- Offer Profile

-

LIMON was founded in 2002. We concentrate on customizing automation products and providing professional solutions for our global customers. Our company mainly focus on linear guideway, ball screw, linear unit, hollow rotary actuator, linear motor and other linear motion components, all of which have been widely used in major industrial fields like LCD panel industry, electronic industry, photovoltaic industry, automation industry, auto industry and so on. We provide more than 1400 solutions for customers.

LIMON Linear Motion Products

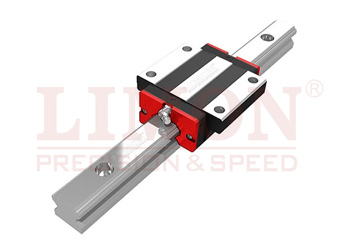

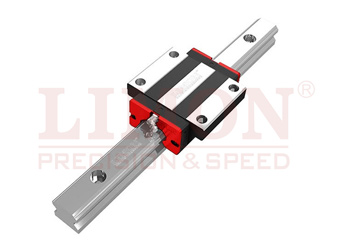

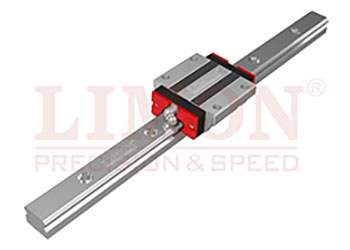

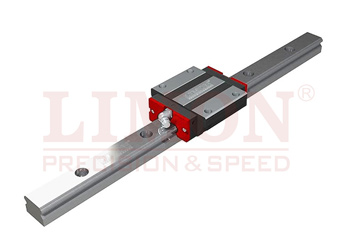

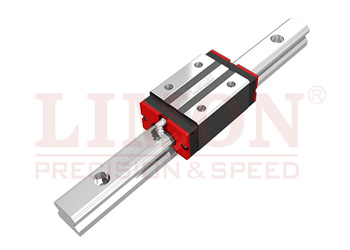

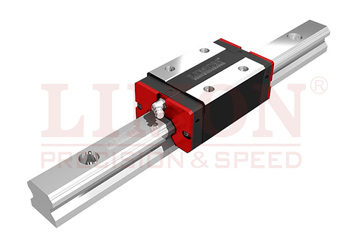

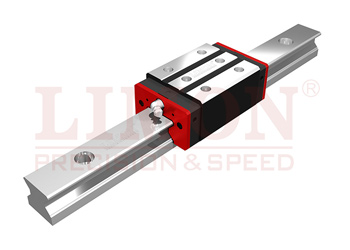

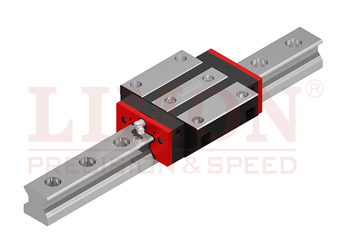

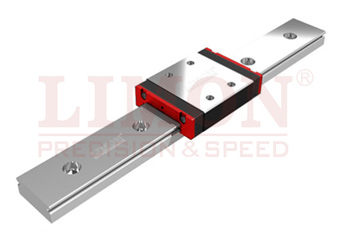

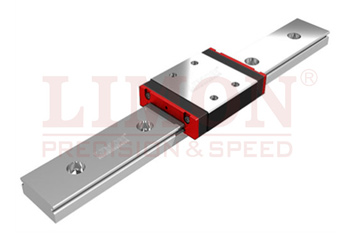

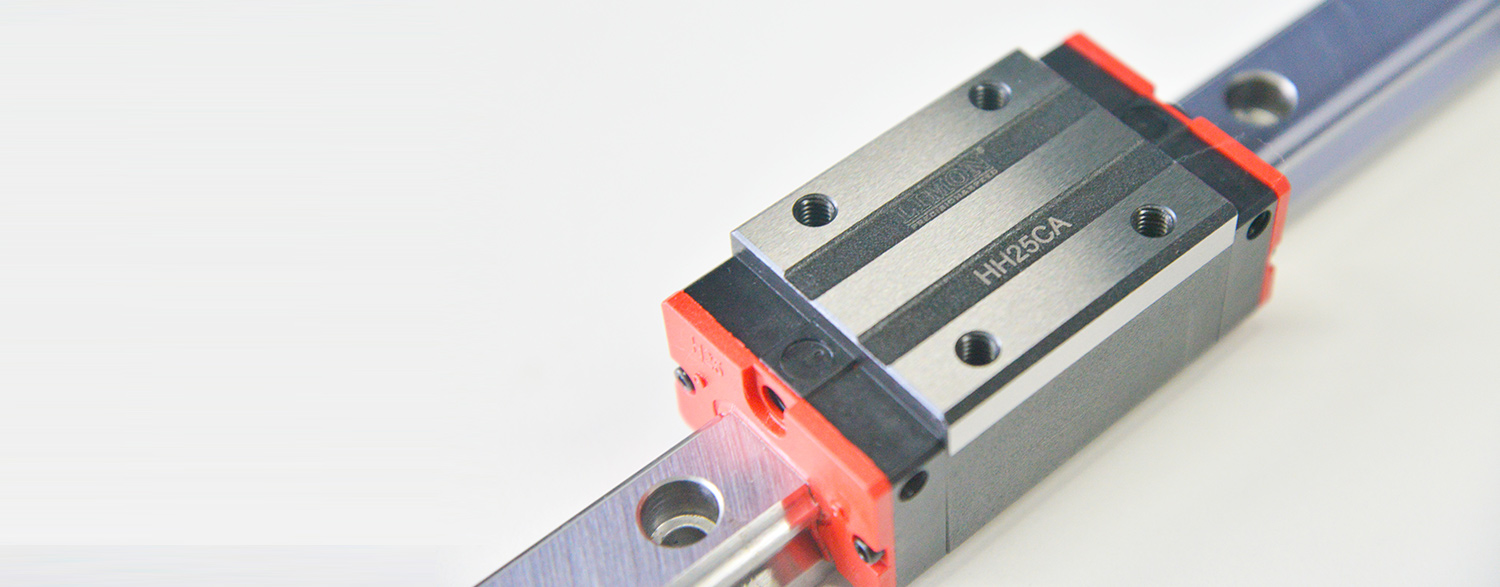

Linear Guideways

-

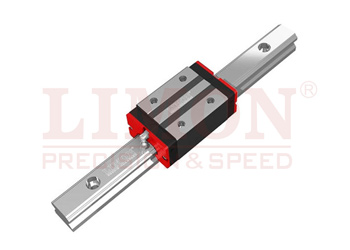

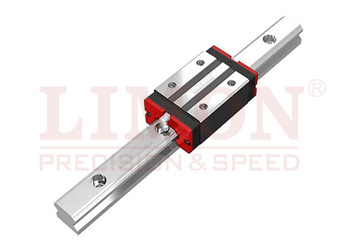

LIMON linear guideway allows a type of linear motion that utilizes rolling elements such as balls or rollers. By using re-circulating rolling elements between the rail and the block, the load platform can easily move linearly with high precision along the slide rail. Compared to a traditional slide, the coefficient of friction for a linear guideway is only 1/50. With these features, linear guideways can greatly enhance moving accuracy, especially, when accompanied with precise ball screws.

