate glass 3.3, stainless steel, Hastelloy®

Standard package- Safety housing with polycarbonate sliding door for safe operation of glass pressure vessels

- Pressure vessel in glass, steel / Hastelloy with suitable stirrer shaft, stirrer, baffle, Pt-100, bottom valve depending on vessel type

- Cover plate with 7 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive cyclone 300 with integrated high torque magnetic coupling, incl. controller cc 300

- Tools and spare parts

Standard options- Reactor lifting / lowering device

- Safety Fast Action Closure for vessel

- ATEX stirrer drive

- Metal-free (inert version) with ceramic stirrer drive

- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

- 200 bar version

versoclave

-

Reactor volume: 0.5 - 5.0 liter

Pressure: -1 (FV) to +60 / 200 bar

Temperature: -20°C to +250 °C

Material: stainless steel, Hastelloy®

Standard package- Stand with open access from all sides

- Pressure vessel in steel / Hastelloy with suitable stirrer shaft, stirrer, baffle, Pt-100 and bottom valve

- Cover plate with 7 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive «cyclone 300» with integrated high torque magnetic coupling, incl. controller «cc300»

- Tools and spare parts

Standard options- Reactor lifting / lowering device

- Safety Fast Action Closure for vessel

- ATEX stirrer drive

- Metal-free (inert version) with ceramic stirrer drive

- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

- 200 bar version

kiloclave

-

Reactor volume: 0.5 - 20.0 liter

Pressure: -1 (FV) to +60 / 200 bar

Temperature: -20 °C to +250 °C

Material: stainless steel, Hastelloy®, Glass lined steel

Standard package- Stand with hydraulic lift and tilt mechanism

- Pressure vessel in steel / Hastelloy with suitable stirrer shaft, stirrer, baffle, Pt-100 and bottom valve

- Cover plate with 7 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- ATEX stirrer drive with adjustable transmission and high torque magnetic coupling bmd300

- Tools and spare parts

Standard options- Safety Fast Action Closure for vessel

- cyclone 300 magnetic stirrer drive

- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

- Metal-free kiloclave inert

- 100 / 200 bar version

pilotclave

-

Reactor volume: 20 - 500 liter

Pressure: -1 /FV) to +200 bar

Temperature: -20 °C to +300 °C

Material: stainless steel, Hastelloy®

Specifications

Think about parameters like:- Pressure range

- Temperature range

- Volume

- Material

- Atex rated equipment ?

- Stirrer drive (gassing stirrer?, viscosity)

- Grade of control / automation

- Accessories

small Lab reactors 10 – 450ml

tinyclave steel

-

Reactor volume: 10 - 25 ml

Pressure: -1 (FV) 10 /100 bar

Temperature: -20 °C to +200 / 300 °C

Material: Borosilicate glass 3.3, stainless steel, Hastelloy, PFTE

Standard package- Vessel holder with protective mesh

- Glass pressure vessel

- Union nut

- Cover plate with 2 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 1 valve

- Tools and spare parts

miniclave steel

-

Reactor volume: 100 - 300 ml

Pressure: -1 (FV) to +10 bar / 100 bar

Temperature: -20 °C to +200 / 300 °C

Material: Borosilicate glass 3.3, stainless steel, Hastelloy, PTFE

Standard package- Vessel holder with protective mesh

- Glass pressure vessel

- Union nut

- Cover plate with 4 openings and standard setup:

- Swagelok fittings with bursting disc, manometer, 1 valve and Pt100

- Tools and spare parts

miniclave drive

-

Reactor volume: 100 - 300 ml

Pressure: -1 to +60 bar

Temperature: -20 °C to +250 °C

Material: Stainless steel, Hastelloy

Standard package- Stand with height adjustable clamp

- Stainless steel / Hastelloy pressure vessel with suitable stirrer shaft, stirrer, Pt-100

- Safety Fast Action Closure

- Cover plate with 6 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive «cyclone 075» with integrated high torque magnetic coupling, incl. controller «cc075»

