- Offer Profile

- Ammeraal Beltech is a global market leader in the design, manufacturing, fabrication and servicing of high-quality, high-performance process and conveyor belts, available today in 150 countries around the world.

Industries

Airports

- Numbers are rising; airports are busier than they have ever been. Passenger baggage is a vital aspect of airport management, and how quickly, safely and accurately it moves around will directly influence overall airport efficiency and consumer satisfaction. Ammeraal Beltech belts are providing outstanding service in airports around the world. Let us help you keep your passengers moving as well.

Automotive

- Reliability, high efficiency, safety and low total cost

of ownership are all key factors in achieving high performance.

We’ve developed belting solutions for almost every conveying application and our belts are being used in all areas of automotive manufacturing plants and other vehicle handling systems around the world.

Carton, Paper & Packaging Materials

- Ammeraal Beltech belts, for speed and accuracy in the

Carton and Box Folding Industry.

Food

- Food Safety and hygiene are always a must in the Food Industry. We know this because Ammeraal Beltech began with bakery belts! For more than sixty-five years, we’ve worked with the Bakery Industry, finding new solutions with them for all the challenges this industry presents. We’re ready to help you, too.

Logistics

- Logistics requires speed, accuracy and reliability, and

that’s exactly what Ammeraal Beltech belting solutions give you.

An industry on the move – and a partner that helps you deliver.

We can find the right belt for every process in your operation.

Metal

- Ammeraal Beltech has specially designed belts for coil-wrapping

machines and for sheet conveying, as well as felt belts for extrusion and

synthetic belts for slitting and polishing.

Ammeraal Beltech has combined innovative materials and experience-led design to develop the best possible belting solutions for the Metal Industry.

Textile

- Textile, Yarn and Fabric Manufacturing

To stay competitive, textile production lines must continue to evolve. As industry requirements rise, so do our standards of performance and product excellence.

Ammeraal Beltech provides belt types for the most important textile sectors. Our comprehensive range is built around six product groups:- Process and Conveyor Belts

- RAPPLON® High Performance Flat Belts

- Endless Woven Belts

- Timing Belts

- uni Modular Belts

- Engineered Belts

Tobacco

- Tobacco and Ammeraal Beltech share a long history. We

have worked with the leading tobacco processing equipment manufacturers and

with the world’s most important tobacco companies and know the unique

challenges they are facing.

Leaf hands, loose leaf, tipped and butted tobacco, threshed, dried and packed tobacco – the production stages that tobacco passes through all have very different application requirements.

Our non-toxic belts are designed specifically to suit these applications and perform reliably, repeatedly and economically.

Tire

- Within the Tire Industry, Ammeraal Beltech has been

setting the standard for many years with consistent high product quality and

market-specific features. Innovations over the years, close co-operation

with customers and leading research institutions have resulted in a number

of new concepts.

E.g. Modular Belts offer long service life and reliable performance, cut down on maintenance issues and boost output. What’s more, when they’re metal detectable belts like our uni CPB, uni OWL, uni QNB or uni MPB, there’s no fear whatsoever of any damage to the extruder head. With our wide selection of solutions all featuring excellent release properties, self-tracking and easy installation, there’s a belt available for every application.

Wood

- Our wide range of solutions and our reputation for

high-quality products that deliver precision performance over a long

lifetime, along with our excellent service network, have made us a trusted

industry partner.

Treadmills

- Working with OEMs, Ammeraal Beltech has developed a range

of energy-saving superior performance treadmill belts for health clubs,

hotels, medical centers and home gyms. We also supply special belts with

waterproof cold-resistant top cover material for aqua gym treadmills.

Our belts are self-lubricating so you’ll never have to spray them again and feature permanent anti-static properties and generate a lower heat build-up.

Ammeraal Beltech treadmill belts can be customized with brand logos or other markings that will last as long as the belt.

Coating & Lamination

- Ammeraal Beltech, one of the leading suppliers in Europe in the belting area, specializes in coating and laminating the most diverse technical fabrics and sheet materials.

Using double belt presses, lamination systems, extruders and mixers in a production space of over 85,000 sq ft, Ammeraal Beltech Switzerland offers an almost endless choice of product combinations for the manufacture of simple or complex composites. Airbag coating

The first airbags were coated at the Ammeraal Beltech Switzerland plant in cooperation with the German automotive industry in 1997. This facility is now the largest airbag coating enterprise in Europe. Areas of application:- Coatings in the sports segment

- Foil lamination for the Automotive Industry

- Decor in interior design

- Multilayer filter membranes

- Release liners in the Wood and Paper Industry

Belts

Synthetic Belts

- Our comprehensive range of Synthetic Belts are able to

fulfil the application needs for light to heavy processing and conveying

applications.

