- Offer Profile

- We offer compressors, blowers, impellers and process engineering in areas such as the chemical industry, refineries, liquid gas storage tanks, effluent treatment, laminating, etc.

Products

-

Innovative, reliable, customised. FIMA products.

Maximum safety, short ROI times, low running and life cycle costs, environmentally friendly processes, extreme load ranges, sophisticated production processes – the technological and economic requirements made of FIMA system solutions call for a high level of design expertise and engineering skills. Implementation areas include production plants in the chemical industry, refineries, liquid gas storage tanks, effluent treatment, laminating, sintered metal production, cryptogenic processes in the aerospace industry, high-speed applications, polisilicon production, transporting flammable and toxic gases, production of organic fuels and many more besides.

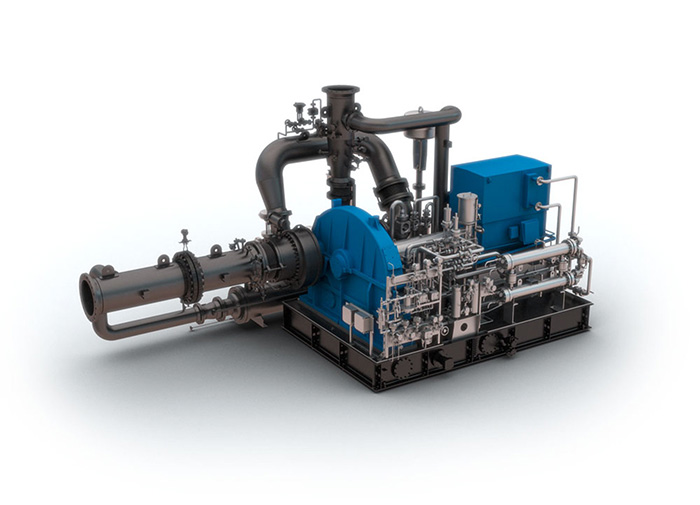

