EGGER

Videos

Loading the player ...

- Offer Profile

- Emile Egger & Cie SA is a

medium-sized, independent and owner-operated Swiss industrial enterprise

with a concentration on the development and manufacture of pumps and Iris®

diaphragm control valves.

Owner-led enterprise since 1947

The Swiss pumping pioneer Emile Egger founded the company in 1947 in Cressier and began to manufacture immediately. Already back then, the speciality was already the pumping of fluids laden with solids and gas. Thanks to its careful, step-by-step expansion, the enterprise was able to retain its independence and has remained a family undertaking to this day. Since then, the grandson of the founder has taken over the controls and thus secured a harmonious succession.

Product Portfolio

Centrifugal pumps and control valves

- Since 1947 Egger is producing centrifugal pumps and control valves in Switzerland for challenging applications. The whole development and production with final quality control are done in our proper workshops.

Concrete-mixer recycling pump T 39-65 UMV2

-

The reliable concrete-mixer recycling pump T 39-65 operates as transporter filler pumps, mixer pumps or tank transfer pumps.

Sewage water with concrete components as cement, fine sand, and low-grained mixed gravel can be pumped with high operational reliability for recycling reuse, in concrete production.

Decades of excellent service for the conveying of demanding and abrasive media in the cement and concrete industries.

Features- High-performance pumps for pumping concrete-mixer recycling water. The wear-resistant chromium cast housing pump in combination with the renowned hydraulics Turo® Vortex ensure a long tool life under difficult and demanding conditions.

Facts & Figures- Pump casing and impeller: Hardened chrome cast iron, hardness 60 HRC

- Shaft: Stainless Steel 1.4021

- Double mechanical seal:

- Primary: MS with encapsulated rotating spring, SiC/SiC

- Secondary: MS with Elastomer bellows, SiC/ Carbon graphite

Advantages- Long tool life

- A robust construction, a thick casing, robust shaft bearings and highly wear-resistant chrome cast materials ensure long operating times.

- Insensitivity to abrasion

- The geometric shape of the impeller is adapted to the vortex casing. That reduces the abrasive attack to a minimum.

- Quiet running

- No radial forces are transmitted to the shaft by the recessed impeller in the casing.

- Non clogging

- Solids up to 65 mm spherical size can be handled without dysfunction.

- Reliability

- The Egger hydraulics, quiet running and proper sealing systems ensure trouble-free operation.

- The Egger hydraulics, quiet running and proper sealing systems ensure trouble-free operation.

- High-performance pumps for pumping concrete-mixer recycling water. The wear-resistant chromium cast housing pump in combination with the renowned hydraulics Turo® Vortex ensure a long tool life under difficult and demanding conditions.

Iris® diaphragm control valve

-

Energy saving valve for the precise and economical control at low loss of pressure of liquids and gases that can be either clean or contain particles.

Applications- Air for aeration in wastewater treatment plant

- Gases

- Municipal and industrial wastewater

- Slurries and viscous materials

- Paper pulp and fibrous suspensions

- Pellets with a particle size over 0,5 mm

- Sugar suspensions

- Drinking water

Features- Highly precise control of the flow rate through concentric Iris® diaphragms (similar to a camera diaphragm).

- Energy-saving and low-noise control valve due to its free centric passage.

