- Offer Profile

-

Lutz Pumpen is one of the leading manufacturers of drum pumps with 6 branches and representations in more than 80 countries. Worldwide, our pumps are used successfully and efficiently in all industrial sectors.

The motto "Safety is our concern" comes first. In addition to the drum pump, we are the ideal partner for your requirements with flow meters, eccentric screw pumps, double diaphragm and centrifugal pumps as well as Orginal accessories. Whether individual products or complete systems - we will find a solution together!

Drum and Container Pumps

- Lutz drum and container pumps are suitable for the safe and economic transfer and filling of neutral and aggressive, non-flammable and easily flammable, thin to slightly viscous liquids as well as for clean or contaminated liquids from mobile or stationary containers of all sizes.

Drum Pump

- The perfect solution and at the same time a useful alternative to a bucket is an electric, compressed air or battery operated drum pump from Lutz. Knowledge, experience and a sense of responsibility are just a few of the arguments that should lead to the idea of giving the handling of fluids in the hands of professionals. Anyone who transfers fluids of all kinds can become a professional, when using a Lutz drum pump.

Battery Drum pump - B1 Battery

- suitable for small quantities

Description:

The Drum pump B1 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.- Replaceable, powerful battery with Li-Ion

- Battery life 25 min at maximum speed

- 1 battery charge emptied approx. 2 x 200 litre container

Features & Advantages- BLDC Motor with high efficiency of up to 70%

- continuously adjustable

- long battery life

- automatic shutdown on overload

- sophisticated quick lock

Battery Drum pump - B2 Battery Niro

- for liquid lubricants and cleaning agents

Description:

The B2 Battery Drum pump is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Features & Advantages- BLDC Motor with high efficiency of up to 70

- continuously adjustable

- long battery life

- automatic shutdown on overload

- sophisticated quick lock

Battery Drum pump - B2 Battery PP

- for thin-bodied acids

Description:

The B2 Battery Drum pump is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Features & Advantages- BLDC Motor with high efficiency of up to 70%

- continuously adjustable

- long battery life

- automatic shutdown on overload

- sophisticated quick lock

Battery Drum pump - B2 Battery PVDF

- for concentrated acids and alkalis

Description:

The B2 Battery Drum pump is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Features & Advantages- BLDC Motor with high efficiency of up to 70

- continuously adjustable

- long battery life

- automatic shutdown on overload

- sophisticated quick lock

Drum pump - Acids

- suitable for small quantities

Motor: MA II 3 - 460W, 230V (for a higher density of the medium )

Description:

The Drum pump is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the removal or decanting of acids.- Media examples: Hydrochloric acid, battery acid, iron-III-chloride, phosphoric acid, chromic acid and citric acid etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimized Drum emptying

- Universally resistant PTFE shaft bearings

- Maintenance without special tools

- Seal modules of the seal-less (DL) pump are exchangeable

Drum pump - concentrated acids and alkalis

- for highly chemical liquids and salts

Motor: MA II 3 - 460W, 230V

Description:

The Drum pump is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for withdrawing or decanting concentrated acids and alkalis.- Media examples: Chloric acid, chromic acid, sulphuric acid, nitric acid, hydrofluoric acid and sodium hypochlorite etc.

- Pump tube equipped with Lutz original hand wheel

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimized Drum emptying

- Universally resistant PTFE shaft bearing

- Maintenance without special tools

- Seal modules of the seal-less (DL) pump are interchangeable

Drum pump - Lye

- for low viscosity chemicals

Motor: MA I 4 - 500W, 230V

Description:

The Drum pump is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the withdrawal or decanting of alkaline solutions.- Media examples: Sodium hydroxide, potassium hydroxide, ammonia water, formic acid and acetic acid etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimized Drum emptying

- Universally resistant PTFE shaft bearing

- Maintenance without special tools

- Seal modules of the seal-less (DL) pump are interchangeable

Drum pump - Mineral oils

- for oils and cooling lubricants

Motor: MA I 4 - 500W, 230V

Description:

The Drum pump is suitable for thin-bodied, aggressive and non-flammable media. Perfectly suited for the withdrawal or decanting of mineral oils.- Media examples: Diesel, heating oil, hydraulic oil, machine oil and motor oil etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting alternative fuels

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimized Drum emptying

- Universally resistant ETFE shaft bearing

- Maintenance without special tools

- Seal modules of the seal-less (DL) pump are interchangeable

Drum pump - Solvent

- for highly flammable hydrocarbons

Motor: : ME II 3 - 500W, 230V

Description:

The Drum pump is suitable for thin-bodied, flammable and highly inflammable hydrocarbons. Perfectly suitable for the withdrawal or decanting of solvents, optionally available with Ex-plug.- Optionally available with Ex - plug

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or transferring alternative fuels, oils, flammable liquids

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Highly resistant noble carbon shaft bearing

- Maintenance without special tools

- Seal modules of the seal-less (DL) pump are exchangeable

- Approved according to ATEX directive 2014/34/EU, category 1/2

Drum pump for residual emptying - solvent

- for highly flammable hydrocarbons

Motor: : ME II 3 - 500W, 230V

Description:

The Pump Set is suitable for thin, flammable and inflammable liquids and hydrocarbons. Perfectly suited for withdrawing or transferring explosive media and solvents.- Optionally available with Ex - plug

- Pump tube equipped with Lutz original hand wheel

- Suitable for Drum emptying alternative fuels, oils, flammable liquids

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimised Drum emptying with a remaining quantity of approx. 0.1 litres

- No leakage if the pumping station is tilted or moved

- Maximum product utilization with reduced drum cleaning and disposal rates

- Approved according to ATEX directive 2014/34/EU, category 1/2

Drum pump Lutz B2 Vario Niro

- for liquid lubricants and cleaning agents

Description:

The B2 Vario Drum pump is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister, hobbocks and drums. The pump is flexible at all times and thus saves important resources.- Infinitely variable speed controller for the transfer and filling of small quantities

Features & Advantages- ealless design (DL) conditionally safe to run dry

- continuously adjustable

- Powerful Motor with improved service life.

- service-friendly and easy to dismantle

Drum pump Lutz B2 Vario PP

- for thin-bodied acids

Description:

T he B2 Vario Drum pump is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister, hobbocks and drums. The pump is flexible at all times and thus saves important resources.- Infinitely variable speed controller for the transfer and filling of small quantities

Features & Advantages- Sealless design (DL) conditionally safe to run dry

- continuously adjustable

- powerful Motor with improved service life

- service-friendly and easy to dismantle

Drum pump Lutz B2 Vario PVDF

- for higher delivery heads

Description:

The B2 Vario Pump Set is suitable for thin-bodied acids, alkalis and chemicals. The set is suitable for removing small containers such as Canister, hobbocks and drums. The pump is flexible at all times and thus saves important resources.- infinitely variable speed controller for transferring and filling small quantities

Features & Advantages- Sealless design (DL) conditionally safe to run dry

- continuously adjustable

- powerful Motor with improved service life.

