- Offer Profile

-

Hennecke GROUP produce high-quality machines, plants and systems for a wide portfolio of technologies for polyurethane processing.

The Hennecke GROUP unites the brands Hennecke Polyurethane Technology (Sankt Augustin, Germany), Hennecke-OMS (Verano Brianza, Italy) and Hennecke Roll Forming Technology (Kreuztal, Germany). An international network, made up of the Hennecke GROUP companies and trade and service partners, provides users with a comprehensive sales and after-sales portfolio as well as competent advisory and engineering services.

Metering Machines

-

METERING MACHINES MADE BY HENNECKE

Mixing and metering without any quality compromise with machine technology for every conceivable and inconceivable application: for more than 50 years, metering machines from Hennecke have been synonymous with top quality polyurethane processing and have been the centrepiece of countless processing plants. The Hennecke lineup comprises modular configurable systems for small to large outputs with first-class metering pumps, a great choice of state-of-the-art mixheads and intelligent automation.

HIGH-PRESSURE METERING MACHINES

FOR THE PRODUCTION OF RIGID AND FLEXIBLE FOAMS AS WELL AS INTEGRAL SKIN FOAMS

More than half a century ago, the HK type series heralded a new era – high-pressure polyurethane processing. Today, high-pressure metering machines form the basis when it comes to processing a whole variety of PU applications. Depending on the plant configuration and the mixhead used, modern metering machines allow all kinds of rigid and flexible foams as well as integral skin foams to be produced. The consistently modular construction offers processors more flexibility, also in the long term, if, for example, they later wish to expand production or combine with production plants.

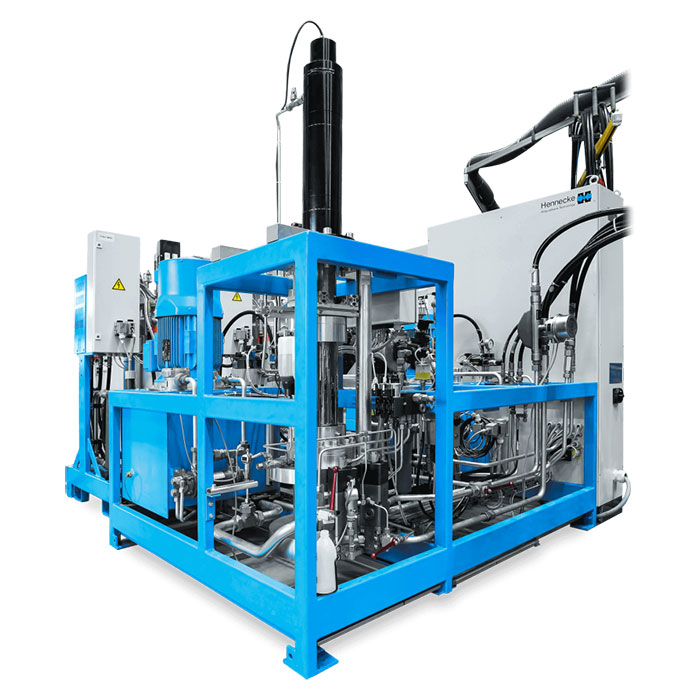

TOPLINE HK-MF

-

Optimised for multi-component applications in the manufacture of moulded foam products

Moulded foam lines rely on a further development of the TOPLINE type series. The "HK-MF" version has been optimised to meet the specific requirements of moulded foam production and is suitable for reliably processing up to six reactive components in a plant network. Users benefit from an extremely compact machine frame that incorporates all elements of a reactive component and, compared with the classical TOPLINE, scores points because the pipework has been significantly reduced. Combined with a temperature control system in the component feed line, this ensures very precise temperature control. When using two mixheads or two injection robots, the "HK-MF" is employed as a twin module. Especially when it comes to multi-component applications with up to twelve metering lines, this means once again that a considerable amount of precious production space is saved. Apart from the efficient raw material temperature control system, HQ axial piston pumps are included in the standard scope of delivery of the WKH unit. If desired, users can opt for state-of-the-art magnetic coupling technology and other features.

TOPLINE HT

-

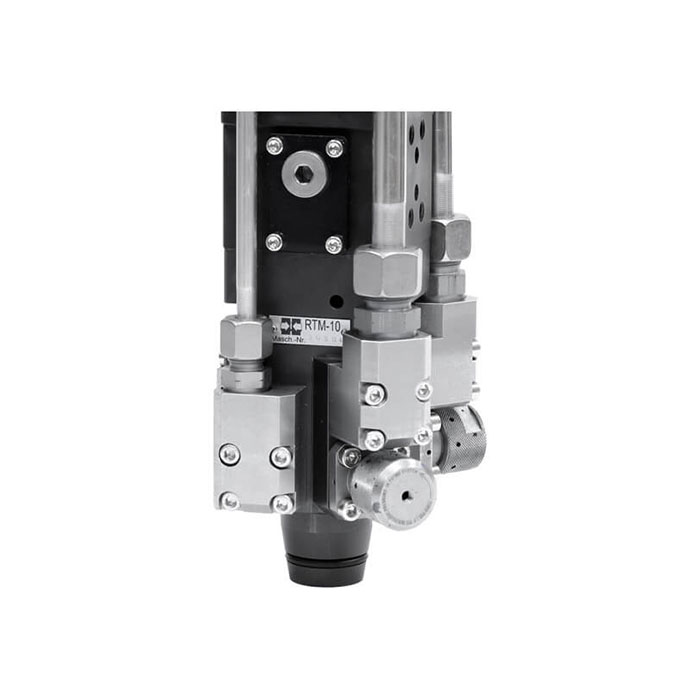

High-pressure piston metering machine for extreme requirements in the area of filled PUR systems

The wear-resistant, reactionless HT metering system with tandem plunger pumps is suitable for extreme demands in various output ranges. HT piston metering machines are capable of processing filled and unfilled components in absolute conformity with the formulation both in a discontinuous and continuous operation. This means that the robust metering machines are for example qualified for processing polyols with different fillers, abrasive colour pigments or high-viscosity raw material systems. TOPLINE HT machines also offer major advantages in the processing of synthetic resin using the RTM method (Resin Transfer Moulding). Two machine types (HT80 and HT180) are available, covering an output range of 8 - 360 cm³/s. In addition to processing polyols with solid flame retardants – for example, ammonium polyphosphate, melamine resin and expanded graphite – the systems are also particularly suitable for processing polyols made of renewable raw materials, recycled polyols, polyols with fillers such as PUR regrind or abrasive fillers such as glass fibers, calcium carbonate, barite, abrasive colour pigments and highly viscous raw material systems.

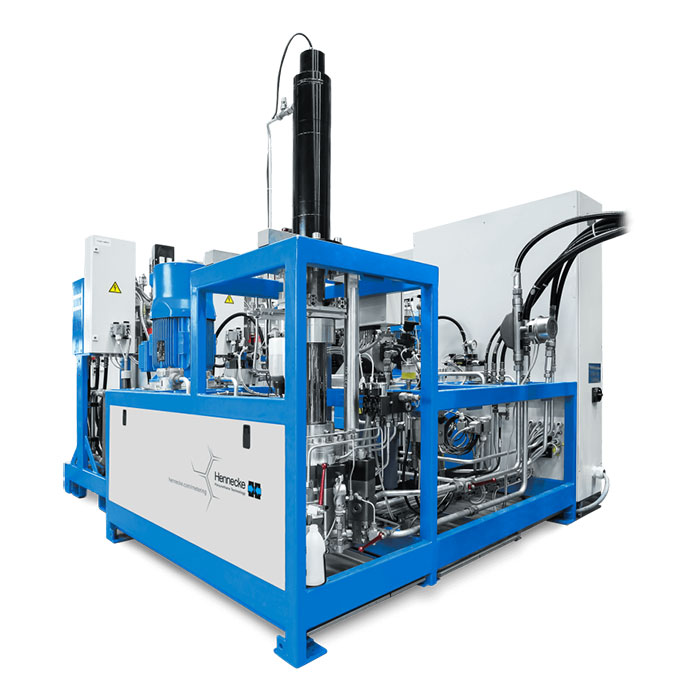

TOPLINE HT500EVO

-

High-pressure piston metering machine for processing abrasive fillers in polyurethane systems

