- Offer Profile

- Flexibility in manufacturing

and above-average savings in costs are in demand today more than ever. Our

answer to this is Technology to the Point:

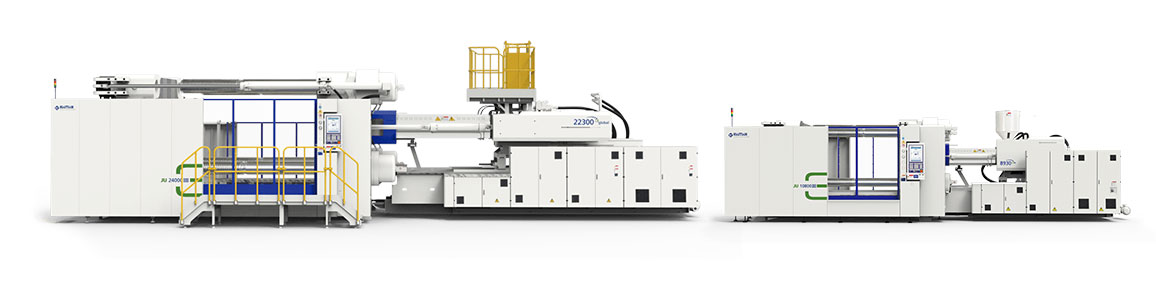

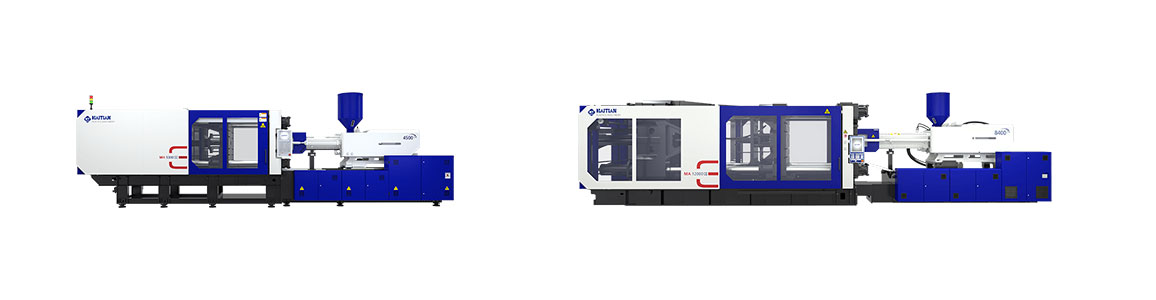

Servo-hydraulic global best-sellers. Fully electric precision technology. Variants for high-speed performance. Two-platen solutions within the smallest of spaces. A wide range of electrics with core-pull functions. Custom-built modular hybrid designs for multi-talented machines… The breadth of range and the performance capabilities of our models leave practically nothing to be desired. The Zhafir and Haitian machines that are currently available range from 400 up to 66,000 kN. We keep numerous “Machines to go” available for you in stock, as well as all important wear and replacement parts. This means that at any time you can react rapidly and successfully to new demands.

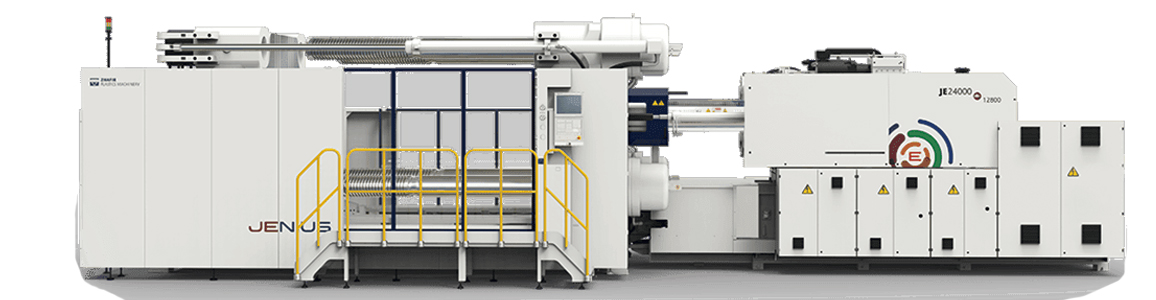

ZHAFIR PLASTICS MACHINERY

-

Success is a matter of competence and visionary power. But there is more to it than just this: the courage to tread on an unknown path; the determination needed to trust one’s own strengths; correct timing; plus humility and a bit of luck as well.

