Spectrum Scientific

- Offer Profile

- Spectrum Scientific, Inc (SSI)

has been manufacturing high volume flat, aspheric and freeform reflective

optics and holographic diffraction gratings since 2004. We primarily use the

optical replication process in our manufacturing allowing us to supply high

fidelity, high specification precision optics at a fraction of the

traditional cost of volume manufacturing.

One of our key capabilities is the manufacture of freeform optics, off-axis paraboloids and ellipsoid mirrors with surface figures down to λ/10 or better. We also manufacture plane, concave and convex holographic diffraction gratings, which can be supplied as blazed gratings using our proprietary blazing technique, which not only offers high efficiency in the UV, but lower stray light than conventional ion etched gratings.

Product Portfolio

Products

- Spectrum Scientific offers a number of standard and off

the shelf optics for OEM and research purposes. Many of these products can

be shipped directly from stock, while non-stock and custom modifications to

existing products can usually ship within a few weeks.

Spectrum Scientific can manufacture custom optics, meeting your criteria exactly. Contact our sales department for custom modifications to existing products, or to obtain volume pricing. Diffraction Gratings

- A diffraction grating is an optical element that

diffracts energy into its constituent wavelengths. The groove density, depth

and profile of a diffraction grating dictate the spectral range, efficiency,

resolution and performance of the diffraction grating.

There are typically two different types of diffraction grating – the ruled grating and the holographic grating. A ruled diffraction grating is produced by a ruling engine that cuts grooves into the coating on the grating substrate (typically glass coated with a thin reflective layer) using a diamond tipped tool. A holographic diffraction grating is produced using a photolithographic technique. The most common type of diffraction grating are plane gratings and concave gratings although they can also be other profiles such as convex or toroidal depending on the application.

Spectrum Scientific offers a wide range of holographic and ruled diffraction gratings, both blazed and sinusoidal in plane, toroidal, concave or convex format.

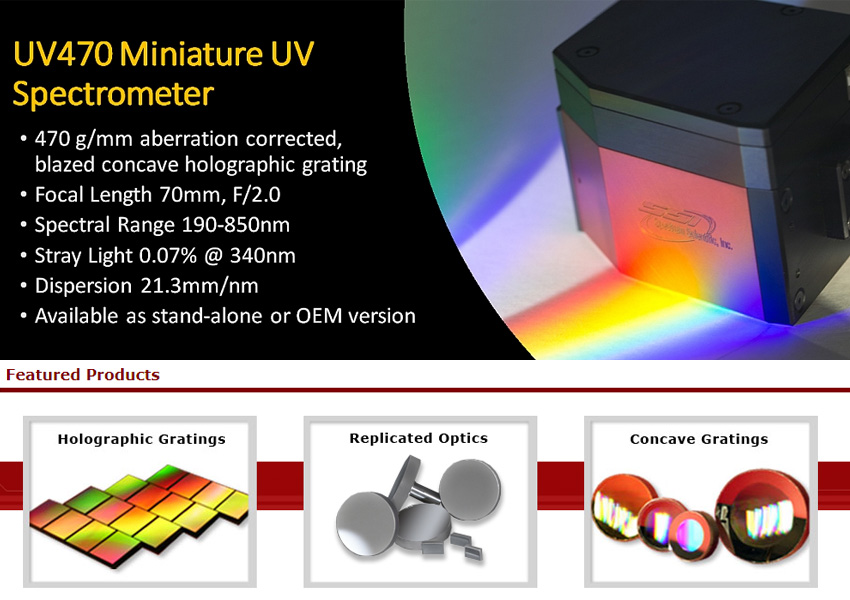

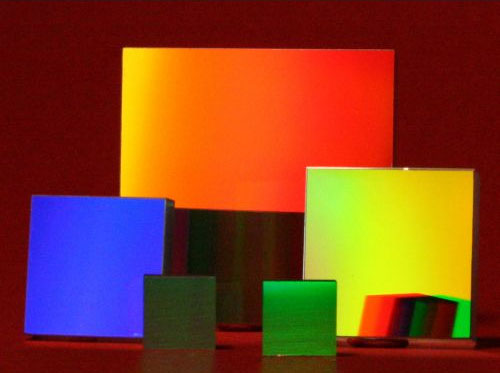

Holographic Diffraction Gratings

- Spectrum Scientific's holographic gratings are produced

using interference lithography. This process results in a smooth groove

surface and eliminates the periodic errors found in ruled gratings. Because

of this, holographic gratings are commonly used in applications where stray

light is a concern. Holographic gratings can have two groove profiles,

sinusoidal and blazed.