LIMON offers a variety of linear guide rail series, each with different sizes, load capacity, precision and more other option.- Size: 15~45.

- Precision: C, H, P.

- Lubrication block & 6 meter guideway available.

- Various accessories, KK, DD, ZZ.

- Korean material & Taiwan equipment.

- Strict quality control from incoming material to finished product.

- Clean assembly room for block.

Ball Screw

-

We are the manufacturer of linear motion products, ball screw is one of our successful product, it performs well at noise control. Ball screw are ideal for converting rotary motion into linear motion or converting linear motion into rotary motion. Ball screw is the most commonly used transmission component in tool machinery and precision machinery. Its main function is to convert rotary motion into linear motion or to convert torque into axial repetitive force, which is high precision,reversibility and high efficiency.

- Size:12mm~80mm.

- Length:6 meter.

- Precision:C3,C5,C7.

- Different application.

- Double nut available.

- Black coating.

- Left and right turning available.

- Strict quality control from incoming material to finished product.

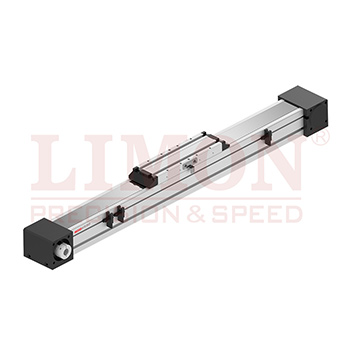

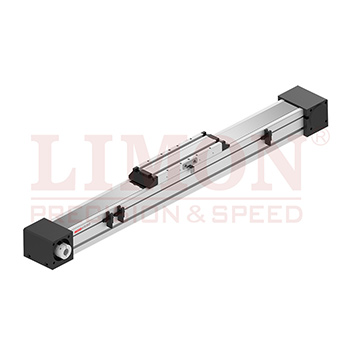

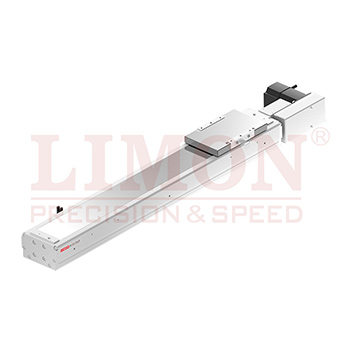

Linear Module

-

Our linear modules are divided into belt driven type and ball screw driven type, we provide both close and open type for different working environment.