- Tools and spare parts

Standard Options- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

picoclave

-

Reactor volume: 100 - 300 ml

Pressure: -1 to +60 bar

Temperature: -20 °C to +250 °C

Material: Borosilicate glass 3.3, stainless steel, Hastelloy

Standard package- Safety housing with polycarbonate sliding door for safe operation of glass pressure vessels

- Pressure vessel in glass, steel / Hastelloy with suitable stirrer shaft, stirrer, Pt-100

- Safety Fast Action Closure

- Cover plate with 6 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive «cyclone 075» with integrated high torque magnetic coupling, incl. controller «cc075»

- Tools and spare parts

Standard Options- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

PPR Parallel Pressure Reactor

-

Reactor volume: 50 ml - 300 ml

Number of Reactors: 2 - 6

Pressure: -1.0 (FV) to +100 bar

Temperature: -20 °C to +300 °C

Material: stainless steel / Hastelloy / Tantalum / PTFE inliner

Modular Hardware:- 2 - 6 Reactors PPR systems are available

- Individual or parallel operation settings for each reactor (temperature, other)

- Configurable hardware: from Basic to complete setup including dosing

- Automated sampling

Operation modes:- Manual: The software controls the reactor hardware, data logging of process data

- Automated: Low to high degree (full process automation including dosing of gas, liquids)

- For full automation, a recipe editor is included in the software to edit existing settings and to define completely new processes.

Multiple safety features guarantee safe hydrogenations and other processes

high pressure 50 ml – 5 liters

midiclave

-

Reactor volume: 0.1 - 1.0 liter

Pressure: -1 (FV) to +200 bar

Temperature: -20 °C to +300 °C

Material: stainless steel, Hastelloy

Standard package- Stand with open access from all sides

- Reactor Lift

- special Safety Fast Action Closure

- Pressure vessel (Type 3 & 4) with suitable stirrer shaft, stirrer, baffle, Pt-100 and bottom valve

- Cover plate with 7 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Stirrer drive «cyclone 075» with integrated magnetic coupling, incl. controller «cc075»

- Tools and spare parts

Standard options- cyclone 300 magnetic stirrer drive

- ATEX stirrer drive

- Electric heating / water cooling

- Measure and control systems

- Wide range of accessories

- Floor stand

novoclave

-

Standard Version:

Reactor volume: 100 - 600 ml

Pressure: -1 (FV) to +400 bar

Temperature: -20 °C to + 400°C

Material: stainless steel, Hastelloy®

High-Pressure Version:

Reactor volume: 100 - 600 ml

Pressure: -1 (FV) to +500 bar

Temperature: -20 °C to + 500°C

Material: stainless steel, Hastelloy®

Standard package- Cover plate with 6 openings (standard setup: manometer, Pt100, bursting disc, 2 valves, and 1 opening as reserve)

- Interchangeable pressure vessel (Type 3) available in 100 / 200 / 300 / 450 / 600ml

- Stirrer drive «cyclone 075» with integrated magnetic coupling, incl. controller «cc075» (speed manually adjustable 0-3000 rpm)

- Electric heating block with integrated automated water cooling system (controlled by PID temperature controller btc via magnetic valve)

- Programmable PID temperature controller btc

- Tools and spare parts

Standard Options

Two pressure/temperature options are available:- -1 (FV) to +400 bar / -20 °C to + 400°C

- -1 (FV) to +500 bar / -20 °C to + 500°C

Alternative stirrer drive:- Stirrer drive cyclone 300 ac

limbo ls

-

Reactor volume: 0.5 - 5.0 liter

Pressure: -1 (FV) to +350 bar

Temperature: -20 °C to +350 °C

Material: stainless steel, Hastelloy

Standard package- Reactorframe with Lift / full accesss to reactor

- Powerful cyclone 075 magnetic drive including controller

- Insulated Steel - / Hastelloy Pressure Reactor (Typ 3E) with electric heating and cooling (by tap water)