- Service-friendly and easy to dismantle

Drum Pump Sets

- Transferring acids, alkalis, mineral oils, explosive liquids or solvents: for all these applications, Lutz offers the ideal pump set for emptying drums and containers.

They are ready for use and quick-mounted in a few simple steps. The pump sets can additionally be combined with a flow meter.

Battery Pump Set - B1 Battery PP

-

The Pump Set B1 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.

- Replaceable, powerful battery with Li-Ion

- Battery life approx. 25 min at maximum speed

- 1 battery charge emptied approx. 2 x 200 litre container

Battery Pump Set - B1 Battery PP incl. counter

-

The Pump Set B1 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.

- Replaceable, powerful battery with Li-Ion

- Battery life approx. 25 min at maximum speed

- 1 battery charge emptied approx. 2 x 200 litre container

Battery Pump Set - B2 Battery Niro

-

The Pump Set B2 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.

- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Battery Pump Set - B2 Battery PP

-

The Pump Set B2 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources. The set is supplied without battery and charger

- Replaceable, powerful battery with Li-Ion

- Battery life approx. 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Battery Pump Set - B2 Battery PP incl. counter

-

The Pump Set B2 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.

- Replaceable, powerful battery with Li-Ion

- Battery life approx. 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Battery Pump Set - B2 Battery PVDF

-

The Pump Set B2 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.

- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Battery Pump Set - B2 Battery PVDF incl. counter

-

The Pump Set B2 Battery is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister or hobbocks. The pump is flexible at all times and thus saves important resources.

- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Pump Set - Acids

-

The Pump Set is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the withdrawal or decanting of aci4ds.

- Media examples: Hydrochloric acid, battery acid, iron-III-chloride, phosphoric acid, chromic acid and citric acid etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Pump Set - B2 Vario Niro

-

The B2 Vario Pump Set is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister, hobbocks and drums. The pump is flexible at all times, thus saving important resources.

- Infinitely variable speed controller for the transfer and filling of small quantities

Pump Set - B2 Vario PP

-

The B2 Vario Pump Set is suitable for thin-bodied, aqueous to slightly viscous media. The set is suitable for removing small containers such as Canister, hobbocks and drums. The pump is flexible at all times, thus saving important resources.

- Infinitely variable speed controller for the transfer and filling of small quantities

Pump Set - concentrated acids and alkalis

-

The Pump Set is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for withdrawing or decanting concentrated acids and alkalis.

- Media examples: Chloric acid, chromic acid, sulphuric acid, nitric acid, hydrofluoric acid and sodium hypochlorite etc.

- Pump tube equipped with Lutz original hand wheel

Pump Set - Explosive media

-

The Pump Set is suitable for thin, flammable and highly inflammable liquids. Perfectly suited for withdrawing or transferring explosive media.

- Optionally available with Ex - plug

- Pump tube equipped with Lutz original handwheel

- Suitable for filling or transferring alternative fuels, oils, flammable liquids

Pump Set - Lye

-

The Pump Set is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the withdrawal or decanting of alkaline solutions.

- Media examples: Sodium hydroxide, potassium hydroxide, ammonia water, formic acid and acetic acid etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Pump Set - Mineral oils

-

The Pump Set is suitable for thin-bodied, aggressive and non-flammable media. Perfectly suited for the extraction or decanting of mineral oils.

- Media examples: Diesel, heating oil, hydraulic oil, machine oil and motor oil etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting alternative fuels

Pump Set - Solvent

-

The Pump Set is suitable for thin-bodied, flammable and highly inflammable hydrocarbons. Perfectly suited for the withdrawal or decanting of solvents.

- Media examples: Ethanol, petrol, butanol, isopropanol, kerosene, methanol and petroleum.etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or transferring alternative fuels, oils, flammable liquids

Pump Set for residual draining - Explosive media

-

The Pump Set is suitable for thin, flammable and highly inflammable liquids and hydrocarbons. Perfectly suited for withdrawing or transferring explosive media and solvents.

- Optionally available with Ex - plug

- Pump tube equipped with Lutz original hand wheel

- Suitable for Drum emptying alternative fuels, oils, flammable liquids

Pump Set for residual emptying - solvent

-

The Pump Set is suitable for thin-bodied, flammable and highly inflammable hydrocarbons. Perfectly suited for the withdrawal or decanting of solvents.

- Media examples: Ethanol, petrol, butanol, isopropanol, kerosene, methanol and petroleum.etc.

- Pump tube equipped with Lutz original hand wheel

- Suitable for Drum emptying alternative fuels, oils, flammable liquids

Container Pumps

- In industry, intermediate Bulk Containers (IBC) are probably the most used transport and storage containers for chemicals. For emptying such containers from above or below, customized solutions are required. Therefore our pump tubes are available in the appropriate immersion depths. We can also provide you with drum pumps that were particularly produced only for containers.

Pump set, IBC pump B200 in PVDF with Safety Box

- for concentrated acids and alkalis

Design: with leakage detection

Seal type: mechanical seal (GLRD)This extremely compact IBC pump is an interesting alternative when a conventional vertical drum pump cannot be used, e.g. for IBC containers or tanks that are stored on shelves.

In these cases access from above is no longer possible, but the floor drain of the IBC can be used.

For this purpose the horizontal container pump B200 is screwed directly to the floor drain of the container for emptying.Examples of liquids:

Bromic acid, nitric acid, dimethyl phthalate, potassium bromate, hydrofluoric acid, nitric acid, sulphuric acid, etc.Properties:

- Centrifugal pump with axial impeller in compact design

- Direct connection to the floor drain of the IBC tank by standard union (S60 x 6)

- Variable drive concept (various universal and air motors)

- Significantly better hydraulic performance compared to hydrostatic outlet

Pump tube B200 Niro

- for highly flammable hydrocarbons

Seal type: Mechanical seal FPM (GLRD FPM)

Design: without Pure

Note: without Ex-approval

Description:

The horizontal Pump tube is suitable for draining highly aggressive, thin-bodied, flammable and explosive liquids from IBC containers or tanks and is the perfect alternative to vertical Drum Pumps.

Depending on the application, various motors are available which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources.- Horizontal connection on the bottom run of the container

- Pump tube equipped with Lutz original hand wheel

- Suitable for draining alternative fuels, oils, flammable liquids

Features & Advantages- Optionally with electric or compressed air drive

- Low loss of the medium when disconnected

- Explosion-proof versions for applications in Ex areas (Zone 1 and 2)

- Easy to dismantle

- Low space requirement

Pump tube horizontal container pump B200

- for concentrated acids and alkalis

Design: with leakage detection

Seal type: mechanical seal (GLRD)This very compact pump is an interesting alternative when containers are stored above each other.