Using the market know-how and experience of Haitian International, we have succeeded in transferring revolutionary ideas and innovative concepts into professional solutions for our customers: All-electric, high-grade energy-efficient, precision injection-moulding machines at an attractive price-/performance ratio. These capabilities create vast competitive advantages for the operator while opening up completely new horizons. ZHAFIR JENIUS SERIES

-

TECHNOLOGY TO THE POINT

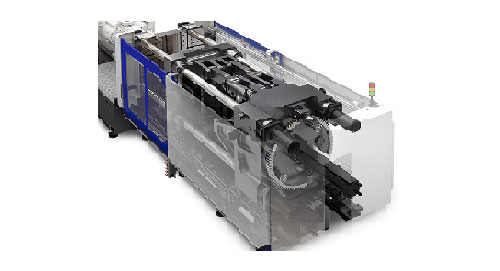

The Zhafir Jenius Series (JE) is an innovative hybrid machine concept which combines the electric drive technology and the two-platen servo hydraulic system. Using an innovative modular concept, the fully electric solution and the servo drive system can be combined in a highly efficient way, while their respective benefits are being retained.

It is benefited from our profound application experience from customers and pay attention to the development tendency of medium and large injection molding technologies. JE has been developed to address the specific quality requirements for industries such as white goods and automotive. With excellent stability, higher efficiency and faster investment return, JE is an ideal choice for the customers in the industry.QUICK CHECK

- DRIVE TECHNOLOGY: Hybrid

- PARALLEL FUNCTION: Yes for injection

- CONTROL SYSTEM: SIGMATEK

- CLAMPING FORCE: 3,600 – 33,000 kN

- CLAMPING SYSTEM: two-platen

- TIE BAR DISTANCE: 2,270 x 1,820 mm

- SHOT VOLUME: 792 – 12,017 cm³

- INJECTION SPEED: 160 mm/s

JENIUS Highlights

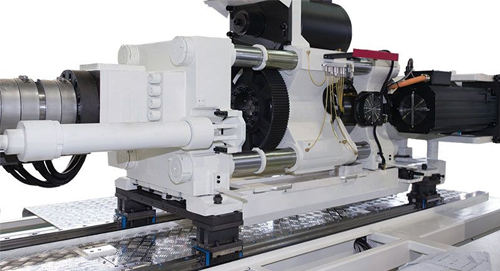

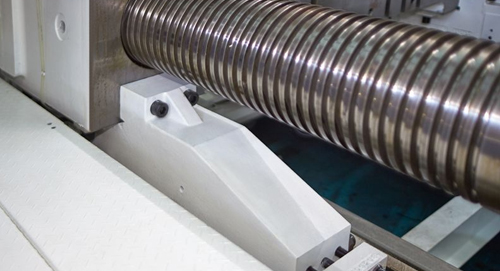

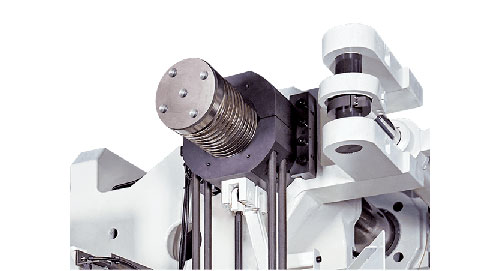

High Precision Injection Unit

- In comparison to a hydraulic injection unit, the servo motor and ball-screw driven injection unit, has substantially improved precision of the injection speed, pressure and position repeatability. It thereby ensures the high precision and high stability of the Zhafir JE Series.