- btc PID reactor temperature controller

- Coverplate with 7 openings, pressure gauge, 2 valves, rupture disc

- Tools and spare parts

Standard Options- Measure and control systems

- Wide range of accessories

metal - free 50ml – 20 liters

miniclave

-

Reactor volume: 100 - 300 ml

Pressure: -1 (FV) to +10 bar

Temperature: -20 °C to +150 °C

Material: Borosilicate glass 3.3, PTFE, PFA, FEP

Standard package- Vessel holder with protective mesh

- Glass pressure vessel

- Union nut

- Cover plate with 4 openings and standard setup:

- Swagelok fittings with bursting disc, manometer, 1 valve and thermowell

- Tools and spare parts

inertclave

-

Reactor: 0.5 - 1.0 liter

Pressure: -1 (FV) to +6 bar

Temperature: -20 °C to +180 °C

Material: Borosilicate glass 3.3, PTFE, PFA, PEEK

Standard package- Safety housing with polycarbonate sliding door for safe operation of glass pressure vessels

- Glass pressure vessel with suitable stirrer shaft, stirrer, Pt-100, bottom valve depending on vessel type

- Cover plate with 6 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- Magnetic stirrer drive cyclone «i» with integrated speed controller

- Tools and spare parts

Standard options- High torque magnetic coupling bmd 250 «i» ATEX

- High torque magnetic stirrer drive cyclone 250 «i»

- with integrated ceramic magnetic coupling, incl. controller «cc300»

- measure and control systems

kilo-, verso-, polyclave inert

-

Reactor volume: 1.0 - 20.0 liter

Pressure: -1 (FV) to +6 / 60 bar

Temperature: -20 °C to +180 / 250 °C

Material: 6 bar version: Glass, Glass lined steel, ceramic, PFA, PEEK, PTFE

Material: 60 bar version: Glass lined steel, ceramic, PFA, PTFE, Tantalum

Standard package- Stand with hydraulic lift and tilt mechanism

- Pressure vessel in glass lined steel with suitable stirrer shaft, stirrer, baffle, Pt-100 and bottom valve

- Cover plate with 7 openings and standard setup:

- Swagelok fittings with bursting disc, manometer and 2 valves

- ATEX stirrer drive with adjustable transmission and high torque magnetic coupling bmd 250«i»

- Tools and spare parts

Standard options- cyclone 250 i magnetic stirrer drive

- 60 bar Tantalum version

- measure and control systems

- wide range of accessories

Hydrogenation systems

bpc 2 Hydrogenator - turn key solution

-

Standard features

- Hydrogenation at 0.5 to 140 bar (7 to 2000 psi) pressure

- High pressure version up to 400 bar (6000 psi) on request

- continuous measuring of H2 uptake or other active gas

- gas consumption in mol, ml

- automatic shut-off upon reaching preselected gas quantity or saturation

- maintaining preselected reaction pressure during experiment

- easy to operate / read touch screen panel

- graphic display of reaction kinetic

- data storage on USB memory stick

- many safety features (e.g. leak detector, automatic stop functions, etc.)

- fast charge

Technical data:- accuracy > 99% at:

- flow rates 0 – 225 liters n/min

Active gas (dosing / measuring):- Hydrogen (H2)

- Ethylene (C2H4)

- Carbon dioxide (CO2)

- Carbon monoxide (CO)

- soon: Propylene (C3H6)

- soon: Oxygen (O2)

Options:- measure / display of pressure, temperature, stirrer speed

- automatic functions as Nitrogen purging, inertisation

- sequence program (including venting valve) to define automated process steps with possibility to link these, as an example:

Automated system preparation before run:

step: flush system with Nitrogen

step: Leakage testing

step: flush system with active gas- RS 232 / Ethernet connection to the bls 2 software with up to 16 channels recorded on PC

- remote control function

- set point for thermostats

- etc.