Common metering machines for liquid components which are equipped with high-speed piston pumps cannot withstand the high abrasiveness of solid fillers long-term. Especially for processing main components containing fillers, Hennecke has therefore developed the TOPLINE HT500evo metering machine with a low-wear plunger pump which produces even under highly abrasive conditions with high precision, repeat accuracy and endurance. The TOPLINE HT500evo has an attractive price-performance ratio and is suitable for parts weighing up to three kilogrammes, with an output of 100 - 500 cm³/s. One of the main applications of this device is the production of comfort flexible foam that is, for example, used in seats and cushions for vehicles, especially in public transportation. Another area of application of the TOPLINE HT500evo are rigid foam applications, as for insulation within the framework of fire protection class B2 in the construction industry. Hennecke offers the TOPLINE HT500evo as an independent 2-component metering machine or as a module device for retrofitting an existing TOPLINE metering machine. In addition to processing polyols with solid flame retardants – for example, ammonium polyphosphate, melamine resin and expanded graphite – the efficient metering system is also particularly suitable for processing polyols made of renewable raw materials, recycled polyols, polyols with fillers such as PUR regrind or abrasive fillers such as glass fibers, calcium carbonate, barite, abrasive colour pigments and highly viscous raw material systems.

ECOPLUS MK2

- The ECOPLUS MK2 is the first model from Hennecke's new 'NEXT-GEN metering machines' and has been completely reworked compared to the previous generation. The cost-efficient starter model provides an easy introduction to Hennecke's quality high-pressure metering for largely manual polyurethane production, without compromising on mixing quality, raw material efficiency and digitalization. As well as making a number of noticeable optimizations to the machine layout, development focused on factors such as sustainability, resource utilization, energy consumption and data integration. All in all, the ECOPLUS MK2 offers higher performance at a lower purchase price. Nevertheless, the focus is on the highest quality in all crucial elements. The mixhead, metering line and automation are all new developments with many detail improvements.

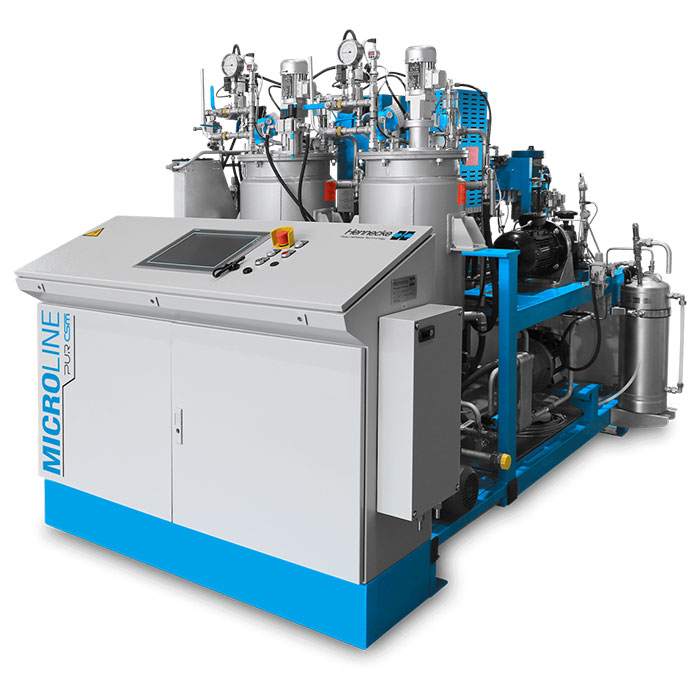

MICROLINE

- By opting for a MICROLINE, users will benefit from a two-component high-pressure foaming machine for precisely metering very small outputs ranging from 2.5 g/s to 130 g/s. The machine design and the major part of the modules are based on the successful TOPLINE high-pressure metering machines. MICROLINE systems are perfectly suited for PU casting and spraying applications. Most typically, the compact metering machine is used in the automotive industry or spray skin applications within the advanced PUR-CSM technology. Adapted to your process parameters, MICROLINE comes with extensive standard equipment right from the factory, including frequency-controlled motors, component temperature control and an intuitive touch-screen control system.

STREAMLINE MK2

-

High-pressure metering machines for HP-RTM, clearmelt and CLEARRIM applications

STREAMLINE metering machines come equipped with comprehensive standard parts, a self-cleaning high-pressure mixhead and an intuitive touchscreen control system. Thanks to an efficient and reliable heating system for tanks and pumps using tried and tested hot air technology, the STREAMLINE ensures effective heating of components as well as excellent mixing results, even when outputs are low. The second generation STREAMLINE offers Hennecke customers a tailor-made processing system for two forward-looking technologies. Hennecke has fully overhauled and refined the STREAMLINE high-pressure metering machines using the experience of our application and process specialists and in consultation with our customers. The improvements have focused particularly on ease of service and operation. The STREAMLINE MK2 provides users with a high-pressure metering system which sets standards by enabling consistent optimization through serial applications. Reliable operation, innovative detailed solutions and space-saving machine design ensure that your production has the decisive advantage.

TOPLINE MK2

-

The new TOPLINE MK2 is the crowning highlight of Hennecke's Next Generation series. The premium high-pressure metering machine covers all conceivable PU applications. This is the case too when it comes to highly demanding raw material systems typically requiring the most exact temperature control possible. It is also the first choice for highly automated applications such as refrigerated furniture production, seat foams or exterior and interior components for vehicle production. The TOPLINE MK2 is used as a stand-alone solution or in all conceivable system configurations where the highest quality, the greatest possible production and process stability as well as automation and scalability are required. Alongside powerful basic equipment, it offers maximum flexibility and adapts to even the most complex process requirements thanks to numerous optional modules.

COLOURLINE

-

High-pressure metering machine with MULTI-CONNECT technology for fast and easy colour change for surface finishing

A tried-and-tested field of application for polyurethane and polyurea system is the surface finishing of decorative elements in the automotive sector, in the furniture industry or for many other decorative applications by coating them with transparent PU systems using the RIM process. While the STREAMLINE machine system can only fully bring its strengths to bear with one transparent or coloured polyurethane system, COLOURLINE with MULTI-CONNECT technology enables fast and easy colour changes. Flexible production with multiple coloured polyurethane systems becomes possible through the system-related distribution of the isocyanate component and the polyol colour component in different units.

TOPLINE MK2

-

The new TOPLINE MK2 is the crowning highlight of Hennecke's Next Generation series. The premium high-pressure metering machine covers all conceivable PU applications. This is the case too when it comes to highly demanding raw material systems typically requiring the most exact temperature control possible. It is also the first choice for highly automated applications such as refrigerated furniture production, seat foams or exterior and interior components for vehicle production. The TOPLINE MK2 is used as a stand-alone solution or in all conceivable system configurations where the highest quality, the greatest possible production and process stability as well as automation and scalability are required. Alongside powerful basic equipment, it offers maximum flexibility and adapts to even the most complex process requirements thanks to numerous optional modules:

- The TOPLINE MK2-platform can be equipped with up to ten mixheads. Almost allHennecke mixheads are available for this purpose: from the MT 3 for low output rates and the smallest part weights to the MT 36-2 for extremely high output rates, multi-component mixheads such as the MT-A 22-4, the MN series for spray applications and the new MT 12-3 CC color-changing mixhead. Of course, the TOPLINE MK2 portfolio also includes a wide variety of sizes from the top MT-A series, both for open shot and for docked processing.