For our basic type, the repositioning accuracy of ball screw driven actuator is ±0.01mm mm, maximum speed, a meter per second. For belt driven actuator, precision is ±0.05mm mm and maximum speed 5 meters per second. The design includes belt support, so it can provide long meters solutions, we have many successful applications, the maximum one reached 12 meters.- Belt/ ball screw driven type available.

- High load-bearing capacity.

- Ball screw driven type precision: +/- 0.01mm.

- Belt driven type precision: +/- 0.05mm.

- Both open type and close type are available for different working environment.

- Integrated design keep the stability and save space.

- Flexible installation and easy operation.

- External oil system, convenient maintenance.

- Customized solution.

- Multi-axis solution available.

- 7 working days for standard products.

Linear Bushing

-

- Diameter:4mm~100mm.

- Wide product range.

- Unique automatic workshop.

- Steel cage available.

- Nickel coating.

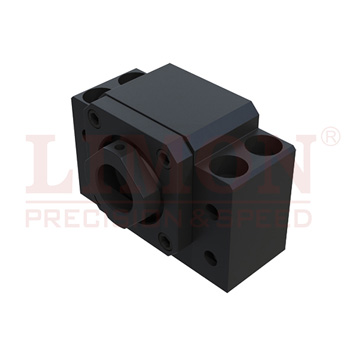

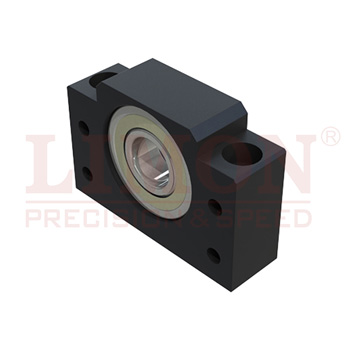

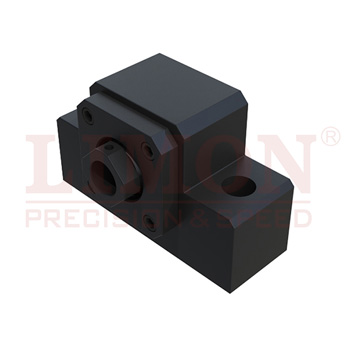

Support

-

- High load.

- High stiffness.

- High rigidity low torque angular contact bearing.

- Small size and easy to install.

- Support units are available in angular and circular series and can be selected according to the purpose.

Hollow Rotary Actuator

-

- High load.

- High Stiffness.

- High repetitive accuracyy: ±15arc-sec.

- Flatness & concentricity: 0.02mm.

- Digital control.

- Integrated with gear ratio.

- Multi-points positioning.

- Competitive cost.

- Replace six-axis solution.

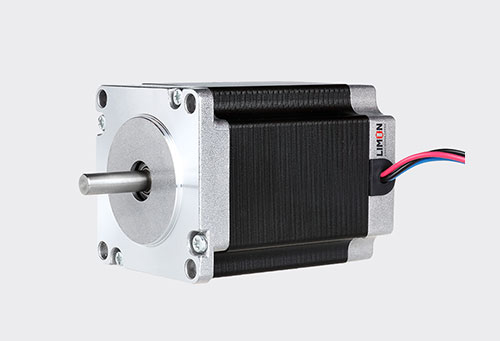

Stepper Motor

-

Stepper motor is a brushless, synchronous electric motor that converts digital pulses into mechanical shaft rotation. Its normal shaft motion consists of discrete angular movements of essentially uniform magnitude when driven from sequentially switched DC power supply. Stepper motor is a digital input-output device. It is particularly well suited to the type of application where control signals appear as digital pulses rather than analog voltages. One digital pulse to a stepper motor drive or translator causes the motor to increment one precise angle of motion. As the digital pulses increase in frequency, the step movement changes into continuous rotation. Some industrial and scientific applications of stepper motors include robotics, machine tools, pick and place machines, automated wire cutting and wire bonding machines, and even precise fluid control devices.

Advantages:- Life of The Stepper Motor

- Holding Torque Of The Stepper Motor

- Maintenance Cost Of The Stepper Motor

- Repeatabiity Of The Stepper Motor

- Excelent Low Speed Torque

- Cost And Compexity Of The Stepper Motor

Stepper Motor Driver

-

Stepper motor driver is an actuator that converts electrical pulse into angular displacement. Stepper motor and stepper motor driver constitute a stepper motor drive system. Stepper motor is a kind of special motor used as control. Its rotation is run step by step at a fixed Angle (called step Angle). It is characterized by no accumulation error, so it is widely used in various open-loop control. The operation of the stepper motor must be driven by an electronic device, which is the Chinese stepper motor driver. It converts the pulse signal issued by the control system into the angular displacement of the stepper motor. In other words, each pulse signal sent by the control system will make the stepper motor rotate one step distance Angle through the driver. So the speed of the Chinese stepper motor is proportional to the frequency of the pulse signal.