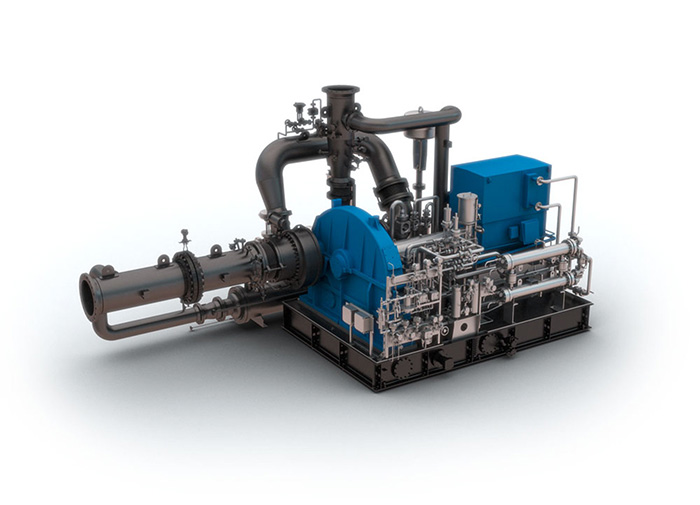

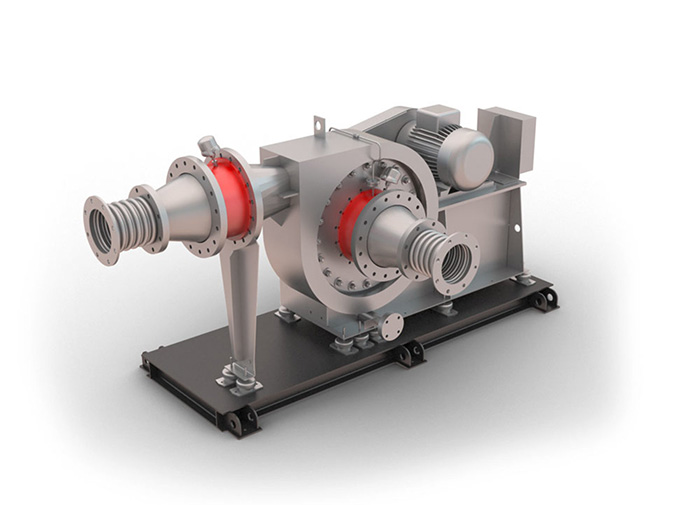

Radial Compressors

-

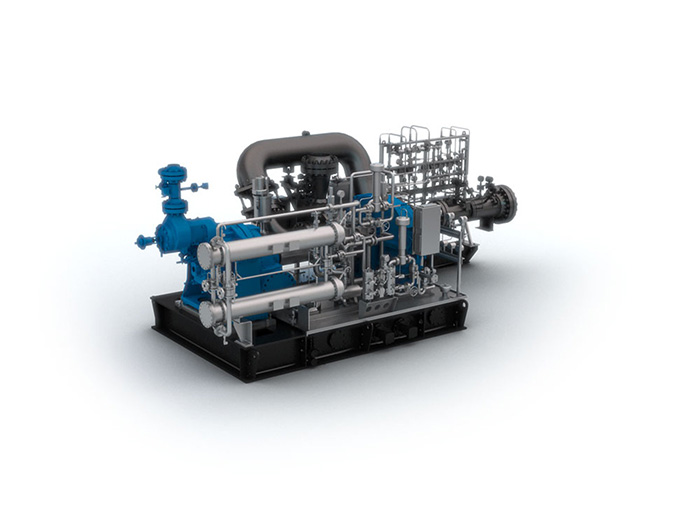

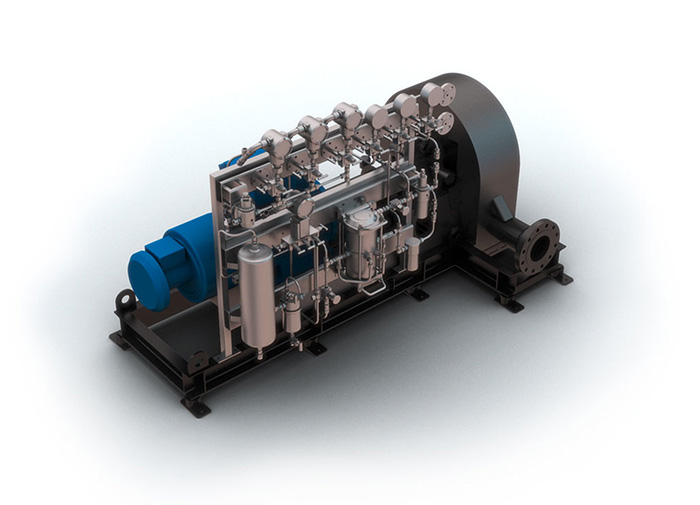

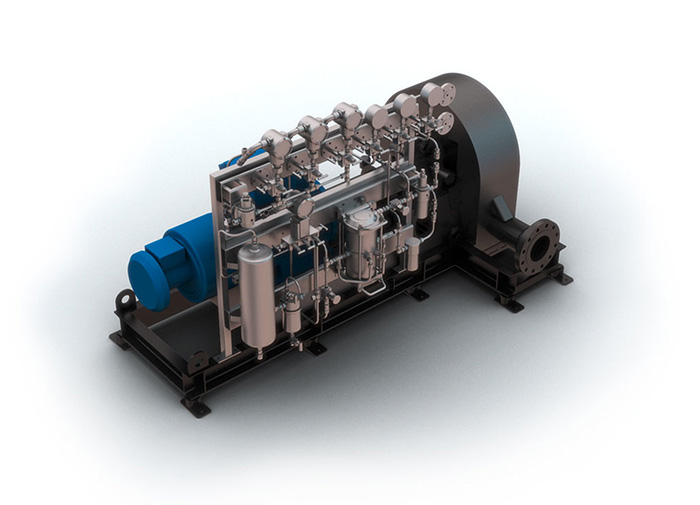

Our radial transmission compressors include single- and multi-stage process gas compressors, process air compressors and mechanical vapour compressors.

In the integral version the impeller is directly mounted on the high-speed shaft. Alternative versions are fitted with intermediate bearings.

FIMA is the acknowledged world market leader in low-volume radial compressors. This type of compressor is frequently implemented in chemical processing plants or refineries to return some of the flue gas to the process.

Applications- Used as a fresh air compressor in the chemical and petrochemical industries to support processes in process engineering.

- Used in sewerage treatment for air enrichment in clarifiers.