stirrer drives / magnetic couplings

low - high torque magnetic coupling

-

Torque range: 50 - 5400 Ncm

Temperature range: - 50°C to + 500°C

Pressure range: full vacuum - 500 bar / 6000 psi

Materials: stainless steel, Hastelloy, Tantalum, Titanium, ceramic, others

low - high torque magnetic drives

-

Torque range: 75, 300 Ncm

Temperature range: - 50°C to + 400°C

Pressure range: full vacuum - 500 bar / 6000 psi

Stirrer speed: 0 - 2000 / 3000 rpm

Materials: stainless steel, Hastelloy, Tantalum, Titanium, ceramic, others

metal free (inert) stirrer drives

-

Metal - free magnetic coupling bmd 250 i / cyclone 250 i / cyclone i

Torque : 250 Ncm

Temperature range: - 20°C to + 250°C

Pressure range: full vacuum - 60 bar / 1000 psi

Stirrer speed: 0 - 2500 rpm

Materials: ceramic

ex proof stirrer drives

-

Ex-proof stirrer drives operate at low and high stirrer speeds and pressures and are equipped with dry running magnetic couplings. Our magnetic couplings are available in Ex version (ATEX) for low and high torque mixing of low to high viscosity products. They are built in stainless steel, Hastelloy, Tantalum.

Ex - proof stirrer drives operate at a lower stirrer speed and are used in lower pressure applications. They are equipped with dry running mechanical seal.

coupling Accessories to pressure reactors

Agitators, stirrers

-

Depending on the stirring or mixing task, Buchi reactors can be equipped with stirrers of different types.

For gas entrainment as in hydrogenations, the Rushton type turbine stirrer is often used.

Bottom valves, other valves

-

Inner diameter: DN3 - DN25

Temperature: 350°C

Pressure: 350 / 500 bar - 5000 / 7000 psi

Material: stainless steel, Hastelloy, Titanium, other

Buchi bottom valves are very compact, available for different operating conditions and functions. Solenoid bottom valves with a pneumatic actuator are used for automated opening / closing with signal feedback of the status.

Needle valves and ball valves for low and high pressures are installed on the reactor head as needed. Solenoid needle and ball valves with pneumatic actuators are used for automated opening / closing with signal feedback of the status

Catalyst baskets

-

Catalyst testing covers several types of research such as catalyst effectiveness, yield, activation, life time and regeneration.

The type of catalyst baskets varies depending on the catalyst being used, the interaction with the chemistry, the temperature, the pressure and the number of catalysts in the basket. Exposure to the reactants can be done through a stationary catalyst bed or a spinning basket.

Sampling systems

- Systems for manual and automated sampling (up to 4 samples per run) during pressure reactions, see also Parallel Pressure Reactor system PPR.

Burettes, feeding funnel

-

Burettes

Volume: 10 - 1000 ml

Pressure: depending on material

Material: Glass, stainless steel, Hastelloy

Burettes are available in glass with protective jacket or as full metal version for higher pressures with sightglass. Feeding funnels enable fast charge of solids and liquids.

Probes for process control

-

Probes are available to measure the different process parameters. These values can be displayed on our monitoring instrument and recorded in our bls software, see measure & control

Frequently measured parameters are:- temperature

- pressure

- stirrer speed

- torque

- pH

IR probes, probes to control particle sizes etc. from other suppliers can be integrated into our pressure reactors or stirred autoclaves.

Condensers / heat exchangers

-

If very fast heating or cooling is required, an internal heat exchanger can be installed.

For distillation under pressure and under vacuum, complete setups in glass or metal can be attached to the reactor head, including column, reflux condenser, receiver.

Pressure Filter

-

Pressure vessel: 100 ml to 20 Liters

Pressure: -1 (FV) to 60 bar

Temperature: 300 °C

Material: stainless steel, Hastelloy, others

Pressure filters with optional heating jacket for temperature controlled filtration.

Safety devices

- Chemical reactions under pressure request high safety standards. Rupture discs and pressure relief valves are often connected to a blow down tank for safety reasons.

Measure & control

Measure / display for Labs & Plants

-

These systems are designed for measuring and displaying of process parameters in chemical Labs and Plants. We offer solutions for installation:

- inside Ex zones (Field controller and display) (Ex)

- outside Ex zone with probes inside Ex zones ([Ex])

- completely outside the Ex zones or non Ex areas (none Ex)

Control temperature, pressure, pH, ..