Advantages:

- The low frequency oscillation of the motor is completely eliminated

- The output torque of the motor is improved

- Improve the resolution of the motor

Linear Stepper Motor

-

The basic principle of linear stepper motor: using a screw and nut meshing, take some way to prevent the relative rotation of the screw nut, so that the screw axial movement. Generally speaking, there are two ways to achieve this transformation at present. The first way is to build a rotor with internal thread in the motor to achieve linear motion with the internal thread of the rotor meshing with the screw. The second way is to use the screw as the shaft of the motor to achieve linear motion through an external drive nut meshing with the screw outside the motor. Therefore, the design has been greatly simplified, making it possible in many applications to use linear stepper motors directly for precise linear motion without the installation of external mechanical linkages.

Advantages:

- Wide range of feed speed.

- Velocity deviation can be less than 0.01%

- High acceleration

- High positioning accuracy (0.1~ 0.01 mm)

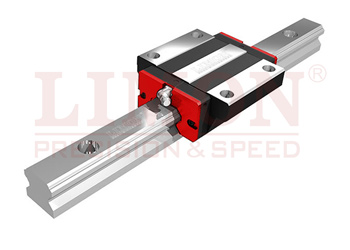

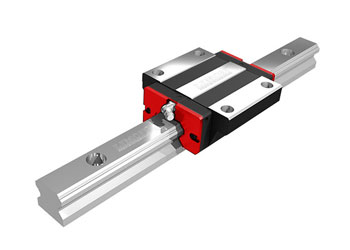

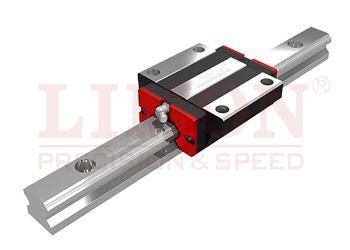

Linear Guideways

-

LIMON linear guideway allows a type of linear motion that utilizes rolling elements such as balls or rollers. By using re-circulating rolling elements between the rail and the block, the load platform can easily move linearly with high precision along the slide rail. Compared to a traditional slide, the coefficient of friction for a linear guideway is only 1/50. With these features, linear guideways can greatly enhance moving accuracy, especially, when accompanied with precise ball screws.

LIMON offers a variety of linear guide rail series, each with different sizes, load capacity, precision and more other option.

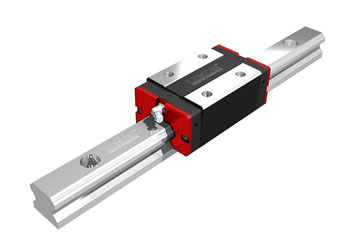

H Series - Linear Guide

-

Applicable industries of H series:

Grinding,Milling, and Drilling machine,Lathe,Electric discharge machine, Wire cutting machine, Wood cutting machine,Precision measure equipment, Machine centerSelf-aligning capability

By design, the circular-arc groove has contact points at 45 degrees. H series can absorb most installation errors due to surface irregularities and provide smooth linear motion through the elastic deformation of rolling elements and the shift of contact points. Self-aligning capability, high accuracy and smooth operation can be obtained with an easy installation.Interchangeability

Because of precision dimensional control, the dimensional tolerance of H series can be kept in a reasonable range, which means that any blocks and any rails in a specific series can be used together while maintaining dimensional tolerance. And a retainer is added to prevent the balls from falling out when the blocks are removed from the rail.High rigidity in all four directions

Because of the four-row design, the H series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. Furthermore, the circular-arc groove provides a wide-contact width between the balls and the groove raceway allowing large permissible loads and high rigidity. E Series - Linear Guide