- Maintenance free

Facts & Figures- Nominal dimensions: DN 25 - 400 mm

1 - 16" - Pressure: up to 10 bar / 150 psi

- Temperature: up to 220 °C / 428 °F

- Materials: Casing: GG, 1.4409, 1.4588

- Segments: Bz hard chrome-plated, 1.4404, M340, 1.4529

- Special materials on request

Advantages- Energy-saving flow control

- No hysteresis

- Robust construction, suitable for frequent start-stop

- Low pressure losses due to larger open channelHigh flow capacity Cv (Kv

- Turbulence-free across the entire range of flow regulation

Operations and drives- Manual operation

- Electric operation

- Pneumatic operation

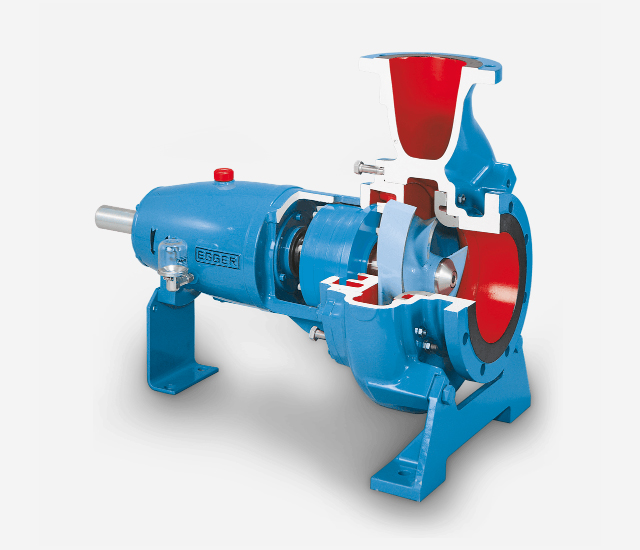

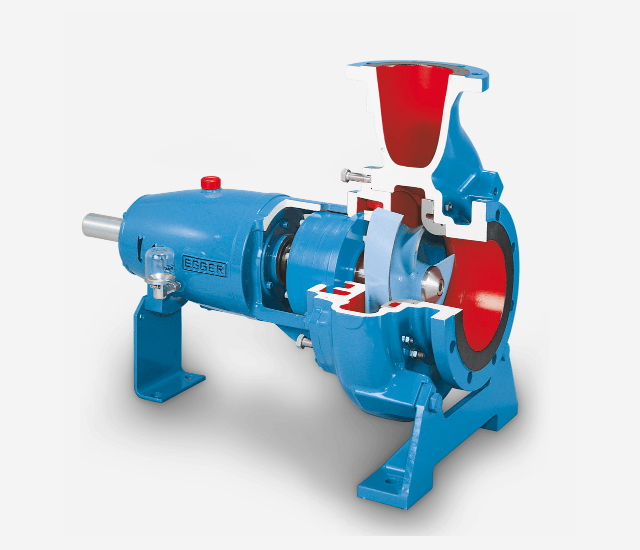

Turo® Vortex Pumps T

-

Turo® Vortex Pumps with a completely open spherical channel. Only 15% of the pumped fluid comes into contact with the impeller. Around the world, thousands of pumps have proven themselves with decades of excellent service.

Applications- Municipal and industrial wastewater

- Every kind of sludge

- High concentrations of fibrous suspensions

- Chemical and crystalline suspensions

- All viscous materials

- Numerous abrasive and corrosive fluids

Features- Gentle pumping of sensitive liquids, such as salt crystal

- Special volute casing, tuned to the hydraulics

- Big free passage even by small flow rates

Facts & Figures- Nominal dimensions: DN 32 - 200 mm

1¼ - 8" - Flow rate: up to 200 l/s 3170 US gpm

- Differential head: up to 140 m, 460 ft

- Pressure: up to 30 bar / 440 psi

- Temperature: up to 180 °C / 355 °F

Advantages- Freedom from clogging by solids

- High, sustained efficiency

- Large, open spherical channel

- Reduced wear

- Low life cycle costs (LCC)

- Long service life (MTBF)

- Economic storage, thanks to its modular design

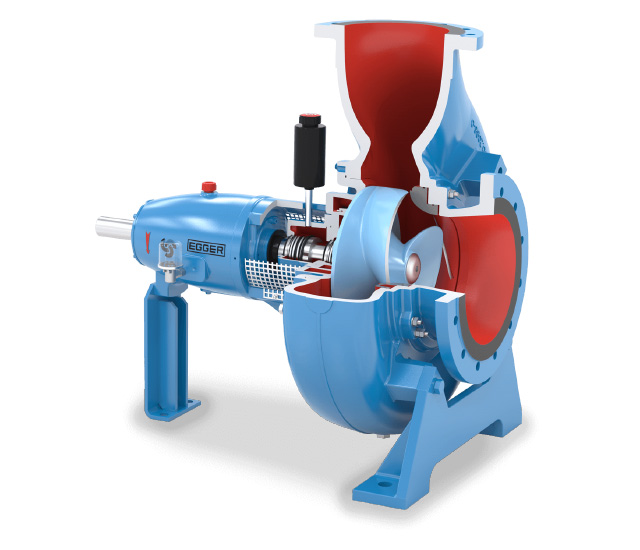

Turo® Vortex Pumps TA

-

Turo® Vortex TA impeller for pumping of raw municipal sewage with a high content of fibers without clogging. Fully recessed impeller for maximal free passage.

