Navigation : EXPO21XX > PROCESS INDUSTRY 21XX >

H41: Polymer & Plastics Processes

> HESTA BLASFORMTECHNIK

HESTA BLASFORMTECHNIK

Videos

Loading the player ...

- Offer Profile

- HESTA Blow Moulding

Technology stands for innovative, reliable and flexible blow moulding

technology. Many of our customers no longer want to go without these

valuable attributes and they know to appreciate our machines during their

everyday business.

Our company operates in international markets all around the world. Our customers include multinational enterprises as well as “hidden champions.” As part of the Gansler Group, we are thrilled about a high degree of production depth. This allows supply processes and product quality to be achieved at the highest level.

“Our vision is to be your preferred partner in the extrusion blow moulding of synthetic hollow bodies. Our strategic goal is to produce tailored solutions, to offer customer-oriented services and, through this customer focus, to satisfy our business partners. The execution of this vision calls for innovative and qualitative high-grade products and services that we offer to our worldwide operating customers. Our employees ensure a decisive advantage over our competition through their high level of creativity, their independence and their professionalism coupled with cross-thematic thinking and their strong, pronounced know-how in blow moulding.”

Product Portfolio

Blow moulding machines for consumer packaging

- One of the largest areas of blow moulding is covered by the package industry. The product range extends from the smallest containers for eye drops all the way to oil containers with viewing strips. Our portfolio has developed over the years and was constantly refined. Some of the special features include, amongst others, vario-parison heads with a decorative layer or viewing strip apparatuses, leak tests, circle cutters and guide rails in the machine.

HESTA200

-

- For items up to 750ml (1,000ml)

- Single-station blow moulding machine

- 1-fold to 4-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 36 & Ø 45

- Clamp force max. 27 kN

- Predecessor model HS

HESTA310/360

-

- For items up to 2,500ml

- Single-station blow moulding machine

- 1-fold to 6-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 50, Ø 55, Ø 60, Ø 70

- Clamp force max. 60 kN

- Predecessor model HMD

HESTA310/360D

-

- For items up to 2,500ml

- Double-station blow moulding machine

- 1-fold to 6-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 50, Ø 55, Ø 60, Ø 70

- Clamp force max. 60 kN

- Predecessor model HMD

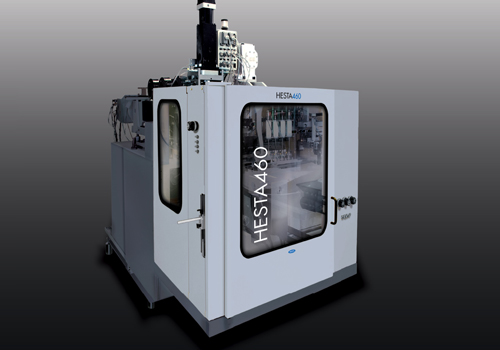

HESTA360/460

-

- For items up to 5,000ml

- Single-station blow moulding machine

- 1-fold to 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 60, Ø 70, Ø 80

- Clamp force max. 120 kN

- Predecessor model HG

HESTA490

-

- For items up to 5,000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 80, Ø 90, Ø 100

- Clamp force max. 120 kN

- Predecessor model HLD

- Also available for 10 litre canisters

HESTA700

-

- For items up to 5,000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 10-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 90, Ø 100

- Clamp force max. 220 kN

- Predecessor model HLD

- Also available for 10 litre canisters

HESTA900

-

- For items up to 5,000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 16-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 100, Ø 120

- Clamp force max. 400 kN

- Also available for 10 litre canisters

Blow moulding for industrial packaging

- Industrial packaging includes, among others, canisters and barrels whose volume contains more than 20 litres.