Synthetic conveyor belts are made of fabrics with a coating on the top and/or bottom side. A belt consists of one or more fabric plies to give certain features such as strength, stability and impact resistance.

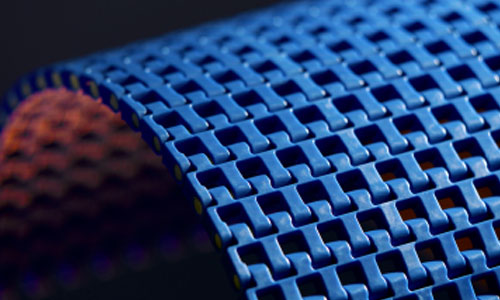

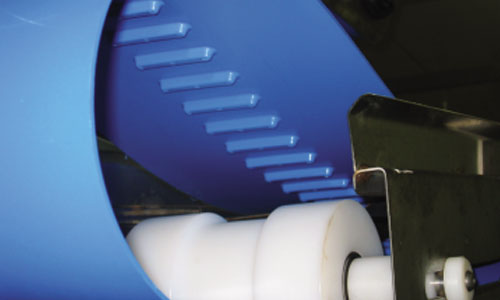

Modular Belts

- Modular Belts are positive drive, low-noise and long

lasting.

Assembled in a bricklay pattern, they can be made to almost any length and width and a wide-range of accessories are available to customize the belt for specific applications or processes.

We are now proud to be able to offer two key modular product brands to our customers.

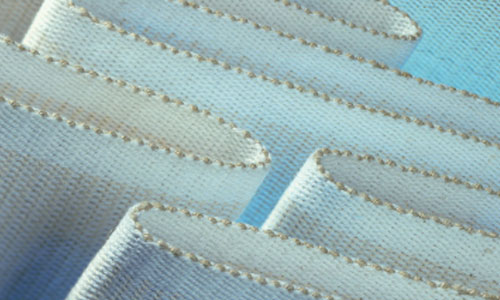

Endless Woven Belts

- Unique belts with unique characteristics

When the absence of a splice is important (or if the splice on a belt is proving problematic), or if you need higher belt strength or wish to ensure continuous product quality, or if a belt needs to absorb moisture or extreme preciseness is required, Ammeraal Beltech’s Endless Woven Belts are the right solution.- Outstanding force / elongation properties

- Operating temperature range: from -112 °F to 662 °F

- Belt tension up to 450 N/mm Belt speeds up to 65 f/s

- Can be used on small pulleys and/or knife edges

- Wear-resistance

- Heavy duty applications

ZipLink® Belts

- ZipLink® is the ultimate solution to drop expensive

machine downtime and improve performance and quality output. In every

industry machine downtime is public enemy number 1. ZipLink® is the

solution! ZipLink® Belts can be installed in minutes on the large majority

of equipment without the need of specialised labour or external service.

This resulting in major savings and extra production time!

ZipLink® Belts have virtually no splice area, meaning no weaker point in the whole belt. This resulting in the chance of production speed increase. More output!

Our ZipLink® Belts have no extra thickness spots, or metal part to damage machineries and goods. Better quality of products!

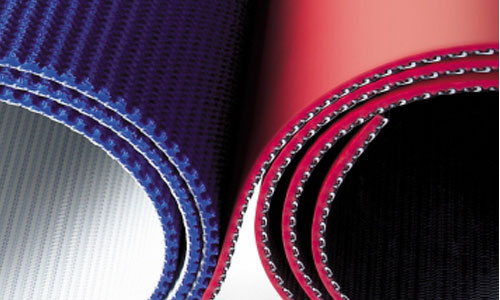

Lightweight Rubber Belts

- In our modern production facility, we produce more styles

and variations of lightweight rubber belting than any other belting

manufacturer.

With over 2,100 single-ply and multi-ply belting constructions, we provide durable belting solutions for almost every industry, and have done so for over 60 years.

Lightweight conveyor belts in rubber elastomer, EPDM and silicone. Produced and delivered efficiently and effectively.