Fields of application

- Flow rate: 150-300,000 [m³/h]

- Max. system pressure: 150 [bar]

- Pressure ratio per stage: up to 2.5

- Rotation speed: up to 35,000 [rpm]

- Drive power: up to 5.0 [MW]

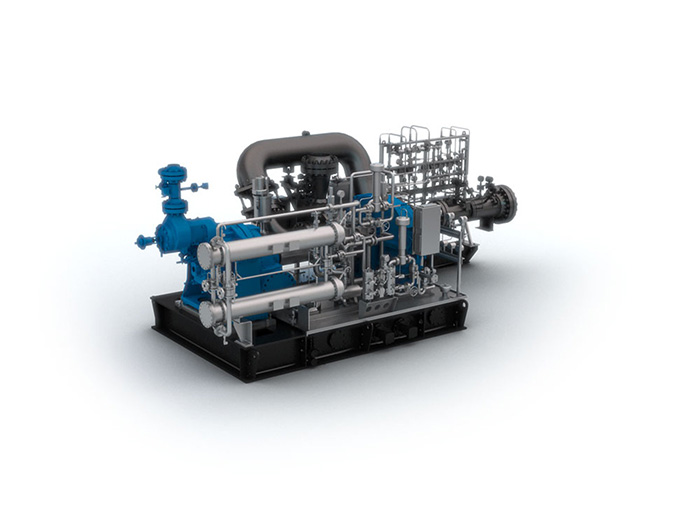

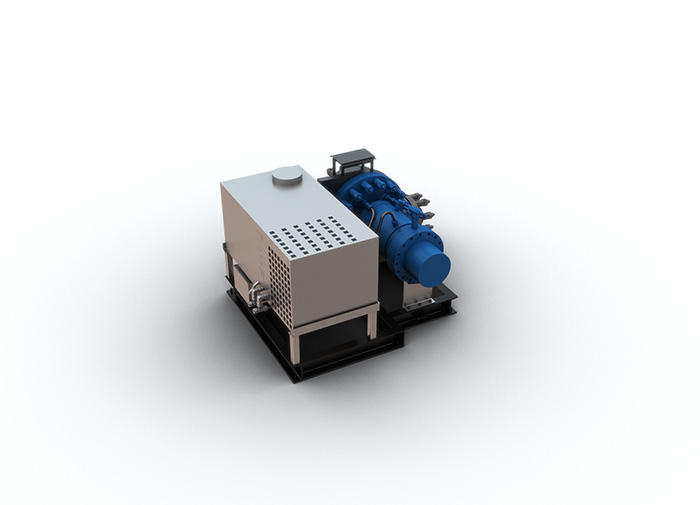

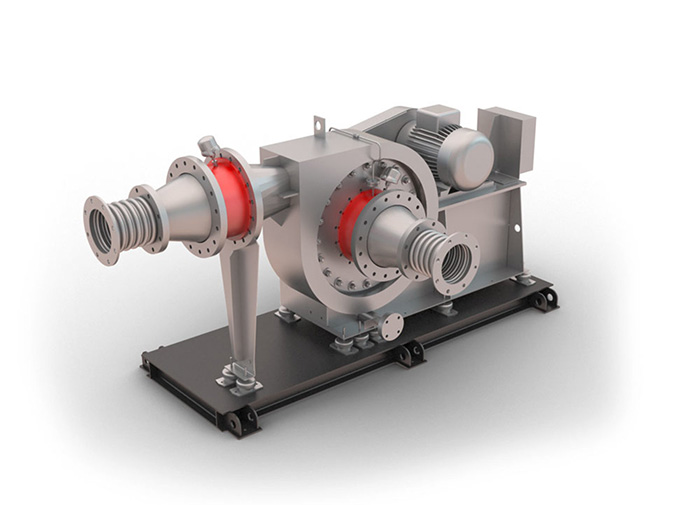

Hermetically encapsulated blowers and compressors

-

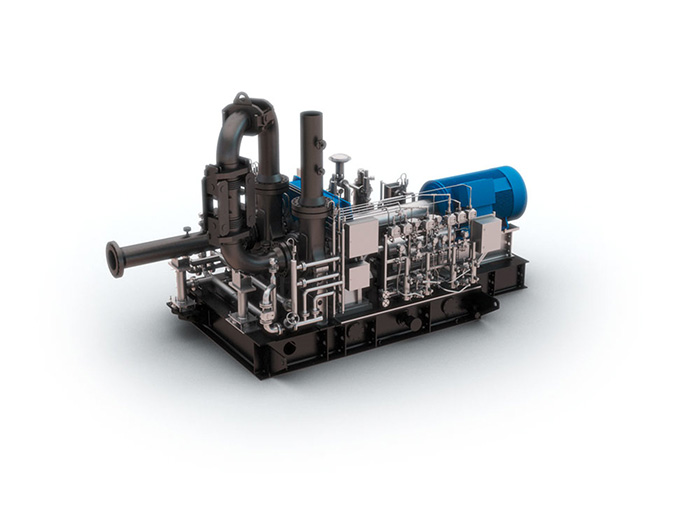

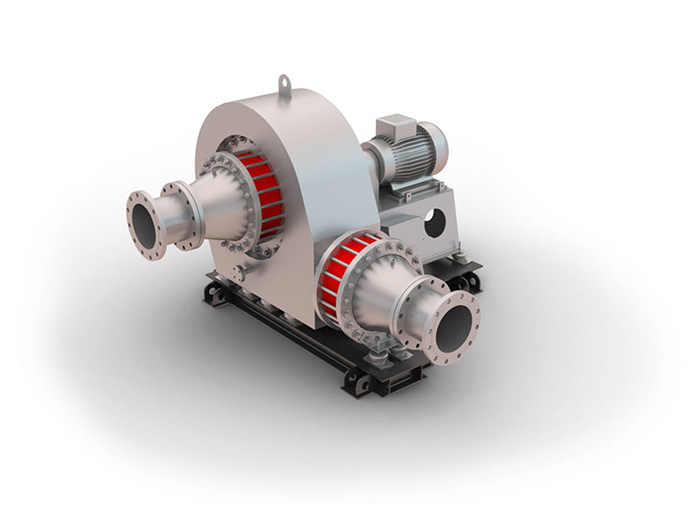

HETICO

(Hermetic tight compressor)

On this versions the impeller and motor are combined in a single casing to avoid the necessity of dynamically stressed gaskets between the processing area and the surrounding ambience.

MACOUCO

(Magnetic coupling compressor)

In comparison to conventional machines, the MACOUCO version offers a high level of environmental friendliness thanks to the design principle on which the magnetic coupling is based.

MAHECO

(Magnetic hermetic tight compressor)

In addition to these technical properties, the MAHECO versions are equipped with an active magnetic bearing that effectively reduces friction and wearing even further. Benefits: high speeds, virtually unlimited life span and improved efficiency.

Applications:- High-pressure applications

- Cryogenic technology applications

- High-speed applications (up to 20.000 rpm)

Fields of application

- Flow rate: 20-10,000 [m³/h]

- Max. system pressure: 150 [bar]

- Pressure ratio per stage: up to 1.5

- Rotation speed: up to 15,000 [rpm]

- Drive power: up to 250 [MW]