HESTA360/460

-

- For items up to 5,000ml

- Single-station blow moulding machine

- 1-fold to 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 60, Ø 70, Ø 80

- Clamp force max. 120 kN

- Predecessor model HG

HESTA490

-

- For items up to 5,000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 80, Ø 90, Ø 100

- Clamp force max. 120 kN

- Predecessor model HLD

- Also available for 10 litre canisters

HESTA700

-

- For items up to 5,000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 10-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 90, Ø 100

- Clamp force max. 220 kN

- Predecessor model HLD

- Also available for 10 litre canisters

HESTA460J

-

- For items up to 10.000 ml

- Single-station blow moulding machine

- 2-fold to 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 70, Ø 80

- Clamp force max. 200 kN

- Also available for 10 litre canisters

HESTA490J

-

- For items up to 10.000 ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 90, Ø 100

- Clamp force max. 200 kN

- Also available for 10 litre canisters

HESTA700J

-

- For items up to 20.000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 10-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 90, Ø 100

- Clamp force max. 400 kN

- Also available for 10 litre canisters

HESTA900

-

- For items up to 5,000ml

- Double-station blow moulding machine

- 2 x 2-fold to 2 x 16-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 100, Ø 120

- Clamp force max. 400 kN

- Also available for 10 litre canisters

Blow moulding machines for automobile components

- Along with classic machines, for this area, we also offer customized solutions per customer request. HESTA specially developed and successfully positioned the necessary blow moulding machines for the demands of this market.

HESTA805

-

- For air ducts and filler tubes

- Single-station blow moulding machine

- Accumulator head 2,500 ml (electric or hydraulic)

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 60, Ø 70, Ø 80

- Clamp force max. 250 kN oder 500 kN

- Predecessor models SG, ST, SB

Blow moulding for medical technology

- Blow moulding also plays a large role in medical technology. The Hesta machines for the production of medical applications are specially adapted to the clean-room environment. Our fully electric machines are especially suitable for the cleanest production possible. We have already proven our specialized know-how in this area in many cases.

HESTA200

-

- For items up to 750ml (1,000ml)

- Single-station blow moulding machine

- 1-fold to 4-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 36 & Ø 45

- Clamp force max. 27 kN

- Predecessor model HS

HESTA310/360

-

- For items up to 2,500ml

- Single-station blow moulding machine

- 1-fold to 6-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 50, Ø 55, Ø 60, Ø 70

- Clamp force max. 60 kN

- Predecessor model HMD

HESTA310/360D

-

- For items up to 2,500ml

- Double-station blow moulding machine

- 1-fold to 6-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 50, Ø 55, Ø 60, Ø 70

- Clamp force max. 60 kN

- Predecessor model HMD

HESTA360/460

-

- For items up to 5,000ml

- Single-station blow moulding machine

- 1-fold to 8-fold Production

- fully-electric, hydraulic or hybrid

- Extruder sizes: Ø 60, Ø 70, Ø 80

- Clamp force max. 120 kN

- Predecessor model HG

Services

Retrofit Service

- Perhaps, you aren’t looking to invest in a new machine, rather you would like to update your existing machine based on today’s technological standards. We have the perfect solution for you: our retrofit service. With our retrofit service, you not only achieve the best possible degree of productivity, but you also produce more energy-efficiently and, thus, also save in energy costs. With new drive systems, a new cabinet, new housing, a new touch-panel and much more, you have no limits and your old machine will be just like new. Through our many years of experience in the area of blow moulding technology, we are up to every task and are always available to you with advice and assistance. Should you have any questions, please don’t hesitate to contact us. We look forward to generating a personalized offer for you.

Prototypes and Material Tests

- Do you have a new material that you would like to test? Do you have special requirements for a product? Or do you need support with a feasibility analysis? Then you have come to the right place. We are ready to provide you with our know-how. Many different types of materials can be tested and recorded.

Turn Key Solutions

-

You don’t want to spend time dealing with the project planning of integrated production lines? No problem! Our sales team is happy to consult you on the opportunities of a turn-key system that includes, along with the blow moulding machine, all peripheral equipment all the way to the packaging of the products ready for shipment.

During the projecting phase, you generally receive multiple layout suggestions from our process specialists. You simply make your choice as to which one meets your needs and ideas. At the end, you receive a completely personal offer elaboration and, should you place an order, ultimately, a ready-to-use production line all from one source – from HESTA!

Financing concepts

- Hesta Blasformtechnik GmbH & Co. KG developed a new financing concept for their customers. Financing is completely handled by Hesta Blow Moulding Technology. At no time are you dependent on a bank and will not face any excessive interest rates. We would be thrilled to answer any additional questions or provide you with a detailed offer.

