- Offer Profile

- sera Companies are

providers in Dosing and Compressor Technology

sera ProDos is dosing pump manufacturer and system supplier of high quality products and services for waste water and water treatment and disinfection as well as accurately measured and controlled dosing and feeding of chemicals and liquids for a wide range of industries like food and beverage, breweries, pulp and paper, chemical, petrochemical, mechanical and plant engineering, energy and power plants, textile, printing, environmental etc.

sera ComPress is manufacturer of single- and multi-stage compressors and customized specific solutions for compressing and feeding of gases, especially high-purity gases free of oil, impurity and leakage.

Dosing Technology Products

- We offer an extensive product range of dosing technology. You can find the individual products here.

Dosing Pumps

- sera dosing pumps and feeding pumps are oscillating displacement pumps for the dosing and feeding of liquids in all industrial fields. We can dose nearly all flowing media, even with aggressive, abrasive, odorous, radioactive, inflammable, viscous or toxic properties - reliably and safely!

Solenoid Diaphragm Pumps

-

Performance range from 0,4 l/h to 35 l/h, counter pressures up to max. 10 bar.

Our sera diaphragm pumps are distinguished by Performance range from 0,4 l/h to 35 l/h, counter pressures up to max. 10 bar. Thanks to sera’s „plug & dose“ (standard configuration) a very simple commissioning is possible. The solenoid diaphragm pumps of the 2 series are available with simple (R204.1) and extensive (C204.1) control electronics. For special dosing problems and to meet nearly all of our customers‘ needs, we offer indivual solutions, e.g.:

- RS-/CS-design for outgasing media, self ventilating

- Multi function valves

- Completely available with dosing kits ("plug & dose")