- In combination with the FIXJET and FLEXJET (SL and GL type) series from the latest Hennecke injector generation, the TOPLINE MK2 mixhead portfolio outperforms in fulfilling all the requirements of modern polyurethane systems in terms of metering accuracy, mixing quality and service life of the components.

- The groundbreaking HX pump is significantly more pressure-resistant, quieter, and more energy-efficient than other common pump models. In addition, integrated sensor technology gives the user extensive information when required, and supports improved machine availability through predictive maintenance.

- The TOPLINE MK2-platform can be equipped with up to ten mixheads. Almost allHennecke mixheads are available for this purpose: from the MT 3 for low output rates and the smallest part weights to the MT 36-2 for extremely high output rates, multi-component mixheads such as the MT-A 22-4, the MN series for spray applications and the new MT 12-3 CC color-changing mixhead. Of course, the TOPLINE MK2 portfolio also includes a wide variety of sizes from the top MT-A series, both for open shot and for docked processing.

LOW-PRESSURE METERING MACHINES

-

FOR PROCESSING CASTING SYTEMS OR HIGHLY VISCOUS COMPONENTS

When it comes to processing raw material systems used in the low-pressure range Hennecke offers you – just as in high-pressure metering – state-of-the-art systems technology as the basis for perfect, high-quality end products. Hennecke also has decades of experience in low-pressure metering systems. For example, in the processing of casting systems or raw materials with high viscosity for making elastomer components or thermoformable foam products. Users also benefit here of course from the advantages offered by modular configurable systems which are flexible and can be adapted to any application.

IMPACT MK2

-

Next generation, low-pressure metering machines for a variety of standard applications

The IMPACT has been a proven classic in the entry-level class for polyurethane applications for over 20 years. With the comprehensive revision, Hennecke is making it easier to enter the premium world of polyurethane metering machines. The low-pressure machine platform with numerous innovations and improvements was moved into the Hennecke NEXT-GEN portfolio while at the same time the entry-level price was lowered significantly. This was made possible thanks to a streamlining of the variant portfolio and significant optimizations in the field of in-house production. At the same time, the new IMPACT MK2 does not forego the proven Hennecke quality: The machine offers intuitive operation via a premium SIMATIC Unified HMI based on the FOAMATIC control system, and has the Hennecke Blue Intelligence technology for an efficiency use of energy and raw materials. The robust and reliable ULTIMIX low-pressure stirrer mixheads ensure a homogenous and thorough mixing, and the integrated cleaning makes them extremely maintenance-friendly. Three sizes, each with two mixing ratios, cover a wide range of customer requirements.

JETLINE

-

Low-pressure metering machines for Wet Compression Moulding applications (WCM)

Wet compression moulding processes are gaining increasing importance in the manufacture of continuous fiber-reinforced structural components with simple geometries and at the same time extremely short cycle times. With its low-pressure JETLINE metering machine, HENNECKE offers its customers a tailor-made system to meet the continually growing demand in this emerging area of application. The compact metering machine is deliberately not intended for the widest possible range of applications and concentrates exclusively on a highly efficient production process for any WCM application process. The new JETLINE offers top process stability, highly reliable components and a robust machine layout. Hennecke's longstanding process expertise in the manufacture of (continuous) fiber composites and decades of experience in low-pressure processing of reactive plastic systems are included as standard. The JETLINE system offers customers significant advantages for simple continuous fiber-reinforced plastics - its level of automation and specific cycle time provide the highest efficiency and product quality.

HK-R 5000

-

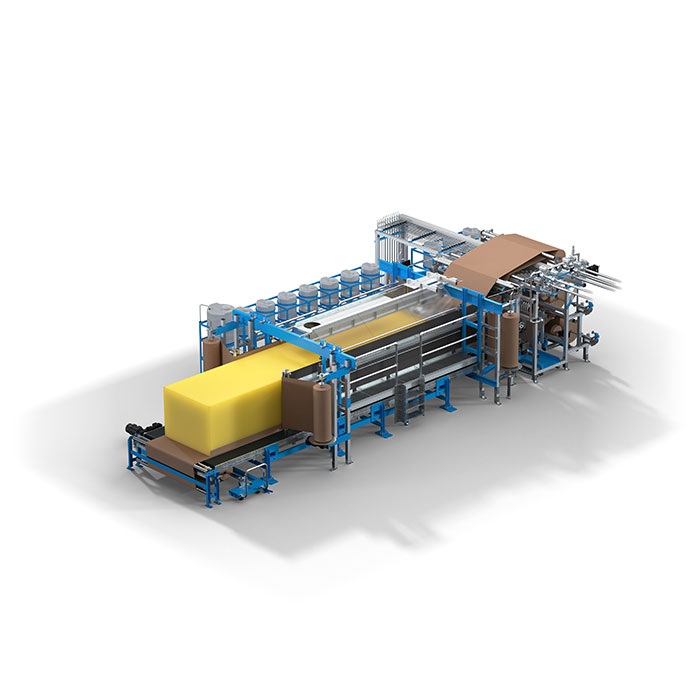

Low-pressure metering machine with high outputs for manufacturing high-grade slabstock foams

The HK-R 5000 is a metering machine whose components are perfectly suited to the requirements posed by the discontinuous production of open-cell polyurethane foam blocks. High-quality, thermoformable foam products are often used to manufacture roof linings in the automotive sector. A special stirrer mixhead and extremely powerful axial piston pumps enable outputs of up to 7500 cm³/s – even if there is a great difference in viscosity. This allows large foam blocks of up to 6m³ to be made. The HK-R measures out liquid materials from amply-dimensioned work tanks. A plate heat exchanger replaces the shell and tube heat exchanger in the return line so as to control the temperature. It is installed in a separate, constant temperature control circuit with a dedicated pump that takes up much less space.

Elastomer casting machines

- For high or low-pressure processing of casting systems or highly viscous components

When it comes to processing casting systems or highly viscous components, Hennecke provides state-of-the-art systems technology as a basis for flawless, high-quality end products. The parts produced with these systems can be divided into solid and cellular elastomer products. Compact polyurethane elastomers are suitable for a variety of moulded parts, high-quality wheels and rollers and also semi-finished products for mechanical processing. These parts are used when maximum abrasion resistance as well as mechanical and physical strength are important. In contrast, due to their excellent material properties, polyurethane elastomers with a micro-cellular structure are used when considerably greater deformation and lower compression hardness are required compared to the solid elastomers. Users also benefit here of course from the advantages offered by modular configurable systems which are flexible and can be adapted to any application.

ELASTOLINE

- When it comes to processing polyurethane-based casting systems and raw materials, the name ELASTOLINE has for decades been synonymous with high-quality end products. Low-pressure ELASTOLINE machines reduce the amount of manual work involved, improve industrial hygiene and streamline operational processes. The high-quality design of all assemblies ensures that these system benefits continue to be reaped in the long-term, even in harsh production environments. Hennecke offers two different types of customized ELASTOLINE low-pressure metering systems: one for MDI and TDI raw material systems (ELASTOLINE F), and one for Vulkollan® or NDI raw material systems (ELASTOLINE V). The compatible low-pressure MEL mixheads are supplied with hydraulic injector control for extremely short and synchronous switching cycles. They ensure that the processor achieves superior formulation constancy.