In these cases an access from above is not possble, but the bottom drain of the IBC can be used. For this purpose the horizontal Lutz B200 is directly connected tot he bottom outlet valve.

Liquid examples:

Bromic acid, sulphuric acid, nitric acid, dimethyl phthalate, potassium bromate, hydrofluoric acid, etc.Features:

- Centrifugal pump with axial impeller in compact design

- Directly connected to the bottom outlet valve of the IBC with standard union nut (S60 x 6)

- Variable drive concept (different universal- and air-driven motors)

- Significantly better hydraulic capacity in comparison to hydrostatic outlet

Pump tube vertical Container pump B50

- for the chemical transfer

Design: Stainless steel (1.4571) Shaft

Description:

The Container pump is suitable for the rapid transfer of corrosive, aqueous to slightly viscous media. Perfectly suited for withdrawing or transferring chemical liquids.- Media examples: Battery acid, iron sulphate, glycols, phosphoric acid, hydrochloric acid, citric acid, etc.

- Pump tube equipped with Lutz original hand wheel

- For filling or transferring IBC containers

Features & Advantages- Adjustable container adapter for common container openings

- high output

- optimized Container emptying

- low wear and tear

- variable adaptation to different container openings

- easy and quick to dismantle due to few components

Submersible Centrifugal Pump B50

-

The submersible pump was particularly developed as vertical, wet-installed submersible pump for quick emptying containers and pools

Features:

- High pump capacity

- High level of efficiency

- Smooth running

- Small space requirement

- Fast assembly

- Simple commissioning

- Easy to service

Pump tubes

- For almost all liquids the suitable and proven materials PP, PVDF, aluminium, stainless steel and HC are available. Our Pump tubes offer carefully matched material combinations for all cases in which thin-bodied, slightly viscous media are pumped.

Pump tube Alu

- for mineral oils

Seal type: Sealless (DL)Description:

The Lutz Pump tube (aluminium) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting alternative fuels

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimized Drum emptying

- Universally resistant ETFE shaft bearing

- Maintenance without special tools

- Sealing modules of the mechanical seal (GLRD) or the seal-less (DL) pump are interchangeable

Pump tube B200 Niro

- for food (PURE Ex-Series)

Seal type: Mechanical seal FPM (GLRD FPM)

Design: without Pure

Note: without Ex-approval

Description:

The horizontal Pump tube is suitable for emptying aqueous and fatty food from IBC containers or tanks and is the perfect alternative to vertical Drum Pumps.

Depending on the applicatio n, various Motors are a vailable which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources.- Horizontal connection at the bottom of the container

- Pump tube equipped with Lutz original hand wheel

- also for foodstuffs containing alcohol, cosmetics and pharmaceutical products as well as flammable cleaning agents

Features & Advantages- Optionally with electric or compressed air drive

- Low loss of the medium when disconnected

- Food grade connections

- Low space requirement

- Approved according to ATEX directive 2014/34/EU, category 1/2

- Approved according to FDA and regulation (EG) 1935/2004

Pump tube HC

- for flammable chemicals

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (HC) is suitable for thin-bodied, inflammable and highly corrosive chemicals. Depending on the application different Motors are available which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- used in areas of fire and disaster control

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Approved according to ATEX directive 2014/34/EU, category 1/2

- Highly resistant carbon and ETFE - Shaft bearing

- Maintenance without special tools

- Seal modules of the seal-less (DL) pump are interchangeable

Pump tube Niro

- for flammable liquids

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (stainless steel) is suitable for thin-bodied, flammable and explosive liquids. Depending on the application different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or transferring alternative fuels, oils, flammable liquids

- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Approved according to ATEX directive 2014/34/EU, category 1/2

- Highly resistant noble carbon shaft bearing

- Maintenance without special tools

- Sealing modules of the mechanical seal (GLRD) or the seal-less (DL) pump are interchangeable

Pump tube Niro

- suitable for B2 Vario and B2 Battery

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (stainless steel) is suitable for thin-bodied, oil-based lubricants, cold cleaners and softeners. With the appropriate Motor it is suitable for medium to large filling quantities. Depending on the requirements, the Pump tube can be operated with the electric motor B2 Vario or the battery version B2 Battery.- Media examples: Lubricant (oil-based), cold cleaner, plasticizer

- For removing small quantities from hobbocks, canisters and barrels

- Suitable for Motor B2 Vario and B2 Battery

- No lubricants and therefore no contamination of the pumped medium

- Optimized Drum emptying

- Maintenance without special tools

- Universally resistant ETFE/PTFE shaft bearing

- Sealless design (DL) conditionally safe to run dry

Pump tube Niro for mixing and pumping

- for flammable liquids

Seal type: Mechanical seal (GLRD)

Description:

T he Lutz Pump tube (stainless steel) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for mixing and pumping alternative fuels, oils, flammable liquids

Features & Advantages- Also available with Tri-Clamp connection

- Optionally with electric or compressed air drive

- Two functions (pumping and mixing) in one unit

- No leakage if the pumping station is tilted or moved

- High mixing and conveying capacity for thorough homogenisation

- Switching between the pumping and mixing functions takes place without interfering with ongoing operation, which is made possible by a small lever on the handwhee

Pump tube Niro for mixing and pumping - PURE

- for food (PURE series)

Type of seal: Mechanical seal FPM (GLRD FPM)

Description:

The Lutz Pump tube for mixing and pumping (stainless steel) PURE is suitable for aqueous and fatty food. Depending on the application different Motors are available which can be combined with the Pump tube at any time. Thus you are always flexible and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- for mixing and pumping of alcoholic food, cosmetics and pharmaceutical products as well as flammable cleaning agents

Features & Advantages- Physiologically harmless design

- Food grade connections

- High mixing and delivery rate for thorough homogenisation

- Two functions (pumping and mixing) in one unit

- Approved according to FDA and regulation (EG) 1935/2004

- Approved according to ATEX directive 2014/34/EU, category 1/2

Pump tube Niro for residual drainage

- for flammable liquids

Seal type: Mechanical seal (GLRD)

Description:

The Lutz Pump tube for residual draining (stainless steel) is suitable for thin-bodied, flammable and explosive liquids. Depending on the application different Motors are available which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for Drum emptying alternative fuels, oils, flammable liquids

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimised drum residue emptying with a remaining quantity of approx. 0.1 litres

- No leakage if the pumping station is tilted or moved

- Maximum product utilization with reduced drum cleaning and disposal costs

- Sealing module of the mechanical seal (GLRD) pump replaceable

Pump tube PP

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for filling or decanting oils such as rapeseed oil and vegetable oil

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimised Drum emptying

- Universally resistant PTFE shaft bearing

- Maintenance without special tools

- Sealing modules of the mechanical seal (GLRD) or the seal-less (DL) pump are interchangeable

