- Offer Profile

-

Heidrive GmbH is a manufacturer of electric motors, specializing primarily in the production of Servo motors and supplying both small and large companies worldwide with high-quality products á la "Made in Germany". Wherever sophisticated drive technology is required, Heidrive motors can be found - from chicken grills to complex robotics. The history of origins goes back over 80 years.

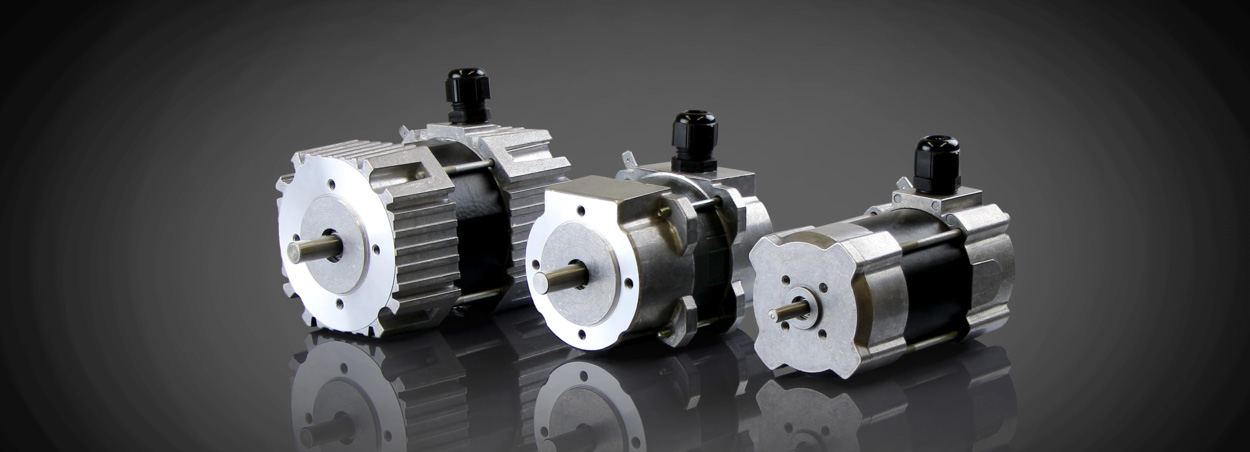

SYNCHRON SERVO PRODUCTS

1 MODULAR SYSTEM - 3 SERIES - MILLION SOLUTIONS

Today's market poses numerous challenges for all manufacturers of synchronous servo products. Every customer worldwide has individual requirements for connector and feedback systems and certifications/approvals and is looking for the right solution for his application.

With our sophisticated and innovative HeiMotion modular system, different drives and components can be configured. This enables us to react to different market requirements and provide suitable solutions. Our three servo motor series HeiMotion Premium (HMP), HeiMotion Dynamic (HMD) and HeiMotion Compact (HMC) serve as the modular basis. These are specially designed for the markets in Europe, Asia and the US and already provide many motor variants as standard.

In addition to the various synchronous servo motors, there is a wide variety of voltages, flanges, brakes, cable connections, encoders or even planetary gears. Thus we also serve more special customer requirements with our modular solution principle. The industry or market in which the customer applications are used is irrelevant. All our customers and interested parties worldwide, receive individual drive solutions and complete drive systems from one source.SERVO MOTORS HEIMOTION PREMIUM

-

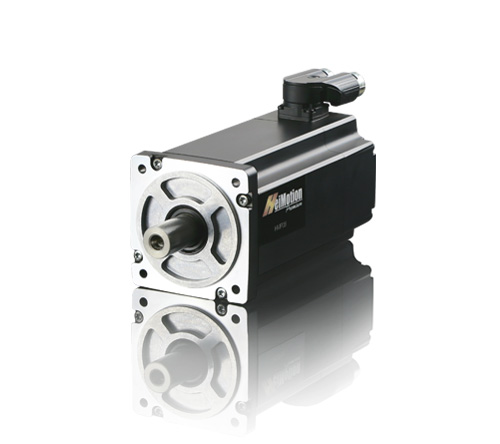

THE POWERFUL ONES

The HeiMotion Premium series is our compressed power package. The DC Servo motors meet the high demands of the European market, for example by approvals such as UL/CSA and are available in seven different flange sizes (40 mm, 60 mm, 80 mm, 100 mm, 130 mm) with varying overall lengths and different torque steps. Our experienced design and development department has developed a special winding technology for this purpose, with which even more compact sizes and low as well as very high speeds with low iron losses can be achieved. Thanks to our innovative modular system, there are also many different choices of encoders, planetary gears, cable connections and many other options.