- Design with Profibus DP-Interface

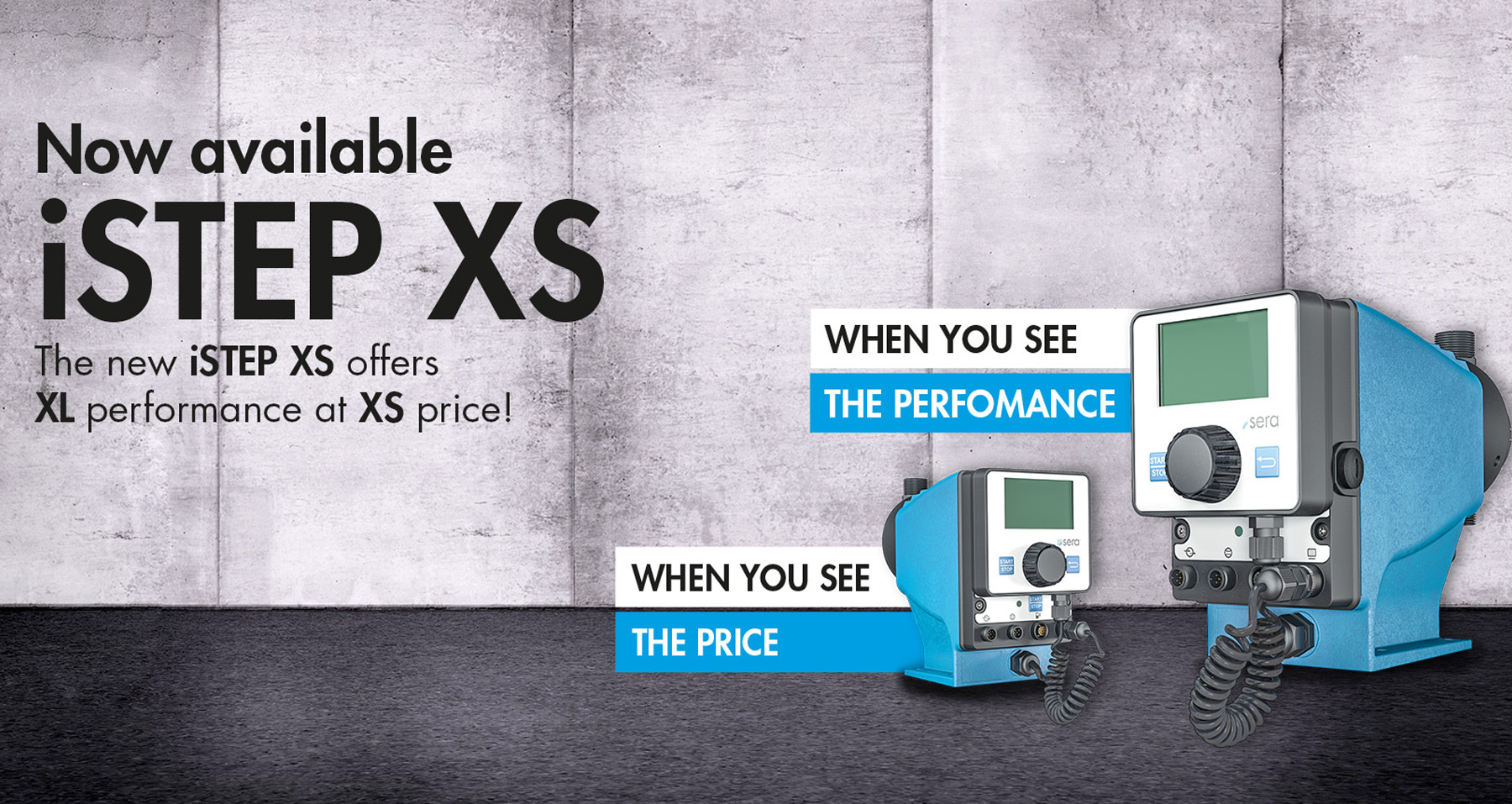

iSTEP - The Stepper Motor Pumps

-

Performance range to 50 l/h, counter pressures up to max. 10 bar

The new sera dosing pump iSTEP® combines an intelligent drive concept with the accuracy of a diaphragm pump. It sets new standards in terms of reproducibility and reliability.

Diaphragm Pumps

- sera diaphragm pumps are leak-free oscillating displacement pumps designed for the dosing of volumes up to 1450 l/h and to withstand pressures up to max. 10 bar.

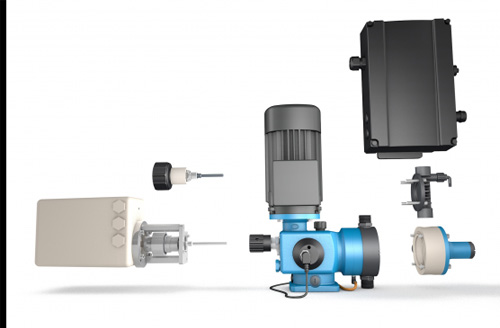

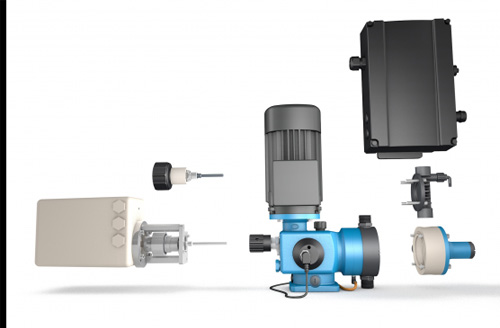

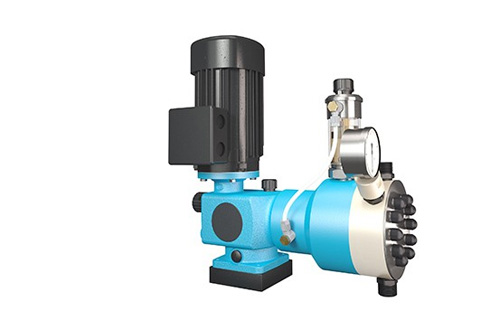

Piston diaphragm pumps

-

Performance range from 7,5 l/h to 850 l/h, counter pressures up to max. 80 bar.

sera piston diaphragm are leak-free oscillating displacement pumps. They are an ideal combination of the high supply pressure of a piston pump and the perfect leak-proof diaphragm pump.

