KraussMaffei

Videos

Loading the player ...

- Offer Profile

- KraussMaffei is among the

world’s leading manufacturers of machinery and systems for the production

and processing of plastics and rubber. Our brand stands for cutting-edge

technologies – for more than 180 years. Our range of services covers all

areas of injection molding machinery, extrusion technology and reaction

process machinery. This gives KraussMaffei a unique selling point in the

industry. With the high innovative power of our standardized and individual

product, process, digital and service solutions, we can guarantee customers

sustained additional value over the entire value-adding chain.

Our range of products and services allow us to serve customers in many sectors including the automotive, packaging, medical and construction industries, as well as manufacturers of electrical and electronic products and household appliances.

Product Portfolio

Extrusion technology

- We provide high-performance machines and systems along the entire value chain for manufacturing nearly all extruded plastic and rubber products.

Compound preparation

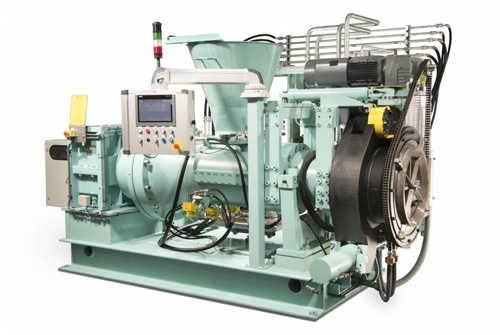

- Rubber technology

Excellent quality and absolute reliability - in order to prove itself in continuous use and to add to the economic success of the company, systems for preparing rubber compounds have to be prepared as well as possible to meet the high requirements. From the strainer solution to the rolling mill technology, the same principles for success apply to every system: the highest quality, maximum availability and flexibility and perfect integration into the workflow of rubber article production.

Compounding plants

- Complete compounding solutions hone your competitive

edge

You need expert support in optimizing processes, concepts, logistics, basic and detailed design, and interface coordination for your compounding system? Or you are planning to set up a new extrusion line? Then you need a strong partner with the necessary expertise in process technology support, facility design and turnkey solutions.

EdelweissCompounding technology

- Recycling and Compounding in one step

EdelweissCompounding lines are rated for throughputs of up to 6 t/h. The main benefit of this extrusion solution is the direct conversion of reclaim material into high-quality compounds in a single heat.

Flexible sheet extrusion lines

- Plastics technology

As a general contractor, KraussMaffei offers all the services required to build a high-performance extrusion line, from line logistics and design to the actual construction of the line, training and production support.

Foam extrusion lines

- Unparalleled product quality and reliability

KraussMaffei provides reliable high-performance machines and systems along the entire value-adding chain in the production of physically foamed plastics sheets, pipes, and boards. They meet all of the requirements for an efficient extrusion process.

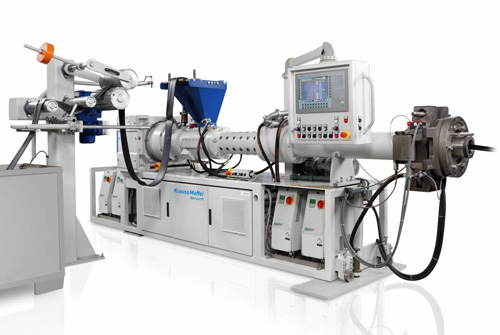

Melt-fed single-screw extruders

- Plastics technology

Perfect mixing, optimum degassing and reliable cooling combined with high throughput rates

KraussMaffei single-screw extruders stand out for simple and robust machine construction, low need for maintenance, highest torques, and flexible configuration of the processing section.

Profile extrusion

- Plastics technology

KraussMaffei supplies individual machines and complete profile production systems for all profile extrusion applications from a single source.

Rigid sheet extrusion lines

- Customized extrusion technology

KraussMaffei, as a highly skilled system provider, for years has offered proven, integrated total system concepts for a variety of sheet products. The advanced application and process knowledge of our application engineers and getting all engineering work from a single source reduces your effort upon start of production and in the rest of the production process.