ELASTOLINE HP

- Elastomer processing under low-pressure has one distinctive disadvantage: for technical reasons, material and solvent losses occur during the pre-shot and flushing shot stages of the production process. The new ELASTOLINE HP is the result of Hennecke's extensive experience in high-pressure metering. Through advances in high-pressure mixing technology, Hennecke has brought the ELASTOLINE HP to the market, with a selection of mixheads that efficiently convert the delivery pressure in the processing of highly viscous media into mixing energy. Here the high-pressure mixheads consistently supply the exact amount of material that is required for the production run. Material savings from this can add up to a five or six-figure Euro sum per year, depending on the production scenario. As well as saving costs, the high-pressure concept also contributes to sustainability and environmental protection by conserving resources. In addition, using a ELASTOLINE HP means that closed molds can be filled; this is simply not possible with a low-pressure stirrer mixhead due to the dynamic pressure that builds up. Furthermore, the compact design of the ELASTOLINE HP's high-pressure mixhead means that it can be mounted on to a mold at almost any angle or on to a closed mold. Thanks to Hennecke's new ELASTOLINE HP high-pressure elastomer casting machines, this technical disadvantage of low-pressure processing is a thing of the past. Hennecke guarantees homogeneous temperature control in the entire metering system for the ELASTOLINE HP too - and for comparatively very high temperatures.

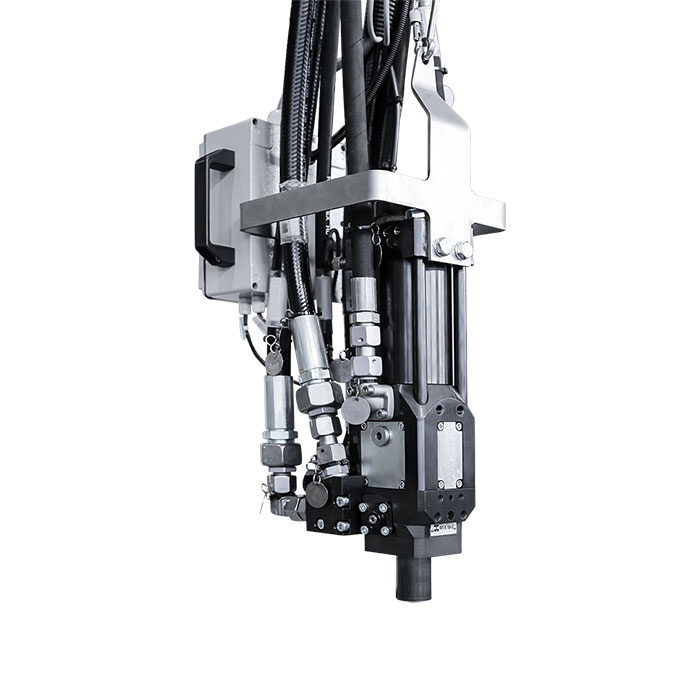

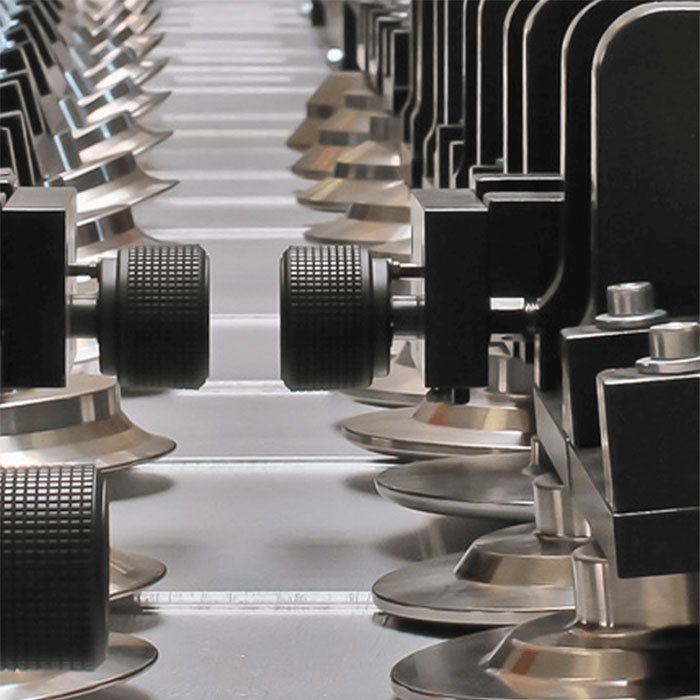

HENNECKE MIXHEAD TECHNOLOGY - High-pressure mixheads

- Making a profit with high pressure

Whether rigid or flexible, integral skin, filling or energy-absorbing foam is concerned, Hennecke has the appropriate high-pressure polyurethane mixhead for almost every application that requires mixing based on the impingement injection principle, from standard to specific applications. Variable sizes and injector shapes as well as a comprehensive range of accessories ensure that the mixheads can be adapted to suit a great variety of conceivable requirements - including yours!

MT-A MIXHEAD SERIES

-

Smart, high-pressure deflection mixheads with state-of-the-art features

The MT-A mixhead series is the most recent product in Hennecke's mixhead portfolio and since 2020 has been available in more and more different varieties. These mixheads share the same basic design as the successful MT deflection mixheads but are made of optimized materials and high-quality surface coatings which provide for high durability, even under difficult production conditions and when using demanding chemical systems. The mixhead also offers the option of additional smart technology: integrated sensors for process monitoring meet the requirements of the topics in Industry 4.0. An integrated connection plate helps to improve hose line management and is now a standard feature in the two-component models. For manual utilization, an ergonomic operating panel makes the mixhead even easier to control. Another new feature of the mixhead is an innovative cleaning and lubrication concept. An enlarged opening to the spacer tube affords generous access without dead space and facilitates manual cleaning. Even surfaces also make this working step much easier. Besides manual cleaning, the user can choose between two options: integrated minimal lubrication inside the spacer tube, or circulation lubrication of the entire spacer tube area. Together with the FLEXJET constant pressure injectors, the MT-A mixheads outperform in fulfilling all the requirements of modern polyurethane systems in terms of metering accuracy, mixing quality and service life of the components. In addition, with the exception of a few models, the MT-A series is downwardly compatible with the MT mixhead series and can be easily retrofitted to existing systems.

MT-E MIXHEAD

-

Available exclusively for the ECOPLUS series

The MT-E mixhead has been specially developed for the ECOPLUS metering machines and offers the perfect balance of simple and functional operability with the high-performance design features of the MT-A series. The two-component MT-E mixhead impresses with its high-quality materials and surface treatments as well as its high durability, even under difficult production conditions. An enlarged opening on the spacer tube and the even surface make manual cleaning easier and reduce the servicing required. Users can control the foaming process directly on the mixhead using the intuitive and robust control panel. The suspension of the mixhead is weight balanced at all times, both with horizontal and vertical mounting. Efficient output is ensured by the reliable FIXJET injectors. Upon request, the MT-E mixheads can be equipped with the FLEXJET constant pressure injectors to optimize the metering accuracy and mixing quality even further.

MT MIXHEADS

-

Deflection mixheads for special applications with tiny to very large outputs

Due to their high precision and durability, the high-pressure MT mixheads have been proven in all application areas for over ten years and are very well-established in the PU industry for all production scenarios. To the user, this translates above all into optimum processing results across the entire range of common PU systems. Our MT mixheads can inject up to four reaction components into the mixing chamber via high-efficiency injectors. The reaction mix then flows into the 90° offset outlet pipe. This deflection supports the mixing process, calms the mixture and ensures a laminar, splash-free discharge into the open mold. Due to their robust design, MT mixheads are also particularly maintenance-friendly and noted for their attractive life-cycle cost. Moreover, they are available upon request with Hennecke's FLEXJET constant pressure injectors which maintain an almost constant mixing pressure over a wide operating range. Output changes can thus be made without injector adjustment. This also effectively expands the application range of the mixhead.