The most important data of the HMP series:- Stall torque: 0.18 - 18.5 Nm

- Rated speed: 2,000, 3,000, 3,600, 5,000, 5,500, 6,000, 9,000 rpm

- Rated torque: 0.12 - 14.4 Nm

The features of the HMP series:- Highest synchronism and accuracy

- Manifoldly configurable and customizable

- High efficiency

- Optimized moments of inertia

- Long service life

- Compact design

- High power density and overload capacity

- Low cogging torque

- Energy efficiency

HMP04

- THE LITTLE ONE WITH GIANT POWER

Flange size: 40 x 40 mm

Stall torque: 0.18 / 0.35 Nm

Rated speed: 3,000 / 6,000 / 9,000 rpm

Rated torque: 0.12 - 0.32 Nm

Rated power: 50 - 200 W

DC bus voltage: 48 / 320 V

HMP06

- THE IMPRESSIVE POWER PACKAGE

Flange size: 60 x 60 mm

Stall torque: 0.7 / 1.5 Nm

Rated speed: 3,000 / 6,000 rpm

Rated torque: 0.5 - 1.2 Nm

Rated power: 200 - 550 W

DC bus voltage: 320 V

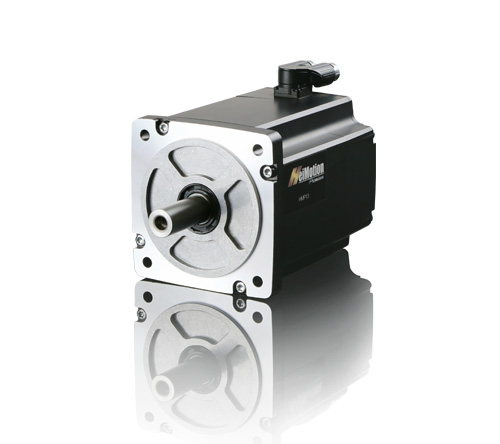

HMP08

- THE AMAZING BUNDLE OF ENERGY

Flange size: 80 x 80 mm

Stall torque: 2.8 / 3.5 Nm

Rated speed: 3,000 / 5,500

Rated torque: 1.7 - 3.2 Nm

Rated power: 750 - 1200 W

DC bus voltage: 320 / 560 V

HMP10

- THE POWERFUL ALL-ROUNDER

Flange size: 100 x 100 mm

Stall torque: 5.6 / 7.5 Nm

Rated speed: 3,000 / 5,000

Rated torque: 3.4 - 6.4 Nm

Rated power: 1500 - 2500 W

DC bus voltage: 560 V

HMP13

- THE REMARKABLE POWER PACKAGE

Flange size: 130 x 130 mm

Stall torque: 5.5 / 18.5 Nm

Rated speed: 3,000 / 3,600 rpm

Rated torque: 4.0 - 14.4 Nm

Rated power: 1000 - 3750 W

DC bus voltage: 320 / 560 V

SERVO MOTORS HEIMOTION DYNAMIC -NEXT GENERATION

-

THE COMPACT DYNAMIC ONES

The ServoMotor series HeiMotion Dynamic is highly dynamic and extremely robust.

Its further development, HeiMotion Dynamic Next Generation, presents itself with a reduced overall length of over 20% compared to the predecessor motors and strongly optimised moments of inertia. The range of additional flange sizes also offers optimal solutions for particularly small installation spaces. The permanent magnet three-phase synchronous servo motors of HeiMotion Dynamic are designed to meet special customer requirements, such as compactness, high acceleration values and energy efficiency with highly dynamic behavior. Available with different flange sizes (60 mm, 80 mm, 100 mm, 130 mm, 150 mm, 190 mm) they are preferably used in the automation and robotic industries.

The dynamics of the servo motors were achieved by optimizing the material on the Rotor, reducing the overall length and using a new winding technology. Among other things, the robustness is achieved by full potting under vacuum. As a result, the coil is thermally ideally connected to the lamination stack and the motor housing. Mechanical influences from outside, such as shocks and vibrations, have no influence on the stability of the windings. The latter are completely enclosed in the potting compound and thus optimally protected.

