CORRON

Videos

Loading the player ...

- Offer Profile

-

Corron develops and manufactures innovative ultra-precision machines for die & mould, automotive part, semi-conductor, IT and medical industries.

The Plant in Cheon-an, South Korea manufactures High Precision Machines, NANO High Precision Machines, High Precision Electric Discharge Machines, 5-Axis Laser machines, customized machines, Retrofitting and automation Line.

Visit us on:

Product Portfolio

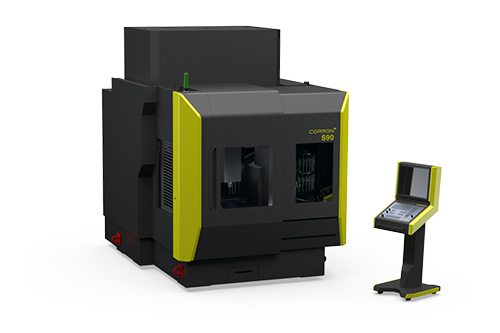

NANO HIGH PRECISION HSC

-

Ultra precision machines made in Korea with high surface quality

Linear type Nano-precision high speed machine

-

- Processing materials: hardened steel, titanium, copper, ceramics, graphite and glass

- Ultra-precision micro machining with best technologies:

- best precision, best machining quality, best surface quality and optimal dynamics

- high-speed precision spindles up to 60.000-36.000 rpm

- HSC PACKAGE can be used for ultra-presision nano processing

- Excellent vibration reduction through the integrated polymer concrete structure