Sinusoidal groove profiles are the most common groove shape for holographic gratings. The grooves are symmetrical and therefore have no blaze direction. A sinusoidal grating offers a wider spectral coverage compared to a blazed grating but has lower efficiency.

Spectrum Scientific is one of the few companies in the world to offer a blazed holographic diffraction grating. A blazed holographic grating has had the sinusoidal profile transformed into a 'saw tooth' profile. This saw tooth profile increases the efficiency of the diffraction grating over the wavelength region of interest without increasing the stray light. Currently this technique is limited to a blaze region of 200-300mm.

Ruled Gratings

- A ruled diffraction grating is produced by using a diamond tipped tool to cut parallel grooves into the coating on the substrate. These grooves are cut in a blazed or ‘saw tooth’ profile which allows the grating to be optimized for a given spectral region. This allows ruled gratings to be optimized for any region of the spectrum. However ruled gratings are limited by large amounts of stray light due to a range of periodic errors, also known as ghosting effects.

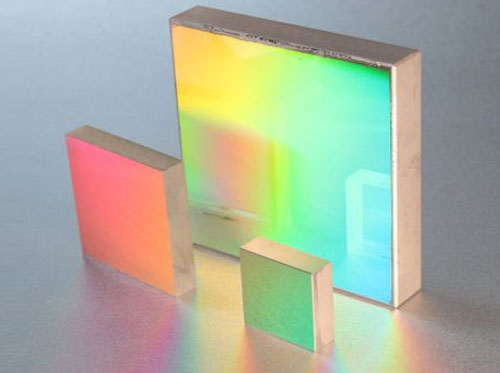

Pulse Compression Gratings

- Spectrum Scientific pulse compression gratings offer high efficiency coupled with excellent surface quality and high damage threshold. Pulse compression gratings are used to compress or stretch laser pulses and are commonly used in Chirped Pulse Amplification (CPA) laser systems. Typical substrate materials for pulse compression gratings include Zerodur®, Pyrex and fused silica. These gratings are supplied with a gold coating. Spectrum Scientific's pulse compression gratings come in a range of sizes for all needs.

Telecom Gratings

- Modern telecommunications allows for vast amounts of information to be moved through optical fibers. Gratings allow for the management of the signals in the fibers by separating the individual wavelengths, allowing access to the information. Spectrum Scientific offers a range of gratings for use in the telecommunication industry.

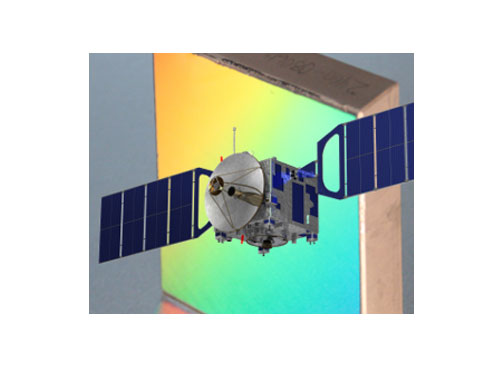

Space Qualified Gratings

- Spectrum Scientific has unrivalled expertise in the

design and manufacture of custom designed optics including supplying

ultra-low stray light, high efficiency gratings for a number of high profile

space projects, including the Orbiting Carbon Observatory (OCO) and Ozone

Mapping Profiler Suite (OMPS).

We operate a silicone free manufacturing facility for space optics with cleanroom production and test areas.