The most important data of the HMD series:- Stall torque: 1.0 - 105.0 Nm

- Rated speed: 2,000, 3,000, 5,000, 5,500, 6,000 rpm

- Rated torque: 1.0 - 66.5 Nm

The features of the HMD series:- Low moments of inertia

- High efficiency

- High robustness

- Very compact design

- Very high power density

- Very low cogging torques

- Energy efficiency

- Very high acceleration values

HMD06

- THE DYNAMIC UNIVERSAL GENIUS

Flange size: 60 x 60 mm

Stall torque: 1.0 / 2.6 Nm

Rated speed: 3,000 / 6,000 rpm

Rated torque: 1.0 - 2.5 Nm

Rated power: 315 - 1.250 W

DC bus voltage: 24 / 48 / 320 / 560 V

HMD08

- THE GIFTED DYNAMO

Flange size: 80 x 80 mm

Stall torque: 2.4 - 5.7 Nm

Rated speed: 3,000 / 5,500 rpm

Rated torque: 2.1 - 5.3 Nm

Rated power: 720 - 2.480 W

DC bus voltage: 24 / 48 / 320 / 560 V

HMD10

- THE DYNAMIC POWERHOUSE

Flange size: 100 x 1000 mm

Stall torque: 3.9 / 10.5 Nm

Rated speed: 3,000 / 5,000 rpm

Rated torque: 3.2 - 8.6 Nm

Rated power: 1.150 - 2900 W

DC bus voltage: 48 / 320 / 560 V

HMD13

- THE DYNAMIC GENIUS

Flange size: 130 x 130 mm

Stall torque: 13.3 / 24.5 Nm

Rated speed: 2,000 / 3,600 rpm

Rated torque: 9.0 - 20.5 Nm

Rated power: 2.400 - 5.000 W

DC bus voltage: 560 V

HMD15

- THE SHORT DYNAMIC STAR

Flange size: 150 x 150 mm

Stall torque: 36.0 / 49.0 Nm

Rated speed: 2,000 / 3,000 rpm

Rated torque: 21.0 - 36.2 Nm

Rated power: 5.850 - 7.855 W

DC bus voltage: 560 V

HMD19

- THE DYNAMIC COMPACT ALL-ROUNDER

Flange size: 190 x 190 mm

Stall torque: 51.0 / 105.0 Nm

Rated speed: 2,000 / 3,000 rpm

Rated torque: 25.5 - 66.5 Nm

Rated power: 7,435 - 13,920 W

DC bus voltage: 560 V

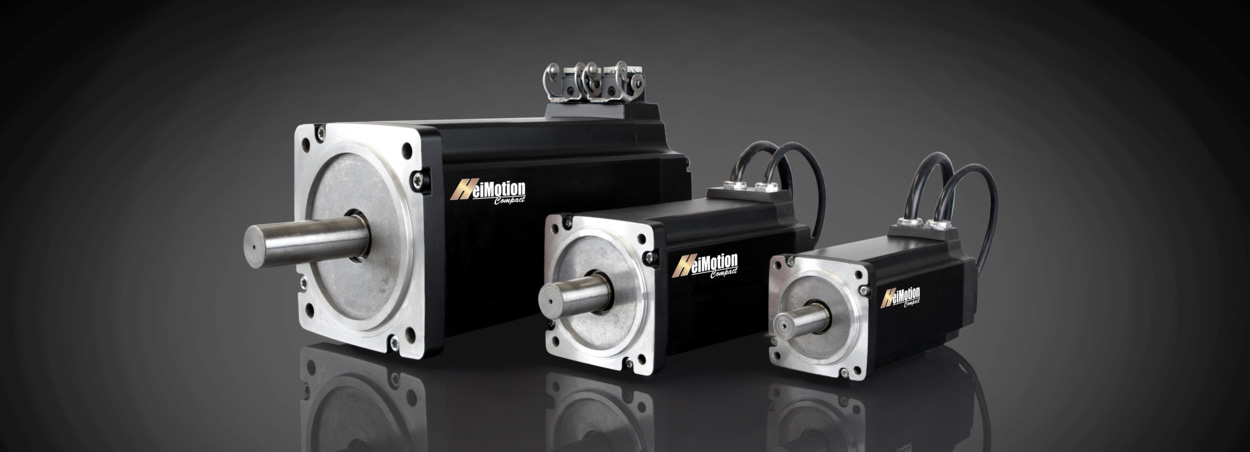

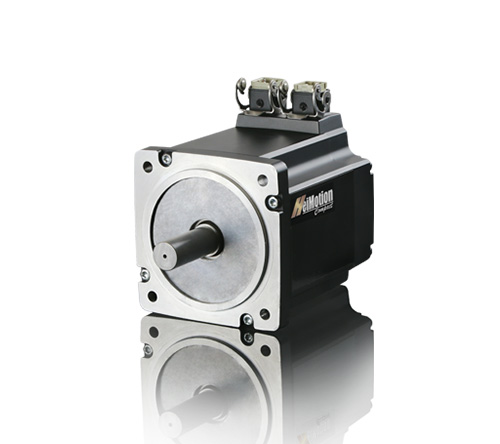

SERVO MOTORS HEIMOTION COMPACT

-

THE LOW COST ONES

The HeiMotion Compact ServoMotor series is especially designed for the Asian region.

This means that the connection technology complies with Asian standards and criteria such as performance gradations and cost advantages are geared to the Far Eastern market. Instead of connectors with plugs, more cost-effective cable connections are used and the selection of encoders is limited, which means that a higher number of units can be produced per production batch. The motors are available in the flange dimensions 60 mm, 80 mm and 130 mm available.

However, the orientation towards the Asian market does not mean that HeiMotion Compact servo motors are not also in use worldwide. This is because our innovative modular configuration system, which gives us a wide range of options in the composition of the drive systems, means that the HMC motors can also be customized and adapted to meet specific requirements.

