- Offer Profile

- Flowserve is a leading manufacturer and aftermarket provider of flow control products and systems for the world's most critical applications. Our products and services are used in several distinct industries including oil, gas, chemical, power generation, water resources, as well as a number of general industries.

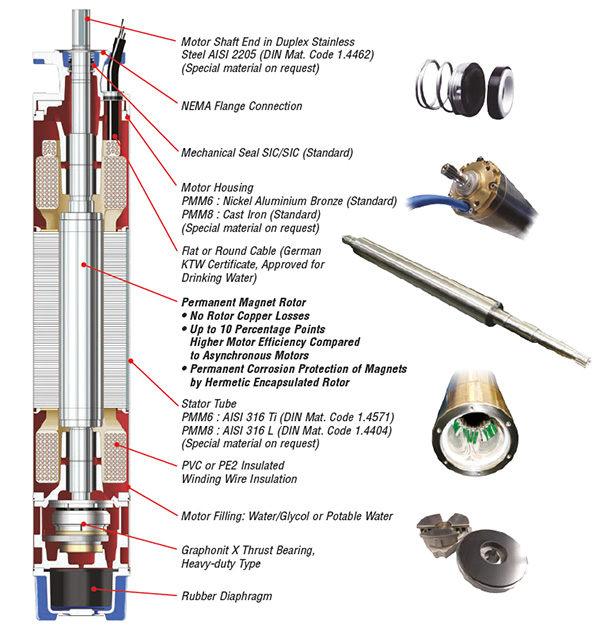

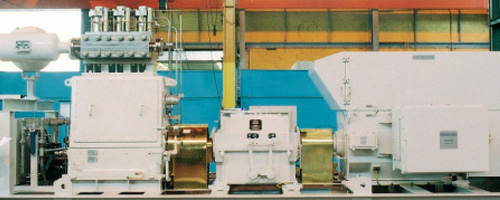

New: Flowserve Pleuger Permanent Magnet Motor Type PMM

Flowserve Pleuger Permanent Magnet Motor Type PMM

-

The Flowserve Pleuger PM motor has been developed for the highest possible energy efficiency.

The permanent magnet technology guarantees approximately 10 percentage points better motor efficiency, resulting in a lower elevated temperature rise of the motor windings, increasing power output more than 100%.

The PM motor construction is based on the reliable Pleuger three-phase AC submersible squirrel cage induction motor. Permanent magnet (PM) motors are rewindable, synchronous electric motors. Variable frequency drives (VFD’s) must be used to start PM motors and bring the motor up to synchronous speed.

Submersible pumps equipped with a PM motor and a VFD are utilized to ensure the pump is operating at EP (Best Efficiency Point).

The PMM8 motor technology has demonstrated over 93 percent efficiency, one of the most efficient eight-inch submersible motors on the market. Operated in conjunction with variable frequency drives, the PMM8 runs at synchronous speed with no rotor losses, which allows the pump to run at best efficiency point under variable flow conditions. Since the new PMM8 is available in the same diameter size as competitor units, customers will often be able to reduce their energy costs by upgrading to the Flowserve motor. Because of the high power output, in many cases the 8-inch PMM8 design can be substituted for conventional 10-inch asynchronous motors. Customers who have installed the PMM technology at their sites are very satisfied with the economic performance. Flowserve is one of the few companies which have both submersible pump and submersible motor competencies including permanent magnet technology.

Product Portfolio

Pumps

-

Tracing its history to 1790 and the earliest application of steam pumping engines, Flowserve has grown into a driving force in the global pump marketplace. No other pump company has the depth or breadth of expertise in successful application of pre-engineered, engineered, and special purpose pumps and systems.

Flowserve centrifugal, positive displacement and specialty pumps and systems are key components in the worldwide oil and gas, hydrocarbon and chemical processing, power generation and water resources industries as well as the general process and industrial marketplace. Flowserve pumps play a leading role in clean energy, greenhouse gas reduction and potable water supply efforts along with the application of advanced production and process technologies.

Valves

-

The Flowserve valve offering represents one of the most comprehensive lines in the industry. Our valves can be custom engineered to perform specific functions for our customers’ unique flow control environments.

Flowserve valves are used in general to the most severe and demanding industries, including high levels of corrosion, extreme temperatures and pressures, zero fugitive emissions and nuclear power plants.