QH Series - Linear Guide

QE Series - Linear Guide

R Series - Linear Guide

M Series - Linear Guide Miniature Guide

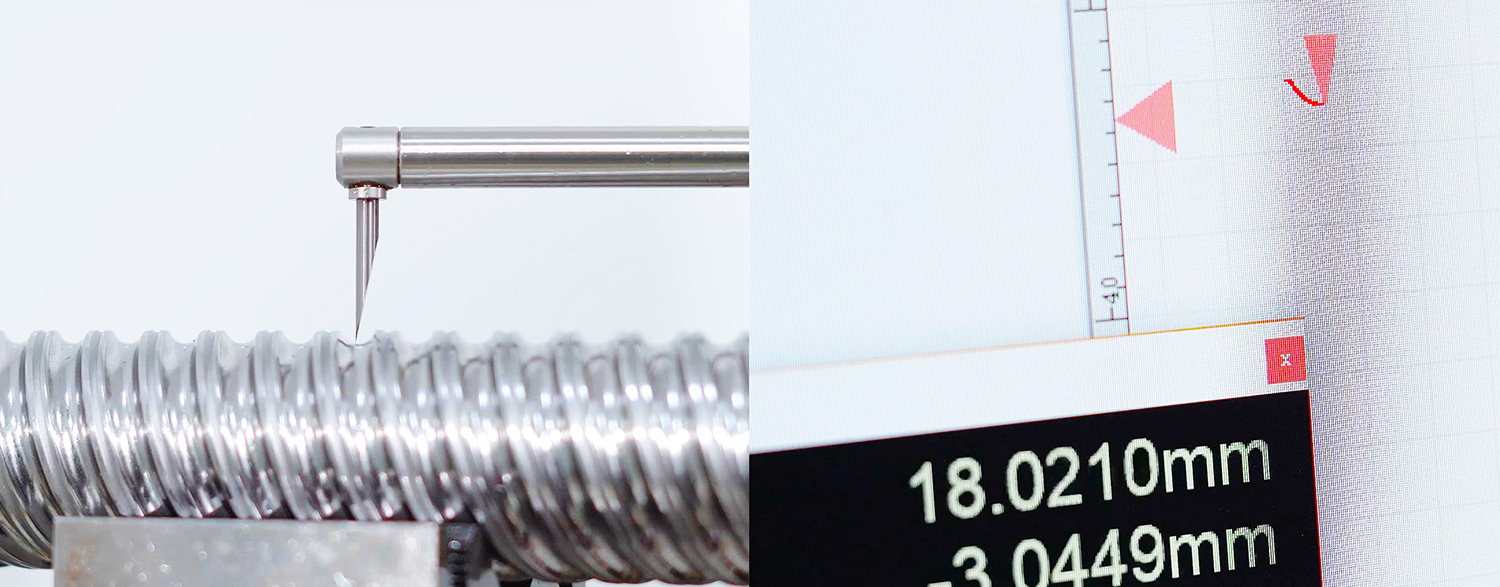

Ball Screw

-

We are the manufacturer of linear motion products, ball screw is one of our successful product, it performs well at noise control. Ball screw are ideal for converting rotary motion into linear motion or converting linear motion into rotary motion. Ball screw is the most commonly used transmission component in tool machinery and precision machinery. Its main function is to convert rotary motion into linear motion or to convert torque into axial repetitive force, which is high precision,reversibility and high efficiency.

Characteristic:

- Full range size 12mm-80mm

- Rolled & grind ball screw

- Bi-direction

- Double nut available

- Steel retainer

- Black coating

- Various option

- Strict quality control

- High Reliability

LIMON applies stringent quality control standards on every production process.With proper lubrication and use, trouble-free operation for an extended period of time is possible - The high efficiency of ball screw is vastly superior than conventional screws. It takes less than 30% torque to make the linear motion into rotary motion.

- High Rigidity and Preload

The ball screw of LIMON is designed with Gothic arch groove,which makes the screw easy to rotate even using minimum axial play. To make the rigidity more appropriate to using condition, you can change the preload between one or two screw nuts to reduce axial play. Regular Ball Screw

SFS Series

SFU Series

SFY Series

SFI Series

SFK Series

SFDC Series

DFU Series

DFS Series

DFI Serise

DFDC Series

Linear Module

- Our linear modules are divided into belt driven type and ball screw driven type, we provide both close and open type for different working environment.

For our basic type, the repositioning accuracy of ball screw driven actuator is ±0.01mm mm, maximum speed, a meter per second. For belt driven actuator, precision is ±0.05mm mm and maximum speed 5 meters per second. The design includes belt support, so it can provide long meters solutions, we have many successful applications, the maximum one reached 12 meters.

What’s more, the motor positions of our module are freely select-able and convertible. Strong inside structure with optimized cover profile. Special design for both space and cost saving. Multi-axis solution is also available, including necessary connecting parts, motor drive, reducer, drag chain belt, etc.

LIMON always concentrate on enriching the value of our products for our customers, we have the ability to design and also can provide customized solutions. Our engineering team is rich experienced, we have the ability to design and also customized solutions. We are committed to supply more efficient and satisfied cases to the clients. Before sales, by using LIMON calculate system and considering the risk analysis, our engineers will choose the most safe, and cost-effective type for our customers.

We have been working with our Taiwan engineers since 2012. Both ball screw driven type and belt driven type are designed to be very flexible with multiple components ability, it is easy to assemble.

Stronger, faster, and able to support more weight than competing choices, LIMON’s extremely efficient electric cylinder type linear actuators were conceived to save space, save energy, save time, and save labor costs. Belt Driven Linear Actuator - I Series

ITO Open type

- Classification: Open type

Drive type: Belt drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 42*53mm.80*79mm.100*106mm.130*130mm.166*106mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

ITC Close type

-

Classification: Close type

Drive type: Belt drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 80*79mm.100*106mm.130*130mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

ITZ

- Driver type: Synchronous belt driver

Sealed type: general environment, semi sealed

Repeat positioning accuracy: ±0.05mm

Maximum dimension of main section: 80*150.5mm

High carrying capacity

High-speed transplanting

Easy to install and operate

Super long travel can be customized

Belt Driven Linear Actuator - H Series

HTO Open type

- Classification: Open type

Drive type: Belt drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 102.5*79.106*122m.130*151mm

Heavy load capacity: Under the same working conditions, the load is nearly 2 times larger than that of the I series

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

HTC Close type

- Classification: Close type

Drive type: Belt drive

Sealed type: Clean room environment, fully enclosed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 106*122mm.130*151mm

Heavy load capacity: Under the same working conditions, the load is nearly 2 times larger than that of the I series.

