- Offer Profile

- Solid-liquid separation plays

an important role in the pharmaceutical and chemical process industries.

Main tasks of this process step are:

- recovering and dewatering the solids from the liquids.

- washing the solids from impurities and/or mother liquor

- avoid cross contamination between the product and the environment/operator

Our equipment is suitable to separate mechanically and/or thermally the solids from the liquid.

Centrifuges

- The Heinkel Drying and Separation Group supplies batch

filtering centrifuges for the pharmaceutical, fine chemical and chemical

industries, where solids-liquid separation takes place mechanically.

We specialize in tailoring our solution to meet the customer’s application needs.

The typical process includes filling, cake washing, spinning and unloading. One possible criteria of selection is based on the way to unload the solids, it characterizes the different design. It can be done:- manually by opening the lid and shoveling off the solids

- automatically by peeling off the cake and discharging through the bottom

- automatically by peeling off the cake in a horizontal axis centrifuge

- automatically by inverting the filter cloth

Series HF300.1 - HF 1300.1

-

Based on its gentle product discharge leaving no residual heel and therefore the possibility of thin cake filtration, the HEINKEL inverting filter centrifuges of the Series HF are ideally suited for use with diffcult to filter products. They are characterized by hermetically closed design and the fully automated, continuous operation.

Special properties for the customer’s benefit:

- Proven, robust design

- Design matches with requirements in the chemical and pharmaceutical industry

- Best choice for demanding products

- Residual heel free product discharge and minimum installations in housing and basket, thus optimal for high potent API products with highest possible product yield

- Considerable residual moisture reduction in respect to conventional filtration by pressure added centrifugation (PAC) possible

Inverting Filter Centrifuge F

-

The HEINKEL inverting filter centrifuge of the Series F requires minimum installation space and is characterized by an integrated clean room design. It is suited for use with diffcult to filter products and characterized by hermetically closed design and the fully automated, continuous operation.

Special properties for the customer’s benefit:

- Advanced development of the proven inverting filter centrifuge Series HF

- Larger basket volume as well as higher centrifugal forces in comparison with Series HF

- Easy installation, especially in clean rooms because of outer smooth surfaces and machine contours

- Inerting system and all junction boxes accommodated in the machine housing

- Easy access to machine housing via maintenance doors at three sides

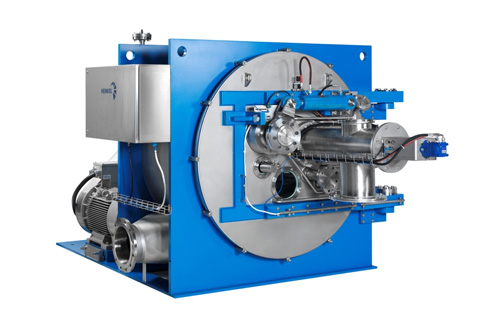

Horizontal Peeler Centrifuge Pharma

-

The HEINKEL horizontal peeler centrifuges in pharma design are characterized by easy cleaning and inspection avoiding product contamination.

Special properties for the customer’s benefit:

- Swinging open housing for easy inspection

- Clean room installation possible

- Hydraulically operated housing locking mechanism by single clamping elements, therefore minimal area for product deposit

- Fully automatic, validated CIP-process possible

- Design virtually free of dead spaces, minimized number of screwed connections in the process housing

- Filtrate outlet at the rear part of the process housing, low dismantling expenses to prepare for the opening of the housing

- High flexibility at frequent product changes

- Quick change of the filter element

- Bearing designed as exchangeable unit

Horizontal Peeler Centrifuge Chemical

-

The HEINKEL horizontal peeler centrifuges in chemical design are used for separating medium to large product quantities that can be washed and then spin-dried. The centrifuges are designed for continuous operation with large product throughputs.