Backed by strong engineering and global support, Flowserve delivers valves engineered to help customers maintain production goals and keep facilities operating at peak efficiency.

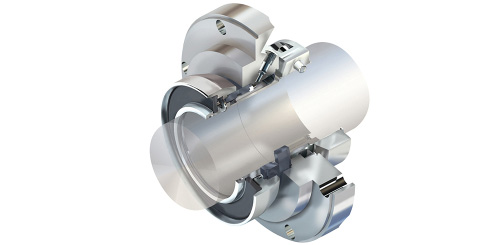

Seals

-

Serving customers for more than 80 years, Flowserve has a longstanding tradition of providing seals and sealing services that are trusted by the industry. Flowserve mechanical seals represent a collection of trusted products that are supported by strong aftermarket services, providing users both safety and environmental benefits.

Flowserve seals are used on a variety of rotating equipment, including pumps, compressors, mixers, steam turbines and other specialty equipment, primarily in the oil and gas, pharmaceutical, chemical processing, mineral and ore processing, and general industries. We combine decades of experience and technological expertise to provide sealing solutions that exceed our customers’ expectations.

Actuation & Instrumentation

-

Featuring the industry’s most complete range of actuators, positioners, controls, switches and accessories, complemented by our comprehensive R&D, engineering and global support services, Flowserve provides every customer with a one-stop solution to their flow control needs.

From electronic positioners and level switches to remotely controlled, fully-automated electric, hydraulic, and pneumatic actuators, Flowserve offers a range of intelligent flow control solutions for every application. Couple the Flowserve range of control solutions with real-time system analysis, predictive maintenance, and remote service capability, and our customers can expect end-to-end intelligence that has no equal in the industry.

Hydraulic Decoking Systems

- Flowserve has been in the vanguard of hydraulic decoking for delayed coker units since the technology’s inception in 1938. That year, a Flowserve heritage company, Worthington Pumps, designed the first high-pressure coke cutting pumps, decoking control valves and coke cutting tools. Today, Flowserve continues to be the innovative leader and is the overwhelming supplier of choice for advanced hydraulic decoking systems, having outfitted over 160 installations globally – more than 95 percent of the world’s units. Process licensors, engineering and construction firms and DCU operators alike turn to Flowserve for proven applications expertise and problem-solving capabilities.

Energy Recovery Devices

-

Having equipped desalination plants for more than half a century, Flowserve understands energy is the largest operating cost for any SWRO facility. Flowserve also understands that high-efficiency equipment and especially energy recovery devices are critical to making the process cost-effective.

That’s why in 2009 Flowserve acquired the Swiss company Calder™. Calder specializes in the design, engineering and manufacture of energy recovery devices and related propriety technologies for reverse osmosis desalination.

By bringing together industry-leading pumps, seals, valves and energy recovery devices as well as unmatched materials expertise and application knowledge, Flowserve is the premier provider of complete, integrated flow control solutions for the global SWRO industry.

Pumps

Reciprocating Pumps

-

Flowserve reciprocating pumps are inherently

designed for reliable high-energy, heavy-duty service

in specialized applications. Meeting API 674 design

and performance criteria, each pump is engineered

to provide continuous-duty operation over a 20-year

design life with regular maintenance. Offering a wide

variety of hydraulic, mechanical and materials options,

Flowserve reciprocating pumps can be constructed to

meet the specific characteristics of the most arduous

applications, including abrasive slurries and high viscosity

liquids. This results in maximum operating

flexibility with minimum life cycle costs.

Pump Customization

The Flowserve family of engineered reciprocating pumps

offers users a wide range of options to customize a solution

for mission-critical pumping needs.- Vertical and horizontal configurations

- Sectionalized or monobloc liquid ends

- Triplex, quintuplex, septuplex and nonuplex

- plunger configurations

- Various plunger size/stroke combinations

- High-temperature, high-pressure and slurry designs

- Custom pressures for continuous-duty pumping

- to 2070 bar (30 000 psi)

- Wide range of liquid end stuffing box and power end

- sealing arrangements, including high-temperature

- or environmentally hazardous services

- Wide choice of drives and drivers

Applications- Oil and gas production

- Pipeline

- Refinery

- Chemical processing

- Power

- Primary metals processing

- Mining

- General industry

- Hydrotesting

Byron Jackson SUBM Geothermal Deep-Well Submersible

-

Byron Jackson oil-filled submersible pumps are built for the most demanding deep well geothermal services. With its internal cooling system, advanced heat transfer design and high volume compensator module, this reliable and long lasting design offers significant total life cycle cost savings.