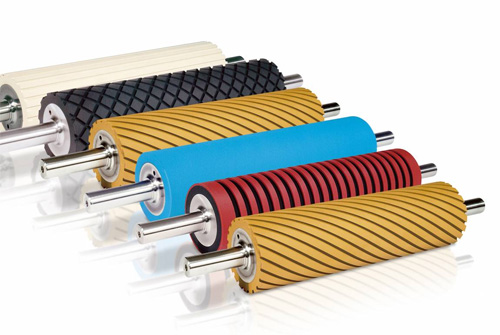

Roll covering systems

- Rubber technology

With the extrusion systems from KraussMaffei, you can easily coat rolls, sleeves or pipes for the most varied industries. The systems, with our high-performance rubber extruders, process every common rubber compound and coat them in the highest quality.

Rubber profile manufacturing systems

- Rubber technology

KraussMaffei Berstorff rubber profile production lines are designed for the most different types of premium-quality profiles: hollow or solid, with smooth or rough surfaces, with individualized contours and with or without steel reinforcement.

Rubber sheet systems

- Rubber technology

We deliver complete rubber sheet production lines as one-stop solutions to ensure professional project implementation, smooth processing and premium product quality. Benefit from our longstanding experience combined with comprehensive in-house technical expertise.

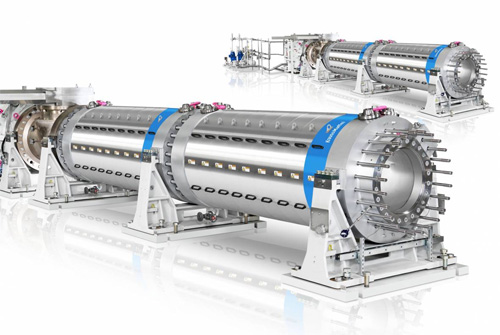

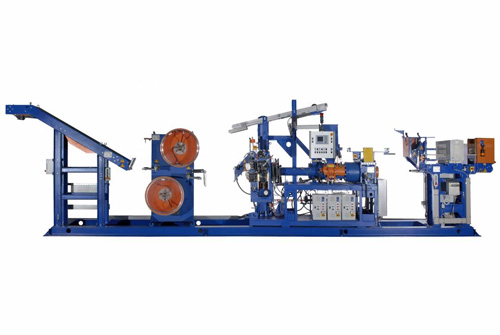

Tire lines

- Rubber technology

Solutions for cost-effective production and premium-quality products

Tire lines from KraussMaffei Berstorff are economical solutions for the continuous manufacture of tire components at a high quality level. Through the special machine designs, these lines stand out for

V-belt systems

- Rubber technology

With their tailor-made technology, open-edge V-belt or V-ribbed belt systems offer production and investment security through high product quality and reliability. Depending on requirements, the extrusion lines can be equipped with various line components.