Pump tube PP

- suitable for B2 Vario and B2 Battery

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (stainless steel) is suitable for thin-bodied, oil-based lubricants, cold cleaners and softeners. With the appropriate Motor it is suitable for medium to large filling quantities. Depending on the requirements, the Pump tube can be operated with the electric motor B2 Vario or the battery version B2 Battery.- Media examples: Lubricant (oil-based), cold cleaner, plasticizer

- For removing small quantities from hobbocks, canisters and barrels

- Suitable for Motor B2 Vario and B2 Battery

Features & Advantages- No lubricants and therefore no contamination of the pumped medium

- Optimized Drum emptying

- Maintenance without special tools

- Universally resistant shaft bearings made of ETFE/PTFE

- Sealless design (DL) conditionally safe to run dry

Pump tube PP for mixing and pumping

- for low-viscosity lyes

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for mixing and pumping oils such as rape seed oil and vegetable oil

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Two functions (pumping and mixing and pumping) in one unit

- No leakage if the pumping station is tilted or moved

- High mixing and conveying capacity for thorough homogenisation

- Switching between the pumping and mixing functions takes place without interfering with ongoing operation, which is made possible by a small lever on the handwheel

Pump tube PP for residual emptying

- for low-viscosity lyes

Seal type: Mechanical seal (GLRD)

Description:

The Lutz Pump tube (PP) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

- Suitable for Drum emptying of oils such as rapeseed oil and vegetable oil

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimised drum residue emptying with a remaining quantity of approx. 0.1 litres

- No leakage when the pumping station is tilted or moved

- Maximum product utilization with reduced drum cleaning and disposal costs

- Sealing module of the mechanical seal (GLRD) pump replaceable

Pump tube PVDF

- for concentrated acids and alkalis

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (PVDF) is suitable for corrosive, aqueous to slightly viscous media. Depending on the application, different Motors are available which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- also available in special immersion depths from 200 - 2500 mm

- Pump tube equipped with Lutz original hand wheel

Features & Advantages- Optionally with electric or compressed air drive

- No lubricants and therefore no contamination of the pumped medium by lubricants

- Optimized Drum emptying

- Universally resistant PTFE shaft bearing

- Maintenance without special tools

- Sealing modules of the mechanical seal (GLRD) or the seal-less (DL) pump are interchangeable

Pump tube PVDF

- suitable for B2 Vario and B2 Battery

Seal type: Sealless (DL)

Description:

The Lutz Pump tube (PVDF) is suitable for thin-bodied, concentrated acids and alkalis. With the appropriate Motor it is suitable for medium to large filling quantities. Depending on the requirements, the Pump tube can be operated with the electric motor B2 Vario or the battery version B2 Battery.- Media examples: Chloric acid, chromic acid, sulphuric acid. Nitric acid, hydrofluoric acid, etc.

- For the withdrawal of small quantities from hobbocks, canisters and barrels

- Suitable for Motor B2 Vario and B2 Battery

Features & Advantages- No lubricants and therefore no contamination of the pumped medium

- Optimized Drum emptying

- Maintenance without special tools

- Universally resistant ETFE/PTFE shaft bearing

- Sealless design (DL) conditionally safe to run dry

Motors

- Requirements and liquids in the market could not be more different. Large quantities, high pressures, viscous liquids, chemical resistance and many more features make the drum pump face a wide variety of challenges and this requires the most different motors. Thus we offer solutions that meet your requirements, as compressed air and electric motors or the mobile battery version.

Battery Motor

- suitable for B1 Battery

Description:

The accumulator motor B1 Battery is suitable for thin-bodied, aqueous to slightly viscous media in laboratories and technical areas. Perfectly suitable for the withdrawal or decanting of smallest quantities.- Replaceable, powerful battery with Li-Ion

- Battery life 25 min at maximum speed

- 1 battery charge emptied approx. 2 x 200 litre container

Features & Advantages- Wear-free, particularly low-noise BLDC motor

- Easy disassembly due to quick release fastener

- Continuously adjustable

- Suitable for very small quantities

Battery Motor

- suitable for B2 Battery

Description:

The accumulator motor B1 Battery is suitable for thin-bodied, aqueous to slightly viscous media in laboratories and technical areas. It is suitable for removing small containers such as Canister or hobbocks. Depending on the requirements, the Motor can be used with various pumping units made of PP, PVDF and stainless steel.- Replaceable, powerful battery with Li-Ion

- Battery life 35 min at maximum speed

- 1 battery charge emptied approx. 12 x 200 litre container

Features & Advantages- BLDC Motor with high efficiency of up to 70%

- Wear-free, particularly low-noise BLDC motor

- Easy disassembly due to quick release fastener

- Infinitely variable

- Extremely high performance at low weight

Compressed air motor for eccentric screw pump

-

Compact and powerful compressed air motor.

- Robust and powerful

- Flow rate adjustable via compressed air supply.

- Overload-proof

Compressed air motor MD1xL

- without comfort handle

Description:

The MD1xL Motor is suitable for viscous, highly inflammable, flammable liquids up to 100.000mPas. With the oil-free, 1000 Watt powerful Compressed air motor you can achieve the same delivery rate as comparable products with 20% less connected pressure and 4% less air consumption.- Optional with comfort handle

- Explosion-proof Motor according to ATEX - guidelines

- Oil-free use

Features & Advantages- High performance and high efficiency due to optimized flow control

- Very good handling due to the low weight

- Long service life

- Very good starting behaviour

- High energy efficiency

Compressed air motor MD2xL

- with comfort handle

Description:

The MD1xL Motor is suitable for viscous, highly inflammable, flammable liquids up to 100.000mPas. With the oil-free, 1000 Watt powerful Compressed air motor you can achieve the same delivery rate as comparable products with 20% less connected pressure and 4% less air consumption.- Optional with comfort handle

- Explosion-proof Motor according to ATEX - guidelines

- Oil-free use

Features & Advantages- High performance and high efficiency due to optimized flow control

- very good handling due to the low weight

- long life span

- very good starting behaviour

Motor MA II 3

- Basic - 460 W - 230 V

Description:

The Motor MA II 3 is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, different Motors with corresponding voltages are available, which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- Optionally with undervoltage release

- Externally ventilated Motor

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Robust and solid construction

Motor MA II 5

- with comfort handle

Description:

The Motor MA II 5 is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, different Motors with corresponding voltages are available, which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- Optionally with undervoltage release

- Externally ventilated Motor

- Also available as acid protection version

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Robust and solid construction

Motor MA II 7

- Description:

The Motor MA II 7 is suitable for aqueous to slightly viscous, aggressive and outgassing liquids. Depending on the application, different Motors with corresponding voltages are available, which can be combined with the Pump tube at any time. Thus you are flexible at any time and save important resources.- Optionally with undervoltage release

- Externally ventilated Motor

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Robust and solid construction

Motor ME II 3

- Description:

The ME II 3 Motor is suitable for thin-bodied, highly flammable, combustible and outgassing liquids. Depending on the application, various Motors with appropriate voltages are available, which can be combined with the Pump tube at any time. This gives you flexibility at all times, thus conserving important resources.- Optionally with undervoltage release

- Externally ventilated Motor

- Explosion-proof Motor according to ATEX - guidelines and IEC Ex

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Protection against fumes

- Long service life

Motor ME II 5

- Description:

The ME II 5 Motor is suitable for thin-bodied, highly flammable, combustible and outgassing liquids. Depending on the application, various Motors with appropriate voltages are available, which can be combined with the Pump tube at any time. This gives you flexibility at all times, thus conserving important resources.- Optionally with undervoltage release

- Externally ventilated Motor

- Explosion-proof Motor according to ATEX - guidelines and IEC Ex

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Protection against vapours

- Long service life

Motor ME II 7

- Description:

The ME II 7 Motor is suitable for thin-bodied, highly flammable, combustible and outgassing liquids. Depending on the application, various Motors with appropriate voltages are available, which can be combined with the Pump tube at any time. This gives you flexibility at all times, thus conserving important resources.- Optionally with undervoltage release

- Externally ventilated Motor

- Explosion-proof Motor according to ATEX - guidelines and IEC Ex

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Protection against fumes

- Long service life

Motor ME II 8

- Description:

The ME II 8 Motor is suitable for thin-bodied, highly flammable, combustible and outgassing liquids. Depending on the application, various Motors with appropriate voltages are available, which can be combined with the Pump tube at any time. This gives you flexibility at all times, thus saving important resources.- Optionally with undervoltage release

- Externally ventilated Motor

- Explosion-proof Motor according to ATEX - guidelines and IEC Ex

Features & Advantages- Double insulation with protective conductor connection

- Optimized cooling air flow

- Double-walled housing protects against corrosion of the internal parts

- Protection against fumes

- Long service life

Single phase motor

- suitable for the Pump tube B50

Description:

The Motor is suitable for the fast transfer of corrosive, aqueous to slightly viscous media. The Motor has been designed in such a way that acid vapours or aggressive atmospheres cannot harm it.- Offers highest chemical resistance

Features & Advantages- Light and handy

- Smooth running and durable

- Quick assembly and disassembly

- Low wear and tear

Three-phase geared motor B4/GT

- with circuit breaker or terminal box

Description:

The three-phase current gear motor B4/GT 4 is suitable for thin-bodied to slightly viscous media. Depending on the application, the Motor can be used for stationary use and plant construction with a cable terminal box or an external circuit breaker. Thus only a low wear occurs and you save important resources.- Ideal solution for long running times

- Optional with cable terminal box or attached circuit breaker

- Special versions are available on request

Features & Advantages- Especially smooth and quiet running

- Robust and durable

- Low wear and tear

- Oil lubricated

- Extremely easy to maintain

Universal motor MI 4 / MI 4-E

- MI4

Description:

The MI 4 Motor is suitable for non-flammable, aqueous to slightly viscous liquids. Depending on the application, different motors with corresponding voltages are available, which can be combined with the Pump tube at any time. This gives you flexibility at all times and saves important resources.- Optionally with speed controller to adjust the delivery rate

- Internally ventilated Motor

Features & Advantages- Easy and quick disassembly

- Light and handy

- Powerful Motor

Flow meter

-

Lutz flow meters are suitable for measuring the volume of clean, low-viscosity to high-viscosity liquids. The modular design offers almost unlimited application possibilities. Individual modules such as basic meter, control unit or relay module can be combined as desired and expanded step by step as needed:

- Liquid measurement without volume preselection from one container to another to add up the quantity detected.

- Liquid measurement with volume preselection. After reaching the preset quantity, an integrated relay module switches off the pump and / or a solenoid valve.

- For assembly to a mobile drum and container pump or stationary in piping systems

- Neutral media such as e.g. water, fuel oil, diesel, hydraulic oils.

- Aggressive acids and alkalis, e.g. hydrochloric acid, sulfuric acid, caustic soda.

- Highly flammable solvents such as e.g. methanol, gasoline, isopropanol, kerosene.

- Viscous media such as e.g. resins, adhesives, paints and varnishes, fluid greases, latex, molasses, glucose.

- External data transmission and signal processing possible (for example via PLC)

Turbine Wheel Meter

Flow Meter TR3-PVDF

- for highly aggressive liquids

Ideal for measuring highly aggressive acids and alkalis and many other non-flammable liquids.

Liquid examples: Sodium hypochlorite, nitric acid, sulphuric acid, etc.

Features:

- Measurement according to the turbine wheel principle

- For thin-bodied fluids

- Display of the partial and total volume

- Range of measurement from 5 l/min - 120 l/min

- Mobile installed on a drum pump or with nozzle connection

Note: This meter replaces our previous TR90 model.

Flow Meter TR3-PVDF

- for neutral and aggressive media

Ideal for measuring highly aggressive acids and alkalis and many other non-flammable liquids.

Liquid examples: Sodium hypochlorite, nitric acid, sulphuric acid, etc.

Features:

- Measurement according to the turbine wheel principle

- For thin-bodied fluids

- Display of the partial and total volume

- Range of measurement from 5 l/min - 120 l/min

- Mobile installed on a drum pump or with nozzle connection

Note: This meter replaces our previous TR90 model.

Nutating Disc Meter

Flow Meter TS Type LM10 Ex

- for solvents, oils and flammable liquids

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: With its rotating swash plate and a magnet, it enables precise measurement of the flow rate and measures solvents and highly flammable liquids, oils and neutral media precisely, quickly and above all efficiently. Optionally, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity. This further simplifies and secures the operation of the systems.- Optional with volume preselection (relay module)

- Media examples: Methanol, petrol, isopropanol, kerosene, formic acid, acetic acid, acetone, styrene, xylene, toluene, etc..

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

- Measurement according to the swash plate principle

- High measuring accuracy

- Variable display orientation

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow meter TS Type SL10

- for acids, alkalis and aggressive media

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the precise measurement of the flow rate and measure oils, aggressive media such as acids and alkalis precisely, quickly and above all efficiently. As an option, the desired quantity can be preselected with a quantity preselection ( relay module), so that the pump or the system switches off automatically after the selected quantity, thus further simplifying and securing the operation of the systems.- Optional with quantity preselection (relay module)

- Media examples: Hydrochloric acid, nitric acid, etc.

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

Features & Advantages- Measurement according to the swash plate principle

- High measuring accuracy

- Variable display orientation

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Simple operation

Flow meter TS Type ST10

- for mineral oils and low viscosity media

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the volume flow and measure thin to medium viscous media such as water and mineral oils precisely, quickly and above all efficiently. As an option, the desired quantity can be preselected with a quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity.thus, the operation of the systems is simplified and secured even more.- Optional with volume preselection (relay module)

- Media examples: Water, oil, diesel, heating oil, hydraulic oils etc.