- Precision cooling

- HEIDENHAIN TNC 640 Control

- Ultra-precision linear motors made in Germany

S LINE NANO MACHINE

-

S35 / 3-AXIS NANO MACHINE

- Traverse: X: 400mm, Y: 300mm, Z: 280mm

- Table: 450x350 mm

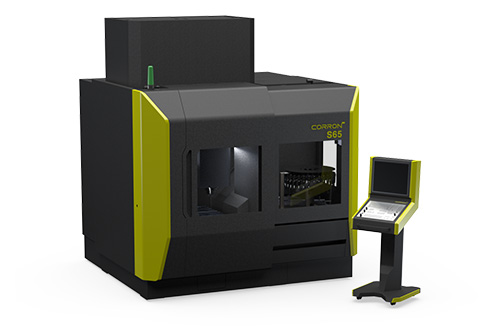

S65 / 3-AXIS NANO MACHINE

- Traverse: X: 640mm, Y: 400mm, Z: 410mm

- Table: 600x540 mm

S65 / 5-AXIS NANO MACHINE

- Traverse: X: 640mm, Y: 250mm, Z: 410mm

- Table: 600x540 mm, φ220

- Rotation: B: ±105, C: endless

S90 / 3-AXIS NANO MACHINE

- Traverse: X: 900mm, Y: 900mm, Z: 540mm

- Table: 450x350 mm

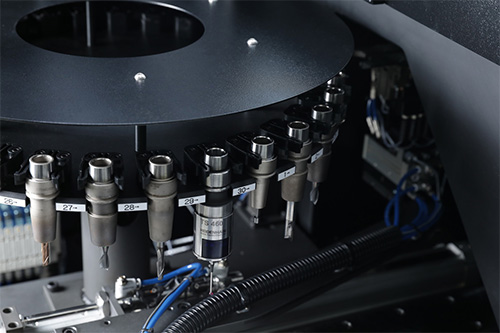

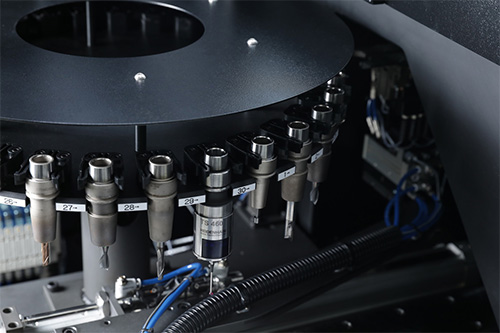

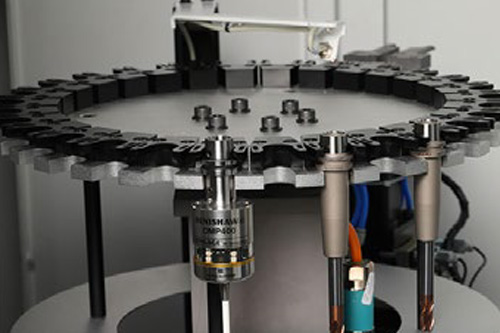

TOOL CHANGER

-

- HSK E40(32) : 30 / 60 / 90

- E50 : 27 / 54 / 81

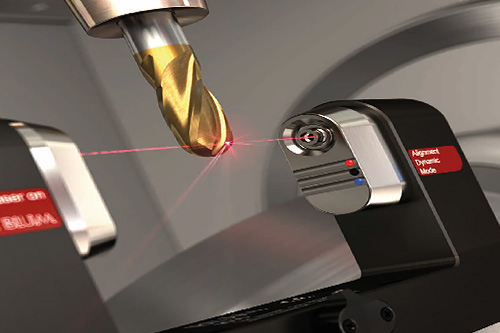

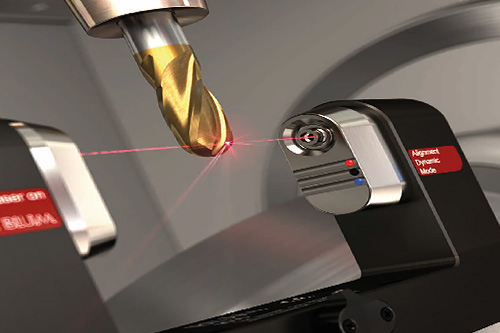

LASER MEASUREMENT

-

- High precision contactless laser measuring device

- Length, width, edge diameter

- Automatic measuring function installed

- Automatic covering device installed to avoid influx of extern pollution

- Cleaning device for workpiece installed

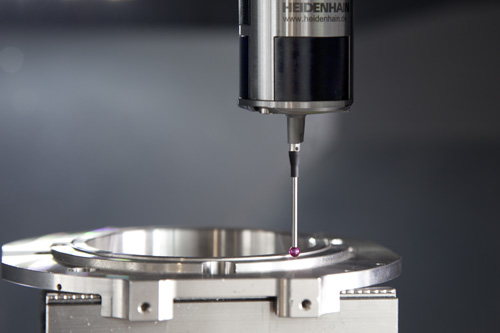

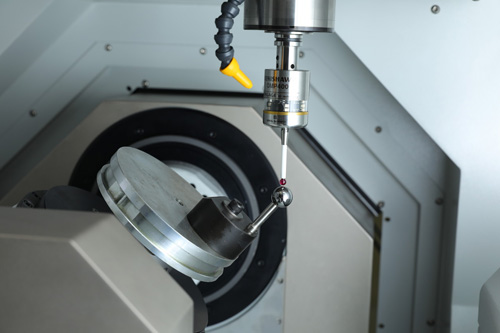

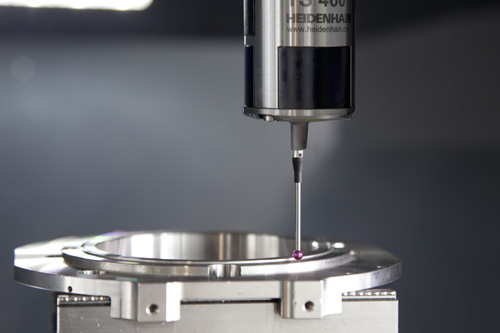

3D TOUCH PROBE

-

- 3D Measurement with excellent accuracy and repeatability accuracy

- Highly reliable modulated optical transmission

- Built-in automatic setting and measurement on the machine

- Built-in automatic kinematic correction function (5-axis)

5-AXIS INDEX ROTARY TABLE

-

- Direct Drive

- No Backlash

- High Precision rotary scale

OPTIMIZED KINEMATIC

-

- Automatic 5-axis re-calibration of the kinematics

- Thermal or rotating axis device error compensation function the kinematics fully automatically, but also to optimise it locally in the work space. Thus, complex servicing operations become obsolete

Ultra-precision graphite processing NANO GRAPHITE G LINE

- Discover high precision machining with Corron

NANO MACHINE FOR GRAPHITE

-

- High precision spindle without oil-leakage

- Best precision, best processing quality, perfect surface quality, opitimum dynamics, high efficiency