Heavy-Duty Impellers and Bowl Cases are designed to provide maximum efficiency over a broad operating range.

Dual Bearings are provided between pump and motor for minimum bearing span and maximum shaft support.

Multiple Seal Options are available to suit varying application requirements.

Oil-Filled Design with internal self-contained force feed oil circulation system maintains continuous fitered and cooled lubrication.

Three-Phase Squirrel Cage Induction Motor provides reliable operation and extends product life.

Class F Insulation System is designed with vacuum pressure impregnated (VPI) epoxy for superior insulation and long service life.

Brands:

Byron Jackson

Applications:

Geothermal Well Services

Industries:

Power Generation

Flowserve Pleuger SUBM Deep-Well Vertical Submersible (Water-Filled Design) Pump

-

The Pleuger SUBM submersible motor pump uses water-filled, wet-wound motors. This design is environmentally friendly, provides high efficiency and offers great reliability.

Heavy-Duty Impellers and Bowl Cases are designed to provide maximum efficiency over a broad operating range.

Compact Adaption System between pump and motor provides maximum shaft support. A power cable is internally connected to eliminate potential leaks.

Pressure Balanced Mechanical Seal available in many materials to best suit application.

Three-Phase Squirrel Cage Induction Motor provides reliable operation and extends product life.

Water and Antifreeze Motor Lubrication simplifies installation and enables pump to operate over a wide range of ambient temperatures.

Wet Type Motor with water-tight insulated windings ensures easy service, improves cooling and extends motor life.

Motor is prefilled with food-grade additives for freeze and rust protection, making it suitable for potable water applications.

Brands:

Pleuger

Applications:

Desalination, Dewatering and Water Supply (mining), Flood Control, Geothermal Well Services, Ground Water Development and Irrigation, Water Supply and Treatment (oil and gas), Cooling Water, Transformer Cooling, Drilling and Production, Water Supply and Distribution (water), FPSO, Fire Protection

Industries:

General Industries, Mining, Water Resources, Power Generation, Oil and Gas

Offshore Pumps

-

Pleuger® Submersible Motor Pumps for On- and Offshore-Applications

- Flows up to 10.000 m³/h

- Heads up to 1000m

- Rated powers up to 5000 kW

- Super Duplex

Plunger pumps for On- und Offshore-Applications- Flows up to 1.000 m³/h

- Pressure up to 2000 bar

- Horizontal and vertical design

- Up to 7 - cylinders

Caverns Pump

-

Flowserve Pump Solution

In General: Submersible Motor Pumps- Flowserve Submersible Motor Pumps are Multistage Centrifugal Units

- no external cooling system

- no external lubrication system

- no monitoring necessary

In General: Submersible Motor Pumps - Operation below Liquid Level

- Positioned by Discharge Pipe or Caisson

- Three-Phase Induction Submersible Motors

- up to 11 kV and 5000 kW

- Bowl diameters up to 48“

- Capacities up to 6000 m³/h

- Heads up to 800 m

Motor Brand: Pleuger - Water filled motor design

- Winding insulation class Y (90° C)

- For low or medium liquid temperaturer

- Oil filled motor design

- Winding insulation class F (155° C)

- For medium or high liquid temperatures

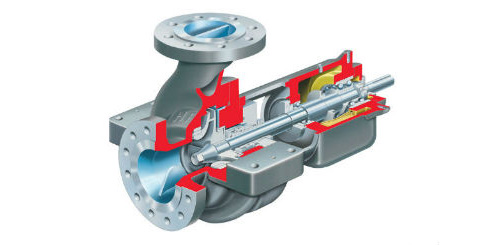

API PROCESS PUMP - ERPN

-

The ERPN is the pump of choice for severe chemical, petrochemical, refining and heavy-duty industrial service where full compliance with API 610 is not required. This pump provides users with the important mechanical, hydraulic, emissions control and safety components required by the latest ISO 13709/API 610 standards.