- Mobile on a Drum pump or with a nozzle connection or stationary in plant construction

Features & Advantages- Measurement according to the swash plate principle

- High measuring accuracy

- Variable display orientation

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Simple operation

Flow Meter TS Type UN10 Ex

- for solvents, acids, alkalis, oils and flammable liquids

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the flow rate and measures solvents, acids, alkalis, highly inflammable liquids, oils and neutral media precisely, quickly and above all efficiently. Optionally, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity. This further simplifies and secures the operation of the systems.- Optional with volume preselection (relay module)

- Media examples: Methanol, petrol, isopropanol, kerosene, formic acid, acetic acid, acetone, styrene, xylene, toluene, etc.

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

Features & Advantages- Measurement according to the swash plate principle

- High measuring accuracy

- Variable display orientation

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow Meter TS Type VA10

- for flammable and aggressive liquids

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the flow rate and measures acids and alkalis, almost all solvents and highly inflammable liquids precisely, quickly and above all efficiently. As an option, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity has been reached, thus further simplifying and securing the operation of the systems.- Optional with volume preselection (relay module)

- Media examples: Hydrochloric acid, nitric acid, styrene, petrol, acetone etc.

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

Features & Advantages- Measurement according to the swash plate principle

- High measuring accuracy

- Variable display orientation

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Simple operation

Flow Meter TS Type VA10 - Pure

- for food (PURE series)

Design:

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: With its rotating swash plate and a magnet, it enables the exact measurement of the volume flow and measures aqueous and fatty foods precisely, quickly and above all efficiently. As an option, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity has been reached, thus further simplifying and securing the operation of the systems.- Optional with quantity preselection (relay module)

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

- also for foodstuffs containing alcohol, cosmetics and pharmaceutical products as well as flammable cleaning agents

Features & Advantages- Measurement according to the swash plate principle

- High measuring accuracy

- Food grade connections

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Approved according to FDA and regulation (EG) 1935/2004

Flow Meter TS Type VA10 Ex

- for solvents, acids, alkalis and flammable liquids

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the flow rate and measures solvents, acids, alkalis, highly inflammable liquids, oils and neutral media precisely, quickly and above all efficiently. Optionally, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity. This further simplifies and secures the operation of the systems.- Optional with volume preselection (relay module)

- Media examples: Methanol, petrol, isopropanol, kerosene, formic acid, acetic acid, acetone, styrene, xylene, toluene, etc.

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

Features & Advantages- Measurement according to the swash plate principle

- High measuring accuracy

- Variable display orientation

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow Meter TS Type VA10 Ex - Pure

- for food (PURE series)

Description:

The first flowmeter with touch screen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design: The rotating swash plate and a magnet enable the exact measurement of the flow rate and measure easily flammable food precisely, quickly and above all efficiently. As an option, the desired quantity can be preselected with the quantity preselection (relay module), so that the pump or the system switches off automatically after the selected quantity has been reached, thus further simplifying and securing the operation of the systems.- Optional with quantity preselection (relay module)

- Mobile on a Drum pump or with a nozzle connection or stationary in plant engineering

- also for foodstuffs containing alcohol, cosmetics and pharmaceutical products as well as flammable cleaning agents

Features & Advantages- Measurement according to the swash plate principle

- Food grade connections

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 10 l/min- 100 l/min

- Approved according to FDA and regulation (EG) 1935/2004

- Approved according to ATEX Directive 2014/34/EU, category 2

Oval gear flow meter

Flow meter HDO 080

- for acids, alkalis, mineral oils, hydrocarbons and solvents

Description:

The flow meter is a compact basic meter with a connection cable and plug for connection to an external control unit. Due to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables the precise measurement of the volume flow and measures thin-bodied to highly viscous media such as acids, alkalis, mineral oils, hydrocarbons and solvents precisely, quickly and above all efficiently.- Media examples: Paints, lacquers, mineral oils, acids, alkalis

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy due to overtravel correction

- Low pressure losses in the system

- Touch screen display with self-explanatory, multilingual user interface

- Measuring range from 0.25 l/min - 8.3 l/min

- Low frictional resistance

Flow meter HDO 120 Alu/LCP

- for non-flammable liquids

Description:

The first flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently.- Optionally in explosion-proof design

- Media examples: Paints, lacquers, mineral oils, acids, alkalis, mineral oils, solvents

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy due to overtravel correction

- Low pressure losses in the system

- Touch screen display with self-explanatory, multilingual user interface

- Relay module for quantity preselection can be retrofitted at any time

- Approved according to ATEX directive 2014/34/EU, category 2

Flow Meter HDO 200 Alu/LCP

- for non-flammable liquids

Description:

The first flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently.- Optionally in explosion-proof design

- Media examples: Paints, lacquers, mineral oils, acids, alkalis, mineral oils, solvents

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy due to overtravel correction

- Low pressure losses in the system

- Touch screen display with self-explanatory, multilingual user interface

- Relay module for quantity preselection can be retrofitted at any time

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow meter HDO 250 Alu/PPS

- for non-flammable liquids

Description:

The first flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently.- Optionally in explosion-proof design

- Media examples: Paints, lacquers, mineral oils, acids, alkalis, mineral oils, solvents

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy due to overtravel correction

- Low pressure losses in the system

- Touch screen display with self-explanatory, multilingual user interface

- Relay module for quantity preselection can be retrofitted at any time

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow Meter HDO 400 Alu/PPS

- for non-flammable liquids

Description:

The first flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently.- Optionally in explosion-proof design

- Media examples: Paints, lacquers, mineral oils, acids, alkalis, mineral oils, solvents

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy due to overtravel correction

- Low pressure losses in the system

- Touch screen display with self-explanatory, multilingual user interface

- Relay module for quantity preselection can be retrofitted at any time

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow Meter HDO 500 Alu/PPS

- for non-flammable liquids

Description:

The first flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently.- Optionally in explosion-proof design

- Media examples: Paints, lacquers, mineral oils, acids, alkalis, mineral oils, solvents

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy due to overtravel correction

- Low pressure losses in the system

- Touch screen display with self-explanatory, multilingual user interface

- Relay module for quantity preselection can be retrofitted at any time

- Approved according to ATEX Directive 2014/34/EU, category 2

Flow Meter MDO 2

- for mineral oils and alternative fuels

Description:

The flow meter with display convinces with its simple, demand-oriented display, operability and compact design. Thanks to the rotating Oval gear meter and a magnet integrated in the measuring chamber, it enables the exact measurement of the volume flow and measures mineral oils and alternative fuels such as diesel, petrol etc. precisely, quickly and above all efficiently.- Media examples: Diesel, heating oil, hydraulic oil, machine oil and motor oil etc.