-

These systems are designed for the control of single processes in chemical Labs and Plants. We offer single channel control solutions for installation:

- inside Ex zones (Field controller and display) (Ex)

- outside Ex zone with probes inside Ex zones ([Ex])

- completely outside the Ex zones or non Ex areas (none Ex)

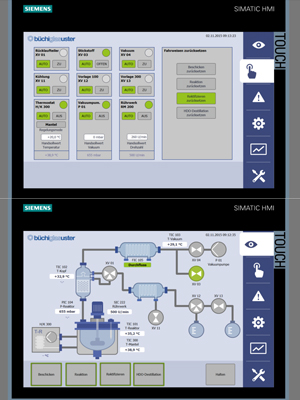

Measure / control software

-

Data logging and control of Büchi devices. The bls software was developed for use with Buchi process measuring and control instruments. It handles data recording, control functions, data export and supports the following Buchi instruments:

- bds md / bds mc measuring / display instrument

- bds mc measure and control instrument

- btc temperature controller

- bpc 2 hydrogenation system

Compatible devices:

bds md, bds mc, cyclone 300, bpc, bpc 2 and btc,

Thermostats Huber, Lauda und Julabo

Standard features- Compatible with Windows 7 and Windows 10

- Simple installation

- Operation of up to 8 devices

- Input of temperature profiles

- Real-time display of up to 12 measured values

- Logging of all measured values

- Data analysis tool with zoom function

- Integrated Log-book /Lab journal

- Data export in ASCII format (*. csv)

Gas / Liquid dosing

-

For gas dosing, we offer solutions for measuring the gas consumption (totalizer) of single and multiple gases at a time:

Measurement of gas consumption of single gas dosing is done with our bpc (Buchi pressflow gas controller). It includes pressure controls and regulations and is typically used for hydrogenations. The bpc control unit is a turnkey solution for dosing and measuring of: Hydrogen (H2), Ethylene (C2H4), Propylene (C3H6), Oxygen (O2), Carbon dioxide (CO2), Carbon monoxide (CO).

Mass flow controllers are used for the dosing of multiple gases.

Dosing of liquids into pressurized and non pressurized reactors is done with dosing- or metering pumps.

Automation / PLC

-

Automation from single process steps to full automation with recipe control

Automation increases reproducibility of single process steps and the productivity of complete chemical processes by fully automated runs.

Buchi adapts and integrates commercially available up-to-date technology of leading suppliers which fulfill current technical guidelines and directives regarding flame proof or ex proof equipment for installation in chemical plants and laboratories where Ex Zone specifications are required. Automation is often customized with existing plant standards.

Buchi solutions cover control of and multiple processes. Customized PLC for chemical plants cover basic control functions:- stirrer speed, vacuum / pressure, Temperature control TCU, data logging

Automation in Chemical Research

In chemical research, reproducibility and productivity is increased by automation. Up to 6 reactors can be operated in parallel by our Parallel Pressure Reactor system, which dramatically shortens the time for research and development.

Buchi solutions for chemical research Labs (and plants):- single channel controller for Lab and plants

- gas / liquid dosing and control

- bpc 2 for hydrogenation

Buchi Autoclaves - General info

Buchi pressure reactor systems

-

Buchi autoclaves and pressure reactors are manufactured according to

international guidelines and regulations as below

- PED - Pressure Equipment Directive (97/23/EC)

- ATEX Zone 0 - 2 classification of the installation site, chemicals used, the chemical process conditions, Directive 94/9/EC

- other international standards, see certificates and approvals

- additional safety measures for operation of glass reactors under pressure

Buchi pressure reactors (or stirred laboratory autoclaves) most outstanding features are the unique modular designs. Pressure reactors (in Borosilicate glass 3.3, glass lined steel, stainless steel, Hastelloy, Titanium, Tantalum) of different types and volumes can be used safely in the same system.

Interchangeable vessels make for easy system upgrades for other tasks like processing of other chemicals, larger volumes, and different pressure ratings.

Extended modularity allows for several reactor systems the ability to integrate a reactor lift and fast action closure for easy operation, a more powerful (Atex) stirrer drive, as well as many other options.

We customize reactors to our customers need, dedicated systems for chemical research, catalyst testing, hydrogenation, polymer research. Talk to us to define your specific pressure reactor.