Operating Parameters- Flows to 1100 m3/h (4800 gpm)

- Heads to 230 m (750 ft)

- Pressures to 60 bar (870 psi)

- Temperatures to 350°C (660°F)

Centerline Supported Pump Casing accommodates nozzle loads in accordance with ISO13709/API 610 design requirements.

Precision Cast Impeller is dynamically balanced to limit vibration and assure smooth operation over a wide flow range.

Flanges are in accordance with ASME B16.5 Class 300 RF standard or 600 RF optional.

ISO 21049/API 682 seal chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Semi-Open Impeller and High Pressure designs available.

Brands:

Worthington

Applications:

Solvents, Waste Processing, Caustic and Chlor-alkali, Acid Transfer, Polymers, Volatile Organic Compounds, Distillation (oil and gas), Drilling and Production, Offsites and Waste Treatment, Paper Stock, Slurry Processing, Auxiliary Services (power)

Industries:

Pulp and Paper, Power Generation, Oil and Gas, Chemical Processing

Standards:

API682

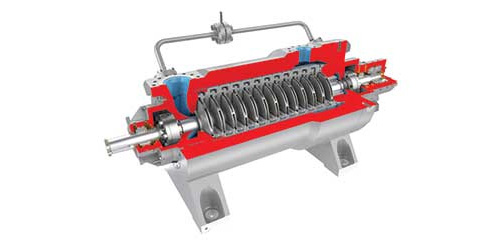

WXB - multistage, diffuser-casing barrel pump

-

The WXB is a multistage, diffuser-casing barrel pump with tandem impellers and a balance drum to carry axial thrust forces. It is designed for users who need the hydraulic range and performance of a ring section pump, but demand the design and maintenance attributes of a barrel pump.

Operating Parameters- Flows to 300 m3/h (1320 gpm)

- Heads to 1200 m (2175 ft)

- Pressures to 150 bar (2175 psi)

- Temperatures to 200°C (390°F)

Radially Split, Multivane Diffuser Construction results in balanced radial loads over the entire flow range, including partial-load operation.

Cartridge-Style Inner Case Sub-Assembly includes the rotor, discharge head, suction head and bearing assembly. This cartridge-style construction allows the entire assembly to be removed as a single unit to facilitate maintenance.

Axial Thrust Balancing Device creates nearly constant axial thrust throughout the pump’s operating range for improved efficiency.

Precision Cast Impellers are dynamically balanced to ensure hydraulic efficiency and performance repeatability. Large-eye first stage impeller optimizes NPSH characteristics.

Radial Bearings are sleeve mounted anti-friction deep groove and thrust bearings are sleeve mounted back-to-back angular contact type. The bearing lubrication system includes an oil bath, a constant level oiler and an oil sight glass.

Brands:

Worthington

Applications:

FPSO, Dewatering and Water Supply (mining), Heavy Oil, Oil Sands and Shale, Hydrocracking, Hydrotreating, LNG, Primary Processing (mining), Residuum and Heavy Oil Upgrading, Water and CO2 Injection, Auxiliary (chemical), Boiler Feed, Boiler Feed (pulp and paper), Descaling, Catalytic Cracking, Crude, Product and CO2 Pipeline, Gas to Liquids

Industries:

Power Generation, Primary Metals, Oil and Gas, Pulp and Paper, Chemical Processing, Mining

ECPJ - rugged, single stage vertical lineshaft sump pump

-

The Flowserve ECPJ is a rugged, single stage vertical lineshaft sump pump designed to perform tough jobs reliably, under a variety of difficult conditions. Based on a modular design system, it is fully compliant with the latest ISO 13709/API 610 (VS4) standards and may be custom engineered for the specific application in which it will be used.

Operating parameters- Flows to 1000 m3/h (4000 gpm)

- Heads to 150 m (500 ft)

- Pressures to 20 bar (285 psi)

- Temperatures to 350°C (660°F)

- Column lengths to 6 m (22 ft)

- 45 sizes available

Pump Casing and Cover features metal to metal fit with fully confined, controlled compression gasket to endure proper sealing and alignment.

Dynamically Balanced Precision Cast Impeller limits vibration and ensures smooth operation over a wide flow range. An anti-rotation impeller nut positively locks the impeller to the shaft without exposing its threads to the pumped fluid.