Piston pumps

-

sera piston pumps are versatilely applicable and despite its high pressure range extremely safe to operate. Due to low-wear components the maintenance of the piston pump is very low and therefore it convinces with accustomed quality and reliability.

Flow rate from 8 l/h to 22 l/h counter pressures upt to 140 bar

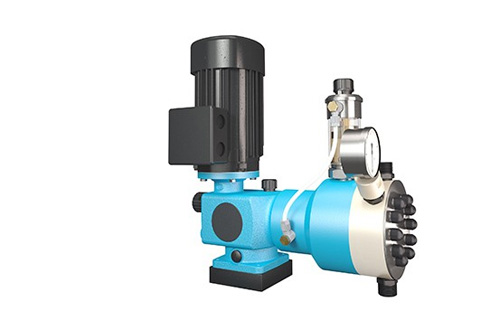

Multi-layer Diaphragm Pumps

-

Performance range from 11 l/h to 1200 l/h, counter pressures up to max. 20 bar.

By using the multi-layer membrane demanding safety dosing tasks can be realised.

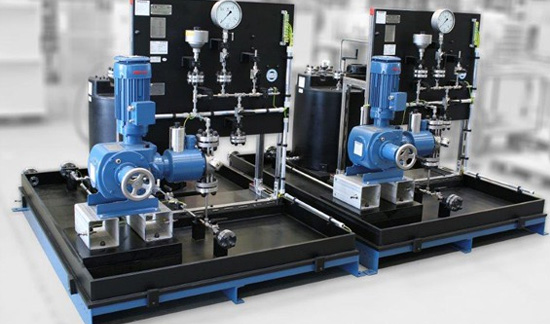

Dosing Systems

- For decades the proven sera delivery program has had an excellent reputation for its high-quality and long-lived products in the area of dosing units. Besides the customized dosing stations sera offers the following types of equipment.

Standardised Compact Dosing Systems

-

We offer two Standardised Dosing Systems: Compact Tank Dosing Unit CTD and Compact Vertical Dosing System CVD.

Our standardised compact dosing systems are are multiple useable, these systems combine quick availability and short delivery times.

Polymer preparation stations

-

Standardised polymer preparation stations of sera PolyLine® are a series of easy, flexible, economical and efficient systems for the treatment of polymers.

The series covers treatment plants, which can be operated with dry or liquid polymers. The systems are equipped with a precise water measurement and level measurement in order to ensure the efficient and economic operation of the systems.

Prepared polymers are used to filter out particles from drinking water and wastewater. Furthermore, the polymers are important components for the application in sludge dewatering.

Customised Dosing Systems

- You want a dosing system for your individual application? We offer also customized dosing systems.

Sodium Hydroxide Preparation System

-

sera has developed sodium hydroxide preparation system, a cost-efficient system solution specifically aimed at industries with fluctuating, but large requirements of alkaline detergents or for countries where a continuous delivery is not secured.

This solution ensures the safe and efficient preparation of soda lye on the basis of sodium hydroxide (NaOH) in solid form (pellets, flakes, beads or powder) and water.

KKV Dosing System

-

sera KKV - dosing systems were developed in collaboration with DyStar for dosing and mixing Levafix® - and Remazol® - padding liquors when dyeing using the single-bath padding process.

sera KKV-Dosing system with automatic monitoring consists of single diaphragm pumps - made of high-quality materials and easy to maintain - combined with an automatic monitoring system.

Feeding Pumps

-

In addition to metering pumps, sera also offers feed pumps for reliable pumping of all media. As part of the Excellence Partnership Program, we also offer you other products in the field of pump and feeding technology. We are at your side as the exclusive supplier of Finish Thompson centrifugal pumps in Germany, Austria and Switzerland.

We are also the exclusive contact for DEBEM pumps for our Swiss customers.