Special properties for the customer’s benefit:

- Proven, robust design

- Versatile options available regarding basket and door design, feed pipes and suspension feeding, residual heel removal concepts as well as various unloading devices

- Bearing designed as exchangeable unit

- Optimal adaptation to changing products and product characteristics

- High throughput capacities because of short cycle times

- Low residual moistures because of high g-forces

- High product purities because of effective wash process

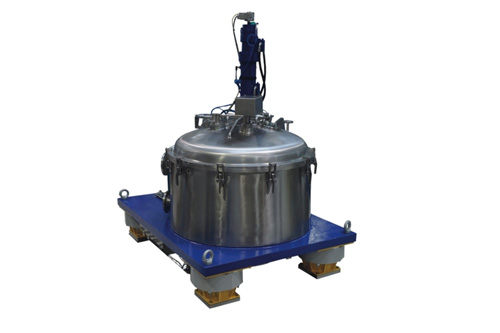

Vertical Peeler Centrifuge Pharma

-

Vertical peeler centrifuges type V 1000 – 1250 BP in cGMP execution are mainly used in the pharmaceutical industry. The process housing opens and closes automatically, thus enabling the complete inspection of all components in the process area. Cleaning is carried out by means of an effective, fully automated CIP system and it is complete with the flooding of the process enclosure if necessary. The GMP and specification compliant documentation ensures optimum qualification.

Special properties for the customer´s benefit:

- Small footprint

- cGMP compliant

- Automatic opening, respectively closing of the process housing

- Optimised product discharge

- Automatic CIP cleaning

- Easy accessibility of all machinery parts in contact with the product

Vertical Peeler Centrifuge Chemical

-

The vertical peeler centrifuges types V 800 BC – V 1600 BC are used for uninterrupted operation with high throughput rates in the chemical and fine chemical industries. As with the horizontal centrifuge series, for the vertical peeler centrifuges a wide selection of baskets with different diameters is available.

Special properties for the customer’s benefit:

- Excellent adaptability to changing products

- High throughputs

- Separation through filtration or sedimentation

- Low residual moisture levels through high spinning factor

Vertical Peeler Centrifuge Gypsum

-

Through many years of experience with renowned plant manufacturers in the area of flue gas desulphurization (FGD) plants, HEINKEL is in a position to ensure smooth, reliable project handling on schedule.

Worldwide plaster from flue gas desulphurisation plants is dewatered in power plants using HEINKEL centrifuges. The broad range of plaster centrifuges with different basket sizes allows for optimum adaptation to changing product properties and throughputs.

Special properties for the customer´s benefit:

- Optimum application for small to medium throughputs

- High availability

- Minimum residual moisture

- Maximum reduction of chloride concentrations through optimised washing process

- Alternatively stainless steel or rubber coated

Top Discharge Centrifuge Pharma

-

The classical HEINKEL top discharge centrifuges are a cost-effective alternative in the pharmaceutical production.

The centrifuge can be easily adapted to the product characteristics and it is therefore suitable for companies that manufacture a variety of products in small to large batches.Special properties for the customer´s benefit:

- Flexible adaptation for difficult to filter products

- Lossless filter cake discharge

- Gentle solids discharge without particle destruction

- Automatic CIP cleaning

- Easy accessibility of all machinery parts in contact with the product

- Excellent washing and extraction effect

- Simple centrifuge design

Top Discharge Centrifuge Chemical

-

The classical HEINKEL top discharge centrifuges are a cost-effective alternative in chemical manufacturing.

The centrifuge can be easily adapted to the product characteristics and is therefore suitable for companies that manufacture a variety of products in small to large batches.Special properties for the benefit of the customer:

- Flexible adaptation for difficult to filter products

- Lossless filter cake discharge

- Gentle solids discharge without particle destruction

- Excellent washing and extraction effect

- Simple centrifuge design

- Reliable system for removal of the filter bag

- Rugged and simple system for the detachable border ring

Dryers & Mixers

- The Heinkel Drying and Separation Group supplies batch

dryers for the pharmaceutical, fine chemical, chemical and food industries,

where solids-liquid separation takes place thermally.

