HAMMEL

Videos

Loading the player ...

- Offer Profile

- The HAMMEL Recyclingtechnik GmbH offers its customers a diverse range of shredding technology - from primary and secondary shredders to screening technology and complete processing plants. The HAMMEL product range offers the right solution for your requirement.

Product Portfolio

HAMMEL PRIMARY SHREDDERS

-

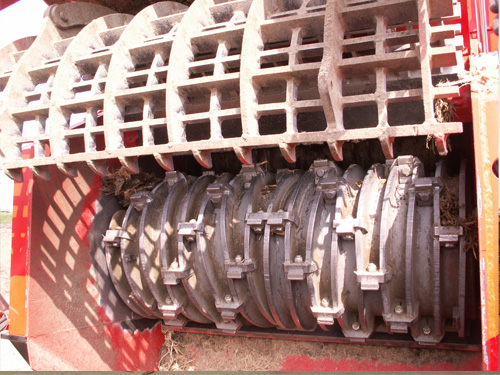

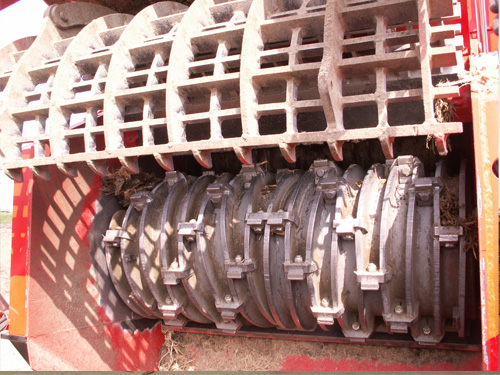

HAMMEL-primary shredders use two unique intertwining shredding shafts, that can be configured according to requirements and operate at a maximum speed of 46 revolutions per minute.

The material placed into the hopper is drawn in by the shafts, torn and broken down to be routed directly to the horizontal belt.

If the hydraulic end pressure reached during the shredding process, the shafts of the HAMMEL shredder reverse automatically. The shafts reverse, moving the material back out, removing anything blockage, automatically.

primary shredder VB 450

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, pallets, cable drums

- Waste: domestic waste, C&I waste

Functional principle- hydraulically operating recycling machine with two slow-moving shafts

Advantages

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

primary shredder VB 650

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: Hausmüll, Industrie- & Gewerbemüll

- Miscellaneous: paper, paper rolls

Functional principle- hydraulically operating recycling machine with two slow-moving shafts

Advantages

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

primary shredder VB 750

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, tires

- Metal: aluminum profiles and bales

- Miscellaneous: paper, paper rolls

Functional principle- hydraulically operating recycling machine with two slow-moving shafts

Advantages

- higher performance for higher throughput

- low energy consumption

- easy to maintain

- user friendly handling with IFM control

- improved accessibility of control panels

- low noise emission

- tilting hopper with an increased angle for optimal material flow

- available as mobile version on tracks or as semi-mobile version on hook lift

primary shredder VB 850

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

- Metal: aluminum profiles and bales

- Miscellaneous: paper, paper rolls

Functional principle- hydraulically operating recycling machine with two slow-moving shafts

Advantages

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

primary shredder VB 950 "RED GIANT"

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

- Metal: aluminum profiles and bales

- Miscellaneous: paper, paper rolls

Functional principle- special intertwining shafts

- material is directly drawn in and shredded by the shafts

- magnetic separation through an over belt magnet

- high volume tilting hopper

Advantages

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

primary shredder VB 1500

-

Applications

- Metal: car bodies, aluminum profiles and bales, engine blocks, mixed scrap, light metal scrap

Functional principle- double diesel-hydraulic drive

- two-sided transmission of force into the special intertwining shafts

- two-piece, large-volume tilting hopper, each with separate control

Advantages

- enormous throughput in the processing of metal

- highest possible mobility through track system

- easy handling via mobile SPS

- better material supply by two-divided tilting hopper

- low wear and tear

HAMMEL SECONDARY SHREDDERS

-

In conjunction with the HAMMEL-primary shredder the HAMMEL-secondary shredder form a powerful complete plant that shreds energy-saving and highly efficient voluminous and bulky materials.

The HAMMEL-secondary shredder work with two different shredding systems - with a knife rotor in wood Applications and with an eccentric rotor for metal Applications. The choice of the screen basket defines the size of the final product, which enables a high quality further processing.

The automatic metal deposition is continuously adjustable and is done by a metal detector and discharge chute. The metal detector is installed at the conveyor belt, and controls a discharge flap, which is installed either at the end of the belt, or before the transfer to the secondary shredder.

NZS 700

-

Applications

- Wood: waste wood, root stems, railway sleeper, pallets

- Miscellaneous: Paper rolls

Functional principle- with high-speed shredding rotor and metal separation via metal detector

Advantages

- high performance

- low energy consumption

- ferrous and non-ferrous metal separation

- uniform end-product

- low noise emission

- low wear and tear

NZS 1000

-

Applications

- Wood: waste wood, root stems, green waste, railway sleeper, pallets

- Miscellaneous: Paper rolls

Functional principle- high-speed metal separation

Advantages

- high performance

- low energy consumption

- ferrous and non-ferrous metal separation

- uniform end-product

- low noise emission

- low wear and tear

HEM 1250

-

Applications

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, light metal scrap

Functional principle- The shredding takes place through newly developed eccentric discs and the special shredding rotor. With a fittet screen basket a precise end product size is achieved.