Applications- Raw sewage

- Municipal and industrial wastewater

- Sludge with a high content of fibers

- All viscous media

- Suspensions with a high content of fibers

Features- Pumping raw sewage without clogging

- Patented vortex hydraulics

- Special axial spiral casing, tuned to the hydraulics

- Interchangeable with Turo® T, TV and TEO

Facts & Figures- Nominal dimensions: DN 80 – 200 mm

3 – 8" - Flow rate: up to 180 l/s

2850 US gpm - Differential head: up to 100 m / 330 ft

- Pressure: up to 16 bar / 230 psi

- Temperature: up to 130 °C / 265 °F

Advantages- Open channel

- Non-clogging

- Quiet running

- Insensitivity to abrasion

- Gentle pumping

- Modular system

- Long tool life

- Reliability

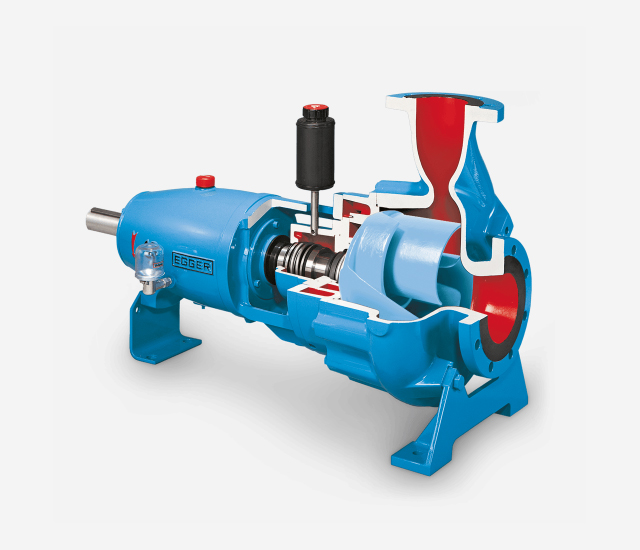

Process Pumps EO | EOS

-

The high-performance pump for homogeneous liquids containing high concentrations of solids and high gas contents. Different numbers of impeller blades for large and small particle sizes.

Applications- Demanding fluids in the chemical and petrochemical industries

- Multiphase mixtures for reactor loops

- Aerated fibre suspensions in the pulp and paper industry

- Wastewater and viscous materials in wastewater technology

- Numerous abrasive and corrosive fluids

- Pumping of fluids with gas contents up to 25 % vol

- Semi-open impeller

- Different numbers of blades

- Nominal dimensions: DN 50 - 500 mm

2 - 20" - Flow rate: 1500 l/s

23800 US gpm - Differential head: up to 150 m, 492 ft

- Pressure: up to 30 bar / 440 psi

- Temperature: up to 180 °C / 365 °F

- High suction capability

- High efficiency

- Externally adjustable wear plate for constant sustained output

- Multifaceted applicability

- Low life cycle costs (LCC)

- Long service life (MTBF)

- Economic storage, thanks to the Egger modular system

Wastewater Pumps EOA | EOSA

-

The high-performance pump for homogeneous liquids containing high concentrations of solids and high gas contents. Different numbers of impeller blades for large and small particle sizes.

Applications- Untreated wastewater (raw sewage)

- Intermediate pumping stations

- Secondary sludge

- Activated sludge, recirculated sludge

- Stabilised digested sludge

- Highly fibrous sludge

- Industrial wastewater

- Self-cleaning impeller and casing profile for wastewater pumping without clogging

- 2-channel EOA series for the discharge of large quantities of untreated wastewater from 120 l/s

- EOSA series with 3 impellers optimised for all types of sludges

- Nominal dimensions: DN 80 - 400 mm

3 - 16" - Flow rate: up to 1100 l/s

15850 US gpm - Differential head: up to 140 m, 460 ft

- Pressure: up to 16 bar / 323 psi

- Temperature: up to 120 °C / 250 °F

- 33Low energy costs

- Self-cleaning impeller profile

- Constant delivery rate

- Long service life and low life cycle costs (LCC)

- High suction capability

- Pumping liquids with high gas content

- Economic storage, thanks to the Egger modular system

Reactor Pump HT | HPT

-

The performant reactor pump developed for high temperature and high pressure applications in the chemical and petrochemical industries. Since many years a reference to handle multiphase liquids such as chemical mixtures with high gas content. Egger HT/HPT pumps are specially designed for loop reactor continuous circulations with catalyst and high gas contents.