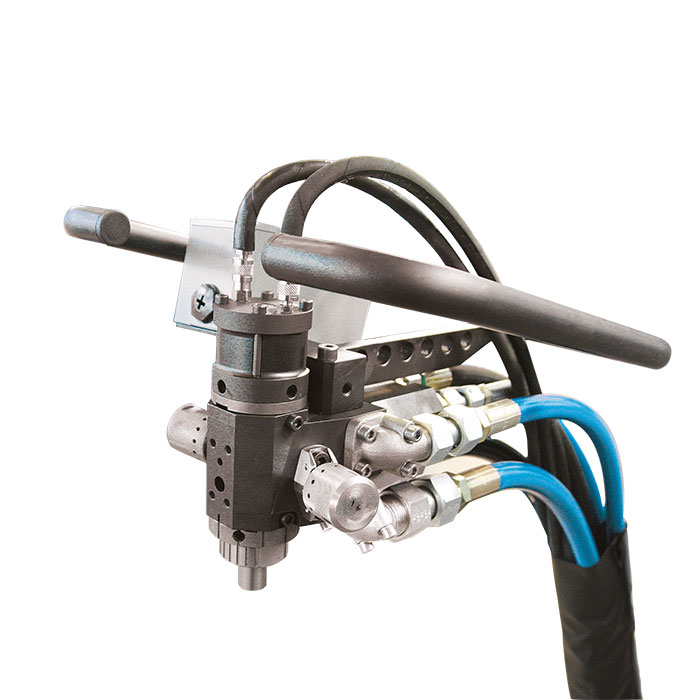

MN MIXHEADS

-

Groove-controlled linear mixheads for RIM applications, filler processing and spraying

Our MN linear mixheads operate on the groove-control principle. Due to their special parameters, they are particularly suitable for polyurethane spray-molding processes (PUR-CSM technology) and applications involving filled components. Hennecke's lineup of 2- to 4-component MN mixheads covers a vast spectrum of outputs, ranging from 6 cm³/s to 10,000 cm³/s. For CSM spray applications, users can optionally add 'smart' MN accessories such as a spraying lance for complex mold geometries or a high-performance cutter for a metered addition of glass fibers. Moreover, MN mixheads are ideal for attachment and thus suited for all RIM and RRIM processes. MN mixheads are optionally available with Hennecke constant pressure injectors which maintain a virtually constant mixing pressure over a wide operating range. Output changes can thus be effected without injector adjustment. At the same time, the application range of the mixhead is effectively expanded.

ML AND MXL MIXHEADS

-

Air-cleaned, high-pressure mixheads for various applications

Air-cleaned "L-type" ML and MXL deflection mixheads operate on the proved impingement injection principle, whereby the entire recirculation of the components is groove-controlled. The patented air cleaning function which is based on the cyclone principle completely eliminates the need for solvents. When operated manually, the low weight of the ML and MXL mixheads makes them more ergonomic to handle and easier to work with, even if the molds are difficult to access. With outputs of up to 9,000 cm³/s, these air-cleaned mixheads are also suitable for demanding tasks such as foam-insulating district heating pipes. Our ML and MXL mixheads are also optionally available with Hennecke constant pressure injectors which maintain an almost constant mixing pressure over a wide operating range. Output changes can thus be made without injector adjustment. This also effectively expands the application range of the mixhead.

Low-pressure mixheads from Hennecke

- Always striking.

Various raw materials and applications make mixing using impingement injection impossible. This is the case, for example, when casting systems or high-viscosity components are used. For many reactive components and additives - e.g., in continuous slabstock lines - mixheads are fitted with special stirrers to ensure that the reactive systems and additives are mixed homogeneously in the mixing chamber and a laminar output is achieved. To a certain extent, processors can influence factors such as the cell structure and cell size of foaming systems by means of particular types of stirrer. High-strength stirrers are used in compact and cellular elastomer systems, ensuring optimal results even when the processing parameters are extremely difficult.

MEL mixheads

- Right from the start, MEL mixheads are equipped with a hydraulic control of the mixhead injectors for extremely short and synchronous switching cycles. This is a novelty that guarantees the processor a superior metering quality. Moreover, MEL mixheads are also fitted with a sophisticated mixing chamber and stirrer geometry in hardened steel so that an excellent mix quality is guaranteed even when raw materials are difficult to mix. MEL mixheads are on offer for six or eight components. They are optionally available with Hennecke constant pressure injectors which maintain a virtually constant mixing pressure over a wide operating range. Output changes can thus be made without injector adjustment.

Stirrer mixhead for slabstock

- Slabstock stirrer mixheads combine injection and stirring principles and guarantee the user a laminar liquid laydown over the entire foaming width. Foam qualities with an extremely uniform pore structure that is free of pinholes and striation are achieved. The actual mixing unit is located centrally in the system’s foaming portal whereas the liquid laydown is discharged onto the bottom conveyor by a funnel that can be adjusted automatically or manually, depending on the system configuration.

Stirrer mixhead for HK-R 5000

- HK-R stirrer mixheads are applied when extremely high-quality foam products for use in the automotive industry, or rather automotive interiors, are made. The highest amount of mixing energy possible is required to ensure a homogeneous cell structure. That’s why HK-R stirrer mixheads are equipped with a tailor-made mixing chamber and speed-controlled stirrers with a special geometry. Additional features such as adjustable mixing chamber pressure and a control-piston operated system for switching from recirculation to shot enable a laminar and absolutely bubble-free flow.

SLABSTOCKS LINES - Continuous slabstock lines

-

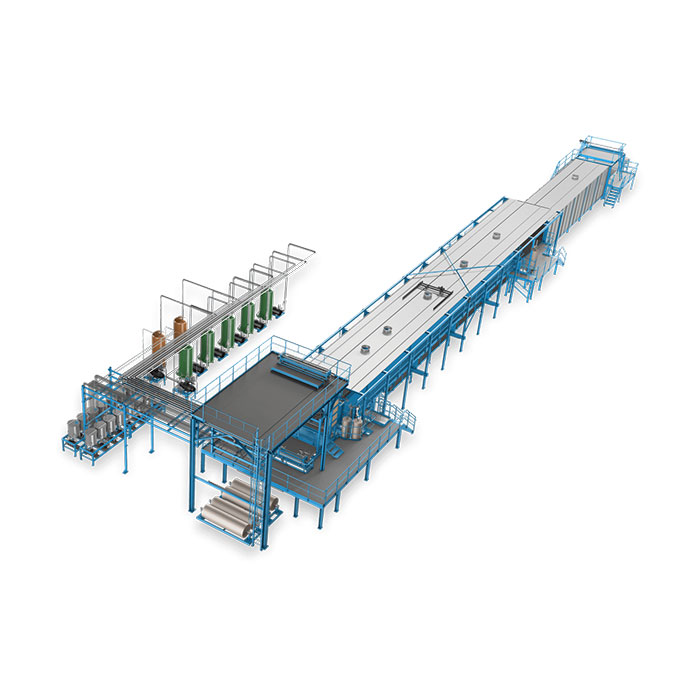

Cost-efficient production of high-quality flexible foams

The combination of precise high-pressure metering and a powerful stirrer mixer makes Hennecke's continuous slabstock lines the perfect partner in the efficient processing of all commercial materials in almost all density ranges. Through the combination of various technologies exclusive to Hennecke, continuous slabstock lines are opening up a variety of prospects for the cost-effective manufacture of high-quality foams of any length, up to 2,500 mm in width and, depending on the foam type and specific density, with a height of up 1,500 mm. The Hennecke systems technology combines the individual advantages of all the well-known concepts for the continuous production of polyurethane slabstock foams and provides the processor with the highest possible quality. Thanks to its individual adaptation to market or environmental requirements, it also offers the highest degree of production flexibility for competitive production results over an extremely long period of time.