NEW- Magnet drum for FE - respectively NE- separation

Advantages

- high performance

- low energy consumption

- processing costs per ton are approx. 50% lower than standard/conventional mega shredders

- high mobility through track system

- accurate end product size due to special shredding rotor

- extreme durable tools

HEM 400 D

-

Applications

- MEtal: aluminum profiles and bales, light metal scrap

Functional principle- The shredding is carried out by a belt directly into the shredding rotor. With a pre-tensioned screen basket, a precise final grain is achieved. A transverse magnet separates the exposed non-ferrous metals.

Advantages

- high performance

- low energy consumption

- Low space requirement

- short set-up time

- extremely long service life

HAMMEL SCREENING TECHNOLOGY

- The HAMMEL screening technology is always adapted to the specific requirements and individual needs of our customers. HAMMEL screeners convince through individual number and size of screen decks, high throughput, customized screen fractions and ideal adaptation to local conditions. HAMMEL screens are available in stationary-electric and mobile-diesel powered version with hook lift frame and wheel axle or track system. The HAMMEL product range offers e.g. discs and roller screens for wood and waste Applications and bar screens for the metal sector.

HZ 16

-

Applications

- Wood: waste wood, green waste, compost

- Waste: domestic waste

Functional principle

- The HZ 16 has a double drum screen which facilitates the screening of 2 fractions

Advantages

- effective screening results

- maximum mobility thanks to compact dimensions and low weight

- clean screening of each fraction with optimal results

- direct feeding or feeding by the discharge belt of a HAMMEL-primary shredder

HZ 52 DT

-

Applications

- Wood: waste wood, root stems, green waste, compost

- Waste: domestic waste

Functional principle- The HAMMEL HZ 52 has a double drum screen which facilitates the screening of 3 fractions while wire-screens achieve a clean separation of various materials.

Advantages

- effective screening results

- maximum mobility through trailer suspension

- high flexibility due to variable mesh sizes

- short set-up time

- quick and easy screen exchange

- clean screening of each fraction with optimal results

- direct feeding or feeding by the discharge belt of a HAMMEL-primary shredder

HAMMEL SORTING TECHNOLOGY

- HAMMEL does not only convince in the area of recycling technology but also with innovative separation and sorting technologies which are continuously refined. The HAMMEL product range also offers effective and individual solutions for separating different materials.

MMA 1400 E

-

Applications

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap

Functional principle- drum separates magnetic (FE-) metals from non-magnetic (FE-) materials

Advantages

- precise separation of magnetic (FE-) metals and non-magnetic (NE-) materials

MWA 1000 E

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap

- Miscellaneous: Special Batches

Functional principle- separation of non-magnetic (NE-) materials

- aluminum is separated from the fluff fraction by the eddy current method

Advantages

- precise separation

MSS 1000 E

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap

- Miscellaneous: Special Batches

Functional principle- separation of stainless steel from the fluff fraction

- through an induction sorting system stainless steel is sorted out using metal sensors

Advantages

- precise separation

MMS 150 DK

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap

- Miscellaneous: Special Batches

Functional principle- separation of NE and FE material as mobile version

- screening out of material > 150 mm

- magnet drum separates FE and NE

Advantages

- fast and efficient separation

- effective subsequent processing of the shredded end product

SMA

-

Applications

- Wood: waste wood, demolition wood, root stems, green waste, railway sleeper, pallets, cable drums

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap

- Miscellaneous: Special Batches

Functional principle- separation of NE and FE material as stationary version

- screening out of material > 150 mm

- magnet drum separates FE and NE

Advantages

- Quick and precise separation

HAMMEL PROCESSING PLANTS

-

According to the underlying site conditions stationary plants are planned as individual machine Components or as a complete concept. In the first processing stage, the input material is pre-shredded by a HAMMEL-primary shredder. Then the separation of the materials via a magnet station or sorting lines may take place.

Following variable screening technology or secondary shredder can be used. The individual plant Components are integrated by innovative discharge and conveyor systems.

Based on your requirements we will develop your complete solution!

Wood Processing

-

Applications

- Wood: waste, demolition wood, stem wood, root stems, green waste, railway sleeper, pallets, cable drums

For the waste wood recycling, the HAMMEL Recyclingtechnik GmbH facilitates processes and techniques to separate contaminants from the waste wood, to yield a reusable product.

The waste wood is processed for the further use with a customized HAMMEL wood recycling plant.

The HAMMEL-primary shredder processes the intake waste wood in a single step to an end product of approx. 300 mm, the discharge conveyor then passes it on to a magnet separator, where iron substances are separated, and is then moved to a vibrating chute. Here, the material is broken up and distributed evenly on the sorting belt in order to facilitate manual sorting of further impurities. The clean material is discharged, depending on size and quality across different belts into the appropriate boxes and is now available for further recycling.Components

- Pimary shredder

- Metal separation

- Secondary shredder

- Screening technology

- Sorting lines

- Discharge and conveyor technique

Advantages

- individual planning

- high performance

- Low energy consumption

- low noise emission

- minimal dust formation

- durable tools

- rugged construction

Waste Processing

-

Applications

- Waste: domestic waste, C&I waste, bulky waste, demolition waste, tires

Waste of any kind or origin is now a valuable resource. The processing of this raw material into its recyclable materials makes sense economically. The HAMMEL Recyclingtechnik GmbH supports you in this task with its individually planned waste processing plants.Components

- Primary shredder

- Metal separation

- Screen technology

- Sorting lines

Advantages

- individual planning

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

- rugged construction

Metal Processing

-

Applications

- Metal: car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap

A HAMMEL a metal processing plant offers you the significant advantage: in only one step you can get from compact input material to materially separate end products. Following is a precise separation of magnetic (ferrous) metals and non-magnetic (non-ferrous) material. Because of the system concept with machine Components you also have a system with maximum mobility.Components

- Primary shredder

- Metal separation

- Secondary shredder

- Screening technology

Advantages

- individual planning

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

- rugged construction