- Offer Profile

-

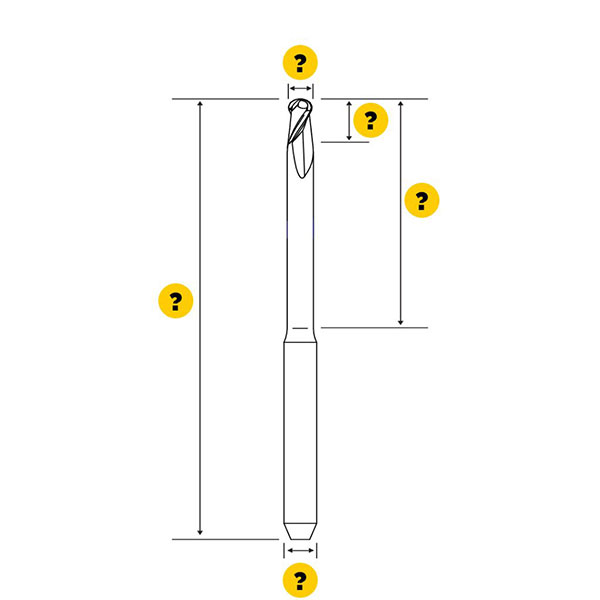

ZECHA Hartmetall-Werkzeugfabrikation GmbH has been a pioneer and trendsetter in the field of micro cutting, blanking and forming tools for over half a century. The company's origins in the chronograph industry can be seen not only in its uncompromising specialisation in the production of miniature tools of the highest precision, but also in its special tool solutions. Experts in the company's own research and development department are constantly developing ground breaking geometries and tools for sophisticated applications and cutting-edge materials. In addition, tool reproducibility is also guaranteed even for years on account of the life number stamped at the end of the shaft of every tool.

DISCOVER OUR TOOL LINES

-

Welcome to ZECHA’s comprehensive overview of our diverse tool lines. Each series is crafted with the utmost precision and innovation, designed to meet the specific needs of various industries. From the world-renowned IGUANA SERIES with its award-winning coatings to the versatile PEACOCK SERIES for tough materials, our tools are engineered to deliver exceptional performance and reliability.

On this page, you’ll find short descriptions for each series, along with icons indicating the materials they’re intended for. Additionally, you can explore more detailed information about each series and access direct links to their respective sections in the ZECHAshop. Find the perfect solution for your most demanding applications and experience the ZECHA difference.

IGUANA SERIES

-

REVOLUTIONARY COATING TECHNOLOGY

The IGUANA SERIES by ZECHA features world-first, laser-sharpened diamond coatings, setting a new standard in tool precision and durability. Designed for high-performance milling, these tools offer exceptional sharpness and wear resistance, making them ideal for machining highly abrasive materials and non-ferrous metals. Discover how the IGUANA SERIES can enhance your production efficiency and deliver superior results in even the most challenging applications. Explore more about this award-winning technology and find the perfect IGUANA tools for your needs.

MARLIN 3D LASER SERIES

-

PRECISION IN THE HARDEST OF JOBS

The MARLIN 3D LASER SERIES by ZECHA represents the pinnacle of precision and innovation in 3D machining. Utilizing the latest laser technology, these tools are designed to handle ultra-hard materials like ceramics and solid carbide with unmatched accuracy. The precise geometries and integrated cooling systems significantly reduce cycle times and enhance surface quality. Explore the MARLIN 3D LASER SERIES to experience superior performance and efficiency for your most demanding applications. Discover the full range and find the perfect tools to revolutionize your machining processes.

PEACOCK SERIES

-

PRECISION AND FLEXIBILITY IN HARD MILLING

The PEACOCK SERIES by ZECHA is specifically designed for hard milling, handling steels up to 67 HRC with ease. Featuring advanced WAD coating technology and optimized geometries, these tools provide exceptional durability and precise cutting performance. The PEACOCK SERIES is cleverly engineered for flexible use, allowing you to reduce the number of tools needed for a job. Whether for intricate details or high-volume machining, the PEACOCK SERIES delivers reliable, high-quality results. Discover the PEACOCK SERIES and find the ideal tools to enhance your efficiency and precision in hard milling applications. Explore the full range and optimize your tool set today.

