- Offer Profile

- Swiss precision engineering

combined with over 35 years experience provides you with the best shut-off

system on the market today. Quality, dedication and service are why we are

the world's No. 1 manufacturer and supplier of needle and

bolt shut-off nozzles for the injection molding industry.

In addition to our needle shut-off nozzles, which are pneumatically, hydraulically, electrically or spring actuated, we offer a full range of products including special nozzles and components for the gas and water injection technologies.

Machine shut-off nozzles

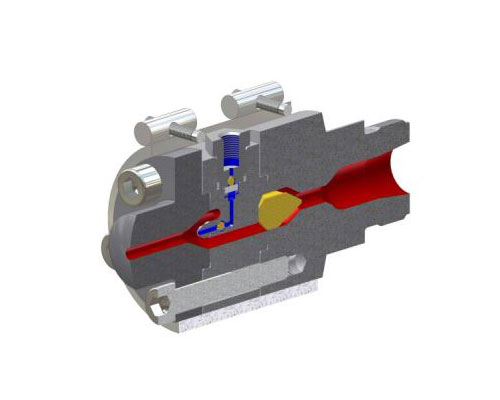

Machine bolt shut-off nozzle type BHP - pneumatic / hydraulic actuation

-

The pneumatically or hydraulically actuated machine bolt shut-off nozzles type BHP are used in processing of thermoplastics.

In this nozzle’s favour are:

Cycle time reduction, shut-off in the nozzle of the melt-stream while withdrawing or dosing. With the BHP nozzle Herzog has designed a system which allows a single throughgoing melt flow channel. Therefore a much bigger flow channel is possible and that is responsible for a reduced pressure drop. With this single channel principle the so called “Memory effect” can be avoided. With the single channel system a cleaning of the unit is done within very short time (similar to an open nozzle).

Finds application in:

Packaging, automobile and leisure industries, medicinal and electronic equipment.Operation:

The assembly integrated actuator (pneumatically or hydraulically activated) controls a radial positioned bolt via a lever mechanism. The melt flow is therefore process dependently separated. The bolt mechanism is constructed in such a way, that with overpressure an automatic opening of the nozzle is ensured. In contrast to a needle shut-off system, the separation takes place further back. Because of this a longer bore exists between the nozzle orifice and the shut-off unit. For some applications this may not be suitable.

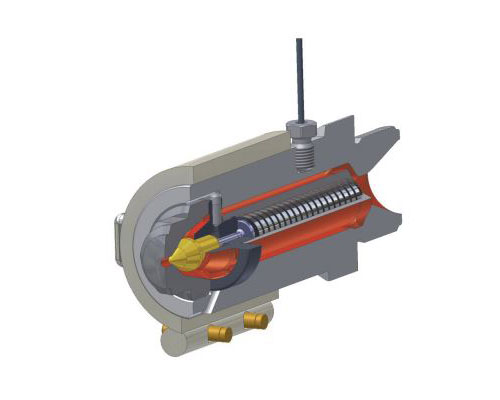

Machine needle shut-off nozzle type HP - pneumatic / hydraulic actuation

-

The pneumatically or hydraulically actuated machine needle shut-off nozzles type HP are used in processing of thermoplastics, principally with low viscosity materials such as: PA, PPS, PE, POM,PP.

In this nozzle’s favour are:

Cycle time reduction, shut-off at the nozzle orifice, withdrawal while dosing.

Finds application in:

Packaging, automobile and leisure industries, medicinal and electronic equipment.

Operation:

The assembly integrated actuator (pneumatically or hydraulically activated) controls a nozzle-axis positioned needle via a lever mechanism. The melt flow is therefore process dependently separated at the nozzle orifice. The needle mechanism is constructed in such a way, that with over-pressure an automatic opening of the nozzle is ensured.

Machine needle shut-off nozzle type A(S) - spring operated

-

The spring actuated machine needle shut-off nozzle s type A(S) are used in processing of thermoplastics , principally with low viscosity materials such as: PA, PPS, PE, POM, PP.

Finds application in:

Packaging, automobile and leisure industries, medicinal and electronic equipment.

Operation:

The nozzle is opened directly from the injection pressure and closed again with spring power. A needle which moves axially in the needle shut-off nozzle is held in the closed position by the force of the spring. The nozzle orifice is normally closed. With the increasing melt pressure exerted against the spring through a ring of exposed surface area on the needle, the nozzle opens at 200 bar . If the melt pressure drops (below 80bar), the nozzle closes.- If the standard opening pressure is not appropriate, the needle must be modified to the requirements (modification of the spring is not possible).