- Quantity preselection can be retrofitted with a relay module at any time

- Suitable for measuring alternative fuels

Features & Advantages- Measurement according to the oval wheel principle

- High measuring accuracy

- Low pressure losses in the system

- Measuring range from 3 l/min - 80 l/min

- Low frictional resistance

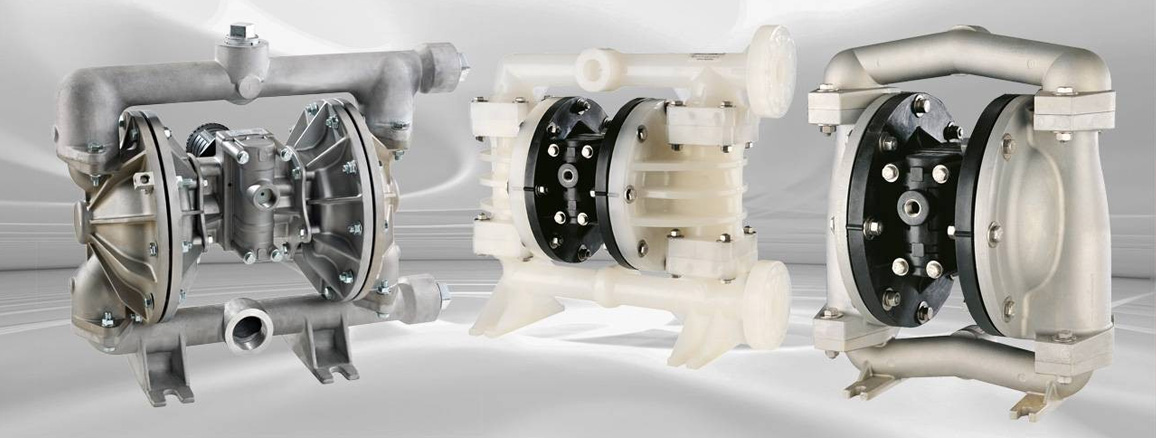

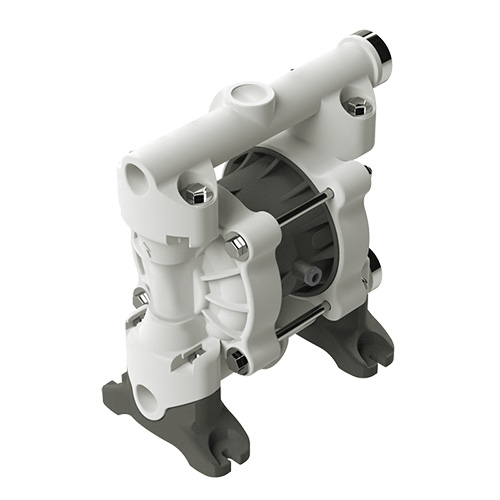

Double Diaphragm Pumps

- Lutz compressed air operated double diaphragm pumps are capable to pump even critical material in a gentle and safe manner in mobile or stationary use. They are just as suitable for aggressive, abrasive or easily flammable liquids as they are for liquids with a high viscosity.

Non-Metallic Version

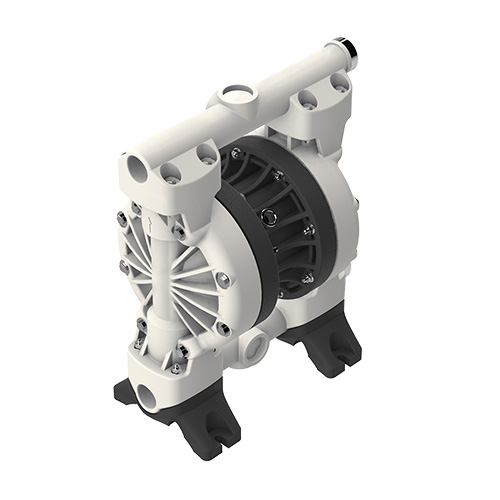

Double diaphragm pump 1 1/2 made of PP (bolted version)

-

Suitable for handling neutral and aggressive liquids

Application examples:

Suitable for filter presses, tank cleaning systems, pigments and resins.Features:

- Absolutely oil-free valve technology

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 492 l/min

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- Flow rate and flow pressure can be infinitely varied

- No wear prone dynamic seals

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

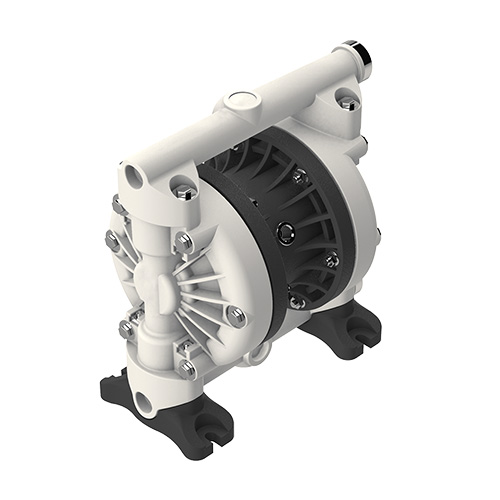

Double diaphragm pump 1 made of PP (bolted version)

-

Suitable for handling neutral and aggressive liquids

Application examples:

Suitable for transfer from drums and containers, transfer of corrosive solutions and chemicalsFeatures:

- Absolutely free of oil

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 156 l/min

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

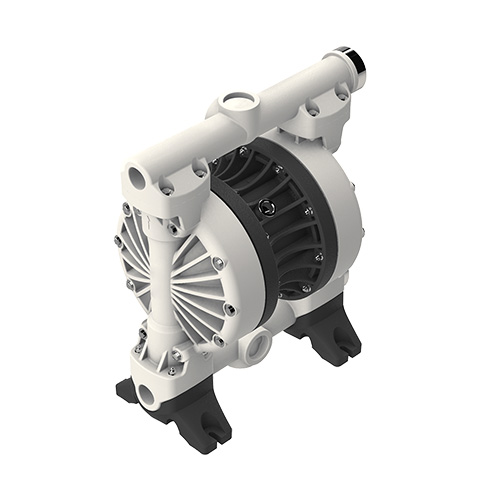

Double diaphragm pump 1/2 made of PP(bolted version)

-

Suitable for handling neutral and aggressive liquids

Application examples:

Suitable for emptying 200 l drums, ink, chemical, solvents, acids and alkalis feed and recirculation.Features:

- Absolutely free of oil

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 65 l/min

- Explosion-proof version approved according to ATEX Directive 2014/34/EU, Category 2

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

Double diaphragm pump 2 made of PP (PTFE version) (bolted version)

-

Suitable for handling neutral and aggressive liquids

Application examples:

Suitable for lacquers, latex, ceramic slip, slurries, polymers, filling and emptying of tank cars.Features:

- Absolutely oil-free valve technology

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 160 GPM (605 l/min)

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- Flow rate and flow pressure can be infinitely varied

- No wear prone dynamic seals

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

Double diaphragm pump 3/8 made of PP

-

Suitable for easily flammable liquids

Application examples:

Suitable for chemical recirculation and feed, liquids with solid particles, e.g. paints and lacquers, galvanic fluids, etc.Features:

- Absolutely free of oil

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 9 GPM (34 l/min

- Explosion-proof version approved according to ATEX Directive 2014/34/EU, Category 2

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

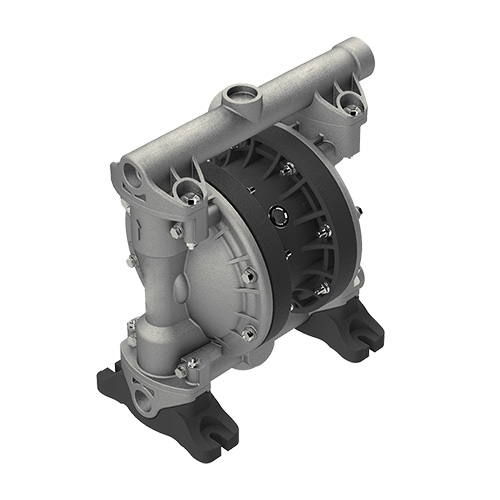

Metallic Version

Diaphragm Pump Mixing System - for Mixing and Pumping (explosion proof)

-

For liquids which have to be mixed prior to processing and then pumped or which are containing small solids, the new diaphragm pump mixing system with an integrated air-operated doublediaphragm pump from Lutz is the perfect solution.

The mixing and pumping process is made via a suction and mixing tube and a 3-way tap. The pre-assembled system is immediately ready for use with a few simple steps and is also suitable for explosive liquids.

Examples for liquids:

Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased viscosity and solids contentMixing system consisting of:

Compressed air-operated double diaphragm pump 1/2" mounted on a base plate, Vibration damper, Universal chemical hose 3/4” bound, 3-way ball valve G 3/4“

Double diaphragm pump 1 1/2 made of Aluminium (bolted version)

-

Suitable for neutral and combustible liquids

Application examples:

For filter presses, tank cleaning systems, pigments and resins.Features:

- Absolutely oil-free valve technology

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 435 l/min

- Explosion-proof version approved according to ATEX Directive 2014/34/EU, Category 2

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- Flow rate and flow pressure can be infinitely varied

- No wear prone dynamic seals

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

Double diaphragm pump 1 made of Aluminium (bolted version)

-

Suitable for neutral and combustible liquids

Application examples:

Drum and container transfer, decanting corrosive solutions and chemicals.Features:

- Absolutely oil-free valve technology

- Absolutely safe to run dry

- Self-priming, even dry

- Just a few components, easily accessible

- Flow rate up to 182 l/min

- Explosion-proof version approved according to ATEX Directive 2014/34/EU, Category 2

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- Flow rate and flow pressure can be infinitely varied

- No wear prone, dynamic seals

- Easy maintenance without special tools

Double diaphragm pump 1/2 made of stainless steel (PTFE version) (bolted version)

-

Application examples:

Suitable for emptying 200 l drums, ink, chemical, solvents, acids and alkalis feed and recirculation.Features:

- Absolutely oil-free valve technology

- Absolutely safe to run dry

- Self-priming, even dry

- Centre block made of corrosion-free plastic

- Just a few components, easily accessible

- Flow rate up to 57 l/min

- Explosion-proof version approved according to ATEX Directive 2014/34/EU, Category 2

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- Flow rate and flow pressure can be infinitely varied

- No wear prone dynamic seals

- No direct chemical attack of the air-conducting parts in case of membrane rupture

- Easy maintenance without special tools

Double diaphragm pump 2 made of Aluminium (bolted version)

-

Application examples:

Suitable for lacquers, latex, ceramic slip, slurries, polymers, filling and emptying of tank cars.Features:

- Absolutely oil-free valve technology

- Absolutely safe to run dry

- Self-priming, even dry

- Just a few components, easily accessible

- Flow rate up to 719 l/min

- Explosion-proof version approved according to ATEX Directive 2014/34/EU, Category 2

Benefits:

- No failure of the pump due to lack of lubrication

- No contamination of the environment or of the product itself by oil vapour

- Gentle pumping of thick-bodied, contaminated and abrasive liquids

- Flow rate and flow pressure can be infinitely varied

- No wear prone dynamic seals

- Easy maintenance without special tools

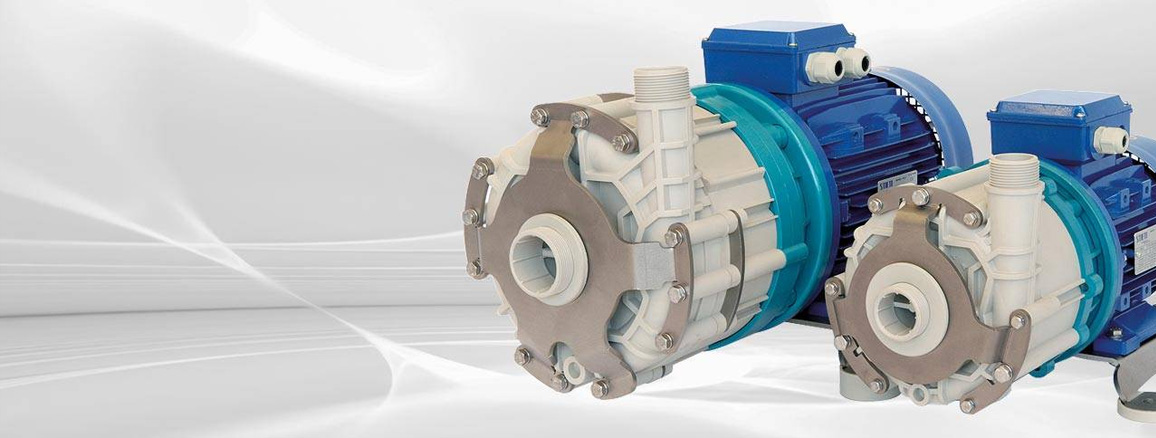

Centrifugal Pumps

- Lutz vertical and horizontal centrifugal pumps ensure the safe delivery of aggressive, corrosive and other hazardous acids or alkalis and other hazardous liquids. Vertical and horizontal pumps from one source, For the industrial application.

Horizontal Centrifugal Pumps

-

Lutz horizontal centrifugal pumps with magnetic coupling of series TMB, AM and TMR are sealless and environmentally safe.

Due to the contact-free magnetic transmission of power, no mechanical seals are required. No leakages arise and the pump housing is hermetically sealed. High-quality materials and special construction features guarantee a long service life.

The series TMR (version "R") is able for dry running by means of a magnetic two axial directions self-alignment system.

Horizontal centrifugal pump series AM

- for aggressive, corrosive and toxic liquids

Application examples:

Ideal for the low to medium performance segment in plant engineering and process equipment manufacturing.