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

Belt Driven Linear Actuator - Y Series

YTO Open type

- Classification: Open type

Drive type: Belt drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 105*66mm.102*70mm.135*93mm.170*108mm.230*134mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

YTC Close type

- Classification: Close type

Drive type: Belt drive

Sealed type: Clean room environment, fully enclosed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 109*82.5mm.135*91mm.170*107mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

Belt Driven Linear Actuator - Multi Axis Solution

-

Linear Motion Systems can be used in various industries. While providing uniaxial modules, LIMON can also provide multi-axis combined projects.

We have a wide range of supports and installation components required for the complete linear unit motion system, including necessary connecting parts, motor drive, reducer, drag chain belt, etc.

Besides, our technicians also participates in customer projects, calculates design strength, and provides customers with a solid and a complete set of solutions. As for size selection and system selection, please feel free to talk to us for more details

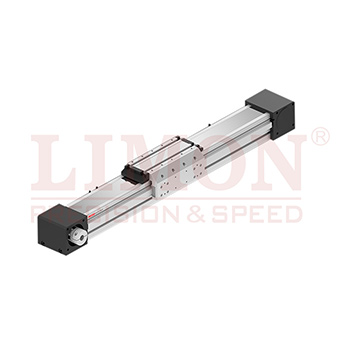

Single Axis Stages - KS Series

- In the beginning, customers would like to buy accessories, then put them into use after self-assembly to reduce cost. However, assembly and testing is necessary. So actually, the comprehensive cost is relatively higher.

So, gradually, linear unit come to the market. After trying, end users will find that linear unit are more convenient and improve the efficiency greatly. Now, we launched KS module, which not only save the cost, but also meets the requirements for high efficiency.

Classification: Open type

Drive type: Ball screw drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.005mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Single Axis Stages - KS 50

Single Axis Stages - KS 60

Single Axis Stages - KS 86

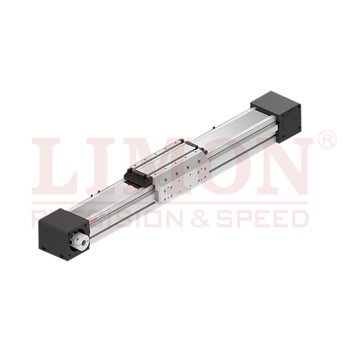

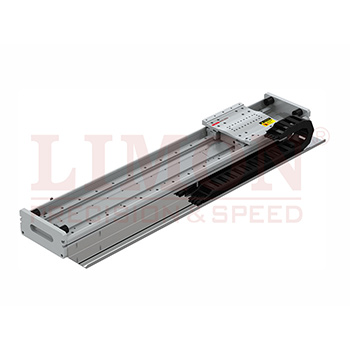

Built in Guideway Ball Screw Linear Actuator - GSC Series

-

The body and sliding seat are formed in one, so the rigidity is enhanced.

Special steel strip structure design, reduce dust, can be used in dust-free environment

It can be installed without dismantling the steel strip

Increase the side of the body against the base level

There are positioning holes at the bottom of the body.

Small size saves space for installation

Aluminum body structure increases the strength, and grinding treatment after aluminum body embedded in track, therefore, the parallelism and straightness while walking will also be improved.Classification: Close type

Drive type: Ball screw drive

Sealed type: Clean room environment, fully enclosed

Repetitive accuracy:±0.01mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

Built in Guideway Ball Screw Linear Actuator

- GSC 50

Built in Guideway Ball Screw Linear Actuator - GSC 80

Built in Guideway Ball Screw Linear Actuator - GSC 120

Ball Screw Driven Linear Actuator - Y Series

- Most of the products can be installed with the same hole position as YAMAHA, which can be exchanged with several Taiwanese brands then, strength of angular contact bearing increases by matching with FK ball screw support. The optimal design of cover is to avoid the over length hanging down.

The belt’s features are the same as the screw type. And we provide the reducer device as the standard product, in this way, our customer can save the cost .

Industrial: LCD panel manufacturing, photovoltaic industry, white goods production line, lithium battery manufacturing, automation industrial.