Spare Parts

-

HESTA has a worldwide network of distribution partners. Upon selecting our partners, we paid close attention to choosing companies that can locally provide you and your company with replacement part packages. This means that with each sale of a machine, a replacement parts package that is appropriate to the type of machine is prepared for you locally. This guarantees quick assistance in the event of an emergency.

You need original replacement parts for your Hesta blow moulding machine or you would like to update it with the latest technology? Simply enquire directly with our spare parts distribution department, which is available to you worldwide.

Worldwide reachability

- Not only does Hesta offer original replacement parts worldwide and technical customer service for all blow moulding machines, but it is represented by distribution partners in more than 50 countries. This allows us to guarantee our customers the fastest help possible. We also offer solid support and service so that you can produce efficiently. Our sales and service personnel on location, along with the specialized departments in Göppingen, ensure seamless replacement parts service and short-term support with process-related questions.

Maintenance contracts

-

In order to be able to ensure a long and successful life of your machine and to constantly maintain the production efficiency, Hesta offers maintenance contracts. Maintenance contracts include mechanical functional testing, the elimination of small malfunctions and deficiencies all the way to the creation of a written inspection report after completion of the work. Hesta offers monthly, quarterly and annual maintenance contracts, depending on the customer’s request.

Along with our customary Start-up Packages, which contain set-up information for a new facility as well as an introduction to our newest technologies and innovations for your staff, we are also glad to assist you in establishing planning security for your future.

Our Basic Package ensures that you have quick access to all wear parts and necessary operating materials directly on site. This allows you to carry out minor repairs on your own.

The Advanced and Premium Replacement Part Packages allow for regularly scheduled maintenance and inspections to be carried out by one of our specialists once you have acquired a HESTA blow moulding machine.

Here at HESTA, we also like to recommend Aseptic Maintenance to our customers. Don’t wait to act until a malfunction that could impact your production process arises. Avoid such incidents by having our specialists replace wear parts through preventive maintenance.

Our Service Packages are, of course, not only limited to new machines. They may also be ordered for existing facilities as well as for blow moulding machines which we have retrofitted.

Training

- Do you and your team need further training in the field of blow moulding, and are you looking for a training provider with an extremely high level of process engineering expertise, and interdisciplinary knowledge? HESTA offers a whole host of opportunities! Our experts can put together a customised training programme for you. You can choose between training courses for career beginners or courses for existing employees who would like to build on their already broad knowledge of blow moulding. We would be happy to invite you to a training course at our site. Our experts can also visit your site, if the training course is for a larger group!

Technology

Non-continuous tube extrusion

-

In a non-continuous tube extrusion process, so-called accumulator heads are used. HESTA offers a range of solutions for several areas of application and various machinery types.

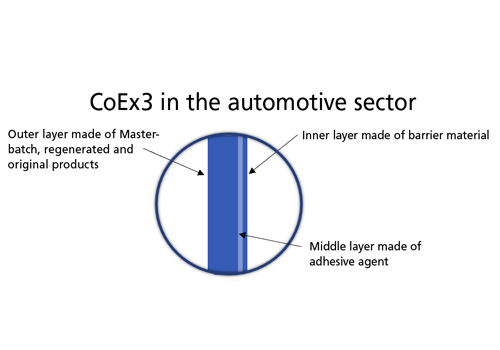

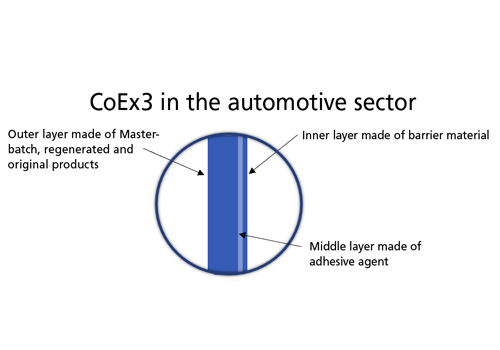

In the automotive sector: For suppliers in the automotive sector, we manufacture accumulator heads with one or more strands. It is therefore possible, for example, to place several filler pipes for fuel tanks next to each other. The accumulator heads used have 1 to 3 layers.