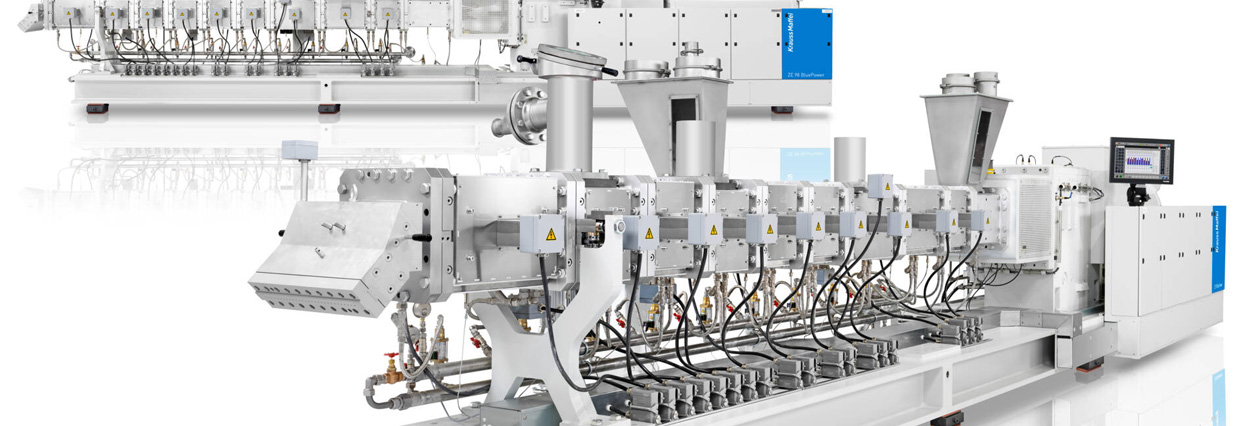

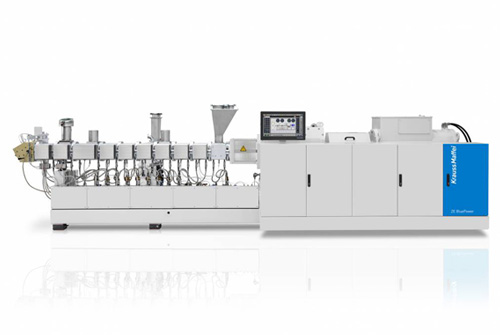

ZE BluePower

- Twin-screw extruders

The ZE BluePower twin-screw extruder series stands out for numerous innovative features in terms of energy efficiency and process engineering. This series is designed to meet the most demanding market challenges as to output rate, product quality, process reliability and flexibility. Benefit from the multitude of energy-saving innovations and the perfectly matched components of this trendsetting twin-screw extruder series.

ZE 28 BluePower II Twin-screw extruder

- A multi-talent for development work and small batch

production

With the extensive modular range of barrel sections and screw components, the ZE 28 BluePower laboratory extruder is a future-oriented machine. It also provides a significantly larger processing window for small batch production with the screw diameter of 28 mm, its diameter ratio Da/Di of 1.65 and high performance of 42 kW with a screw speed of up to 1200 rpm.

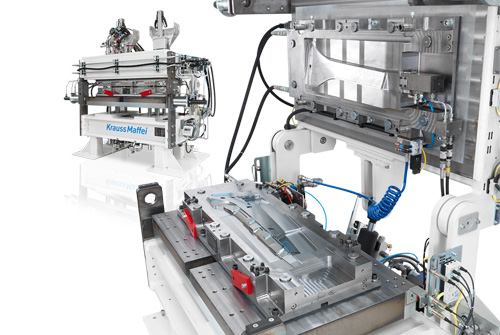

Reaction Process Machinery

- As a system provider, we provide molds and trimmer technology as well as process and system solutions for manufacturing innovative components made from polyurethane or other reactive materials.

Additives

- Raw material manufacturers provide PU components either

in barrels, IBC containers or pumped from a tanker.

- Automatic daily tank filling

- Consistently high component quality thanks to optimal preconditioning of PU components

- High process reliability thanks to innovative color metering systems

- Maximum reliability and availability

CCM mixing head

- Elegant decorations with depth effect in a one-shot

process

In an automated CCM (Clear Coat Molding) process, premium quality parts are flow-coated with a transparent two-component polyurethane system. CCM mixing heads guarantee optimal temperature control for extremely delicate raw materials like wood. Even small output rates are mixed perfectly and poured into the mold cavity without bubbles.

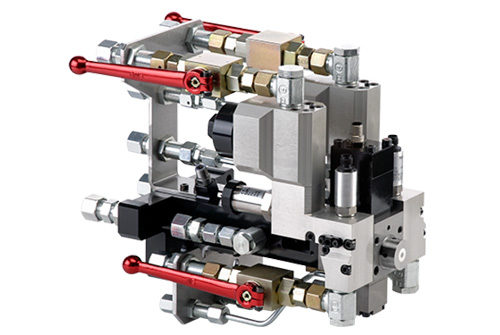

Filler mixing head

- For abrasive PU systems

These armor-plated mixing heads are modified versions of KraussMaffei linear and transfer mixing heads and have been developed specifically for processing PU systems with abrasive fillers.

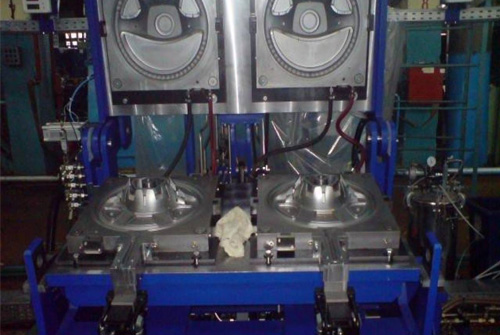

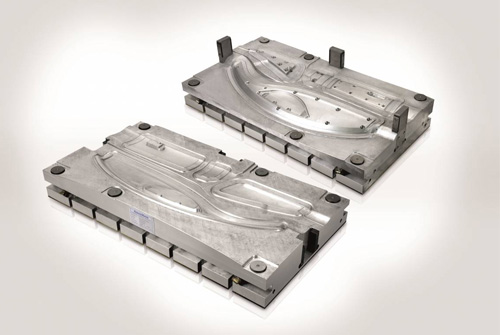

Foaming tools for CCM

- Outstanding product quality

Reliable compact hydraulic drives for cost-effective and user-friendly operation. Adaptation to customer and part requirements is possible thanks to the standardized mold moving unit.