The typical process includes filling, drying, cooling, unloading and cleaning.

One possible criteria of selection is based on the agitating device of the different designs:- orbiting screw

- vertical shaft

- cantilevered horizontal shaft

- both ends supported horizontal shaft

Conical Screw Vacuum Dryer

-

The BOLZ-SUMMIX conical screw dryer is a vacuum contact dryer that is particularly suitable for drying hazardous and toxic products containing solvents or water, to a very low final moisture content, due to its closed design and indirect product heating.

Technical data

Special properties for the customer’s benefit:- Short drying times

- Fully closed system

- Speeds adapted to the product characteristics

- Perfected CIP installations and complete drainage

- Almost 100% product discharge

- Operator safe, product and environment friendly

- Hight process and product flexibility, drying, mixing, homogenising etc

- Filling volume 10 – 100% of working capacity

- Very high containment level, almost 100% solvent recovery

- Low drive power compared to other systems

- Very gentle product handling

- No buttom bearing up to 6m3 working capacity (easy discharge, easy cleaning)

- Safe, ATEX conform sealing system

- Wide variety of seal lubricants

- No lump breaker after drying process

- Clean room installation (Dryer discharge)

- shorter drying times with heated screw

- dry running mechanical seals

Vacuum Pan Dryer

-

The Turbodry agitated vacuum pan dryer has proven to be excellent for the drying of sensitive, pasty and other “diffcult” products that pass through a highly viscous stage during the drying process. The dryers have proven to be particularly suited for the drying of heat sensitive products as well as products with fragile crystal structure and thus sensitive to shear forces. Excellent product discharge and shortest cycle times.

Special properties for the customer’s benefit:

- In compliance with cGMP and FDA guidelines, also in aseptic/ steam sterilizable versions

- Shortest possible drying times, suitable for the drying of sensitive, pasty, sticky and other “diffcult” products such as those turning highly viscous during the drying process

- Simultaneous axial and radial agitator movements permit uniform mixing of the entire product mass, without the formation of lumps or balls

- Double mechanical seal, dry running contacting or non-contacting lift-off or liquid lubricated, externally interchangeable

- Agitator supported by the top head, with the seal in contact with the vapors only

Horizontal Vacuum Paddle Dryer / Reactor

-

The Termomix vacuum paddle dryer/reactor is intended for monoproduction applications or bulk production facilities as mixer, reactor, precipitator and dryer.

Special properties for the customer’s benefit:

- Economic, robust multipurpose machine for heavy industrial applications

- The agitator is supported on both ends providing excellent mixing characteristics, with externally interchangeable stuffing boxes or mechanical seals

- Large heating area resulting in an outstanding heat transfer rate by heating the vessel walls, the vessel ends as well as the agitator shaft and arms

Conical screw mixer

-

The BOLZ-SUMMIX conical screw mixer works according to the proven principle of a rotating mixing screw being guided along the wall of the conical vessel at constant close distance by means of an orbital arm. The product flow maintains an intense yet gentle mixing and product displacement. Suited for demanding bulk solids of the pharmaceutical, chemical and food industries, it ensures a unique and gentle mixing process.

Special properties for the customer’s benefit:

- Small drive power without mechanical or thermal product demolition by wear/attrition

- High mixing result and effciency, perfect blending and good mixing time

- Unique suitability for a wide range of industrial products with various character like density, particle size and shape, proportions etc. without risk of segregation

- Maximum flexibility with just partial load from 10 to 100%

- Well suited for multi-product application and frequently changing product volume

- Central, unrestricted and residue-free product discharge with a homogeneous product flow

- Good cleanabilty with a complete and residue free drain of cleaning fluids

Conical Screw Cooker

-

Mixing, stirring, cooking and sterilising are basic operations in food production and processing. The BOLZ-SUMMIX cookers with their conical construction and rotating mixing screw, have proven particularly useful for processing natural products such as coffee beans, cocoa nibs, gluten or nuts such as chestnuts. Various processes can be realised such as a heat treatment process by direct steam injection and heated jacket with continuous mixing, injection/absorption of process liquid, cooking and sterilising as well as extraction of components.