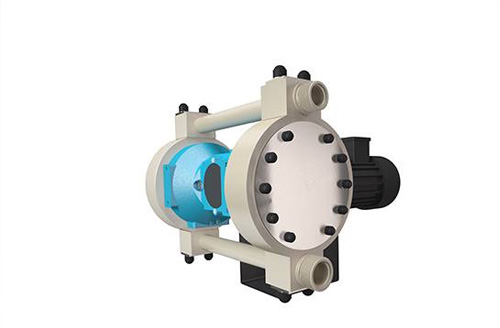

airPUMP Air operated diaphragm pumps

-

Performance range from 5 l/h to 850 l/h, counter pressures up to max. 7 bar

sera air driven diaphragm pumps are cost-effective, leakage free displacement pumps.They are driven by dry, non-lubricated compressed air.

BENEFITS

- Easy to install

- Simple to operate

- Portable

- Self-priming

- Submersible

- Dry running

- Solids handling

YPICAL INDUSTRIES

- Mining

- Paints and Coatings

- Ceramics

- Pulp and Paper

- Electroplating and Anodizing

- Wastewater

- Marine

- OEM‘s

- Chemical Manufacturing and Distribution

centrifugalPUMP

-

sera is the exclusive distributor of Finish Thompson

The proven sera product range has enjoyed an excellent reputation in the field of dosing pumps for high quality and durable products for decades. In addition, as an exclusive distributor of Finish Thompson Inc., sera now offers magnetically coupled centrifugal pumps for a wide range of applications.

Feeding pumps

-

Performance range from 2200l/h to 3100 l/h, counter pressures up to max. 4 bar

sera feeding pumps are oscillating displacement pumps with two pump heads for feeding and dosing of liquids in all areas of industry.

Peristaltic pumps

- PeriBest pump hose technology

- maximum resistance to abrasion

- incomparable suction capacity

- unlimited dry run

- no valves or mechanical seals

- full dosing control

- Dosing accuracy of +-1%

Dosing Systems Accessories

- For the installation of dosing systems, dosing systems accessories are required as an important component.

Agitators

-

Our agitators include electric agitators - with control, manual agitators and manual stamping mixers in survey.

Wide range of applications thanks to coordinated material combinations and high level of security through optional gas-tight version. The agitators can be used for critical mixing processes by performing with electronics and individual controllability and offer high process reliability through extensive communication in the execution with electronics.

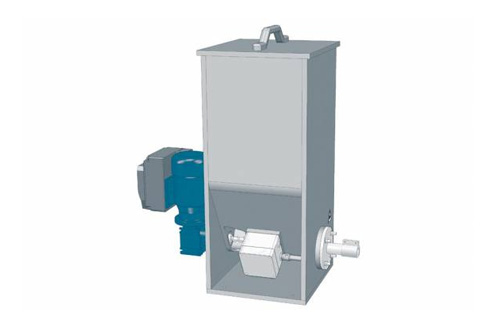

Dry material feeder

-

For precise metering of fluids that do not tend to stick.

sera dry material feeder are being used to precisely dose free-flowing transported media not tending to adhere such as polymers in powder form.

Solenoid float switch

-

sera solenoid floats can be used for level monitoring.

sera solenoid float can be used for level monitoring. A Reed contact which serves as a level sensor is switched by the solenoid of a float.

Tank/ Collecting basins

- Round tanks made of PE and collecting basins

Fittings

- Important elements used in plant engineering and pipeline systems.

Priming Aid/ Siphon Vessel

-

Max. flow quantity up to 4000l/h

sera priming aid/siphon vessel for the improvement of the suction performance in metering pumps.

In addition, the siphon vessels and priming aid have the task to simplify commissioning of dosing pumps. Especially in those cases where the pumped medium where the medium is removed via a siphon pipe of a storage tank, it is ensured that the suction line is filled hydraulically.

At the same time the priming aid also functions as a suction-side pulsation damper.

Injection Fittings

-

Max. flow rate up to 1500l/h

sera injection fittings help the medium which is transported by the dosing pump to be injected into the system to be treated.

Calibration Pot

-

Content up to 20 litres

sera calibration pots serves to determine the liquid flow of dosing pumps under real working conditions.

The calibration pot is intended to be installed in the suction side of the dosing pump. The pot can be filled either according to the principle of interconnected tanks or with the help of a dosing pump.