Foaming tools for integral foaming applications

- Outstanding product quality

Reliable, compact hydraulic drives for cost-effective and user-friendly operation. Adaptation to customer and part requirements is possible thanks to the standardized mold moving unit.

Foaming tools for LFI

- Outstanding product quality

Adaptation to customer and part requirements is possible thanks to the standardized mold moving unit. Heat-balanced for optimal curing cycle Mold made of polishable tool steel or high-strength aluminum for excellent surface quality.

Insulation systems

- High flexibility and reliability

In our product portfolio, you will find a wide range of cabinet foaming plants, door foaming plants, commercial refrigerators and display cabinets, as well as cabinet and door foaming molds.

LFI process mixing head

- Fibers and PU in Composite material

The LFI-PU (long-fiber injection polyurethane) process is used in the production of high-strength, lightweight parts.

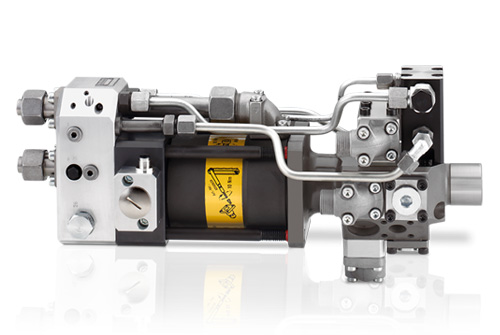

Linear mixing head

- PROVEN AND RELIABLE

Linear mixing heads operate on the counterflow injection principle: Pressure energy is transformed into speed energy, reliably ensuring very thorough mixing of the components. The mixing heads are available in designs for 2 to 5 components.

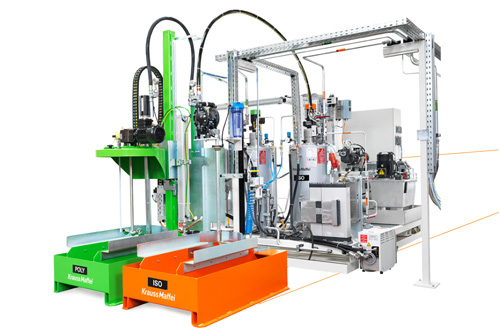

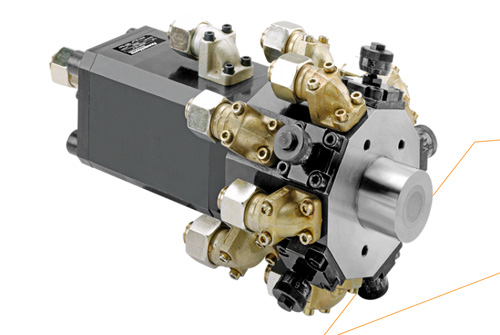

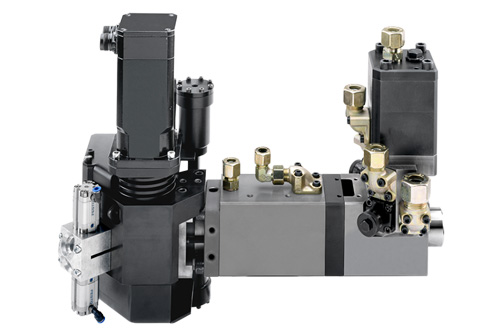

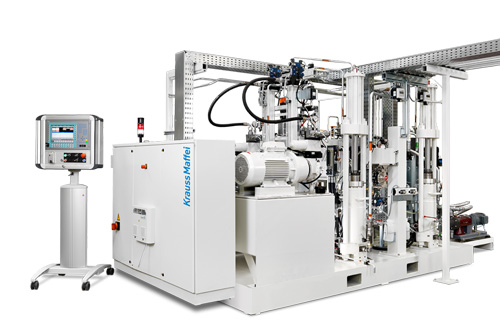

Metering systems

- RimStar

series

Precise, reliable, user-friendly and economical in operation. These properties define our RimStar series. The core idea behind the design is having immense machine flexibility, meaning that the RimStar can be used in many applications in PU processing. Thanks to its modular design, it supports flexible configuration, allowing it to be tailored to customer-specific requirements.