The most important data of the HMC series:- Stall torque: 0.7 - 18.5 Nm

- Rated speed: 2,000, 3,000 rpm

- Rated torque: 0.6 - 14.4 Nm

The features of the HMC series:- Compact design

- Precision

- Robustness

- Excellent efficiency

- Economically attractive

HMC06

- THE MOST COMPACT PERFORMANCE MODEL

Flange size: 60 x 60 mm

Stall torque: 0.7 / 1.5 Nm

Rated speed: 3,000 rpm

Rated torque: 0.5 - 1.2 Nm

Rated power: 200 / 400 W

DC bus voltage: 320 V

HMC08

- THE COMPRESSED PERFORMANCE PROFESSIONAL

Flange size: 80 x 80 mm

Stall torque: 2.8 / 3.5 Nm

Rated speed: 3,000 rpm

Rated torque: 2.3 - 3.2 Nm

Rated power: 750 / 1000 W

DC bus voltage: 320 / 560 V

HMC13

- THE GREAT COMPACT

Flange size: 130 x 130 mm

Stall torque: 5.5 / 18.5 Nm

Rated speed: 2,000 rpm

Rated torque: 4.8 - 14.4 Nm

Rated power: 1000 - 3.000 W

DC bus voltage: 320 / 560 V

SERVO MOTORS WITH PLANETARY GEARS IN DIRECT MOUNTING

-

FEATURES AND BENEFITS

The ServoMotor series HeiMotion Premium and Dynamic can be supplemented by planetary gears in direct mounting from 40 mm to 130 mm. The modular motor-gearbox combinations meet special requirements such as high radial loads or different mounting types on the machine.

Planetary gear motor

The Heidrive servo motors can be combined with various compact planetary gears in direct mounting from 40 mm to 130 mm. In addition to the standard combinations, different motor and gear sizes can also be combined.

Direct mounting for servo motors

In the design requirements for the planetary gear motor, the main focus was on the reduction of overall length and low noise. Noise reductions of up to 6 dB could be achieved by eliminating the clamp coupling and the significantly more precise connection of the sun gear. The single-stage gearbox is available in ratios from 1 to 10, the two-stage version is available in ratios 9 to 64. Further advantages of the planetary gears in direct mounting are a low mass moment of inertia and low weight.

E-GEARBOX - ECONOMY

- APPLICATIONS AND

USES

- TOOL CHANGER

- TURNING TABLES

- COFFEE PRODUCTION

- FIRE FIGHTING

- MELCOBOTS

- STORAGE AND RETRIEVAL MACHINES

- CUTTING MACHINES

- LOTHING MACHINES

- AND MANY MORE

FEATURES AND ADVANTAGES- HIGHEST VARIANCE

- ECONOMICAL GEAR UNITS FOR STANDARD APPLICATIONS

- COMPACT LENGTH

- LOW NOISE

- LOW BACKLASH

- HIGH EFFICIENCY

- HIGHEST QUALITY REQUIREMENTS

- ANY MOUNTING POSITION

- AND MANY MORE

H-GEARBOX - HEAVY DUTY

- APPLICATIONS AND

USES

- TENSILE COMPRESSION TESTING MACHINES

- PORTIONING MACHINES

- SHAPING MACHINES

- MELCOBOTS

- AND MANY MORE

FEATURES AND ADVANTAGES- ECONOMICAL FLANGE GEAR

- OUTPUT FLANGE TO DIN ISO 9409

- LOW BACKLASH

- HIGH TILTING RIGIDITY

- LOW WEIGHT

- LOW NOISE

- HIGHEST QUALITY REQUIREMENTS

- ANY MOUNTING LUG

- AND MANY MORE

F-GEARBOX - FLANGE OUTPUT

- APPLICATIONS AND

USES

- TOOL CHANGER

- AND MANY MORE

FEATURES AND ADVANTAGES- ECONOMICAL FLANGE GEAR

- OUTPUT FLANGE TO DIN ISO 9409

- LOW BACKLASH

- HIGH TILTING RIGIDITY

- LOW WEIGHT

- LOW NOISE

- HIGHEST QUALITY REQUIREMENTS

- ANY MOUNTING LUG

- AND MANY MORE

P-GEARBOX - POWERFUL ECONOMY

- APPLICATIONS AND

USES

- PORTIONING MACHINES

- SHAPING MACHINES

- STORAGE AND RETRIEVAL MACHINES

- AND MANY MORE

FEATURES AND ADVANTAGES- ECONOMIC GEARS

- HIGHER RADIAL AND AXIAL FORCES

- LOW NOISE

- HIGHEST QUALITY REQUIREMENTS

- ANY MOUNTING POSITION

- HIGH EFFICIENCY

- LOW WEIGHT

- LOW BACKLASH

- AND MANY MORE

DECENTRALISED SERVO MOTORS - HEITRONX

-

INTEGRATED AND MOUNTED SERVO MOTORS

Small, intelligent and powerful is how integrated drives can be described in a few words. The fully digital Servo positioning units are primarily intended for use in decentralized multi-axis applications where many motors are installed in one machine. These flexible space miracles are used primarily in robotics and automation and, thanks to their performance, are driving the success of the industry.