BALL SCREW DRIVEN TYPE

Close type: 100/110/135/170/220

Open type: YSO100/110/135/170

Repeated positioning accuracy: 0.01mm

Maximum length:15000mm

Maximum speed:1000mm/sec

This series is uniaxial modules. While providing uniaxial modules, LIMON can also provide multi-axis combined projects, including necessary connecting parts, motor drive, reducer, drag chain belt, etc. Besides, our technicians also participates in customer projects, calculates design strength, and provides customers with a complete set of solutions.

YSO - Open type

- Classification: Open type

Drive type: Belt drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.01mm

Maximum outline size of the main section:105*66mm.105*70mm.135*78mm.107*97mm.230*97mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

YSC - Close type

- Classification: Close type

Drive type: Belt drive

Sealed type: Clean room environment, fully enclosed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 108*78.5mm.109*82.5mm.135*91mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

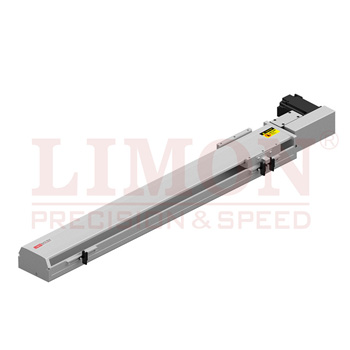

Linear Motor Driven - ZLO Series

- Application industry:

3D Scanner, Image Scanning, Laser Testing, High-end automation equipment, LCD panel high-speed laser drilling machine, all-linear motor six-axis CNC drilling machine, high-speed and high-precision SMT mounter, high-speed transplanting equipment

Before the advent of practical and affordable linear motors, all linear motion had to be converted from rotating machinery by using ball or roller screw or belt or pulley. For many applications, such as heavy load and the drive shaft is vertical. These methods are still the best. However, linear motor has many unique advantages over mechanical system, such as very high speed and very low speed, high acceleration, almost zero maintenance (no contact parts), high precision and no idle return. To complete the linear motion, only the motor is needed, and there is no gear, coupling or pulley. It is very meaningful for many applications. Those unnecessary parts that reduce performance and shorten mechanical life are removed.

Basic Information:

Maximum acceleration: 4G

Ultra-high absolute positioning accuracy <1 min

Full closed loop feedback system

Anti-deformation and vibration design

Core-free vibration (Yaskawa: 0.4; Jacobs: 0.76; hiwin: 0.8)

Setting time is short: the test method is running 0-30.30-0 back movement, which takes 0.052s

ZLO17

- Classification: ZLO Series

Drive type: Motor drive

Sealed type: General environment, semi-sealed

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

ZLO22

- Classification: ZLO Series

Driver type: Motor drive

Sealed type: general environment, semi sealed

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

Linear Motor Driven - WLO Series

- Application industry:

3D Scanner, Image Scanning, Laser Testing, High-end automation equipment, LCD panel high-speed laser drilling machine, all-linear motor six-axis CNC drilling machine, high-speed and high-precision SMT mounter, high-speed transplanting equipment

Before the advent of practical and affordable linear motors, all linear motion had to be converted from rotating machinery by using ball or roller screw or belt or pulley. For many applications, such as heavy load and the drive shaft is vertical. These methods are still the best. However, linear motor has many unique advantages over mechanical system, such as very high speed and very low speed, high acceleration, almost zero maintenance (no contact parts), high precision and no idle return. To complete the linear motion, only the motor is needed, and there is no gear, coupling or pulley. It is very meaningful for many applications. Those unnecessary parts that reduce performance and shorten mechanical life are removed.

Basic Information:

Maximum acceleration: 4G

Ultra-high absolute positioning accuracy <1 min

Full closed loop feedback system

Anti-deformation and vibration design

Core-free vibration (Yaskawa: 0.4; Jacobs: 0.76; hiwin: 0.8)

Setting time is short: the test method is running 0-30.30-0 back movement, which takes 0.052s

WLO14

- Classification: WLO Series

Drive type: Motor drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section: 148*89mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

WLO17

- Classification: WLO Series

Drive type: Motor drive

Sealed type: General environment, semi-sealed

Repetitive accuracy: ±0.05mm

Maximum outline size of main section:148*89mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

WLO22

- Classification: WLO Series

Driver type: Motor drive

Sealed type: general environment, semi sealed

Repeat positioning accuracy: ±0.05mm

Maximum dimension of main section: 230*120mm

Strong carrying capacity

High-speed transplanting

Easy assembly and operation

Long stroke can be customized

Linear Motor Driven - PSA Series

- Application industry:

3D Scanner, Image Scanning, Laser Testing, High-end automation equipment, LCD panel high-speed laser drilling machine, all-linear motor six-axis CNC drilling machine, high-speed and high-precision SMT mounter, high-speed transplanting equipment

Before the advent of practical and affordable linear motors, all linear motion had to be converted from rotating machinery by using ball or roller screw or belt or pulley. For many applications, such as heavy load and the drive shaft is vertical. These methods are still the best. However, linear motor has many unique advantages over mechanical system, such as very high speed and very low speed, high acceleration, almost zero maintenance (no contact parts), high precision and no idle return. To complete the linear motion, only the motor is needed, and there is no gear, coupling or pulley. It is very meaningful for many applications. Those unnecessary parts that reduce performance and shorten mechanical life are removed.