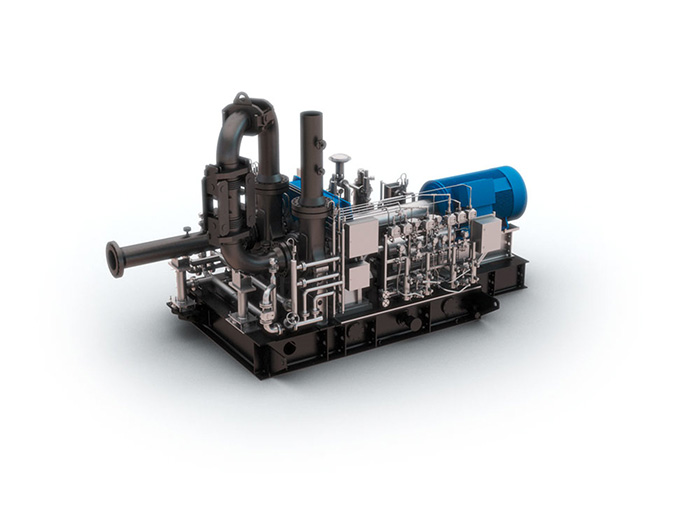

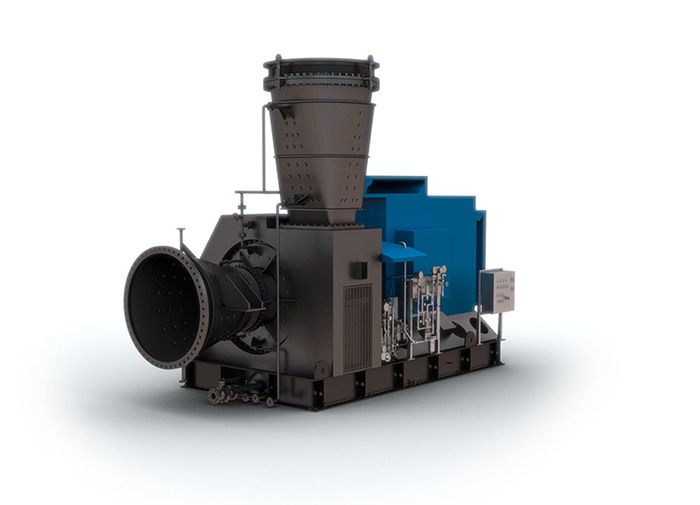

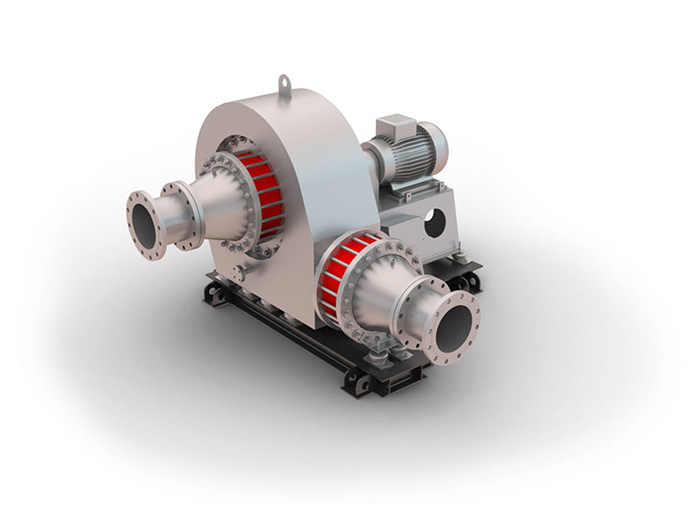

Radial fans

-

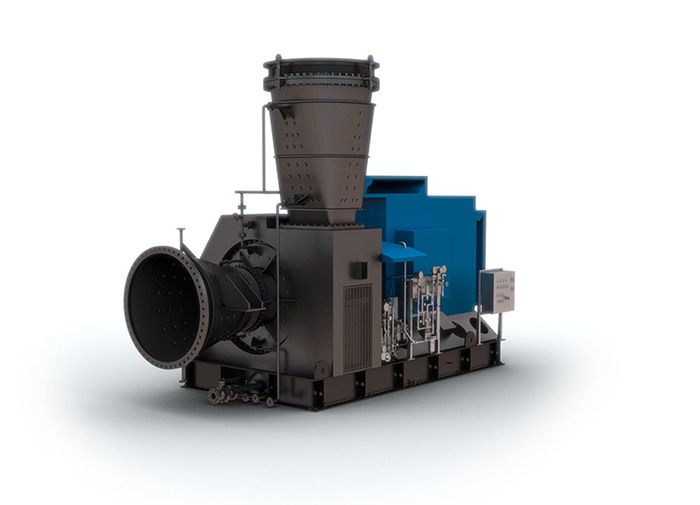

FIMA radial blowers are characterized by their rugged design (heavy duty industrial version) and endurance. We offer

customized solutions in pressure-resistant, gas- and corrosion-proof designs for the majority of applications in the chemical and petrochemical industries.

Thanks to their high safety and quality standards our system solutions are frequently implemented along with environmentally hazardous substances or potentially explosive compounds.

Applications- process gas blowers

- exhaust gas blowers

- smoke gas blowers

- fresh air blowers

Fields of application

- Flow rate: 80-500,000 [m³/h]

- Max. system pressure: 100 [bar]

- Pressure ratio per stage: up to 1.5

- Rotation speed: up to 12,000 [rpm]

- Drive power: up to 5.0 [MW]