Within automation, the drive forms the heart of the system, as it brings the machine to life and represents the decisive Interface. The fact that there must be differently configured drive types for different applications becomes clear at the latest when one takes a closer look at installation space, budget and the special customer requirements. For example, in an application the drive must be able to withstand strong vibrations or is exposed to high temperatures. In other applications, however, the requirement is to install as few cables and additional modules as possible due to the limited installation space. The latter is becoming increasingly important, particularly in automation and robotics. Decentralized drives are experiencing an upswing here and are finding their place in almost every application. However, if you take a closer look at the decentralized drives currently on the market, most electric motors are fitted with the Controller system rather than integrated - the installation space that actually needs to be gained is minimized, since space is required, especially at height.

The features at a glance:- Highest synchronism and accuracy

- High efficiency

- Optimized moments of inertia

- Durable

- Compact design

- High power density

- Low cogging torque

- Energy efficiency

- Optimized temperature management

HMPI04

- THE POWERFUL DWARF

Flange size: 40 x 40 mm

Peak torque: 0.3 / 0.4 Nm

Rated speed: 3,000 / 6,000 rpm

Rated torque: 0.13 - 0.25 Nm

Rated power: 50 - 100 W

Supply voltage: 24 / 48 V DC

HMDI06

- THE POWERFUL ONE WITH THE POWERBOOST

Flange size: 60 x 60 mm

Peak torque: 0.4 - 1.8 Nm

Rated speed: 3,000 / 6,000 rpm

Rated torque: 0.2 - 0.9 Nm

Rated power: 95 - 315 W

Supply voltage: 24 / 48 V DC

HMPA / HMDA08

- THE CONVINCING PERFORMER

Flange size: 80 x 80 mm

Peak torque: 1.4 - 4.5 Nm

Rated speed: 3,000 / 5,500 rpm

Rated torque: 0.6 - 2.3 Nm

Rated power: 290 - 720 W

Supply voltage: 24 / 48 / 230 V DC

HMPA / HMDA06

- THE POWERHOUSE ON TOP

Flange size: 60 x 60 mm

Peak torque: 0.9 - 3.5 Nm

Rated speed: 3,000 / 6,000 rpm

Rated torque: 0.3 - 1.1 Nm

Rated power: 130 - 375 W

Supply voltage: 24 / 48 / 230 V DC

HMDI06

- THE EXTRA SECURE SERVICE PROVIDER

Flange size: 60 x 60 mm

Peak torque: 3.8 - 5.0 Nm

Rated speed: 3,000 rpm

Rated torque: 0.83 - 1.42 Nm

Supply voltage: 24 / 48 V DC

HMDI08

- THE HYPER-SAFE COMPACT

Flange size: 80 x 80 mm

Peak torque: 7.1 - 7.3 Nm

Rated speed: 3,000 rpm

Rated torque: 1.35 - 2.7 Nm

Supply voltage: 24 / 48 V DC

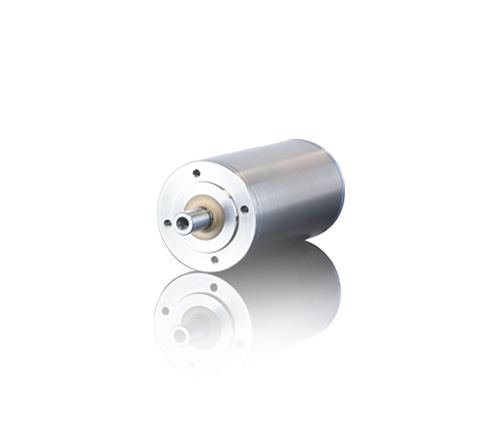

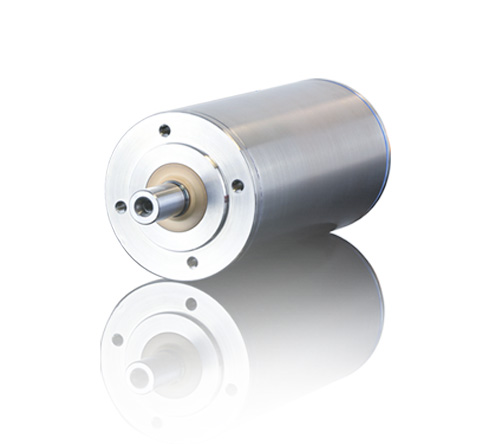

SERVO MOTORS STAINLESS STEEL

-

THE HYGIENE GENIUSES

The stainless steel Motor series is our hygienic performance package. The stainless steel Servo motors are specially designed for production environments with high demands on hygiene, corrosion protection and cleanliness, which are particularly required in the food and beverage industry. Thanks to the smooth surface, the intelligent sealing concept and the Ecolab certification, they are also excellently suited for the chemical or pharmaceutical industry.

They are available in various flange sizes (70 mm, 89 mm, 110 mm) and versions such as with planetary gear and with integrated electronics. The perfect rounding off of the drive package is that, on request, the drive is also available with a stainless steel plug or with a gearbox in a stainless steel housing.