Applications- Multiphase liquids for loop reactor circulation

- Boiling liquids with low available suction head

- Abrasive and corrosive liquids

- Chemicals with high system pressure and high temperature

- Complex media in the chemical and petrochemical industries

- Pumping of fluids with gas contents up to 25 % vol.

- Centerline mounted process design according to API 610 OH2

- Dimensions: DN 50 – 500 mm

2– 20" - Flow rate: Up to 1500 l/s,

23800 US gpm - Differential head: Up to 150 m, 492 ft

- Pressure: HT up to 45 bar, 650 psi

- HPT up to 100 bar, 1450 psi

- Temperature: up to 330 °C / 625 °F

- Material execution: Austenitic, Duplex, Super Duplex, High Nickel alloys,…

Advantages- Customized pump layout according to client request

- Centerline mounted single stage overhung pump according to API 610 OH2

- Process design enabling an easy and quick disassembly and assembly of back pull out unit and motor

- Very low NPSHR values resulting in very high suction capabilities

- Suitable for handling boiling liquids with low available suction head

- High hydraulic efficiency

Processes- Polymerization

- Hydrogenation

- Ethoxylation

- Esterification

- Alkoxylation

- Phosgenation

- Chemical mixtures

Typical Products- Fatty acids

- Fatty alcohols / Ethoxylates

- Hydrogenated fats

- PMMA and MMA (Acrylglas)

- Polyethylene suspensions (LDPE/HDPE)

- Acrylic acids

- TDA / TDI

- Poly(ether)ester

- Produced Water (petrochemical industry)

- Sand water slurries

Elbow Pumps RPP | RPG

-

The typical pump for large capacity at low discharge heads (circulation pump with axial impeller). Available in welded or cast construction with reinforcing ribs.

Applications- Crystallisation plants

- Vaporisation plants

- Reactor loops

- Sludge recirculation

- Pumping stations

Features- Thick blade profiles for long service life

- Gentle transport with sensitive, crystalline fluids

- Available in a wide range of metallic materials

Facts & Figures- Nominal dimensions: DN 250 - 700 mm

10 - 28" (gegossen) - DN 250 - 1400 mm

10 - 56" (geschweisst) - Flow rate: up to 8300 l/s

130000 US gpm - Differential head: up to 10 m, 33 ft

- Pressure: up to 6 bar, 90 psi

from DN 600 4 bar, 60 psi - Temperature: up to 140 °C / 285 °F

Advantages- Robust construction – long service life

- Gentle transport

- Fiber repellent

- Saving energy – suction behavior

- Tough applications with corrosive fluids

Zone 0 Pump

-

Egger submerged sump pumps can be used in all explosion endangered zones. Together with PTB in Braunschweig, Egger has developed a safety concept specifically designed for Zone 0 explosion risks. It enables applications to be used in Zone 0 with medium temperatures up to 150 °C. Since 2000, Egger owns a valid Type Examination certificate and can rely on many years of experience in the use of submerged sump pumps in Zone 0 explosion-risk environments.

Applications- Drainage of tank pits

- Safety tanks

- Storage tanks

- API separators

- Surface water

- Petrochemical process waste water

- Inflammable liquids

- No bearings in the pumped liquid

- Suited for fluids containing solid particles

- Submerged lengths of up to 10 meters possible

- Tight pit cover to the atmosphere available

Pilot Pump S

-

To validate new processes for commercial systems, the processes are first tested in pilot systems. Often the delivery rates are low, ranging between 0.5 to 8 m³/h, and cannot be realised with a reactor pump. For this reason, Egger has developed a pilot pump S that meets all requirements for commercial process pumps. This series has been designed for boundary conditions of 25vol% gas fraction, 100 bar system pressure and a temperature of 280°C.