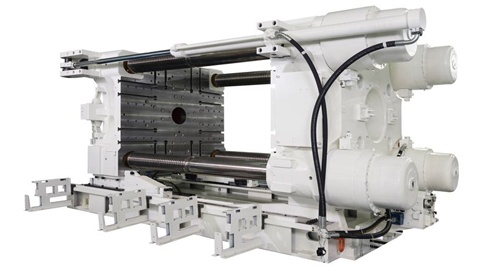

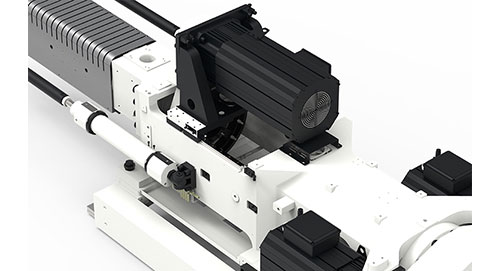

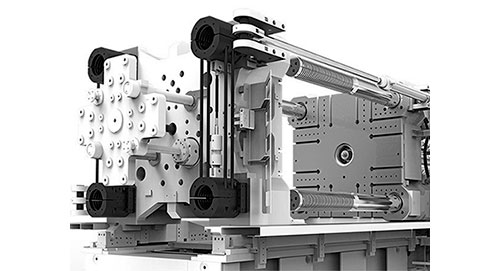

Space Saving Clamping Unit

- The compact design of the two-platen clamping structure has been integrated into the Zhafir JE Series, with optimized space layout and providing larger mold space, extended mold movement stroke and ejector stroke.

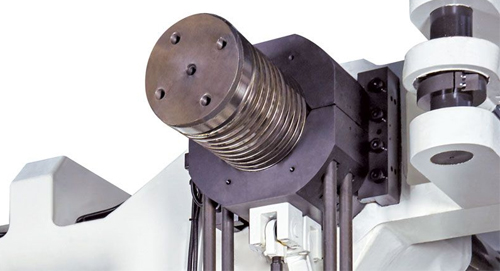

Precise Clamping System

- Parallel lock nut operation ensures fast and accurate response.

High Rigidity

- Large moving platen ensures high platen rigidity during movement with increase mold weight loading. Reduced platen vertical movement for long core molds.

Latest Software & Control

-

With optimized layout and cycle instruction in the SIGMATEK control system, the signal processing speed has improved, which can be seamlessly connected with the peripheral automation equipment. More user-friendly interface, makes it more convenient for the user.

- Latest CPU, substantial increase of operational performance

- Optimal layout

- Automatic equipment for convenient interconnection

- Multitude of application software

- Interfaces for integration into cyber physical system (CPS)

ZHAFIR VENUS III SERIES

-

TECHNOLOGY TO THE POINT

Zhafir has been making a greater impact on the market for electric injection-molding machines than almost any other manufacturer. This is substantiated not just by the dynamic sales growth and the fast-increasing inquiries that Haitian International’s sales teams receive around the globe. Since the introduction 10 years ago, the Zhafir solutions have risen to be the second strongest brand in Asia.

With clamping force sizes of 400 to 8,000 kN and specifically modified performance versions such as the “Venus p”, “Venus h”, and “Venus hs”, Zhafir already offers by far the most extensive portfolio of fully electric machines. High quantities and a tremendous depth in production within the Haitian Group guarantee a first-class price-performance ratio in future as well.QUICK CHECK

- 400 – 8.000 kN

- Application-oriented injection units up to 500 mm/s

- Fully electric drives for clean and quiet operation

- Intelligent motion control for short dry cycle times

- Tailor-made servo drives

- Square tie bar distance for more freedom

- Intelligent mold protection

- Latest control technology

- Linear guides (optional)

ZHAFIR ZERES SERIES

-

TECHNOLOGY TO THE POINT

The Zeres Series builds a bridge from electric injection molding technology to traditional hydraulic machine applications. Identical in construction to the Venus Series, it also has integrated servo-hydraulics. Main movements such as mold and injection are electric, side axes such as nozzle movement, core puller and ejector are servo-hydraulic. In this way, the Zeres gives the processor not only the wide electric range of applications but at the same time also more production efficiency because of energy savings in the double-digit percentage range. Currently, the Zeres Series is available in clamping forces from 400 to 13,800 kN.

Tailor-made electrical servo drive systems in combination with a new inverter generation enables a high-performance and unique price/performance ratio with high precision and dynamics. The 3rd technology generation of Zhafir is a system platform with intelligent and extremely fast adaptive software. The Zeres Series enable extremely open integration and connectivity with all common interfaces and seamless connection of industrial automation or any MES system.