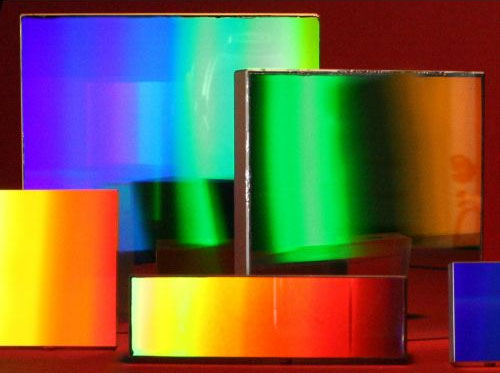

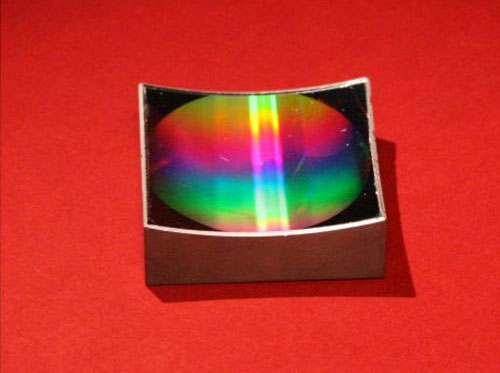

Concave Gratings

- Spectrum Scientific is one of the few companies in the world capable of manufacturing high quality blazed holographic concave gratings. Our proprietary technique allows us to optically blaze concave gratings without ion-etching which results in high peak efficiency and low stray light. SSI offers a wide range of both aberration corrected and monochromator concave gratings.

Monochromator Concave Gratings

- A constant deviation monochromator concave grating is used in scanning monochromators to scan the signal from the entrance slit across the exit slit. Spectrum Scientific’s constant deviation monochromator concave grating removes the need for collimation and focusing optics. This reduces the number of optical elements in the system, increases throughput and allows for a more compact instrument design.

Flat Field Concave Gratings

- Spectrum Scientific's flat field imaging concave grating

has grooves that are neither parallel nor equidistant.

This type of concave grating is designed to minimize astigmatism and coma and are suitable for spectrographs or other linear array devices. This makes the aberration corrected concave grating ideal for use with planar array detectors such as photo diode arrays (PDA) or charge coupled device (CCD) detectors.

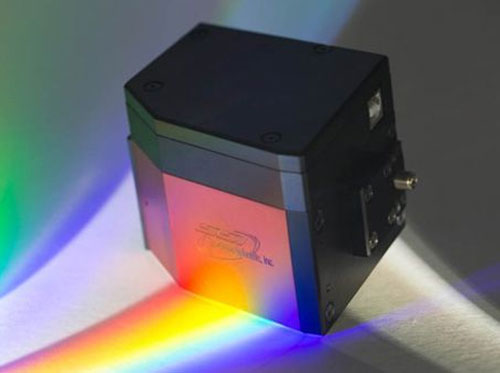

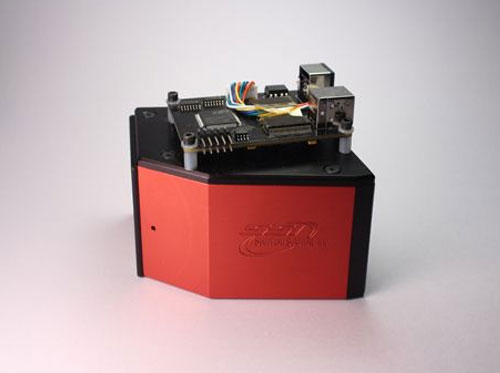

Spectrometers

- Spectrum Scientific, Inc. is excited to announce the

development of a line of spectrometers. We are currently in the beta-testing

phase of the 470 spectrometer, which utilizes our own 470 groove concave

grating. Various spectrometers are currently being modelled and prototyped.

Please contact us to request more information or a specific design today!

A spectrometer utilizes a diffraction grating to disperse light into orders, which can be read using an image sensor. By employing gratings made in-house, using our proprietary blazing method, Spectrum Scientific’s spectrometers offer high performance in a low cost package.