QUEEN BEE SERIES

-

SPECIALLY DESIGNED FOR TOUGH MATERIALS

The QUEEN BEE SERIES by ZECHA is engineered to deliver exceptional performance for steels below 58 HRC. Featuring advanced WAD coating technology and optimized geometries, these tools ensure precise cuts and outstanding surface quality. Designed for both dry and wet milling, the QUEEN BEE tools offer superior durability and efficiency, making them indispensable for production, mold making, and general machining. Discover the QUEEN BEE SERIES and experience the perfect combination of design and reliability for some of the most difficult materials. Explore the full range and find the ideal tools to enhance your machining capabilities.

SEAGULL SERIES

-

PATENTED STABILITY AND PRECISION IN GRAPHITE

The SEAGULL SERIES by ZECHA is crafted for precision and stability in milling operations. Featuring patented cutting geometries and a short, stable flute design, these tools significantly reduce deflection, ensuring high accuracy and durability. The SEAGULL SERIES excels in applications requiring tight tolerances and superior surface finishes. Ideal for both roughing and finishing, these tools offer reliable performance across a variety of materials. Discover the SEAGULL SERIES and experience the benefits of innovative design and exceptional precision in your machining processes. Explore the full range and enhance your toolset with ZECHA’s SEAGULL SERIES

KINGFISHER SERIES

-

STAYING COOL FOR DIFFICULT MATERIALS

The KINGFISHER SERIES by ZECHA is designed to excel in milling a wide variety of difficult-to-mill materials. Equipped with advanced WAD coating technology and integrated internal or shaft cooling, these tools ensure superior durability, precise cutting, and effective heat management. The KINGFISHER SERIES delivers exceptional performance and flexibility, making it the perfect choice for challenging applications. Discover the KINGFISHER SERIES and see how these innovative tools can enhance your machining capabilities. Explore the full range and find the perfect solutions for your toughest milling tasks.

MORE ZECHA MILLING TOOLS

-

DRILLS, THREAD WHIRLERS; GRINDING PINS AND MORE

Beyond our renowned series, ZECHA offers a diverse range of specialized tools to meet all your machining needs. Our selection includes high-precision drills, thread whirlers, grinding pins, engraving tools, and more. Each tool is designed with the same commitment to quality and innovation, ensuring superior performance and durability. Whether you need to drill, thread, grind, or engrave, ZECHA’s specialized tools provide the precision and reliability you require for any application. Explore our extensive range of specialized tools and find the perfect solution to enhance your machining processes.

BLANKING AND FORMING TOOLS

-

ZECHA PRECISION AND QUALITY IN OTHER TOOLS

ZECHA’s blanking and forming tools are engineered to deliver unparalleled precision and reliability in your stamping and forming processes. Designed with the highest quality materials and advanced manufacturing techniques, our tools ensure accurate cuts and consistent forms, even in the most demanding applications. Whether you are working with metals, plastics, or composite materials, ZECHA’s blanking and forming tools provide the durability and precision needed to maintain high productivity and exceptional quality. Discover our range of blanking and forming tools and experience the ZECHA difference in your production line.

CUSTOM TOOLS

-

UNLOCK PRECISION WITH CUSTOM DRILLS AND END MILLS FROM ZECHA

When it comes to machining excellence, standard tools can only take you so far. At ZECHA, we understand that unique challenges require bespoke solutions. That’s why we specialize in crafting custom drills and end mills tailored precisely to your needs.

Don’t settle for off-the-shelf solutions when your projects demand more.

Partner with ZECHA to create custom drills and end mills that push the boundaries of what’s possible.