API 682 Seal Chambers allow for installation of cartridge style single, dual unpressurized and dual pressurized mechanical seals to meet required safety and environmental requirements.

Modular Design with a range of impeller and casing designs allows the hydraulics to be tailored to the service requirements.

Thrust Pot with API 40° angular contact bearings in back-to-back arrangement enables standard (non thrust) electrical motors to be used and fulfills API 610 bearing life criteria..

Brands:

Worthington

Applications:

Auxiliary (chemical), Drilling and Production, Flood Control, Ground Water Development and Irrigation, Water Supply and Treatment (oil and gas), Molten Salt Transfer, Offsites and Waste Treatment, Renewable Fuel Production, Shipping, Heavy Oil, Oil Sands and Shale

Industries:

Oil and Gas, Power Generation, General Industries, Chemical Processing, Water Resources

Standards:

API610, API682

WUJ - radial flow or axial flow pump

-

The Flowserve WUJ vertical turbine is a radial flow or axial flow type, multistage, heavy-duty single casing pump. It is designed for wet pit or deep well applications.

Operating Parameters- Flows to 3000 m3/h (13 200 gpm)

- Heads to 2000 m (6560 ft)

- Pressures to 200 bar (2900 psi)

- Temperatures from -200°C (-328°F) to 350°C (660°F)

Choice of Radial or Mixed Flow Hydraulics to best meet service requirements. Choose radial flow hydraulics for low-flow, high head applications; mixed flow hydraulics for high-flow, low head applications.

Axial Thrust Tilting Pad Bearing Configuration allows use of standard motors for high horsepower or ultra-high thrust operating conditions.

Stiff Shaft Design ensures stable operation under all service conditions.

ISO 21049/API 682 Compliant Mechanical Seal Chamber accommodates all cartridge mounted seal designs, including single, dual unpressurized or pressurized liquid or gas designs.

Features:- Flanged spacer-type coupling

- Screen-type, non-sparking coupling guard

- Casing and impeller wear rings

- Reinforced motor stand

- Optional inducer

Designed to the following international standards:- ISO 13709/API 610, latest edition

- ASME Sections VIII and IX

- German Pressure Vessel Association (AD)

- British Standard BS 5500

- Pressure Equipment Directive 97/23/EC

Brands:

Worthington

Applications:

LNG, Sewage Collection and Treatment, Water Supply and Distribution (water), Catalytic Cracking, Condensate Extraction, Crude, Product and CO2 Pipeline, Hydrotreating, Distillation (oil and gas), FPSO, Ground Water Development and Irrigation, Flood Control, Hydrocracking, Water Treatment, Dewatering and Water Supply (mining)

Industries:

General Industries, Mining, Water Resources, Power Generation, Oil and Gas

Standards:

API610, API682

WUC - radial flow or axial flow pump

-

Compliant with ISO 13709/API 610 (VS6), the Flowserve WUC vertical turbine is a radial flow or axial flow type, multistage, heavy-duty double casing pump. It is designed for continuous unspared duty at a variety of high-pressure services, operating at temperature extremes and handling difficult liquids.

Operating Parameters- Flows to 3000 m3/h (13 200 gpm)

- Heads to 2000 m (6560 ft)

- Pressures to 200 bar (2900 psi)

- Temperatures from -200°C (-328°F) to 350°C (660°F)

Flanged Spacer Type Coupling permits easy maintenance of thrust bearings and mechanical seals without disturbing or removing driver.

Separate Axial Thrust Bearing Assembly designed to withstand total hydraulic thrust and rotor weight.

ISO 21049/API 682 Compliant Mechanical Seal Chamber accommodates all cartridge mounted seal designs, including: single and dual pressurized or unpressurized liquid; and gas designs.

Screen-Type Non-Sparking Coupling Guard provides safety while allowing visual inspection of coupling and mechanical seal areas.

Casing and Impeller Wear Rings feature a minimum 50 Brinell hardness difference between them. These rings prevent galling, allow economical retention of operating efficiency and maintain mechanical stability.