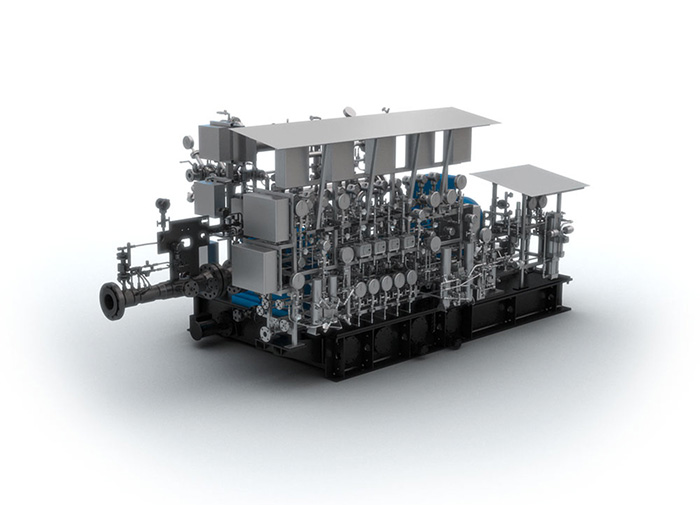

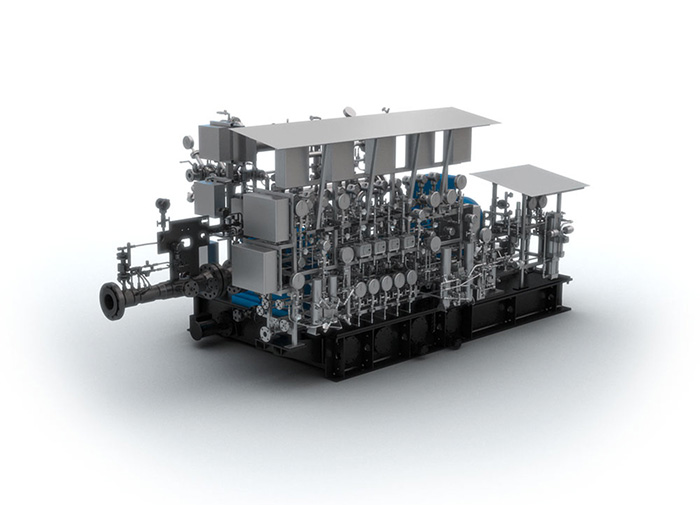

Explosion-proof blowers

-

Both the gas or gas mixture to be transported and the ambient atmosphere inside

and outside the production plant may be explosive and thus extremely dangerous.

No matter whether the risk of explosion is temporary, long-term or constant, the

safety of your production line and, above all, your employees take first

priority. Explosions must therefore be prevented and the risk excluded as far as

possible.

Nevertheless, in the event of the gas mixture igniting it must be ensured that the explosion is confined to the machine and damage to the plant and personal injury prevented. We ensure greater safety with our explosion-proof blowers and their tested components from well-known manufacturers. In application areas like Zone 21 or 22 through to the most dangerous Zone 0 applications, in which the risk of explosion is permanent, we are your competent partner.

Safety specifications

Inner equipment:

Zones 0, 1, 2, 21, 22

Outer equipment:

Zones 1, 2, 21, 22

Explosion groups and temperature classes of gas-air mixtures:

Zone 0 IIA, IIB3 and IIB, T1 to T4

Zone 1 and 2: IIA, IIB and IIC, T1 to T6Fields of application

- Flow rate: 20-10,000 [m³/h]

- Suction pressure: min 800 [mbar]

- Discharge pressure: min 1300 [mbar]

- Motor power: up to 160 [kW]

- Pressure rise: up to 300 [mbar]

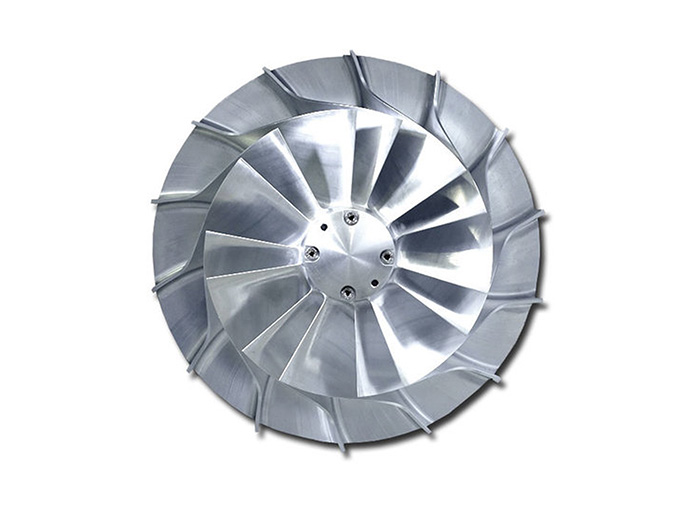

Impellers / Rotors

- FIMA possesses long-standing expertise in the production of heavy-duty impellers made from all types of steel and alloys. In-house specialists test the quality of the processed metals as well as those at all stages of production. FIMA impellers are continuously improved in the company’s own R&D department, using for instance, CFD (computer fluid dynamics).