Spectrum Scientific’s line of spectrometers is available with either a concave grating or a plane grating. These spectrometers can be offered as a package complete with software and a detector or as a spectrometer engine, customizable with the user’s own software and detector.

UV-470 Standard

- Spectrum Scientific’s UV 470 spectrometer incorporates

our aberration corrected concave holographic grating. Our grating is blazed

to obtain peak performance in the UV region. The UV 470 spectrometer

operates in a spectral region from 190-850 nm.

The single holographic optical element design, delivers low stray light (0.07% @340 nm) which enhances the signal to noise ratio. You can select your slit size or order the UV 470 without the driver board for OEM Applications.

UV-470-151

- Spectrum Scientific’s UV 470 spectrometer incorporates

our aberration corrected concave holographic grating. Our grating is blazed

to obtain peak performance in the UV region. The UV 470 spectrometer

operates in a spectral region from 190-850 nm.

The single holographic optical element design, delivers low stray light (0.07% @340 nm) which enhances the signal to noise ratio. You can select your slit size or order the UV 470 without the driver board for OEM Applications.

UV-470 OEM

- Spectrum Scientific’s UV 470 spectrometer incorporates

our aberration corrected concave holographic grating. Our grating is blazed

to obtain peak performance in the UV region. The UV 470 spectrometer

operates in a spectral region from 190-850 nm.

The single holographic optical element design, delivers low stray light (0.07% @340 nm) which enhances the signal to noise ratio. You can select your slit size or order the UV 470 without the driver board for OEM Applications.

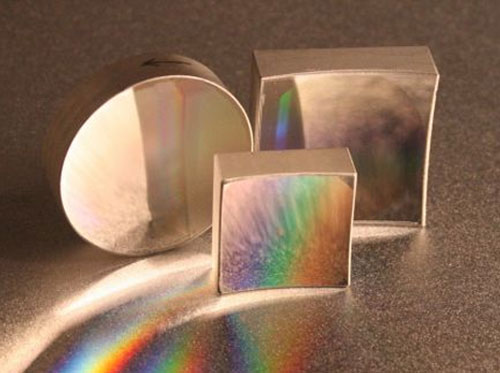

Precision Mirrors

- Spectrum Scientific offer a cost-effective solution to

producing low or high volume precision mirrors and optical components. The

optical performance and environmental stability of replicated optics is

equivalent to optics produced using conventional methods.

Available on a wide range of substrates including glass, aluminum and silicon carbide, replicated optics can be used in a variety of applications where complex optical surfaces are utilized. Often an optical surface can be replicated onto the mounting structure leading to easier alignment and further cost savings.

Replicated optics are manufactured by first producing a master to the required specification and then transferring the optical quality of the master to a substrate through a replication process rather than by conventional polishing (see the replication process explained). This process allows the production of optics that have nearly identical specifications as the originals at a fraction of the cost.

We offer silicone free production and test areas and are ISO 9000:2008 certified and space qualified.

In addition to custom manufactured mirrors, Spectrum Scientific offers a range of standard mirrors. If we do not have a mirror that meets your requirement, please contact our sales department as new mirrors are manufactured on a regular basis.

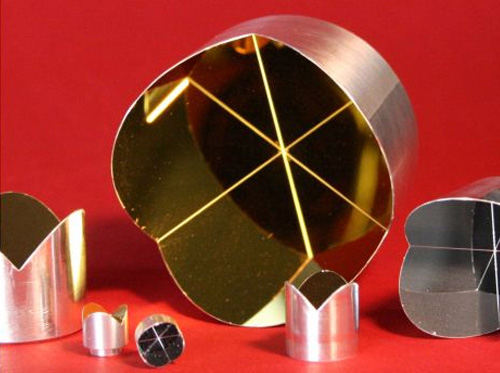

Hollow Retroreflectors

- Spectrum Scientific’s hollow retroreflectors (HR) have a rugged, one-piece construction made from solid aluminum, making them insensitive to vibration, position and movement. They are ideally suited for Michelson type interferometers, FTIR spectrometers and laser based tracking systems. Our standard HR coatings include aluminum and gold, in both bare metal form and with protective overcoats. We also offer custom mounting features directly incorporated onto the retroreflectors.