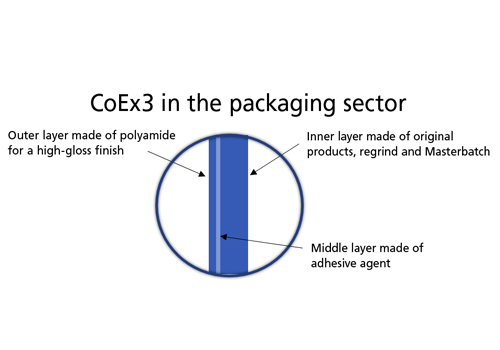

For the packaging sector: In the packaging sector, accumulator heads are best for particularly long or heavy products.We therefore offer the possibility to produce long packages measuring up to 1000 mm from unstable materials such as polyamide, or stabilised PET materials. In part, the accumulator head technology is combined with so-called “shuttle machines”.

Continuous tube extrusion

-

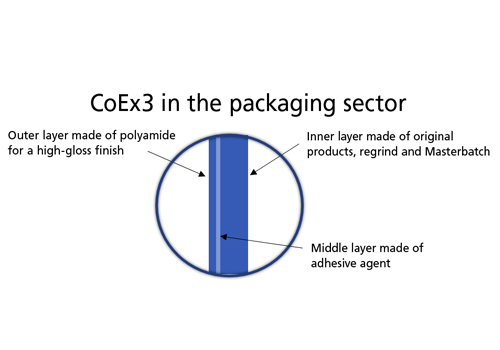

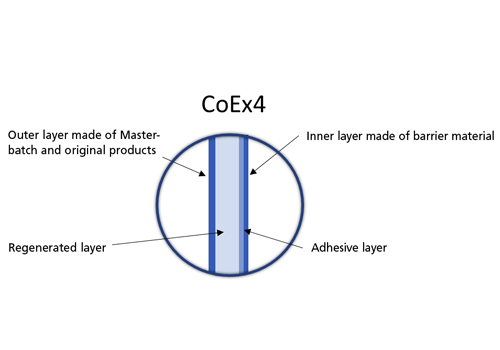

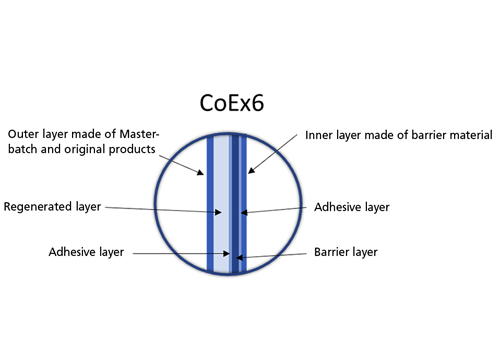

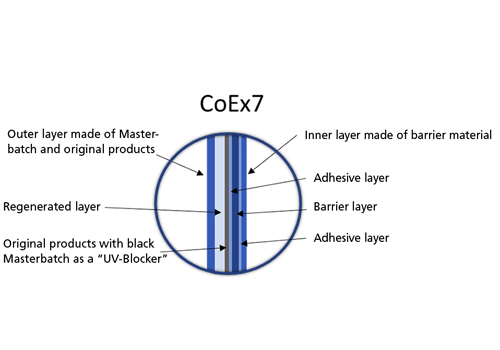

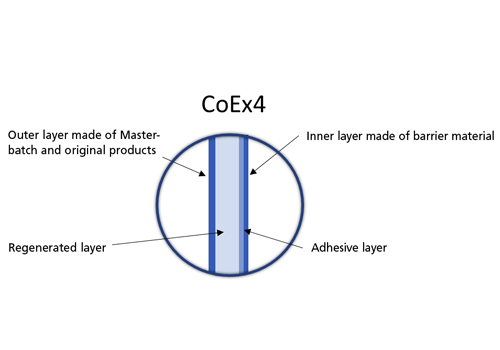

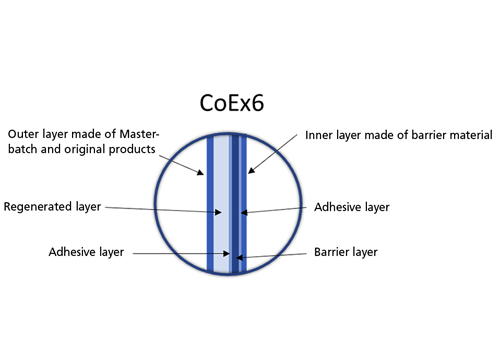

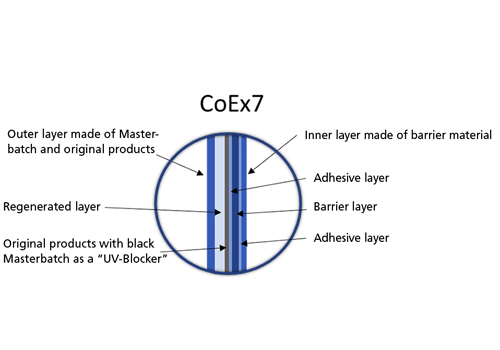

In a continuous tube extrusion process, so-called mandrel holder heads or side-fed dies are used. HESTA has a wide range of head designs available. NIn addition to the tried and tested 1-layer heads in the mandrel holder design, you can also benefit from the innovative side-fed design for faster colour changing times, which we use in up to 3 layers. For so-called CoEx applications with up to 7 layers, we rely on our well-established partner, W. Müller GmbH.