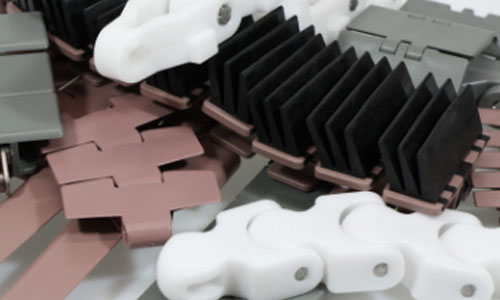

Plastic & Steel Chains

- Innovative and flexible chain solutions for all

applications and industries.

We are now proud to be able to offer two key product brands to our customers.

Volta Belts

- Volta Belting’s homogeneous belts are known for their

high material strength, superior dimensional exactitude and stability. The

materials are cut- and wear-resistant and impervious to water, oils and

other fluids. They are easy to install on-site, with a minimum of

contamination to the work area, and, if damaged, can be repaired efficiently

by closing tears or replacing sections.

In general industries, the belts come into their own by offering superior durability (“for a lifetime”) and savings in maintenance and downtime. Volta Belts serve specialized industries such as:Food

- Meat & Poultry

- Fish & Seafood

- Vegetable Processing

- Bakery & Confectionery

- Dairy

Non-Food

Automotive

Metal Processing

Ceramic Tile & Clay/Shingle Roof Tile

Recycling

Brick Manufacturing

Injection & Blow Molding

Volta Belting also offers the largest range of round and trapezoid (V) profiles. In a number of key industries, the profiles can be used as rings to drive roller beds.

RAPPLON® High Performance Flat Belts

- Ammeraal Beltech offers a complete range of high-quality Power Transmission Belts for industry, suitable for a wide variety of production equipment.

From classic nylon core belting to belt constructions with special fabrics for low tensions and thermoplastic inner layers, we can offer you the best belting solution for your specific application.

Surface covers include fabric, leather, natural rubber, elastomer and many thermoplastic coatings. For special applications seamless covers are available.

- Stable running at high-speed

- Excellent tracking

- Wear-resistant

- Maintenance-free

- Energy efficient

Timing Belts

- The Timing Belt range offered by Ammeraal Beltech is the

ideal solution if your product or production process demands accurate

synchronisation of time and distance.

Produced in a new state-of-the-art factory, our Timing Belts offer different pitches, tooth shapes, dimensions, cord and covering materials.

Ammeraal Beltech positive drive Timing Belts: for slip-free or synchronous conveying to repetitive precise positioning of your products.

Engineered Belts

- In addition to the more common belts we keep in stock, we

also have a vast range of custom made belt options available for clients to

choose from.

With our Engineered Belts we pay special attention to the individual requirements of your plant or machinery. Even extremes of strength, exact dimensional tolerances and surface quality specification can be catered for using our modern fabrication techniques.

Ultrasync Belts

- For positive drive and synchronous conveying

Ultrasync Belts are fabric based positive drive belts, combining the advantages and characteristics of synthetic conveyor belts and positive drive belts like modular and timing belts.

Applications:- Synchronous conveying and positioning

- Food processing

- Tire and wood processing lines

- Packaging machines and lines

- Hygienic paper production lines

- Vacuum applications

- Improved tracking & non-stick profiles

- No slippage, even in wet and oily conditions

- Bi-directional conveying

- Reduced maintenance

- Available in Food Grade

- Available in blue color for detection of contamination

Homogeneous Round & V-belts

- In many Food Industry processing applications, Food Grade

polyurethane and polyester round & V-belts are best suited to fulfill the

application requirements, particularly when handling sliced meats, cheese

and for topping and packaging lines.

Typical applications:- Food processing

- Transport systems

- Cooling lines

- Topping lines

- Packaging lines

Ultrascreen Belts

- Ultrascreen Mesh Belts are made of polyester monofilaments and are fabricated with lateral and longitudinal strips to provide stability. All belts have completely-closed belt edges for improved hygiene and safety. An excellent choice when draining is required, for example in the processing of vegetables, fruit and seafood.

PTFE Belts

- Ammeraal Beltech’s PTFE belts are the smart solution for a

wide variety of baking and freezing applications.

Applications:- High-temperature or open-flame ovens (e.g. pita & piadina bread)

- Non-stick applications

- Press-baking processes (e.g. tortillas, pizza bases, flatbreads)

- Cryogenic freezing chambers