QUICK CHECK

- 400 – 13.800 kN

- Application-oriented injection units up to 500 mm/s

- Integrated hydraulics for extended application variety

- Intelligent motion control for short dry cycle times

- Tailor-made servo drives

- Square tie bar distance for more freedom

- Intelligent mold protection

- Latest control technology

- Linear guides (optional)

VENUS & ZERES Highlights

Precise Repeatability

- Linear guides for low friction provide fast response, clean operation, accurate pressure control. An improvement of back pressure and repeatability.

Mold Protection

- Intelligent algorithms ensures highly reactive and precise mold.

Clean ASnd Precise

- Optional linear guide for mold open/close and non contact tie bar design for more clean and higher platen paralleslism.

Smart Control System

- Latest technology from Sigmatek.

Open Integration

- With all common interfaces for intelligent industrial automation and free choice of integration partners

Constant Injection Speed

- High stability for injection molding; Optimal servo dynamics and injection speed control.

SERVO-HYDRAULIC SOLUTIONS

-

The diversified range of injection molding machines in the Haitian Plastics Machinery portfolio covers all the applications in the standard sector, and fulfill international quality standards.

With clamping forces between 600 and 66,000 and our international distribution of economic and highly efficient injection molding machines, we create critical competitive advantages for our customers. HAITIAN JUPITER III SERIES

-

TECHNOLOGY TO THE POINT

The Haitian JU III Series, as developed based on Haitian’s extensive experience in sustainable research and development of two-platen solutions in the past two decades, has significant improvements to the previous machine generation and provides more advantages for many different molding applications. The new design incorporates additional functions and user benefits which greatly enhance the machine performance and part quality. With flexible clamping unit to injection unit combinations, the machine can be tailored to specific or general molding applications.

As a product with Technology to the Point, the new generation of the Haitian Jupiter Series provides a wide variety of combination possibilities in a compact footprint, which maximizes the usable space of the plants to the customers’ benefit. No matter large parts such as trash bins and logistics boxes, or high-precision automotive parts and high-tech parts with high surface quality such as white goods, JU III Series provides the best solution for customers.

QUICK CHECK

- Available from 4,500 to 66,000 kN

- Short dry cycles

- Large mold space, compact machine design

- Energy-efficient servo-technology

- Fast response time and high positioning accuracy (± 0,05 %)

- KEBA control technology

JUPITER Highlights

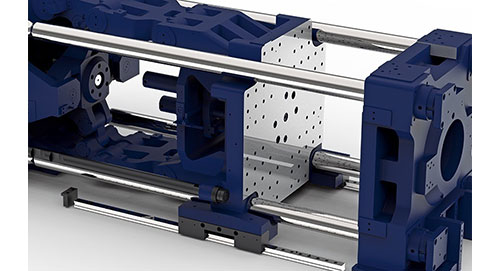

Space Saving Two-platen

- Extended opening and ejection stroke for diversified application needs and a larger mold area.

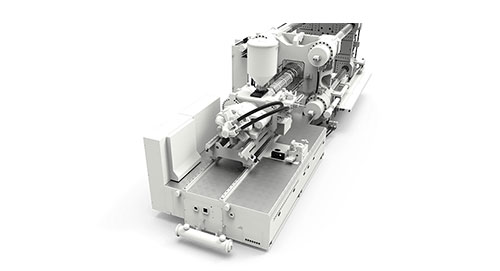

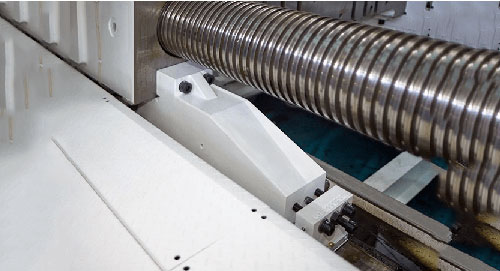

New Injection Unit

- Linear guides for lower friction and energy consumption resulting in more precise movements. Free selection between differential and non-differential injection function, providing larger injection molding capacity and extending the application scope of the process.