- A temperature resistant material (bis max. 520°C) is used for the spring construction.

- The nozzle size required depends on the injection rate per second (cm3/s).

Machine needle shut-off nozzle type SHP - spring operated

-

The spring actuated machine needle shut-off nozzles type SHP are used in processing of thermoplastics, principally with low viscosity materials such as: PA, PPS, PE, POM, PP.

Finds application in: Packaging, automobile and leisure industries, medicinal and electronic equipment.

Operation: The nozzle is opened directly from the injection pressure and closed again with spring power. A needle which moves axially in the needle shut-off nozzle is held in the closed position by the force of the spring. The nozzle orifice is normally closed. With the increasing melt pressure exerted against the spring through a ring of exposed surface area on the needle, the nozzle opens at 200 bar. If the melt pressure drops (‹ 45bar), the nozzle closes.- If the standard opening pressure is not appropriate, the needle must be modified to the requirements (modification of the spring is not possible).

- The nozzle size required depends on the injection rate per second (cm3/s).

Machine needle shut-off nozzle type NE (Elastomer) - pneumatic actuation

-

There are multiple fields of LSR applications and they are rising in importance. LSR molded parts are frequently seen in the automobile industry, home and sport components, pharmaceutical, medicine and electronic industries.

The pneumatically controlled nozzle type NE has a needle shut-off mechanism which stops the melt stream directly at the mold interface. Rubber, liquid silicone rubber and other elastomers can be processed without fear of premature vulcanization due to the nozzle's integrated cooling system, which uniquely regulates temperature through the entire nozzle. The nozzle can also be fitted with an interchangeable diving tip for cold channel applications.

The type NE nozzle is suitable for processing with injection pressures of up to 3,000bar and an injection rate of 500cm3. It is designed to allow for easier cleaning and a simple installation. It has been also optimized for melt-flow which results in less friction on the processed elastomer. It is available in custom lengths.

Machine open nozzles

Machine nozzle for Gas Injection Technology (GIT) type GM

-

Under GasInjectionTechnology GIT one understands gas delivery in the mass core of the injected part. Principally one differentiates between two different types of injection process:

- Injection in the mold (See mold injectors)

- Gas delivery via the machine nozzle (Theme of this documentation)

How does it work?

The gas searches the easiest way through the soft core of the injected part and displaces the mass until the cavity is filled out.

Since the initial attempts with Gas / Water injection technology, the company Herzog AG has successfully set itself apart with gas introduction components (injectors and machine nozzles).

The machine nozzle is used here, where the gas introduction is to be made by the sprue bushing. This has the advantage that no adjustments must be made at the mold. The resulting opening at the injected part from the gas introduction, can be closed by postinjection.

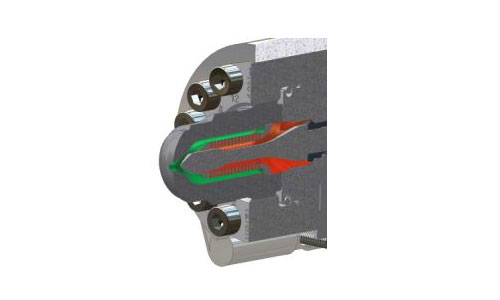

Mold injectors for Gas Injection Technology (GIT)

Mold injector for Gas Injection Technology (GIT)

-

Gas injection technology

With gas injection technology, gas is injected into the plastic melt at the end of the injecting process. The injected gas displaces the melt on the inside thus resulting in a cavity being formed.

Short shot, cavity is partially filled with plastic melt. The plastic melt is pressed against the mold wall with the injected fluid.

Full shot, entire cavity is filled with plastic melt. The injected fluid forces the melt into an adjoining cavity. Full shot back pressure procedure, entire cavity is filled with plastic melt. The injected fluid forces the melt through the sprue bushing back into cylinder vestibule.

The GIT (GAIM) mold injector

Gas injectors are installed directly into the mold. One or more injectors are assembled into the mold, depending of the size and geometry of the molded part as well as the fluidity of the melt. With an installation either parallel or diagonal to the form direction, the mold injector must be used with an extraction mechanism.