Applications- Pilot plant reactors

- Laboratory pilot plants

Features- Multiphase mixtures with solids and gas

- Hydration

- Ethoxylation

Facts & Figures- Nominal dimensions: DN 15 and DN 25

½ “ and 1” - Flow rate: up to 8 m³/h

35 US gpm - Differential head: up to 45 m , 150 ft

- Pressure: up to 100 bar / 1450 psi

- Temperature: up to 280 °C / 540 °F

- Material execution: 1.4593, 1.4517, Hastelloy

Advantages- Executions with heating jacket available

- Reinforced bearings

Hybrid Pumps TEO

-

Pump with a hybrid impeller. Combines the advantages of our semi-open impeller with those of a Turo® vortex impeller. Suitable for the transport of fluids with high gas content and large diameter solids.

Applications- Grinding oil emulsions with a high proportion of air

- Emulsions with chips in the automotive industry

- SiC slurries in the solar industry

- Sewage sludge in the wastewater technology

Features- Stable suction characteristic during the transport of fluids with up to 10% gas content

- Interchangeability with a Turo® Vortex impeller

- Nominal dimensions: DN 32 - 80 mm

1¼ - 3" - Flow rate: up to 35 l/s

550 US gpm - Differential head: up to 30 m, 100 ft

- Pressure: up to 10 bar / 145 psi

- Temperature: up to 80 °C / 175 °F

- High efficiency, also with viscous fluids

- Large, open spherical channel

- Stable startup level, especially for gas-containing fluids

- Excellent suction and stable pumping characteristics

- Low life cycle costs (LCC)

- Long service life (MTBF)

Technology

Pump Technology

-

Industrial focus on innovative pump technology. Production of pumps and the solution to hydraulic requirements is a core corporate competence. Egger is the industry leader in the area of difficult liquids and liquids with a tendency to clog.

Since its founding in 1947, the enterprise has focussed on the integrated manufacturer of pumps. This specialization has led to great depth of experience – on the one hand, in the production of pumps with all of their components and on the other, in mastering the many requirements made available by a wide assortment of pumps in a large variety of industries. Both management and staff are technical experts in pump technology. Knowledge of materials, hydraulic expertise and experience in the execution of processes make Egger a sought-after consultant when it comes to the pumping of fluids.

Hydraulics

-

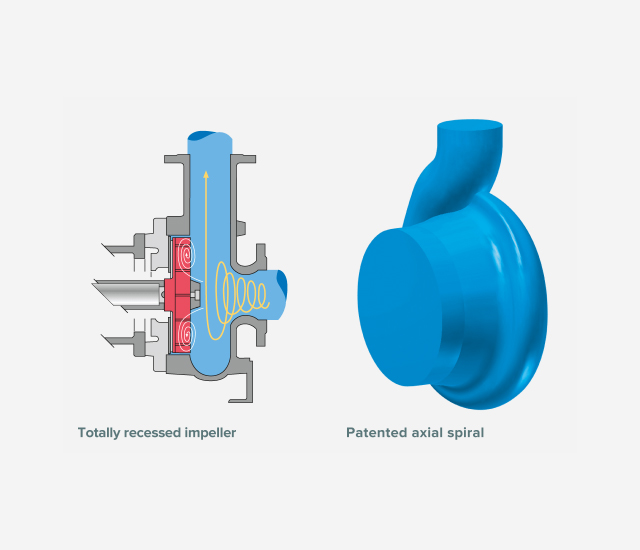

- Hydraulics for Vortex Pumps T

The vortex impeller is an «open» impeller whereby power transfer to the fluid being transported is comparable to the principle of a hydraulic coupling. Egger, the pioneer in vortex impellers, has rigorously optimized their special hydraulic properties to today’s industry needs. Various impeller variations have resulted from this, offering optimal conditions for each application.