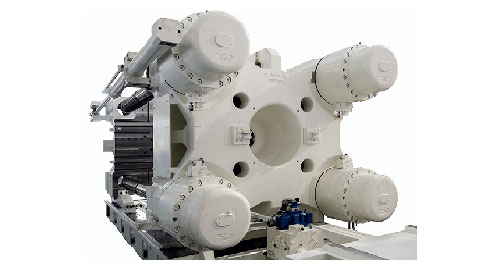

Fast And Balanced Locking Mechanism

- The four short-stroke clamping cylinders on the fixes platen enables quick set-up of the clamping force on the mold. Real-time monitoring trough the pressure sensor contributes to the high repeatability of the clamping force.

Parallel Lock Nut

- Parallel lock nut operation ensures fast and accurate response.

Moveable Platen Support

- High-rigidity movable platen support device and guide mechanism on the botoom side of machine bed ensures the presicion of movable platen during loading of heavy molds.

HAITIAN MARS III SERIES

-

TECHNOLOGY TO THE POINT

The new generation of our bestseller is more powerful than ever thanks to significant improvements. New motors and intelligent motion control provide more precise processes in a wide application field like consumer goods, toys or construction. Optimized core components such as the closed-loop injection unit increase the efficiency and production quality of the world‘s most successful injection molding machine.

Clever software concepts complement the newly-formed hardware base with all common interfaces for open connectivity with smart manufacturing solutions. The intelligent answer to the growing demands in the plastics processing industry – and modern response to the environmentally relevant challenges of our time. The new Mars III Series is extremely energy-efficient, economically and very attractive in terms of price/performance ratio. Technology to the Point like never before.

QUICK CHECK

Sold more than 300,000 times- Available from 600 to 33,000 kN

- World’s best-selling injection molding machine

- New high-drive servo system (developed by Haitian)

- Fully improved design structure

- Full closed-loop process, high repeat accuracy

- Energy saving

- Interactive with open integration

MARS Highlights

Servo Drive System

- New high performance servo drive system supported by the digital realtime fieldbus. Highly dynamic and responsive.

Injection Unit

- Fully closed loop for high repeatability of the injection process. Linear guides for low friction and high precision.

Clamping Unit

- Optimized platen design for even distrivution of clamping force and less deformation and higher precision. Intelligent open close algorithm.

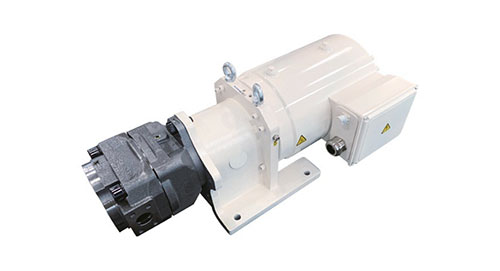

MARS TECHNOLOGY

-

SINCE OVER 10 YEARS

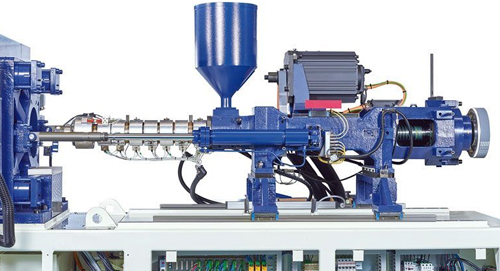

The innovative Mars Series progressed to become an important driving force behind our success, setting new standards in repeat accuracy, precision, and energy savings with its servo-hydraulic drive system. Since its introduction of the Mars Technology in 2006, more than 230,000 units of the Mars Series have been sold and servo-hydraulic drives are now indispensable to the industry.

INNOVATIVE SUCCESS-TECHNOLOGY

The patented servo motor/gear pump drive system was designed as a system and is not the combination of standard market components as used by our competitors. This translates into a significant advantage for repeatable high precision and low energy consumption for different molding applications and processing materials.

Patented servomotor to gear pump design. The direct drive connection between the servo-motor and the gear pump provides excellent drive torque giving maximum acceleration and deceleration speeds for all machine functions. The patented drive system is a true advantage for high stability and repeatable molding conditions. Servo motors ranging from 7.5 kW to 110 kW are specially designed to meet the high demands of the plastic injection molding machine process requirements.

The European servo motor controller from KEB is matched to the drive motor for optimal efficiency and repeatable accuracy.

High-efficiency gear pump for stable operation and low energy consumption.