In the automotive sector: We provide various machine types to suppliers in the automotive industry. For example, our SG805 model can be fitted with a continuous CoEx head. Suction blow applications can be mapped in 6 layers on this machine, in order to avoid expensive 3D loading procedures using robot technology. Our shuttle machines are ideally suited to smaller fuel tanks, e.g. for garden tools or two-wheeled vehicles.

In the packaging sector: Our packaging machines have been successfully used for several years. Our customers belong in the following industries: cosmetics, domestic goods, industrial packaging, and food and medical technology. Whether you want to produce optically high-quality packaging using “glass effect materials”, or multi-layer containers with up to 7 layers for the food industry, HESTA has the right machine!

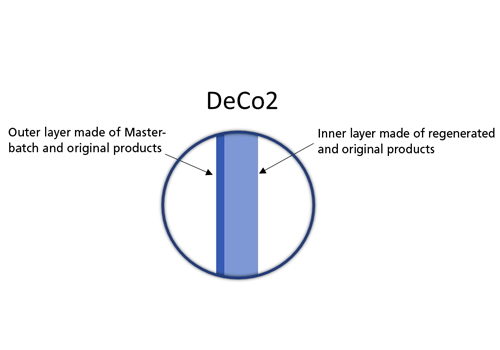

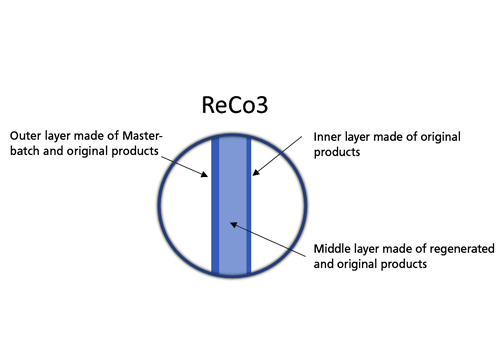

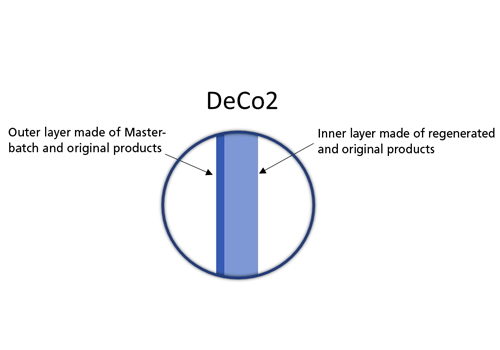

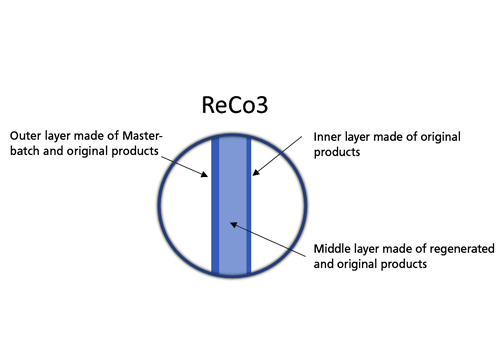

Layer configurations