During the filling respectively calibration process the ventilating joint must be opened. After the filling/calibration the ventilating joint must be closed immediately.

Line Strainer

-

Maximal flow quantity up to 6000l/h

Fluids may contain impurities in piping systems. Here the sera line strainer is used. sera line strainers increase the working safety of the dosing pump and the complete system by detaining impurities and floating materials.

Two Way Ball Cock

-

Up to 10 bar

The two way ball cocks of typ 8001 - 8009 are radially installable and dismountable. They are beeing used for manual shut-off or release of liquid flow in pipelines.

Valves

-

sera valves are made of high quality materials and ensure operational safety.

Valves are used on the one hand for the passage of fluids, on the other hand, to the shutting off of fluids (gases and liquids).

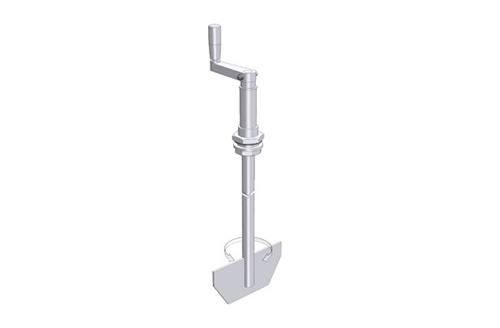

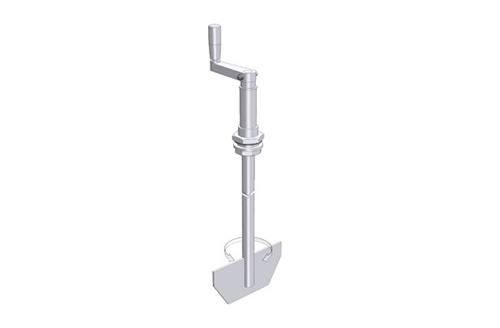

Suction Lances

-

Suction lances are used for the removal of chemicals

An integrated foot valve prevents backflow of the aspirated fluid. The types SL-02, S-03 and S-04 are additionally equipped with a float switch (for empty message).

Pulsation Damper

-

Our pulsation damper with and without separating diaphragm.

sera pulsation dampers are leak-free, low maintenance and have a long service life. They are easy to use and reduce noise.

Process Measuring and Control

- The dosing of all liquids can be optimized by using measuring and control technology.

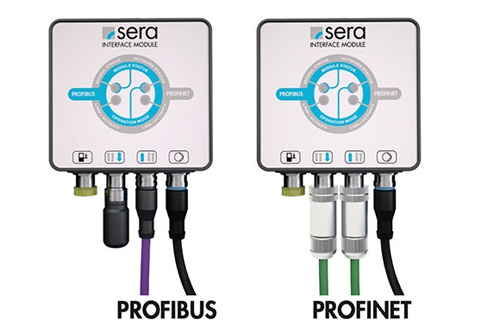

PROFIBUS / PROFINET

-

PROFIBUS has been the established fieldbus for machines and systems for years. Based on serial bus technology, it revolutionized the automation world in the 1980s and created the basis for decentralized concepts for the first time. In the 1990s, Ethernet spread to IT and industry. With the PROFINET standard, Ethernet was expanded to include the properties for networking in automation and has been used successfully since then. Today, both systems have become indispensable in production. With additional expansions, PROFINET is also used in process automation.

PROFINET

PROFINET is based on an Industrial Ethernet standard for data transmission and thus not only enables the linkage of the field level, but also ensures a combination with industrial IT functions, which enables continuous use in production and process automation.

The control electronics of the sera dosing pumps can be expanded with an INTERFACE MODULE. This is connected directly to the electronics and offers the option of integrating the respective dosing pump into a PROFINET structure. With two PROFINET connections, it can be integrated in both ring and tree structures.

Messtechnik

-

For the measuring of process-values as pH-value, redox or Cl2 different designs of measuring systems are characterized by high measuring accuracy.

A measuring device typically consists of an electrode – integrated in a fitting – as well as of an associated measuring transmitter. A selection of the devices depending on the application is possible on request.

Process and Control

-

Our process and control include complete engineering and circuit diagram design and more.