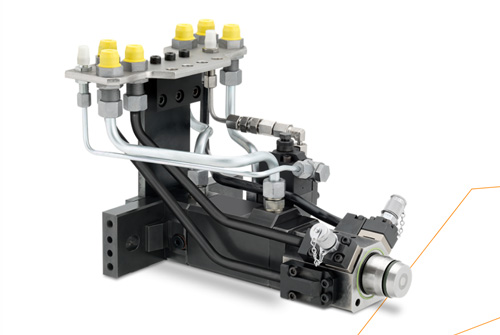

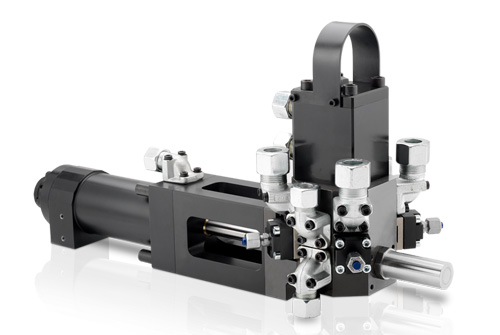

Mixing head for high-pressure RTM

- For RTM processes with high-pressure mixing

This compact and high-efficiency linear mixing head is ideal for processing quick-curing resin systems in a high-pressure RTM process for manufacturing lightweight and high-strength components.

MKE-3B mixing head

- For RTM processes with high-pressure mixing

This compact and high-efficiency linear mixing head is ideal for processing quick-curing resin systems in a high-pressure RTM process for manufacturing lightweight and high-strength components.

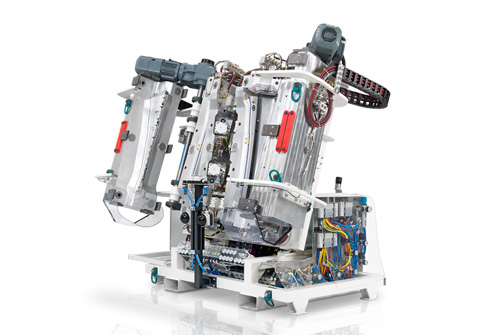

Mold carriers and plants

- Compact and easy to maintain

Our comprehensive range of mold carriers and plants makes KraussMaffei your expert partner for advanced PU processing. Whether you make refrigerator doors or vehicle instrument panels, leisure products or wall cladding – whatever your special requirements and tasks, we can offer you a wide range of machine components that can be quickly and flexibly adapted to your individual needs at any time.

Mold technology for pultrusion

- More speed in pultrusion

More speed in pultrusion: further development of the pultrusion process offers more productivity and efficiency for straight and bent profiles.

Molds for soft foam applications

- Outstanding product quality

Reliable, compact electric drives for cost-effective and user-friendly operation.

ND Low-pressure metering machines

- Outstanding product quality

The low-pressure metering machines from KraussMaffei are particularly suited to producing small, complex, premium-quality parts made from polyurethane.

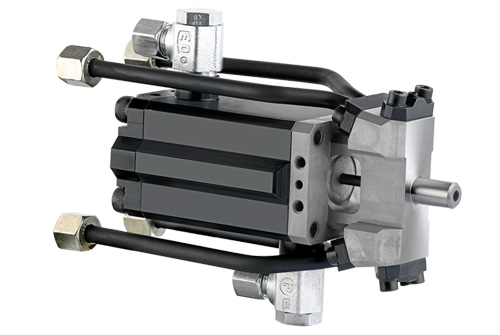

Piston machines

- Comet series

The Comet metering machine shows its strengths when it comes to processing polyurethane formulations with abrasive fillers. It is also perfectly in tune with our guiding principle of providing immense machine flexibility in order to enable cost-effective use in the widest variety of projects.

Punching machines

- KraussMaffei is the specialist in all types of punching and trimming and in linking trimming systems to complete, automated production lines. You benefit from our comprehensive expertise.

Spray mixing head

- Compact and rugged

KraussMaffei has developed spray mixing heads for many different spray applications with enhanced design freedom.

Transfer mixing head

- Versatile for sophisticated systems and laminar

mixture output

The high quality of the uniform mixing is mainly the result of the special angle of injection into the mixing chamber. Components are recirculated at high pressure before each shot, in a tried-and-tested recirculation groove system. Transfer mixing heads are available for 2 to 6 components.