Service

-

Competent, customer-friendly and flexible. service@FIMA.

If your focus is on the manufacture of customised machinery, you require one thing above all else: qualified committed service teams at local level to ensure that you, the customer, get what you need. This includes installation, trial runs and commissioning, maintenance and modification work, and the seamless management of maintenance history files for all FIMA systems. The excellent reputation of our service is founded on two pillars: flexibility and customer centricity on the one hand, and on the other, handcrafted precision, responsibility and comprehensive technological know-how. In this way, we offer the best possible service for your industrial gas blowers, compressors and turbocompressors, not to mention centrifugal dryers (TZT) and bottom valves (TBV), which are deployed in process engineering.

A brief overview of our extensive portfolio of services:

- System optimisation: increase in performance and energy efficiency

- spare parts

- commissioning

- installation & test runs

- inspections

- repairs (at your premises or FIMA)

- courses/training

- service agreements

- troubleshooting

- conversion, adjustment and modernisation

- maintenance & repair

- FIMA plug and play: replacement of machinery of the same design

- and so forth

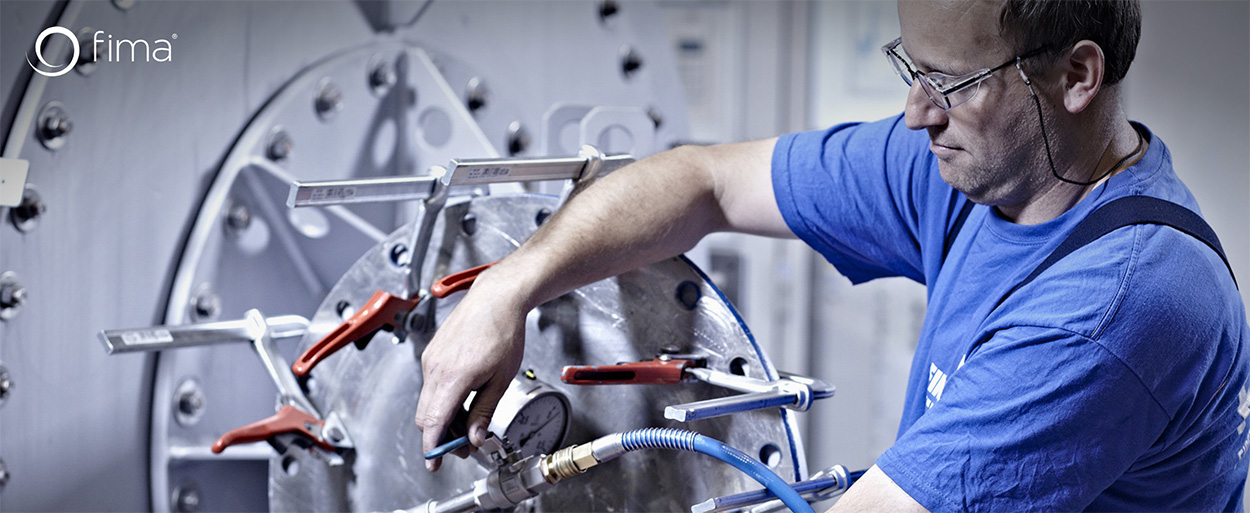

Outdoor assembly

-

From machinery set-up, commissioning and subsequent regular maintenance and repair, the FIMA service package covers the entire life span of the delivered equipment.

We not only perform regular maintenance and repairs, but of course also take care of any required performance adjustments in the course of plant optimization. Our service technicians remedy unforeseen faults at short notice as reliably as we conduct training for our customers' operating and maintenance personnel, it's all part of our service.

Wherever our service technicians and engineers are deployed in the field, they can rely on qualified support from our in-house team of experts. This applies both to fluidic and mechanical matters, e.g. in connection with vibrational or acoustic problems.

Repair, conversion, adjustment

-

Backed by many years' experience FIMA is also expert when it comes to addressing increasing demands for plant upgrades or prolonged life spans. In doing so, we incorporate the latest insights from ongoing development work on our machinery into all our overhaul and

modernization projects.