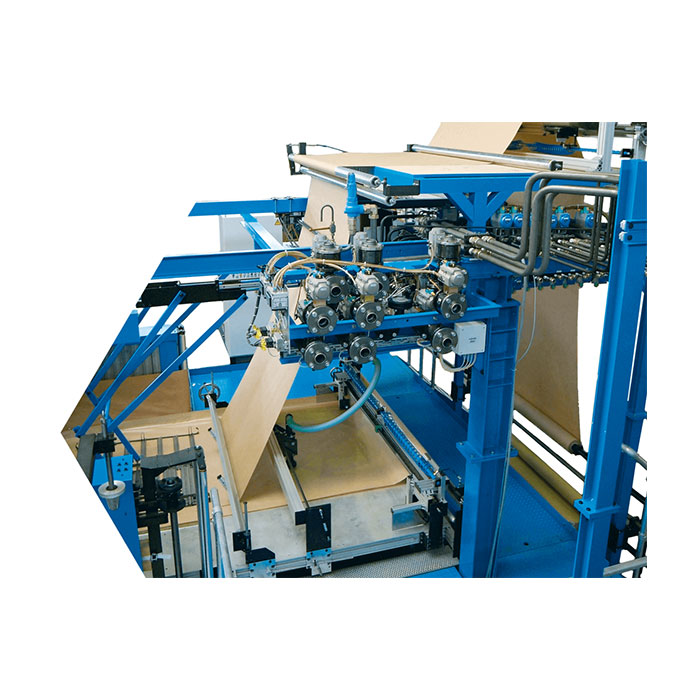

MULTIFLEX

-

Modular production lines for the continuous and efficient manufacture of high-quality slabstock foams

For almost eight decades Hennecke has developed and produced high-quality plants for polyurethane processing. Hennecke is considered the market leader in the field of slabstock machinery and equipment. This know-how is reflected in the MULTIFLEX systems. The latest generation of one of the world's most renowned slabstock lines impresses processors with its attractive price-performance ratio, which – thanks to a highly efficient raw material yield, outstanding foam qualities and the state-of-the-art FOAMWARE system control – ensures a fast return on investment. Based on analyses and statements by leading slabstock foam producers and raw material manufacturers, the use of Hennecke high-pressure technology saves up to 5 percent isocyanate compared to low-pressure slabstock machines. With an annual slabstock foam production of 5,000 tonnes and an isocyanate price of EUR 3.00/kg, this corresponds to a saving of around EUR 200,000 per year. A further considerable cost saving results from the use of the proven LIQUID-LAYDOWN system together with the Hennecke rectangular process (FLAT-TOP system). 4-sided paper covering over the produced foam block – where the top rind is converted into usable foam – allows slabstock foam producers to achieve up to 5 percent higher foam yields compared to production without cover paper. And not forgetting: physical properties in terms of hardness and bulk density distribution are significantly optimized. This ensures the user a highly efficient raw material yield and the best foam quality. What is more, production can be further optimized by automating the FLAT-TOP-Systems (patented AUTO-FLAT system).

QFM

-

Production lines for the continuous manufacture of high-quality polyether and polyester-based slabstock foams

The results of over 60 years of research and development are reflected in Hennecke’s QUADROFOAMAT (QFM) slabstock lines. Thanks to the fact that all components across all viscosity ranges are precisely metered, output settings are exactly reproducible, the adjustment range is large and because the plant has been combined with the extremely successful UBT technology including fall-plates, QFM lines open up many horizons for the efficient production of pinhole-free ether and esther foams that are up to 2,500 mm wide and, depending on the foam type and density, up to 1,500 mm high. A computer-controlled flow metering system provides additional production reliability, in particular when formulations or colours need to be changed on the fly without stopping the plant. Depending on foam type, formulation and plant configuration, cell sizes of 8-100 ppi are possible.

JFLEX EVO

- Before the introduction of the JFLEX series, the capacity range between discontinuous and continuous slabstock systems was not covered in the market for polyurethane processing systems. The target group here are foam manufacturers who want to achieve better quality and a higher raw material yield than is possible with discontinuous systems, but do not want to make the high investment in conventional continuous systems. With the JFLEX series, Hennecke has had a revolutionary slabstock line since 2013 that offers users with medium production volumes all the advantages of continuous production. The innovative production system impresses with its extremely compact dimensions and excellent price-performance ratio. The usual Hennecke quality down to the last detail comes as standard. JFLEX evo, the latest generation, presents itself with decisive improvements that offer the user further significant advantages in terms of operation and the possible range of applications. Itself with decisive improvements that offer the user further significant advantages in terms of operation and the possible range of applications.

Discontinuous slabstock lines

-

Minimal use of space, easy start-up, flexible production

When small batches are produced or special foams such as visco-elastic foams are being made, the discontinuous production of flexible slabstock foams is often the most suitable solution. This is also true in terms of economic efficiency. Discontinuous slabstock lines made by Hennecke are very convincing because they require less invest and less space. Of course, the company also has decades of experience in discontinuous lines and only uses tried-and-tested quality components.

BLOCFOAMAT

-

Compact slabstock systems for discontinuous applications

Machines of the BLOCFOAMAT type have a track record of over 30 years in discontinuous slabstock production. When it comes to manufacturing rectangular and round blocks, BLOCFOAMAT users exert maximum influence on the quality and property of the foam, thus producing the high-grade basis of a great number of end products including mattresses or upholstered furniture. On top of this, the type series stands out for its efficient machine layout and attractive pricing. The current BLOCFOAMAT generation offers even more options and allows a wide range of polyether-based products to be made.

Laboratory systems

-

Slabstock systems technology for test series and laboratory purposes

Hennecke's laboratory systems are used to conduct test series for different raw materials and additive systems in continuous slabstock production. For example, a variety of test formulations can be precisely transposed to real production conditions, without interrupting the current production run or wasting a large amount of valuable raw materials.

LABFOAM

-

The ideal partner for slabstock test series and product innovations

The use of a LABFOAM laboratory plant quickly pays off - especially if you already produce slabstock products continuously. Even if LABFOAM systems operate discontinuously, their major area of application is about conducting test series for different raw materials and additive systems used in continuous slabstock production. Thanks to high-precision metering pumps, superior mixing technology and modern automisation, different test formulations – as opposed to manual production – can exactly be transposed to real production conditions. Thus you can judge the specific character and quality of a formulation without interrupting your current production or wasting a large amount of valuable raw materials in test series. There is also the option of equipping LABFOAM systems with patented NOVAFLEX equipment.

HENECKEN-OMS

-

For over 50 years, Hennecke-OMS has been offering its customers integrated production solutions for processing polyurethane. Today the company is amongst the leading global manufacturers of machines for polyurethane processing and has a multitude of innovative products in its history that have set market standards.

The Hennecke-OMS product portfolio includes the worldwide largest range of plants for producing sandwich panels. Hennecke-OMS enjoys decades of experience in the manufacture of sandwich panel plants and provides its customers with a huge range of diverse technologies and production systems. This is the case for all sandwich panels, regardless of whether they have flexible or rigid facings.When you choose plant technology from the global leader, you will benefit from our comprehensive product portfolio for all conceivable applications: ranging from extensive standardized plants for cost-efficient production to highly flexible solutions for state-of-the-art manufacture using multi-functional plant technology. This includes both continuous and discontinuous panel lines, for large-scale production as well as for individual end products with a specific range of properties.

Continuous sandwich panel lines - PANELMASTER STEEL

-

Plant technology for the continuous production of polyurethane sandwich panels with a core structure made of polyurethane or mineral wool

Rigid polyurethane foam has the lowest thermal conductivity of all insulating materials and is therefore used in the form of metal composite elements in industrial and cold store construction, as well as in cooling chambers for supermarkets and in thermal assemblies for trucks. With its highly developed, continuously or discontinuously operating sandwich panel lines, Hennecke-OMS has played a decisive role in this success story right from the start. The PANELMASTER STEEL plant is designed for the continuous production of top-quality sandwich panels with different facings, panel thicknesses and profiles and the option of a core structure made of polyurethane or mineral wool. Thanks to the company HPT GmbH, the Hennecke GROUP also has a highly-specialized provider of high-performance trapezoidal sheet roll forming systems, which can be seamlessly incorporated into the existing plant concept for the PANELMASTER STEEL continuous sandwich panel lines. In the continuous production of sandwich elements with metal facing, Hennecke-OMS is one of only a few suppliers that can offer its customers convincing all-round solutions from a single source.