The most important data of the stainless steel series:- Stall torque: 0.16 - 150.4 Nm

- Rated speed: 3,000 min-1

- Rated torque: 0.13 - 118.6 Nm

The features of the stainless steel series:- Especially for demands on cleanliness, hygiene and corrosion protection

- Ecolab certification

- Intelligent sealing concept

- Stainless steel

- Development of the surface design according to EHEDG and FDA

- FDA-compliant shaft seal

- Maintenance free

- Compact design

- Configurable and customisable

HMD06 STAINLESS STEEL

- THE GLOSSY STAR

Flange size: 70 mm

Stall torque: 0.7 - 1.8 / 2.0 - 64 / 0.16 - 0.6 Nm

Rated speed: 3,000 / 1,000 - 47 rpm

Rated torque: 0,7 - 1,75 / 2,0 - 44 / 0.13 - 0.48 Nm

Rated power: 220 - 550 / 205 - 510 / 40 - 150 W

HMD08 STAINLESS STEEL

- THE CLEAN CHAMPION

Flange size: 89 mm

Stall torque: 1.7 - 4.0 / 5.0 - 150.4 Nm

Rated speed: 3,000 / 1,000 - 47 rpm

Rated torque: 1.6 - 3.9 / 4.7 - 118.6 Nm

Rated power: 500 - 1,210 / 470 - 1,140 W

HMD10 STAINLESS STEEL WITH INTEGRATED ELECTRONICS

- THE STEEL HERO

Flange size: 110 mm

Stall torque: 2.7 - 7.3 Nm

Rated speed: 3,000 rpm

Rated torque: 2.5 - 6 Nm

Rated power: 785 - 1,885 W

THE PERFECT SERVO DRIVE

-

FOR YOUR HEIDRIVE MOTOR

The Servo drives HCJ, HCD, HCB and HCF are the ideal addition to the Heidrive Motor portfolio. All motor/servo drives combinations have a CANopen fieldbus Interface with CiA-402 standard and extensive digital and analog inputs and outputs. Other bus systems such as Profibus interface or EtherCAT can also be retrofitted as an option. Depending on the equipment, all common encoder systems such as incremental systems (ABZ, UVW, single-ended and differential) but also absolute systems (Resolver, Sin-Cos encoder, HIPERFACE®, EnDat etc.) can be used.

HCD

- THE PERFECT ASSISTANT

Compatible motors: HMP04, HMP06, HMP08, HMD06 (differences depending on version)

Switch frequency: 4, 8, 12, 16 kHz (Factory setting 8 kHz)

Supply voltage: 1 x 230 VAC

Output Voltage: 3 x 0 - 230 Veff

Continuous output current: 4 Arms

Maximum output current: 8 Arms

Rated power: 800 W

HCF

- THE SOPHISTICATED CONTROLLER

Compatible motors: HMP04, HMD06, HMD08 (differences depending on the version)

Switch frequency: 8, 16 kHz (Factory setting 8 kHz)

Supply voltage: 24 - 48 VDC

Output Voltage: 3 x 0 - 33 Vrms

Continuous output current: 8 Arms

Maximum output current: 16 Arms

Rated power: 240 W

HCB

- THE COMPACT ALLROUNDER

Compatible motors: HMP04, HMP06, HMP08, HMP10, HMP13, HMD06, HMD08 (differences depending on version)

Switch frequency: 8 / 16 kHz

Supply voltage: 1 x 230 V / 3 x 400 V

Continuous output current: 2, 4, 8, 12 Aeff

Rated power: 400W, 800W, 1,6kW, 3,2kW, 4,8kW

Interface: CANopen (CiA 402), Ethernet, EtherCat, PROFINET

DC bus voltage: 325 / 565 VDC

HCJ

- THE INTELLIGENT COORDINATOR

Compatible motors: HMP04, HMP06, HMP08, HMP10, HMP13, HMP15, HMP19, HMD06, HMD08, HMD10, HMD13, HMC06, HMC08, HMC13 (differences depending on version)

Switch frequency: 2, 4, 8, 12 16 kHz

Nominal voltage: 1 x 230 V, 3 x 400 V

Continuous output current at 230 V: 3 - 8 Arms

Continuous output current at 400 V: 2 - 16 Arms

Interface: EtherCAT, PROFINET IRT, CANopen, PROFIBUS DPV1

DC bus voltage: 325 / 565 VDC

BLDC MOTORS / EC MOTORS

MOTOR SERIES UP TO 300 W

EC Motors

EC motors are also called brushless DC motors. The design corresponds to that of a three-phase synchronous Motor with a permanently excited magnetic Rotor. There are no life-limiting components (except ball bearings), such as the carbon brush in DC motors. In contrast, the control behavior and characteristic of EC motors is similar to that of a DC motor. Due to the simple and robust design and the low demands on the control electronics, this motor type can be used with a simplified frequency inverter with block commutation. A plastic-bonded neodymium magnetic ring is used inside. Due to its compact magnetic ring, it is particularly suitable for higher speeds. Compared to a conventional asynchronous motor, the EC motor has a higher power density. In combination with a rotor position detection system based on Hall technology (RLE), it can also be used as a variable-speed drive. The EC series from Heidrive GmbH consists of three sizes in different lengths and covers a power range from 35 W to 220 W. This corresponds to a nominal torque of 0.1 Nm to 0.7 Nm. The motors specified here have a 3-fold overload capacity.