Sightglass metal & glass reactor

-

Understanding a process can be done by measuring and recording different process

parameters. Of great importance can be changes, which are hard to measure, but

which can be easily observed simply by looking at the reaction through the

pressure vessels' glass wall or through a sightglass on metal reactors, designed

for higher pressure.

Buchi glass reactors for pressure applications can safely by operated at 6 / 12 bar pressure (85 / 165 psi) due to special design - and safety features. High pressure sightglass for steel / Hastelloy pressure reactors are available in a standard configuration up to 60, 100 bar, 250 bar.

Fast Action closure, reactor lift

-

Safe, fast and easy operation with the fast action closure

If the pressure vessel is to be opened frequently, a fast action closure becomes very helpful. Our fast action closure solutions are manufactured and comply with the European Pressure Equipment Directive PED. Reactors can only be opened in unpressurized condition.

Opening and closing the reactor becomes very easy and does not require any tool. With our vessel lift option even heavy reaction vessels can be opened and closed without the need of attending multiple gym lessons beforehand.Nut and Bolt closure of the reactor is the more economic version. It is often the choice picked if reactors are not opened frequently.

The Reactor Lift is very convenient for the operation of heavier pressure vessels. It is available for Nut and Bolt closure as well as for Fast Action Closures.

Jacketed & el. heated reactors

-

Temperature control of pressure reactors in Lab and Pilot Plants

Accurate temperature control of chemical reactors is important for the chemical process as well as for safety reasons (on exothermic reactions especially).There are 2 ways of accurate temperature control of chemical pressure reactors:

Electrical heating for pressure reactors

In case of electrical heating, heating elements are integrated in the temperature control block (limbo and limbo li high temperature / high pressure reactors) or on other Buchi pressure systems on the reactor itself. Integrated cooling coils can be connected to water or compressed air. The Buchi btc PID temperature controller ensures accurate process temperatures and efficient heating. This temperature control systems is used on Lab - and Pilot scale pressure reactors made of stainless steel, Hastelloy and other metals. It is also available in (ATEX) Ex version.

The typical temperature range is from room temperature up to 500°C.

Temperature control units (TCU) used with jacketed reactors

TCUs are used for accurate temperature control in combination with jacketed reactors. By circulating a heat transfer oil through the reactors jacket, efficient heating and cooling of the process media as well as stable process temperature is achieved. Temperature control with TCUs is used for chemical reactors made of glass, glass lined steel, but also made of stainless steel, Hastelloy and other metals.

TCUs installed outside of the Ex zone, connected to reactors inside Ex Zone 1 or 2, require an additional Buchi isolation barrier. For large TCUs, see also glass equipment, auxiliary equipment.

Chemical reactors can be operated by TUCs with heat transfer oils of different temperature ranges from -80°C up to 300°C - info on request. Typical operation temperature: -50 °C to +250 °C

Case Studies / Applications

- Chemical Reactors and process equipment require customized solutions due to involved chemistry, processes, environment and operating conditions. Our proven engineering - and manufacturing expertise lead to perfect solutions for R&D and production scale.

Large scale Hastelloy® high pressure reactor

-

Reactor: pilotclave

Material: Hastelloy®

Jeff Hunter, EVP and Chief Business Officer, Novan Inc. about the pilotclave and his experience with Buchi:

“Buchi has a long history of providing high quality solutions for pharmaceutical applications. The proposed reactor was competitively priced and met our technical specifications. For Novan, the materials of construction (Hastelloy®), minimalization of dead volumes, pressure / temperature ratings, and vessel capacity were the most critical requirements. Advantages of Büchi include responsiveness of the local distribution partner, transparency during the equipment build in Europe, and effective installation/trouble shooting. Novan is very satisfied with the Büchi high pressure reactor and, in fact, we ordered a second unit during Q2 2017.

High temperature polycondensation reactor

-

Reactor: pilotclave, 20 liter

Pressure: 10 bar

Temperature: -10 to + 325°C

Material: Hastelloy® C22

A high temperature polycondensation reactor which includes an integrated distillation column and a powerful magnetic coupling for stirring. The vessel is equipped with a heated bottom valve to allow for the extraction of the polymer at an even temperature. A lifting device was included to allow for easy maintenance and mobility of the system.