Continuous insulation board lines - PANELMASTER FLEX

-

Plant technology for the continuous production of insulation boards with flexible facings and a core structure made of polyurethane, polyisocyanurate or phenolic foam

Continuous sandwich panel lines for producing polyurethane insulating boards with flexible facings are primarily used for heat insulation of house and industrial roofs as well as wall, floor and ceiling insulation. Trust in the production system of a global leader! Continuous panel plant technology from Hennecke-OMS allows for large-scale, high-speed production of top-quality insulation boards with a variety of flexible facings, thicknesses and edge profiles. Our comprehensive system solutions produce packaged and stacked end products at high speed due to the use of process and handling systems.

DISCONTINUOUS SANDWICH PANEL LINES -PANELFOAMER

-

PLANT TECHNOLOGY FOR THE DISCONTINUOUS PRODUCTION OF METAL COMPOSITE ELEMENTS AND INSULATION PANELS FOR MULTIPLE APPLICATIONS

Given their excellent range of properties, sandwich panels with a polyurethane core provide an alternative to traditional construction methods - not only in economic, but above all in ecological terms. PANELMASTER production lines are used worldwide for the continuous manufacture of insulating panels. But in many applications, the discontinuous production process offers decisive advantages and important unique features. For instance, when using facing material with specific properties or incorporating special mechanical fixings within the panel. Discontinuous panel manufacture also makes sense for lower production volumes or when extraordinary dimensions are required. Cold storages and cooling trailers are an important field of application, as is the construction sector, both private and commercial. Users all over the world rely on flexible PANELFOAMER systems concepts by Hennecke-OMS.

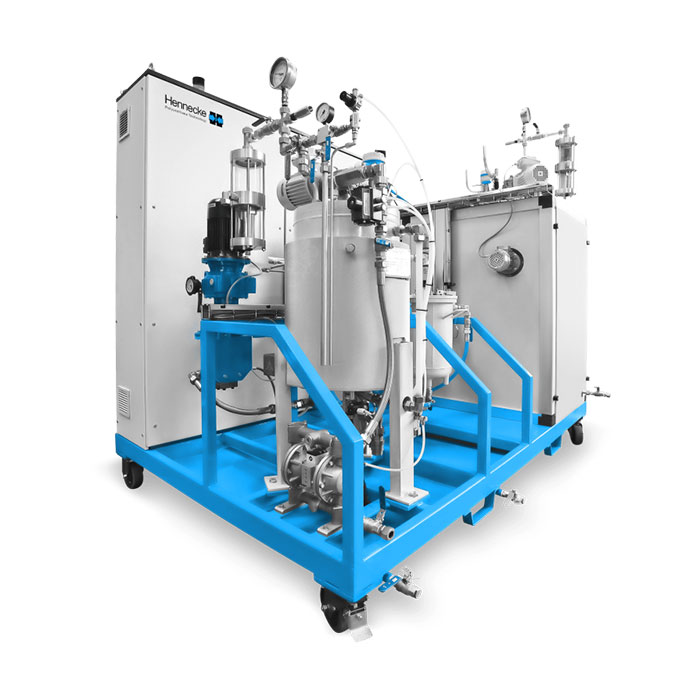

PERIPHERAL EQUIPMENT - ECOFILLER PLUS

-

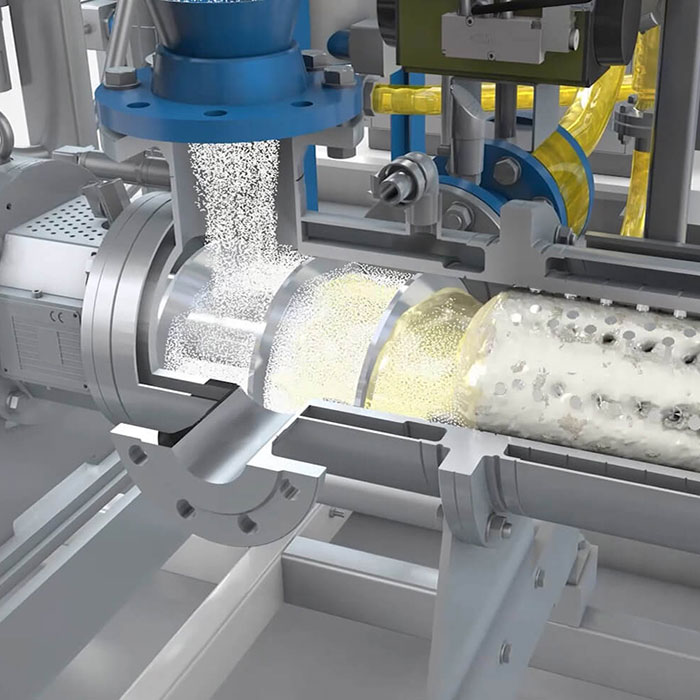

An innovative, sustainable, high-pressure PUR metering add-on for quick mixing of liquids with solids

The ECOFILLER PLUS belongs to a range of Hennecke GROUP projects aiming to offer market players more sustainable technologies and services along the polyurethane processing chain. Developed in several stages, the ECOFILLER PLUS utilizes new technology for re-introducing PUR cuttings and material waste from the customer's own rigid foam production back into the production process. This makes production more resource-efficient, whilst protecting the environment at the same time. Besides recycling, the main use of the ECOFILLER is to obtain a final product with improved fire behavior thanks to the specific use of powders as flame retardant.

The ECOFILLER PLUS features an innovative loading, preparation and mixing stage for the liquid media, and solid fillers, as well as offering a number of other benefits:

- instantaneous mixing

- more frequent mixing loads

- reduced mixing time

- improved mixing quality

- formulation modification via the HMI whilst production is running.