Special properties for the customer’s benefit:

- Short process time with gentle and effective product mixing and intensive heat transfer

- Injection of steam via a ring channel

- Vacuum and pressure rated equipment

- Total drain of solid and liquid in a short time

- Flexible hence suited for a wide range of products, process and heat treatment

- Quick adding of required process liquids

Filter & Filter-dryers

-

The Heinkel Drying and Separation Group supplies batch Nutsche filters and

filter dryers for the pharmaceutical, fine chemical, chemical and food

industries, where solids-liquid separation takes place thermally, they are

versatile units designed for multipurpose production facilities. The typical

process includes filling, filtering, drying, cooling, unloading and cleaning.

One possible criteria of selection is based on the different designs:- Pharma execution

- Chemical execution

- Sterilizable execution

- Pilot plant

Pilot Plant Filter Dryer & Vacuum Dryer

-

Laboratory & pilot plant equipment

-

Even with today´s simulation techniques and computing power, pilot-sized process

equipment is still indispensable for the development and refinement of new and

existing products. During years of cooperation with companies in the

pharmaceutical and chemical industries, HEINKEL DRYING AND SEPARATION GROUP has

continually developed its tried-and-trusted pilot plant equipment which is

already in use in many places worldwide.

The company is thus doing justice to increased requirements of industrial customers for safe handling, completely contained operation, flexibility and efficiency. The equipment meets the demand for devices suitable for use in potentially explosive areas in ATEX zones. The compact design of the pilot units facilitate transport from one place to another within the production plant – through narrow corridors and doorways or via lifts from one floor to another.

Heinkel Group supplies various centrifuge, dryer and filterdryer units which can be installed with minimum requirement in respect to installation and cost. The equipment can also be rented for short term and product specific testing. More information about test machines can be found > here.

Tests can be accompanied by our highly experienced process engineers, who will use test results for throughput calculations, up-scaling and documentation.

Pilot Plant BS-pilotDRY

-

The pilotdryer BS-pilotDRY from BOLZ is well suited for a wide range of various pilot-scaled trials and tests within the product and process development, but also for ongoing quality monitoring of a production. Mainly used as a traditional conical screw dryer, in addition it can also be used as a central shaft dryer. The hybrid stirrer technology allows drying and mixing processes to be simulated and tested in only one appliance using different mixing tools. Therefore relevant comparisons are possible which facilitate the selection of the most suitable stirring mechanism or agitator tool for the product and thus for the future production equipment.

Special properties for the customer’s benefit:

- Mobile and portable skid design

- Simple „plug and use“ installation

- Complete process unit with ancillaries

- Flexible filling volume 10 to 100%

- CIP-cleaning included

- All product contact surfaces heatable

- Suited for a wide range of processes

- Ideal for „scale-up“ calculations

- Optional with central shaft agitator

Laboratory System BS-miniDRY

-

Especially for the simulation of complex processes and production steps in research and development, BOLZ developed the BS-miniDRY. Thanks to its compact design and ready for “plug and use” it is simple to install and flexible to use. Identically designed like a bigger production scaled conical screw dryer, it is perfect for product trials and scale-up. A wide range of drying and mixing process steps can be simulated by making use of the flexible filling volume, already starting with a feed of only 150 ml.

Special properties for the customer’s benefit:

- Mobile, compact and easy transport design

- Easy installation „plug and use“

- Designed to fit into a ventilation booth

- Flexible filling volume 10 to 100%

- Ideal for „scale-up“ calculations

- CIP-cleaning included

- Possibility for various changes of the agitator tool (from orbital arm system to various central shaft agitators)

- Designed as a complex process system or also as a reduced economical version