Brands:

Worthington

Applications:

Acid Transfer, Catalytic Cracking, Condensate Extraction, Crude, Product and CO2 Pipeline, Dewatering and Water Supply (mining), Water Treatment, Hydrocracking, Hydrotreating, Industrial Gases, LNG, Snowmaking, Distillation (oil and gas)

Industries:

Power Generation, Water Resources, Oil and Gas, General Industries, Mining, Chemical Processing

Standards:

API682, API610

HWMA - single stage, vertical in-line overhung pump

-

The HWMA is a single stage, vertical in-line overhung pump with a separate bearing bracket. With its small footprint, this low flow, high head process pump is a space-saving alternative to many overhung process pumps in upstream and downstream services.

Replaceable Volute Insert permits precise hydraulic customization. Each insert is engineered for specified head and flow requirements. Accommodates future system changes.

Casing and Cover feature metal-to-metal fits with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Raised Face Flanges are to ASME B16.5, Class 300 for one stage and Class 600 for two stage models.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Stiff Shaft Design limits deflection at seal faces to 0.05 mm (0.002 in) max. Vibration levels are well below that required by ISO 13709/API 610.

Heavy-Duty Motor Support Head features a registered fit motor mount and does not use spacer plates.

Brands:

IDP

Applications:

Heat Transfer Fluids, Gas to Liquids, Acid Transfer, Hydrogen, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, LNG, Caustic and Chlor-alkali, Leaching Acid, Chemical and Liquor (pulp and paper), Cooling Water (power), Plating, Galvanizing and Other Coatings, Residuum and Heavy Oil Upgrading, Solvents, Digester, Volatile Organic Compounds, Distillation (oil and gas), Water Supply and Treatment (oil and gas), Drilling and Production, Water and CO2 Injection, FPSO, Gas Treating and Sulfur Recovery, Heavy Oil, Oil Sands and Shale

Industries:

Oil and Gas, Power Generation, Primary Metals, Mining, Chemical Processing, General Industries, Pulp and Paper

Standards:

API682, API610

Industry

Power Generation

-

Throughout our rich history, Flowserve has been closely identified with power generation. Our experience with power generation applications has continued to position Flowserve as a market leader in fossil fuel, combined cycle, nuclear power and renewable energy solutions. By combining high-quality, technology-driven products with industry expertise, Flowserve delivers reliable solutions for our customers’ critical applications.

At Flowserve, we are constantly working to help our customers meet their environmental goals. From improving safety and efficiency for our customers to optimizing product performance and reliability, few other companies can match the depth and breadth of expertise from Flowserve in the power industry.

Chemical Processing

-

Providing products and services that define chemical industry standards, Flowserve solutions deliver maximum value and dependability to our customers safely and reliably.

Our solutions are used around the clock to help process, transfer, and store some of the world's most hazardous and corrosive chemicals while improving system performance and plant uptime, providing customers with a competitive advantage.

At Flowserve, we want to help our customers exceed their business goals through the use of our collective resources and extensive experience in the chemical industry.

Water Resources

-

Flowserve solutions are hard at work every day, providing fresh water to major urban projects and supporting some of the world’s largest environment restoration projects.

As the water industry faces supply and demand challenges related to global population growth, increased consumption and urbanization, Flowserve is able to provide reliable and efficient solutions.

Critical to this need are applications such as desalination and the ability to move large volumes of water to areas where it is needed. Flowserve has supported the desalination industry with products for more than 50 years and continues to deliver the advanced products and services required in the worldwide demand for fresh water.

General Industry

-

Day and night, Flowserve solutions are working behind the scenes to help move, control and protect products that our customers depend on. As a trusted partner, our success across markets and regions worldwide demonstrates our continued strength in these various industries.

Our technological advances in surface hardening, system level flow designs, sealing technologies and auxiliary services positions many of the Flowserve heritage product brands as industry leaders in their respected fields.

Oil & Gas

-

On every continent and in every ocean, the world’s largest and most technologically advanced companies extract millions of barrels of oil each day. Over the course of a year, almost 3000 billion cubic meters of natural gas are harvested. Approximately 3.25 million kilometers (2.0 million miles) of pipelines along with a vast fleet of the largest ships on Earth transport this oil and gas to gas plants and refineries for processing into fuels, lubricating oils, waxes, asphalt and petrochemical feedstocks.

The people, products and services of Flowserve play a crucial role in the day-to-day operational success and the future technological advancement of the world’s largest and most critical industry. Wherever oil and gas are produced, transported and processed, you will find Flowserve petroleum flow and control products and systems.