The sera program of controls includes a number of standadised basic controls for economic integration of sera metering pumps into automatic processes.

Depending on the type of dosing we differentiate between three groups:

Batch dosing

Proportional dosing

Dosing in a control circuit

Hydrogen Technology

COMPRESSORS

METAL DIAPHRAGM COMPRESSORS

-

sera metal diaphragm compressors deliver absolutely contamination-free compression of sensitive and valuable gases.

Metal diaphragm compressors are the best choice for microelectronics, semiconductor and doping technology applications.RANGE OF APPLICATIONS

- Gas bottle filling and transfilling units

- Production of specialty gas mixtures

- Recycling of noble gases

- Gas shielding for surface treatment processes

- Nitrogen compressors for butyl production

- Hydrogen refuelling stations

- Airbag inflator gas filling

- Natural gas filling in air separation plants

- Power-to-gas compressor units

- Experimental and research facilities

- Hermetically sealed between outside and interior

- Compression of toxic and explosive gases

- Completely lubricant-free compression

- No contamination occurs from piston ring or rod sealing wear

- High resistance to corrosion

- No purge or seal gas systems required

- Pressurised start-up

An almost complete lack of outward leakage makes it possible to safely compress gases that have an extremely critical impact on humans and the environment. Because of this, sera metal diaphragm compressors are often used in applications involving toxic gases.

Depending on the process requirements, different material qualities of medium-contacted components are chosen. This allows a high degree of corrosion resistance and long service lives to be achieved for gas-contacted parts.

DRY-RUNNING PISTON COMPRESSOR WITH ELECTRO-HYDROSTATIC DRIVE

- sera has provided reliable gas compression solutions without oil, contamination or leakage for many decades. Our newly developed, innovative dry-running piston compressors with electrohydrostatic drives perfectly complement our established metal diaphragm technology. They enable reliable and energy-efficient compression of particle-free gases such as hydrogen, nitrogen, helium, argon or ethylene to extreme pressures without the use of lubricants. These innovative piston compressors from sera are ideal when large quantities of gas need to be compressed cost-effectively and safely.

Contamination of the medium with hydraulic fluid from the drive system is eliminated by the vertical format and the design of the compressor units. This makes it possible to safely dispense with complex and expensive sensors for detecting drive fluid.

ADVANTAGES AT A GLANCE- Oil-free, safe compression

- Robust design

- High availability

- Energy-efficient drive unit

- Compact footprint

- Easy servicing

AREAS OF APPLICATION

- Hydrogen refuelling stations

- Power-to-Gas

- Technical gases

- Airbag inflators

- Hot isostatic presses

- Pressure testing technology

Power-to-Gas Compressor Unit & Hydrogen Refuelling Stations

WASSERSTOFFTANKSTELLEN

-

“Water will be the coal of the future”. Jules Verne recognised this as early as 1870, writing in his novel “The

Mysterious Island” that tomorrow’s energy will be water which has been decomposed by electricity, and that

its elements (hydrogen and oxygen) will provide the earth with an indefinite supply of energy.

At a time when fossil fuels are running out and environmental protection is becoming increasingly essential to

our planet, sera GmbH has made a commitment to this very vision – which is why we have developed and

launched our innovative hydrogen refuelling station as a ground-breaking step towards the preservation of

our environment. Hydrogen technology: the fuel of the future.

ADVANTAGES AT A GLANCE- MODULAR DESIGN

Thanks to standardised modules, the hydrogen refuelling station

can be perfectly tailored to customer needs. Subsequent add-ons

are no proble - HIGH FLOW RATES

Our innovative piston compressor allows for high flow rates,

which makes frequent refuelling easily achievable even with high

discharge volumes. - RELIABLE & LOW MAINTENANCE

Our compressor’s slow stroke puts little strain on wearing parts,

giving them a long service life. - EASY TO SERVICE

Our system container has been designed so that every technical

component is easily accessible. This lets you minimise servicing

time and guarantees smoothness in use. - QUIET OPERATION

During development, special care was taken to keep noise emissions

as low as possible so that the sera hydrogen refuelling station can also be used in noise-sensitive areas. - LOW ENERGY CONSUMPTION

The electrohydrostatic drive and low friction in our innovative compressor technology ensure low energy consumption.