Service set for mold injectors

-

Precision parts require precise tools - due to the compact size of Herzog mold injectors, installation and cleaning needs to be accomplished carefully. This can be easily achieved with the help of our in-house designed service set.

Set contents:- Torque wrench

- Mold installation sockets

- Assembly / disassembly tool

- Holding / countering tool

- Special cleaning tools

- Thread glue

- Spare parts case

Optional extras (for shut-off nozzles)

Screen filter for nozzle type HP

-

Clean, foreignparticle-free melts are essential for a troublefree and economical production of injected parts. The partial molding channel only holds back a minimum amount of larger foreign particles in the hot channel.

Screen filters which are built into the machine nozzle or the hot channel are an economical solution in restricting foreign body intrusion into the molded part. The screen filter is accomodated in the tip of the Herzog needle shut-off nozzle. The needle of the shut-off nozzle actually passs through the filter. The filtration of the injected mass is made by the radially arranged drillings. The large number of drillings causes a minimal decrease in pressure. The filter drillings must be in the diameter selected so that partially injected points are not affected by the dirt particles.

Thermal system (heater bands & temperature sensors)

-

The thermal system plays a considerable role in the optimal function of shut-off nozzles. Heating systems contain a heating unit, temperature sensors and the associated controllers.

The heater band should be durable and have sufficient power reserves. The temperature sensors must exhibit a fast response mode and a long service life. The system is determined by ist weakest factor. If a wrong heating system is implemented, this could perform unreliably and impair or detract from the performance of the nozzle substantially.

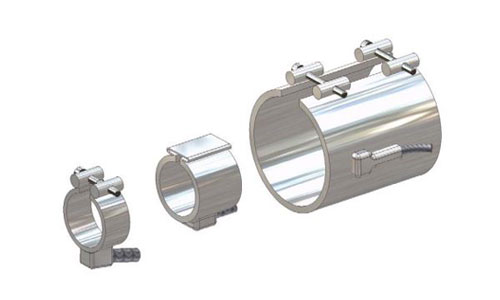

Flexible actuator feed

-

Our pneumatic and hydraulic actuators turn slightly and system-dependently, around the suspension axle, during the piston stroke. If this pivotal movement is restricted, the piston rod may wear over a short period of time. Machine-side feed using rigid piping is unsuitable.

Technical Data- PTFE piping with steel cladding

- galvanized steel fittings

- metal seal washers

- temperature resistant up to 250°C

- max. operating pressure 200bar at 250°C

- flexible area max. bend 180°

Other products

Injection valve

-

The range of applications for dosing valves are mainly in the extrusion area.

With this specific valve different additives and auxiliary materials can be purposefully inoculated into the plastic at a defined place. Both solid and fluidic materials can be added.

The connection dimensions are custom manufactured.

Applications:- Dosing procedure

- Injection of liquid material

Implementation possibilities:- Valves

- Opening pressure can be manually adjusted

- Volumetric flow rate can be set in a wide range

- Can be supplied with corrosion protection

- Versatile application

Nonreturn valve

-

Trapped material with a simple valve

Hot runner systems gaurantee that the material between machine nozzle and cavity remains plastic. With existing systems which are equipped with a shut-off system, only Herzog AG‘s valve element can gaurantee that the mass does not leak out when the machine nozzle is withdrawn.

The injection procedure is introduced by the stroke of the plastifying screw. The plastic flows through the machine nozzle into the hot channel and on into the cavity. The needle shut-off in the hot runner system ensures that no mass flows uncontrolled into the cavity.

When the machine nozzle is withdrawn, the existing material in the hot channel which is under pressure can cause some leakage. This leakage can be avoided with the implementation of the Herzog valve, which is constructed and works on the principle of a nonreturn valve.

These valves can be built into every mold.

Piston position sensor type SHE

-

Today's molding processes require a thorough monitoring system for a fully automatic operation. Disruptions need to be automatically detected and transferred to the machine control.

The function of our shut-off nozzle is monitored by the type SHE sensor. The sensor is integrated in the hydraulic or pneumatic actuator and detects the end position of the piston. From both signals the shut-off condition “open” or “closed” can be derived and passed on to the machine control through the signal amplifier.

Criteria:- compact design

- repeat-exact, non-contact detecting of piston position

- continuous trouble free operation up to 155°C

- Signal amplifier with switch display

Retrofit:

All Herzog shut-off nozzles can be retrofitted in minutes by replacing the actuator and extending with Hall sensors, signal amplifier and connection cables.