Our portfolio does not stop at our own products.Service for other makes

At your request, we will also be happy to service machinery from other manufacturers. As plants grow old or an improvement in performance, availability or reducing environmental impact is called for, modernization and retrofitting is often a low-cost solution. Typical measures include:

- integration of new impellers with improved performance data

- improved shaft seals and reduction of seal gas consumption

- conversion to improved warehousing systems

- retrofitting with automated machine monitoring systems

- reduction of noise emission thanks to appropriate soundproofing

- improved paintwork and corrosion protection

Original spare parts

-

No matter when or to where machinery was delivered, we supply customers with the original spare parts they require in top quality, at top speed. This is guaranteed not least by the clearly structured processes maintained at FIMA as a certified company, also in its after-sales service.

All processes are managed by our competent committed staff, from request processing through to shipping. Reliable spare parts supplying is guaranteed by a database with a seamless record of all previous repairs and spare part deliveries for every single machine sold by us.

Aside from constant updating of service history files, we also attach importance to the thorough evaluation of the reports compiled by our service personnel. Based on the latter, we can make the customer qualified recommendations on which spare parts to stock, and forecast which maintenance jobs should be planned.

Our strong customer orientation guarantees fair prices for you, at any time. To make sure we reach this goal, our prices are checked regularly. Despite all our efforts to reduce the prices, we stick to the high FIMA quality standards to fulfil the requirements of our customers.

Company

-

Made in Germany for global markets

We are an innovation and growth-oriented company with an excellent international reputation in fluid mechanics. Our core competencies are development, production, control engineering and after sales service. A major share of our revenue is generated outside Germany, on all continents of the world. Globalization or – in other words – the worldwide interlacing of markets affects us personally on a day-to-day basis. For us it means mutual respect and international allegiance. Respect and trust are key requirements for successfully completing demanding projects based on cooperation.

Research & Development

-

As a quality-conscious innovative market driver we continually invest in our in-house applied research and development. Aside from system solutions, we concentrate on material research, flow simulation and measuring engineering.

Examples of our research work include the HETICO compressor that for the first time combines impeller and motor in the same casing, the magnet bearing compressor MAHECO that, among others, is used in high-speed silicon production applications.

Quality is paramount. One key focus of our R&D activities is the development of flow-optimized impellers based on CFD (Computer Fluid Dynamics).

Production

-

Technology leader

Our products must satisfy the highest standards. Day in, day out, year in, year out.

At FIMA our principle has always been to accept nothing less than excellent quality in our products. Our systems and system components form part of our customers’ highly sophisticated plants. Our products must blend in seamlessly with their respective technological environment in order to ensure smooth production and processing. We meet this responsibility with the greatest precision.

Extreme requirements spectrum.

FIMA is world market leader in the Zone 0 blower sector for transporting permanently explosive gases. This also says a lot about our promise of quality. After all, anyone with a leading edge in areas with such extreme requirements, is sure to guarantee availability and a long service life when it comes to other technical challenges.

Planning & Design

-

Precision analysis. Customized concepts.

The field of fluid mechanics is a complex one. What are the challenges involved, for instance, with regard to existing plants and infrastructures? What are the technical requirements, for example, in respect of reliability, stability and safety? What special conditions must be taken into account, in respect of e.g. climate, environmental and site influences?

Our analyses draw on decades of experience in fluid mechanics and processes, e.g. in the petrochemical, organic fuel, chemical, production, pharmaceutical, iron and steel and energy sectors.

As a confirmed solution-oriented company, we focus on technological compliance and flexibility as our guiding principles. So you can rest assured that we also achieve the optimum solution when working with other makes.

Co-developing customized solution approaches with FIMA pays off. As soon as we have jointly defined all the criteria relevant to the project, we get down to work. And design reliable systems and system components that are tailored to your requirements.

Quality

-

Premium quality is one of FIMA's foremost corporate goals, and it is crucial to company success in the long term.

For FIMA, quality is the comprehensive fulfilment of the requirements and wishes of our customers. It is ensured by all customer expectations and requirements being recorded and complied with at an early stage.

Quality starts with the mindset and inner attitude of each individual employee. Only our customers and their customers respectively judge the quality of our service. The prerequisites for quality are a shared vision, and the will of each employee to ensure maximum quality.

All employees are thus part of the quality system. Their ideas to improve our work processes and products make a fundamental contribution to our company’s success.