Off-Axis Parabolic Mirrors

- Spectrum Scientific’s off axis parabolic (OAP) mirrors

eliminate aberrations that are present when trying to use spherical mirrors

in off axis conditions. OAP mirrors ensure high resolution in compact design

systems and are key elements in spectrometers as well as astronomical

optical instruments. OAP mirrors feature light weight monolithic designs

which can incorporate mounting features onto the mirror itself.

OAPs are achromatic focusing on collimation and have low scatter for UV applications. Spectrum Scientific offers optimized coatings for the deep UV as low as 120nm as well as coatings to suit VIS, NIR and IR.

Our OAPs can be replicated onto a range of materials including glass, metal, invar and silicon carbide.

Ellipsoidal Mirrors

- Spectrum Scientific’s ellipsoidal mirrors are perfect for

minimizing the number of optical components in a system by efficiently

refocusing light from one focal point to a second without the need for

additional optical components thus allowing for a more compact optical

system. They are commonly used in PCB, LCD or PDP production as well as

fiber optic illuminators.

Our ellipsoidal mirrors can be provided on a range of materials including glass, metal or silicon carbide.

Ellipsoidal mirrors are normally manufactured to order and we do not currently offer off-the-shelf mirrors.

FreeForm Optics

- Freeform mirrors are optics that have a non-symmetric

optical surface and offer many advantages over conventional optics:

- Improved Performance

- Redistribution of tolerances in the system design

- Reduction of the number of optics

- Fewer optics to align

- Reduction of the optical system volume

- Additional aberration correction

- A range of substrates including metal, glass, invar and silicon carbide

- Ellipse and Paraboloid profiles

- Sizes from 0.5 inch diameter

- Typical surface figure down to λ/8 (λ/14 possible)

- Surface roughness down to 3.5Å

- Gold or Aluminum coating

Space Qualified Mirrors

- design and manufacture of custom designed optics

including the replication of low CTE materials such as Zerodur and Silicon

Carbide (SiC) for off-axis-parabolic, ellipsoidal and freeform mirrors for

space borne telescopes and space optical interconnect systems.

SiC possesses the highest combination of specific stiffness and thermal stability of any optical material making it ideal for small satellite applications in low-earth orbit (LEO) and our optical replication process delivers high fidelity, high specification, high volume SiC mirrors at a fraction of the traditional cost.

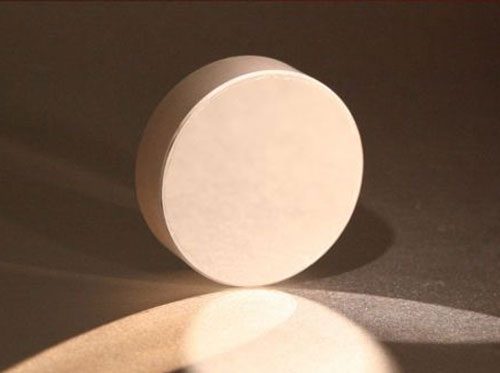

Standard Flat Mirrors

- Spectrum Scientific offers flat standard mirrors in both

12mm and 25mm sizes. Fused silica substrates are used to provide a thermally

stable mirror and the aluminum coating is tuned to provide maximum

reflectivity. These mirrors are commonly used in interferometers, imaging

systems and laser applications.

Custom Monolithic Mirrors

- Spectrum Scientific's capabilities include custom monolithic mirrors of varying sizes. Spectrum Scientific also has the capability to manufacture larger segmented mirror array systems. Both monolithic and segmented mirror arrays are commonly designed to be asymmetrical and are used in large aperture telescopes. Materials include, metal, glass, invar and silicon carbide. Our design engineers will work with you to create a custom mirror that suits your exact needs. Please contact our sales department to learn more.