BLDC Motors

The design of BLDC motors is very similar to that of the EC motors described above. However, a highly efficient permanent magnet rotor is used here. The sintered rare earth magnet segments (Nd-FeB) used result in a higher efficiency and thus a higher power output. The higher energy density of this motor type also allows a more compact size reach. BLDC motors use a higher quality and very robust Hall-based encoder system (HES) with various signal outputs. BLDC motors are particularly suitable for dynamic drives in 4Q operation. The BLDC series from Heidrive GmbH consists of two sizes, each with two overall lengths and covers a power range from 200 W to 800 W. This corresponds to a nominal torque of 0.65 Nm to 2.55 Nm. The motors specified here have a 4-fold overload capacity.

EC06

- THE SMALL RESILIENT ONE

Cutting Diameter: 60 mm

Stall torque: 0.17 / 0.28 Nm

Rated speed: 3,000 rpm

Rated torque: 0.11 - 0.19 Nm

Rated power: 35 - 60 W

DC bus voltage: 24 / 48 / 320 V

EC07

- THE POWER DENSITER

Cutting Diameter: 70 mm

Stall torque: 0.34 / 0.51 / 0.68 Nm

Rated speed: 3,000 rpm

Rated torque: 0.30 - 0.57 Nm

Rated power: 95 - 180 W

DC bus voltage: 48 / 320 / 560 V

EC08

- THE ROBUST SPEED WHISPERER

Cutting Diameter: 80 mm

Stall torque: 0.75 / 1.0 Nm

Rated speed: 3,000 rpm

Rated torque: 0.51 - 0.70 Nm

Rated power: 160 - 220 W

DC bus voltage: 48 / 320 / 560 V

BLDC07

- THE EFFICIENT UNTWISTER

Cutting Diameter: 70 mm

Stall torque: 0.67 / 1.35 Nm

Rated speed: 3,000 rpm

Rated torque: 0.64 - 1.27 Nm

Rated power: 200 - 400 W

DC bus voltage: 48 / 320 / 560 V

BLDC09

- THE POWERFUL MASTER

Cutting Diameter: 90 mm

Stall torque: 2.4 / 3.2 Nm

Rated speed: 3,000 rpm

Rated torque: 1.91 - 2.55 Nm

Rated power: 600 - 800 W

DC bus voltage: 48 / 320 / 560 V

ASYNCHRONOUS DRIVE SOLUTIONS

-

OUR ASYNCHRONOUS MOTORS - RELIABLE, DURABLE AND MAINTENANCE-FREE

Our portfolio of asynchronous motors includes capacitor and three-phase motors as well as shaded-pole motors, which are used, for example, in fan heaters, fans, printing presses and pumps.

Our asynchronous Motor portfolio is primarily geared towards durability, reliability and economy. This is the most commonly used type of drive, especially when it has to be measured against environmentally friendly requirements. It goes without saying that all our products always comply with the EU DIN regulations. In most cases our values are far above the specified EU standards. A good example of this are our three-phase motors, which are convincing up to 550 W with smooth running and a very low noise level.

Currently, the development of generators and battery-powered systems are increasingly in the focus of the energy turnaround. Here, asynchronous motors are the perfect solution. Friction and other no-load losses can be increasingly reduced through permanent further development, also in the area of materials. Nominal losses can therefore be reduced, which has a positive effect on the lifetime and performance of the drives. Since asynchronous motors do not have to run in conformity with the mains current, there are many safe technical configuration options which can be adapted to the specific requirements of each project.