Injection Molding Machinery

- With our hydraulic and all-electric injection molding machines, we are your high-performance partner for the realisation of all process variants and special processes.

Compact robots of the LRX series

- Progressive. Productive. Efficient.

The compact robots of the LRX series are a reliable pillar for your production.

The progressive design with decentralized control cabinet concept and rigid X axis provides a new form of accessibility.

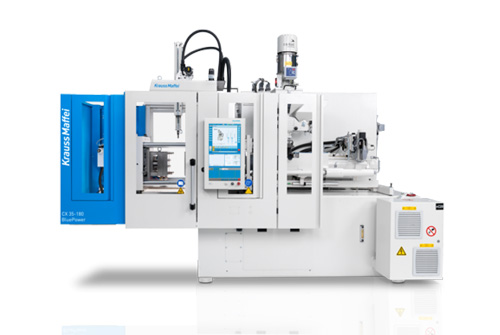

CX series (350 - 4,200 kN)

- The flexible multi-talented device with a compact

design

KraussMaffei's newly upgraded CX series offers the right solution for every customer wish: With the fully hydraulic CX series, KraussMaffei offers especially compact, efficient and flexible two-platen machines.

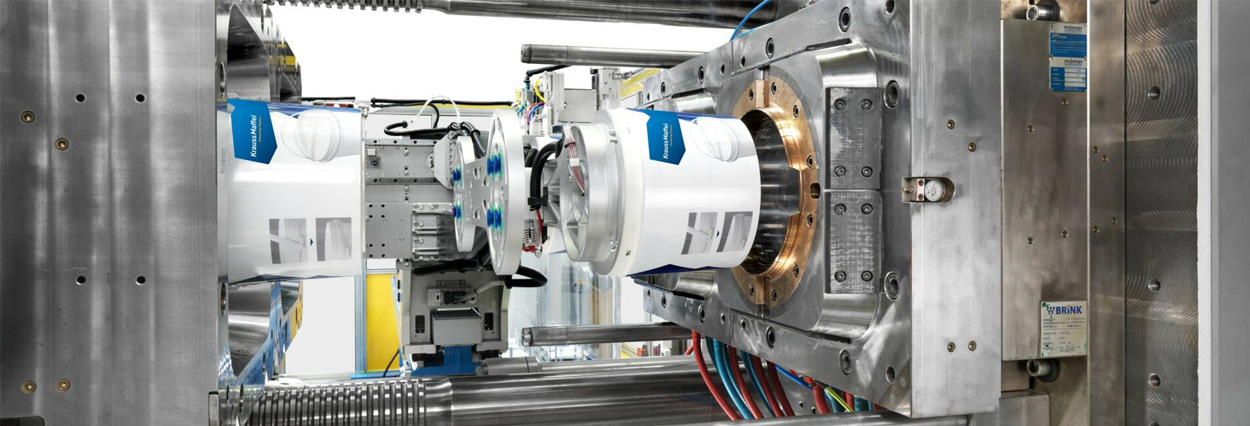

GX series

- The new dimension in injection molding

Use to your advantage the first-class hydromechanical dual platen concept of the GX Series in conjunction with the single-piston injection system. Thanks to the modular design, the compact dual platen clamping unit can be individually configured with all available injection units.

Industrial robots of the IR/IR-S series

- No limits for your requirements

IR stands for industrial robot. They implement complex demolding processes with a wide variety of grippers and freely programmable sequences of movements for wide swiveling ranges. Six axes enable enormous flexibility, even in spots where linear robots cannot be ideally used.

Linear Robot

- IN VERSIONS TWIN X AND TWIN Z

Flexible production options: The possibilities for combining several axes can be extremely varied. Several different application options for multiple kinematics in versions Twin X and Twin Z.

Linear robots in the LRX/LRX-S series

- Flexible for standard processes or special solutions

The linear robots in the LRX/LRX-S series from KraussMaffei distinguish themselves by their wide range of variants. They cover a clamping force range of 350 kN to 54,000 kN, and can be used universally for all types of injectionmolding machines – irrespective of brand or manufacturer.

LRX EasyControl linear robot

- Productive. Intuitive. Cost-effective.

The new LRX EasyControl linear robots provide both beginners and experienced injection molding processors with an efficient solution for simple pick-and-place applications.

Mobile automation cell

- Plug-and-play

The mobile automation cell was specifically developed for the flexible production of injection molded parts.