- MODULAR DESIGN

POWER - TO - GAS KOMPRESSORSTATION

- With sera power-to-gas compressor units, innovative system solutions can be created for converting renewable

energy into hydrogen for use in a range of applications. Direct use of green hydrogen in mobility and

transportation is just as feasible as buffering in storage facilities and direct supply into the natural gas grid

or H2 pipelines.

Power-to-gas energy storage can help to balance out increasing fluctuations of wind and solar energy in

power generation, or keep power from being fed directly into the grid at times when generation is particularly

high.

ADVANTAGES AT A GLANCE- Energy-efficient

- Reliable

- Completely lubricant-free H2 compression

- Modular construction

- Compact

- Flexibly upgradeable

RANGE OF APPLICATIONS

- Buffer storage in stationary medium-pressure, high-pressure and cavern storage facilities

- Trailer filling for supplying H2 refuelling stations

- Feeding into the natural gas grid

- Feeding into H2 pipelines

Most sera power-to-gas compressor units use our hydraulically driven dry-running piston compressors. Due

to its design and focus on maximum technical reliability, this compressor technology is ideal for the various

applications of power-to-gas. The compressor units are extremely compact and take up comparatively little

floor space.

Industries

- sera dosing technology, with high-quality dosing pumps and dosing systems, is used in a variety of industries worldwide. Our products create added value and provide high-quality products for the consumer. Our dosing technology is used in numerous industries. Here you will find a collection.

Food and Beverage

- Our dosing systems and metering pumps can be used in the food and beverage industry. We will show you where and how!

Water and Wastewater Treatment

- In water treatment and wastewater treatment, legal requirements must be considered. Both in industrial as well as in municipal wastewater treatment plants modern and high-quality dosing is necessary!

Industry & Process Solutions

-

We offer for a different other industries dosing Technology. Read more here!

Applications

- Our dosing systems, dosing pumps and MSR-Technology can be used for a lot of applications.

CIP - Cleaning in place

-

CIP Cleaning – Hygiene of the highest standard

We offer you the optimal dosing technology for CIP- Cleaning in place when it comes to the production of milk.

CIP means Cleaning in Place. The cleaning of the unit happens at the spot. Therefore the unit must not be disassembled for the cleaning.

The CIP cleaning is mainly used in the Food industry as well as the Dairy industry. Parts that get in contact with the medium are cleaned at the spot to remove deposits quick and efficient.

Boiler Feed Water Treatment

-

Boiler feed water is called the water which supplies the steam generator of steam boilers. This water is made of additional water and condensate.

To condensate losses, additional water is feed from outside to the water-steam-system.

Water, dissolved gasses and salts can cause corrosion and deposits in the water-steam system. To prevent this, several conditioning agents are supplied.

For the conditioning of boiler feed water, sera offers dosing units for several mediums.

Disinfection of Water

-

Water is one of the most valuable assets in the world. It becomes shorter and many people haven´t got the luck to get it in good quality.

Waters are often dirty and not usable for the use of humans. To make the water drinkable, it requires sophisticated disinfection processes.

For the disinfection of water sera has developed chlorine dioxide generators.

Chlorine dioxide increasingly asserts its role in the treatment of drinking water. It is used to destroy germs, spores, yeasts and viruses and to dissolve biofilms. The key advantage of ClO2: It is ecologically absolute compatible in spite of its strong disinfecting performance.

Dosing of Chemicals

-

We offer for almost every dosing task in you process the necessary equipment. Besides the proven dosing pumps and feeding pumps as well as the standardized dosing systems also customer specific dosing systems are available.

Moreover for complete mixing and preparation units we are able to supply control cabinets. The monitoring of all process parameters can be realized on site and a signal exchange with a control board can be done hardwired or via bus systems.

Because of the use of modern dosing pumps and systems your process will be optimally controlled and monitored. Thus an efficient use of chemicals is ensured.