HENNECKE ROLL FORMING TECHNOLOGY

-

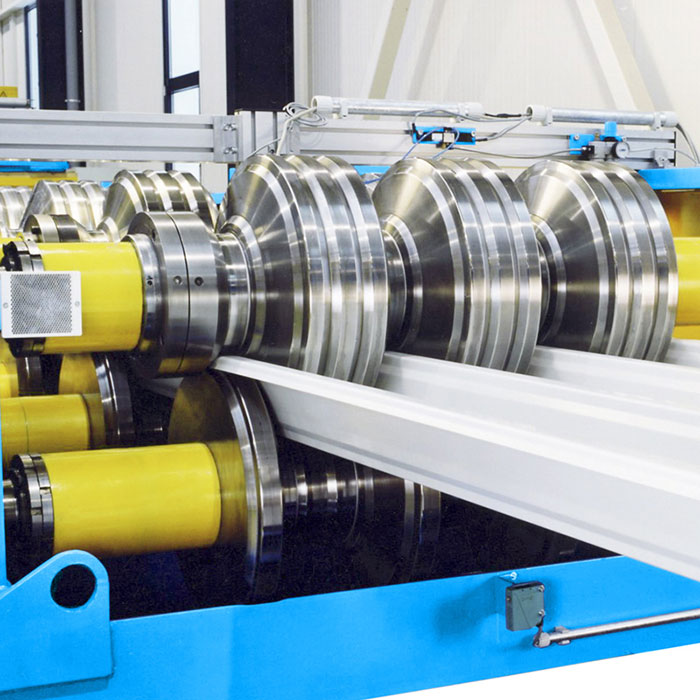

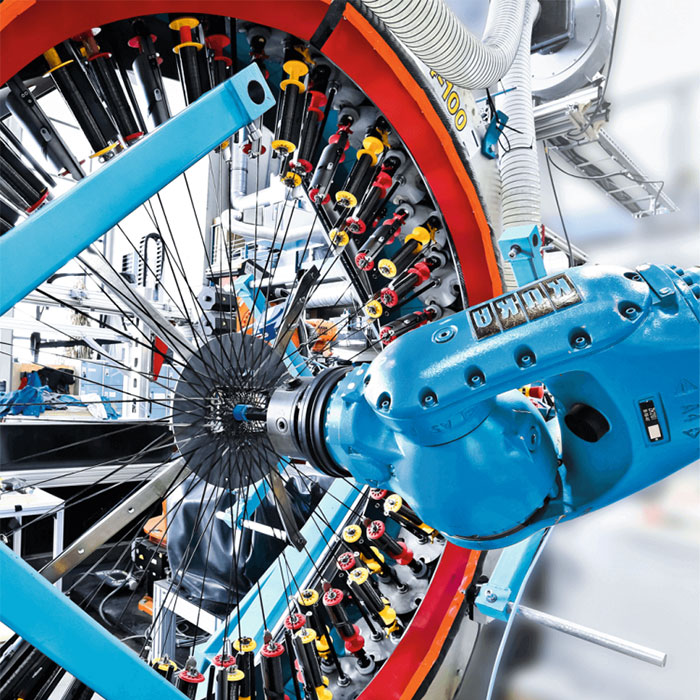

Hennecke GmbH Roll Forming Technology has been developing, designing and building high-class roll forming systems for over 40 years. Alongside roll forming plants for insulated roof and wall sandwich panels, the portfolio includes roll forming machines and presses for manufacturing sectional door panels, as well as cut-to-length systems and high-performance trapezoidal sheet roll forming plants.

With its CONTIMAT and PANELMASTER systems, the Hennecke GROUP has made a name for itself worldwide in the continuous production of high-quality sandwich panels. For panels with metal facings, Hennecke GmbH Roll Forming Technology, based in the Siegerland region of Germany, offers suitable machine technology for surface and edge profiling. The highly specialized company has over 40 years of experience in manufacturing roll forming machinery. The Hennecke GROUP is therefore one of only a few companies worldwide with overall system competence and can offer its customers complete solutions for everything ranging from sheet metal decoiling to packaging the finished stack. When it comes to modernizing and expanding plants that have been manufactured by other companies, Hennecke GmbH Roll Forming Technology is also a highly competent partner.

SANDWICH PANEL ROLL FORMING LINES

-

SURFACE AND EDGE PROFILING FOR SANDWICH COMPOSITE ELEMENTS

- Insulation roof panels

- Insulation thermal walls

- Insulation cold storage elements

- Insulated industrial sectional doors

- Garage sectional doors (with and without finger protection)

- Sandwich fire safety elements

TRAPEZOIDAL SHEET ROLL FORMING LINES

-

PRODUCTION OF HIGH-QUALITY TRAPEZOIDAL SHEETS WITH OPTIONAL PROFILE GEOMETRIES

- Single or double-shell trapezoidal facings for roof and wall covering

- Trapezoidal sheets with anti-condensation fleece

- Corrugated sheets for roof and wall cladding

SPECIAL ROLL FORMING SYSTEMS

-

WE WILL BE HAPPY TO ADAPT TO YOUR PROFILE – SPECIAL APPLICATIONS ACCORDING TO CUSTOMER REQUIREMENTS

Hennecke GmbH Roll Forming Technology can create almost any profile shape. The high level of flexibility in the individual departments means we are able to provide our customers with almost any plant tailored to their individual requirements and specifications. We also have the perfect solution for your product idea. Get in touch with us!

- Manufacture of high-quality siding profiles

- Manufacture of high-quality cassette panels

Individual components

-

All components in our plant portfolio are also available separately. In most cases, it is unimportant whether these are plant technology components from Hennecke GmbH Roll Forming Technology or from another manufacturer.

Available individual components (selection):

- Strip processing lines

- Coil handling equipment

- Strip connection systems

- Protective film laminating machines

- Linear stations

- Surface profiling stations

- Roll forming gears

- Roll forming tools

- Separation plants and tools

Technologies

PUR-CSM SPRAY TECHNOLOGY

-

Manufacture of fibre-reinforced components or compound molded parts in a spraying process

PUR Composite Spray Molding Technology (PUR-CSM) enables the manufacture of fibre-reinforced components or compound parts from filled or unfilled PU systems in a spraying process. As a basis and development platform for all known CSM products, the patented technology offers extremely competitive advantages over other traditional processes and products. For example, users do not need any solvents for cleaning the standard spray units within the individual process steps. Moreover, the same mixhead can be used for processing different raw material systems simultaneously even if outputs are different. Apart from the typical raw materials systems, fillers and chopped fibreglass can be processed and sprayed, which significantly improves the product properties. Thanks to these benefits, many new standard products that are now part of Hennecke’s machinery and equipment portfolio have been developed. The best examples are our systems for the large-scale production of lightweight interior parts, sanitary products or spray skin applications in both the automotive and non-automotive sector.

HP-RTM TECHNOLOGY

-

Manufacture of fibre-reinforced structural components with high-pressure technology

By combining high-pressure technology and the conventional RTM process Hennecke has broken new ground in polyurethane processing technology. Its High-Pressure RTM process (HP-RTM) offers users a new concept as well as an appropriate processing system for manufacturing extremely lightweight high-performance parts. By comparison to the “conventional” RTM process that is characterised by long process times because of the many manual procedures involved, HP-RTM technology scores regarding the degree of automation and specific cycle times. It offers significant advantages when it comes to the realization of larger quantities.

PPT TECHNOLOGY

-

Safe processing of the eco-friendly blowing agent PENTANE

PENTANE has been and is still largely responsible for the fact that rigid and integral skin foams can be manufactured without an impact on the environment. Pentane Process Technology (PPT) was launched by Hennecke already in 1993 and has been playing a leading role since. The processing of pentane as a substitute for CFCs was mainly driven by the refrigerator and freezer industry. Apart from this application, Pentane-blown PU systems are also used in the production of sandwich panels, district heating pipes and steering wheels made of semi-rigid integral skin foam. Because PENTANE can create an explosive atmosphere at certain gas concentrations, PPT technology comprises a catalogue of primary and secondary measures that prevent the emergence of explosive mixes right from the start. One additional safety plus is realised by technical precautions which have been developed in close cooperation with TÜV Süddeutschland (Southern German Technical Inspectorate).

CLEARRIM TECHNOLOGY

-

Transparent and resistant polyurethane coatings for decorative applications

A tried-and-tested field of application of polyurethane is the surface finishing of parts e.g. by coating them with transparent PU systems using the RIM process (Reaction Injection Moulding). Hennecke's CLEARRIM technology provides an innovative concept combined with the suitable machine technology for producing parts with high-quality and functional surfaces in a surprisingly efficient way. It focuses on the use of a thin polyurethane layer by which thermoplastic support elements or support elements with natural surfaces are effectively finished. This allows users to achieve scratchproof, resistant high-quality surface structures for decorative parts in the automotive and furniture industries or for countless other decor elements. CLEARRIM is also ideally suited for a combination with other processing techniques.

NOVAFLEX® TECHNOLOGY

-

Production of CO₂-blown polyether-based foams

Since being introduced in 1995, the patented NOVAFLEX® technology has established itself as an industry standard in the continuous production of slabstock. Today, over 100 NOVAFLEX® systems are in use across the world. The technology replaces standard blowing agents such as CFCs or methylene chloride with CO2. It thus not only makes sense from an ecological point of view but also in terms of cost since CO2 is considerably less expensive than other blowing agents and in additon has a higher blowing effect. And there are no disadvantages when it comes to quality: NOVAFLEX® foams distinguish themselves through their particularly fine-celled and uniform pore structure. The result is excellent even with flexible foams that have a low density of 14-15 kg/m3.