MX series(10.000 - 55.000 kN)

- Powerful, versatile and durable injection molding

machine

Our MX Series is recognized around the world and is principally characterized by the hydro-mechanical dual platen clamping unit, which we developed ourselves. With the MX, you can increase your process quality and your production efficiency.

NETSTAL ELION (800 - 4200 kN)

- Speed. Precision.

Reliability

Speed, precision, reliability, user friendliness and operational efficiency: these are the most important characteristics of the NETSTAL ELION series. Thanks to a consistent modular design and a large number of equipment options, the NETSTAL ELION can be adapted perfectly to meet the needs of various application areas.

NETSTAL ELION MED (800 - 2800 kN)

- Highest precision inside the cleanroom

All-electric injection molding machine for medical technology applications: highest precision inside the cleanroom.

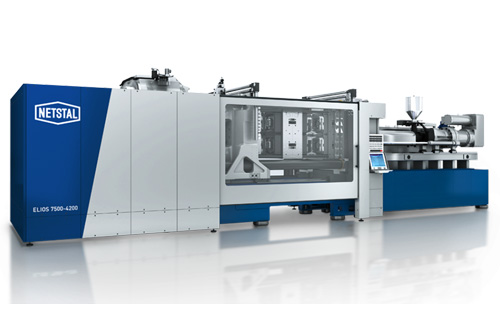

NETSTAL ELIOS (4500 - 7500 kN)

- Performance, newly driven

With NETSTAL ELIOS high-performance machines you can produce perfect thin-walled packaging at the lowest unit costs. Shortest cycle times, dynamic injection and best process stability are the key to success.

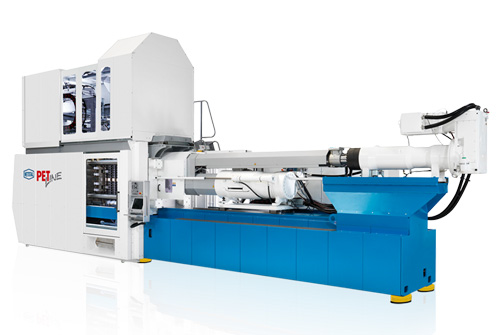

NETSTAL PET-LINE (2400 - 5000 kN)

- High-performance for the production of preforms

High-performance injection molding systems for the production of preforms

PETFORM (1750- 3200 kN)

- Flexible and efficient

Flexible and efficient modular platform for the production of preforms

PX series (250 - 3.200 kN)

- All-electric injection molding machine: Power meets

flexibility

The PX series is the answer to your requests for more flexibility while increasing productivity. You can assemble your PX precisely to your production requirements from a wide selection of components based on a modular design.

Sprue picker SPX10

- Fast. Precise. Economical.

The servo sprue picker from KraussMaffei features a very compact and stable design. It forms a unit together with the machine, providing the optimal solution on the market for use in small spaces.

Our Industries

Automobil

- The use of high-quality plastic components in vehicle construction is almost unlimited - so is our comprehensive range for you. Whether it's technically sophisticated components for the car body, a reduction in component weight or intelligent interior surfaces - we offer you everything from development to cost-effective, high-performance series production from a single source.

Construction

- Whether in building construction or civil engineering, for insulation tasks or for interior design - plastics are convincing in the construction industry due to their long service life, low weight and high flexibility. We accept the challenges of this future market with innovative strength and offer you reliable turnkey solutions.

Compounding & Recycling

- We are a technological pioneer in the compounding and up-cycling of plastic waste. Our EdelweissCompounding plants for plastics recycling and compounding meet the highest requirements in terms of quality, performance and reliability.

Beverage packaging

- The system solutions we develop are geared toward the highest quality, the shortest cycle times and at the lowest production costs.

Cooling technology

- Our expertise and technologies in the White Appliance and Insulation sector are your advantage: In our product portfolio, you will find a wide range of cabinet foaming plants, door foaming plants, commercial refrigerators and display cabinets, as well as cabinet and door foaming molds.

Medical technology

- We are your competent partner for turnkey medical industry injection molding solutions.

Technical parts & consumer goods

- Attractive design, high functionality, cost-saving efficiency - plastics perfectly demonstrate their advantages in everyday applications. As an experienced complete supplier, we offer you flexible, fully automated machines and systems for your individual production requirements.

Packaging

- We offer smart system solutions for demanding thin-walled and IML applications and logistics packaging