- Dry processing, wet processing, graphite processing for electrodes, graphite processing for glass (does not fall into the product)

- Safe to dust inside and outside of the machine with hermetic structure

- Using German latest CNC Controller : HEIDENHAIN TNC 640

- 100% ONLY German and Swiss main parts : LM Guide, Electro parts, Hydraulic, ETC

- German Latest 3rd Generation precision Linear Motor

- 3D Measuring for workpiece

The Nano MAchien can process Heat-treated steel, Titanium, SUS, Micro drilling, Copper, Ceramic, Graphite and Glass

LINEAR DIRECT DRIVE

-

- Adopted 3rd generation linear direct drive

- Triple precision cooling system configuration

- High stability even under maximum laod

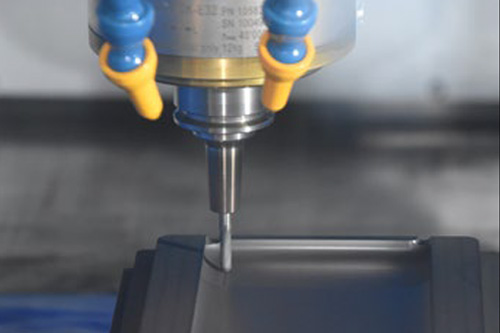

HIGH FREQUENCY SPINDLE

-

- New Spindle for Oil Drywell

- Optimized Graphite machining without oil polution

- Thermal Sensitive Sensor and Cooling Holder

POLYMER CONCRETE

-

- Machine Bed with Integral

Polymer Concrete - Vibration reduction effect 10 times faster than Cast Iron

- Thermal Symmetrical Gantry Type

- Accurate Cooling for Heating Parts

- Machine Bed with Integral

TOOL CHANGER

-

- HSK E40 TYPE : 30EA

- HSK E50 TYPE : 27EA

- Additional ATC possible

LASER MEASUREMENT

-

- High precision contactless laser measuring device

- Length, width, edge diameter

- Automatic measuring function installed

- Automatic covering device installed to avoid influx of extern pollution

- Cleaning device for workpiece installed

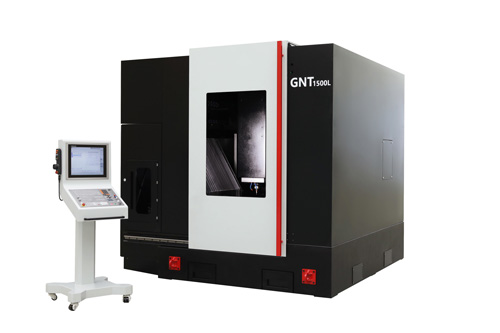

Gantry Structure Precision HSC

-

G150/S150 GANTRY TYPE

- Gantry Structure with all sections excellent in accuracy

- Enclosed structure, internal / external dust safety

- Internal Vibration absorber during graphite processing

- Excellent vibration damping with polymer concrete bed structure

- Solutions : Tools, Molds, Optical components, Precision Components, Graphite, Ceramics

G 150 /3-AXIS NANO MACHINE FOR GRAPHITE

-

- Traverse: X: 1500mm, Y: 800mm, Z: 400mm

- Table: 1540x840 mm

TOOL CHANGER

- HSK E40 TYPE : 30EA

HSK E50 TYPE : 27EA

Additional ATC possible

LASER MEASUREMENT

-

- High precision contactless laser measuring device

- Length, width, edge diameter

- Automatic measuring function installed

- Automatic covering device installed to avoid influx of extern pollution

- Cleaning device for workpiece installed

3D TOUCH PROBE

-

- 3D Measurement with excellent accuracy and repeatability accuracy

- Highly reliable modulated optical transmission

- Built-in automatic setting and measurement on the machine

- Built-in automatic kinematic correction function (5-axis)

LINEAR DIRECT DRIVE

-

- Adopted 3rd generation linear direct drive

- Triple precision cooling system configuration

- High stability even under maximum laod

HIGH FREQUENCY SPINDLE

-

- New Spindle for Oil Drywell

- Optimized Graphite machining without oil polution

- Thermal Sensitive Sensor and Cooling Holder