Catalyst Testing - from Chemist for Chemist

-

This innovative Parallel Pressure Reactor System was developed upon request from DOTTIKON EXCLUSIVE SYNTHESIS AG ("DOTTIKON"), the Swiss-based specialist in hazardous reactions. DOTTIKON needed a powerful system to test different reaction conditions for catalyst reactions under high pressure as an important prerequisite for a reliable and effective scale-up of chemical processes to large scale production.

It was a joined effort by three specialists that brougth about the successful development of such a sophisticated tool.

Reactor technology- Meeting ambitious user requirements

- 6 high pressure reactors, fully corrosion resistant, with fast action closure

- magnetically coupled, corrosion resistant gassing stirrers

- individual settings (temperature, pressure, stirrer speed) for each reactor

- dosing of solutions in different dosing speeds into reactors (pump - hydrogenation)

- possibility to work with several gases simultaneously

- fully automated, multiple sampling during the run to understand the reaction kinetics

- compact setup to fit in a 120 cm fume hood

- fully automated control and data logging by user-friendly software

Oligonucleotide research

- Synthena AG is developing oligonucleotide based therapeutics primarily for the treatment of genetic neuromuscular diseases by using its tricyclo-DNA molecular platform. It was founded 2012 as a spin-off of the University of Berne. Synthena started the Business with two 15-litre miniPilot reactors and a 30-litre Nutsch filter from Büchi. In our interview, Dr Branislav Dugovic, Chief Technology Officer at Synthena, talks about his first experiences with Büchi equipment.

Hydrogenation plant - 100 liter

-

Reactor: 100 liter

Pressure: 40 bar

Temperature: -10 to +250°C

Material: Stainless steel

Batch pressure reactor system for hydrogenation. The vessel is equipped with heating jacket and internal emergency rapid cooling coil to safely control exothermic reaction. The gas sparging tube allows efficient gas dispersion into the liquid phase. With the sight glass the process can be visually observed and inspected. The distilled vapors are stripped, condensed and collected in the receiver vessel.

UV sensitive chemicals processing

-

Size: 200 liter

Pressure: -1 to +0.5 bar

Temperature: -10 to +200°C

Material: Borosilicate glass 3.3, stainless steel

Round flask glass reactors with stained glass are used for processing of UV-sensitive chemicals. These round flasks with immersion heaters are used as reactors in ATEX zone 1.Heating cartridges inside the large glass flasks ensure fast and precise process temperature control. The flasks are installed on load cells for continuous weight control and dosage.

Suspension polymerization

-

Reactors: 3x 20 liter

Pressure: 20 bar

Temperature: -10 to +250°C

Material: Stainless steel

An automated turn-key pilot plant for suspension polymerization bridges the gap between process development in the lab and production plant.

The entire system was skid-mounted and shipped to the customer, and put into operation within a few days.

Solvent recovery plant

-

Size: 400 + 1000 liter

Pressure: -1.0 to +0.5 bar

Temperature: -60°C to +200°C

Material: Borosilicate glass 3.3

Glass process systems consisting of 400 lt. and 1000 lt. glass lined tank, glass distillation overheads with shell & tube heat exchangers, packed rectification columns, distillate coolers and receivers.

Kilolab for vacuum - pressure process

-

Glass Reactor miniPilot: 10 liter / -1.0 to +1.0 bar

Pressure Reactor kiloclave: 5liter / 60 bar

Hydrogenation system bpc

Glass Nutsch Filter: 10l

Gas scrubber: 6l

Temperature: -90°C to +200°C

Material: Borosilicate glass 3.3, Stainless steel, PTFE ,PFA

This compact and versatile kilolab shows the combination of different Buchi equipment in one plant.

Reactors, filters, gas scrubbers, dosing and control components, were installed in minimal space at the R+D kilo lab at Teva ratiopharm in Ulm, Germany.

Hydrogenations, low-temperature reactions (-80°), chemical processes with strong bases are executed in the system, which serves for Final Step processing also.