Non-clogging, safe delivery rate due to the recessed impeller and a patented axial spiral

Insensitivity to abrasion – gentle pumping

Higher, longer-lasting efficiency through optimal flow geometries

Great freedom from clogging by particles and fibers – open spherical channel

- Hydraulics for process pumps EO/EOS

The semi-open radial impeller with special profile is a logical development of the original Egger impeller, which brought about the founding of the firm in 1947. The EO and EOS impeller family is distinguished most significantly by their number of blades; their hydraulic properties are virtually identical.

High efficiency pumps for homogeneous slurries containing high concentrations of solids

Transport of fluids with high gas content – high suction capability

Higher, longer-lasting efficiency through adjustable impeller openings – also under conditions of wear

- Hydraulics for Vortex Pumps T

Performance range

-

As service range (also characteristic field), we designate the graphic representation of the volume transported and discharge head as a function of the rated speed in the definition of the pump performance. Detailed information can be found in our download center.

- Units used

Volume transported Q in l/s and m3/h

Differential head H in m (water column)

- Conversion

1 m3/h = 0,277 l/s = 4,4 US gal/min

10 m = 32,8 ft = 0,98 bar = 14,22 psi

- Units used

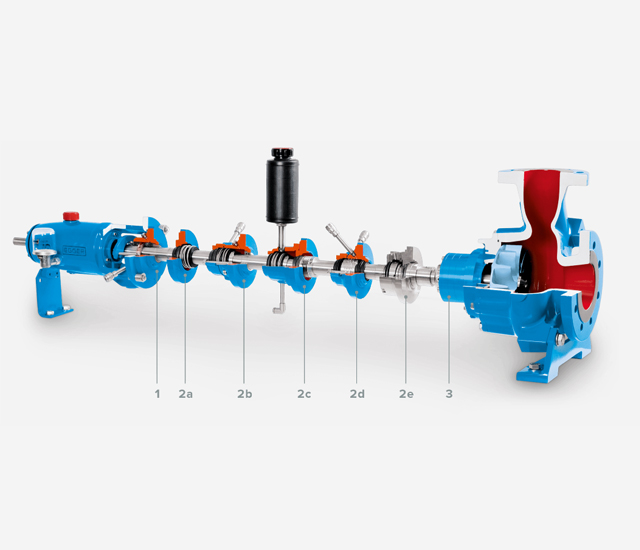

Mountings | Designs

-

The Egger Modular System enables an optimized and economical stock keeping, thanks to five standardized bearing housing sizes. Spare parts can be easily interchanged between many pump types and hydraulics. The pump shaft is not in contact with the pumped media and is sealed by a standardized shaft sleeve. Furthermore, the Egger Varioseal® System ensures a great flexibility in the choice of seal.

- Economical storage

As there are only five standardized bearing housing sizes, spare parts can be easily interchanged between many pump types and hydraulic systems. The storage of spare parts is thus optimized.

- Flexibility in the choice of seal due to Varioseal®

Egger pumps have a standardized sealing space for mechanical seals and gland packing rings. This allows for a great flexibility in the choice of seal.

- One pump shaft for all pumped media

The pump shaft is not in contact with the pumped media and is sealed by a standardized shaft sleeve. Thus, no special material is required for the shaft.

- Fast delivery

Thanks to the Egger modular system and our systematic storage of assemblies, a quick delivery of spare parts can be guaranteed.

- Economical storage

Seals

-

Varioseal® shaft seals: Egger's building block system even gets extended to the design of the pump shaft seal. A variety of standard and customized seals can be configured, depending on the fluids being transported and the safety requirements. Thanks to our Varioseal® system, various shaft sealing units can be interchanged without remachining.

- 1 Stuffing box packing

- 2a Single mechanical seal

- 2b Single mechanical seal

with external flushing - 2c Double mechanical seal

in tandem arrangement with pressureless internal sealing liquid - 2d Double mechanical seal

in back-to-back arrangement with pressurized sealing liquid, optionally with internal pumping screw - 2e Cartridge-mechanical seal

Hydrodynamic shaft seal Eurodyn®

with 4 discharge repellers

Materials

- On the basis of the specification, the specific fluid to be pumped and other boundary conditions, we utilise proven materials. For pump casings and impellers, one can choose from a wide range of suitable material solutions, from grey iron through to wear resistant high-chrome iron to stainless steel and nickel-based alloys. Depending on the customer's wishes, generally all cast materials are available.