CAPACITOR/THREE-PHASE MOTORS

- HIGH SPEED DRIVE

Input power: 35 - 540 W

Output power: 11 - 403 W

Rated speed: 1,200 - 2,750 rpm

Rated torque: 0.042 - 1.45 Nm

SHADED-POLE MOTORS

- POWERFUL AND RELIABLE

Input power: 10.5 - 97.0 W

Output power: 0.7 - 29.4 W

Rated speed: 2,600 rpm

Rated torque: 0.0026 - 0.1080 Nm

Voltage: 230 V / 50 Hz

FLAT GEAR

- HIGH AXIAL AND RADIAL FORCES DUE TO BALL BEARINGS

Connection voltage: AC 230 V

Frequency: 50 Hz

Output power: 20 - 80 W

Rated speed: 1,300 / 1,200 rpm

Rated torque: 15 - 59 Nm

HELICAL GEAR

- STRONG AND COMPACT

Motor types: three-phase motors, capacitor motors, EC motors, DC motors

Speed: 7 - 1,049 rpm

Torque: 0.37 - 136.47 Nm

Ratio: 2.86 - 183.53

HELICAL BEVEL GEARS

- STABLE AND INSENSITIVE

Motor types: three-phase motors, capacitor motors, EC motors, DC motors

Speed: 8 - 459 rpm

Torque: 0.76 - 148.52 Nm

Ratio: 6.54 - 171.12

WORM GEAR UNITS

- HARDENED AND GROUND

Motor types: three-phase motors, capacitor motors, EC motors

Rated speed: 23 - 300 rpm

Rated torque: 4.9 - 29.7 Nm

Ratio: 10 - 60

Service factor: 0.61 -

4.07

GEARED MOTORS COMPACT

- COST-EFFECTIVE AND VERSATILE

Motor types: three-phase motors, capacitor motors, EC motors

Output power: 20 - 220 W

Rated speed: 1,200 - 3,000 rpm

Rated torque: 0.13 - 1.27 Nm

Mass moment of inertia: 0.18 - 3.30 kgcm2

INDUSTRIES - INNOVATIVE DRIVE SYSTEMS

-

OUR INDUSTRIES

Our synchronous servo products and asynchronous products are used in a wide variety of industries, such as robotics, storage and transport systems, industry, aerospace, agriculture, medical, gastro, refrigeration and beverage technology and in a wide range of applications, such as industrial robots, driverless transport trolleys, production lines, transport loading systems in aircraft, milking machines, respirators, large commercial coffee machines, ice cube makers or for dispensing beverages from vending machines.

With absolute certainty you have already had contact with our products, even if unconsciously. Have you already flown with the largest airlines in the world or have you had a coffee with the most famous café chain from America? Gotcha!In addition to the industries listed here, which represent our main sectors, we are represented in many other applications and industries.

ROBOTICS

-

FOR A NETWORKED FUTURE

In times of smart and digital automation, integrated drives are experiencing a rapid upswing due to their dynamics and enormous flexibility. We have recognised this potential and offer specially designed drives for robot and AGV manufacturers based on the newly developed modular system.

LOGISTICS

-

FOR INDUSTRY 4.0

Autonomous navigating vehicles are revolutionizing warehouse logistics and will play an increasingly important role in a future of Industry 4.0. Heidrive GmbH is also continuing to expand its ServoMotor portfolio in order to play a leading role in new developments. It is like everywhere where technology has its fingers in the pie: It makes everything faster, more compact, quieter, more efficient and more cost-effective. This is also the case in the field of warehouse logistics, which is experiencing a revolution in automation and driverless transport systems (AGVs), especially with new wireless technologies. It is precisely here that a great deal of time and money can be saved with the new information technologies. This is one of the reasons why many large companies are strongly pushing the expansion of automation units. But the many advantages - such as barrier-free networking of different storage and work areas - can quickly become a weak point for the entire production process. For example, if a single system fails, causing other components to fail and, in the worst case, paralysing the entire logistics system. For this reason, in addition to safety, the reliability and quality of the individual components of the driverless transport system are indispensable and must be taken into account right from the selection stage. The lynchpin of the driverless transport system is the drive unit, which is permanently exposed to loads of up to 1500 kg. The servo and geared motors from the Kelheim-based drive specialist Heidrive offer a high overload capacity. With the help of these, a long service life can be guaranteed with high efficiency.

AUTOMATION

-

FOR FLEXIBLE PRODUCTION SYSTEMS

Digital change and increasing internationalization in all industries ensure that the degree of automation in manufacturing companies is continuously increasing. Flexible and automated production systems have become indispensable in order to meet the increasing demands on today's production in terms of speed, product variety and process optimization.

There are no limits to the automation technology. Whether it is, for example, an automation solution for tool change in CNC machines or drives for fully automated dosing or positioning systems in the automotive industry, we always stand by our customers in automation technology as a competent partner. With our portfolio of drive solutions we meet the most diverse requirements and thus cover a wide range of applications. In addition, we develop drive solutions specially tailored to the needs of our customers.

INDUSTRY

-

FOR AUTOMATED PRODUCTION

In the manufacturing industry, performance and innovation are more important than ever. Particularly in the production of large quantities of goods that are almost homogeneous among themselves, it is impossible to imagine modern production facilities without standardized and automated production processes. In the age of Industry 4.0, comprehensive digitalized and industrial production is already feasible in almost all production plants, thus offering companies from a wide range of industries new opportunities to realize innovative products and high performance. We, Heidrive GmbH, would be pleased to support you in your projects and, as a competent drive specialist for industrial plants for all sectors, are available to you as a strong partner.

AEROSPACE TECHNOLOGY

-

FOR FULLY AUTOMATIC PROCESSES

The aerospace industry covers all technology on and in flying objects, such as aircraft, spacecraft and satellites, and is one of the most demanding and forward-looking areas in industry. Wherever innovative systems and technologies are in use, automation is a major issue. From fully automated production involving all parts of missiles to sophisticated propulsion systems in aerospace technology, everything is possible. Because automation does not only take place on solid ground, but also in the air. With our customer-specific products, we can respond to the special requirements of our customers and together we can advance and further develop this industry.

AGRICULTURE

-

AUTOMATION OF AGRICULTURAL PRODUCTION PROCESSES

The two topics of digitalisation and automation do not even stop at the agricultural sector. Smart technologies and advanced machinery in this versatile field have been developed continuously in recent years, creating innovative systems for humans and animals.