Basic Information:

Maximum acceleration: 4G

Ultra-high absolute positioning accuracy <1 min

Full closed loop feedback system

Anti-deformation and vibration design

Core-free vibration (Yaskawa: 0.4; Jacobs: 0.76; hiwin: 0.8)

Setting time is short: the test method is running 0-30.30-0 back movement, which takes 0.052s

PSA14*14

- Classification: PSA Series

Load: 15kg

Flatness/Straightness: ±0.01mm/±0.005mm

Speed: 1m/s

Accelerated Speed: 1G

Stroke: 140*140mm

Repetitive Positioning Accuracy: ±2μ

Absolute Positioning Accuracy: ≤5μ

PSA25*25

- Classification: PSA Series

Load: 15kg

Flatness/Straightness: ±0.01mm/±0.005mm

Speed: 1m/s

Accelerated Speed: 1G

Stroke: 250*250mm

Repetitive Positioning Accuracy: ±2μ

Absolute Positioning Accuracy: ≤5μ

PSA35*35

-

Classification: PSA Series

Load: 15kg

Flatness/Straightness: ±0.01mm/±0.005mm

Speed: 1m/s

Accelerated Speed: 1G

Stroke: 350*350mm

Repetitive Positioning Accuracy: ±2μ

Absolute Positioning Accuracy: ≤5μ

Hollow Rotary Actuator

-

Accurate data: Now LIMON hollow rotary actuators are sized in 60,85,135,200. The surface is through high and middle heat treatment which the grinding precision can be ISO6 and surface hardness HRC 65.Also the repetitive accuracy is ±15arc-sec, and concentricity&flatness ±0.05 mm.

Strength: These data above is under the strict control by LIMON to show its quality, now the hollow rotary actuator is applied in different industries especially in the 3C industry like the grinding machine of mobile phone shells also highly matched with the linear module for some applications.- Bottom and Workbench Contact, except the four screw holes, the center ring directly below the bearing also contacts the worktable.

- Our pinion module is larger than other brands, other brand modulus is 0.8-0.9, we are 1.25, so at high deceleration ratio of 18, our gear strength is better.

- There are steel rings at the bottom, and the load is borne by steel parts, in case the bearing presses the aluminium structure to deform clearance.

- An integrated design of gear and cross roller bearings is under developing, it can improve rotation accuracy and stability.

- Electroless nickel plating on working face, heat-treat, to prevent rusting and scratching.

Industries: Now the hollow rotary actuator is applied in different industries especially in the 3C industry like the grinding machine of mobile phone shells, also visual testing equipment, Laser equipment industry, Semi-conduct equipment industry, etc.

- High load

- High stiffness

- Digital control

- Multi-points positioning

- Repeated positioning accuracy: ±15arc-sec

- Flatness & concentricity: 0.02mm

- Competitive cost

- Replace six-axis solution

DY200 Hollow Rotary Actuator

DY130 Hollow Rotary Actuator

DY85 Hollow Rotary Actuator

DY60 Hollow Rotary Actuator

Linear Bushing

- LIMON linear bushing have the advantages of wide product range, unique automatic workshop, different design and nickel coating & steel cage available. We start to export linear bushing from 2003. Due to our reliable quality and service, we soon become a leading manufacturer of linear bushing in China , and we built a good image and reputation in the oversea market.We have more 15 year experences for linear bushing parts. In the begining we help our JAPANESE customer do OEM. After so many year experence, now we are the leading manufactuer of linear bushing in China and also we are the only automatic manufacturer to produce linear bearing in China.

Linear Motion Ball Bearing

Linear Motion Ball Bearing

Flanged Linear Motion Ball Bearing

Slide Unit

Shaft Support

Support

- The support seat is the bearing fixed seat connecting the screw rod and the motor. It is the shaft end product of the standard ball screw. Support units are composed of a bearing housing,bearing,holding lid,seal,lock nut and set screws.The support unit can be used on Fixed and supported ends for the ball screw,which mounts the ball screw in the desired position. Limon offers various ball screw support units to satisfy the mounting or loading requirements of any application.The support unit can be used in the fixed end and the support end of the ball screw respectively to fix the screw in the correct position. It is compact in size, easy to install, and can be installed in a narrow space. Because the bearing already contains proper grease and is adjusted to the proper condition, it can be assembled to the equipment immediately without additional adjustment and processing, so as to reduce the assembly time and improve the accuracy and stability of assembly.

Applicable industries:Automation industry, Semi-conductor industry, Industrial machine, Medical industry, Green energy industry, Machine tool, Automated storage and retrieval system and etc.