IMO

Videos

Loading the player ...

- Offer Profile

- The IMO Group in the

metropolitan region of Nuremberg with headquarters located in Gremsdorf has

more than 20 years of experiencing in designing and manufacturing Slewing

Rings and Slew Drives.

We are certified according to the standards DIN EN ISO 9001, 14001 and OHSAS 18001. Several times, IMO has achieved awards for its produvt innovations at Exhibitions for IDeas-Invention-New Products. In our sector we are one of the leading suppliers.

Product Portfolio

Slewing Rings

-

Depending on the application and type, large diameter IMO Slewing rings can be up to 6 meters in diameter and weigh more than 20 tons. They are used for various applications,

including construction machinery, agriculture & forestry, tunneling & mining, ship building, conveyor & transportation systems, and medical technology.

Additionally, IMO is a leading supplier of blade, yaw, and main bearings for an- and offshore wind turbines, and even provides balde bearings for tidal stream systems.

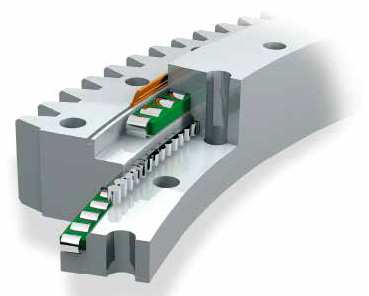

- Large-diameter anti-friction Slewing Rings designed to handle simultaneously occurring axial, radial and moment loads.

- The Slewing Rings can be combined with pinion, planetary gearboxes and motors which can be selected and acquired by the customer.

- Equipped with a sealed raceway system and an open gearing (if toothed)

Ball Slewing Rings with flange rings

-

- Single Row design with four-point raceway geometry

- Untoothed rings with flange thickness of 12 and 21 mm

- Ball diameters 20 and 32 mm

- Available ex stock or with a short delivery time as standard series in 14 sizes

- Raceway diameters of 311 to 1,091 mm or 955 to 1,455 mm

- For applications with light loads

- Enables lightweight structures in spite of large bearing diameters

- Applications: Handling technology, manlift platform, turntables

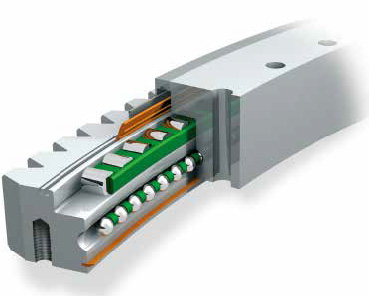

Ball Slewing Rings

-

- Single row and double row designs

- Ball diameters 12 to 80 mm

- Four-point raceway geomatry

- Optional preloaded raceway systems and centerings

- Enables robust designs for arduous application conditions

- High resistance to 'false brinelling' in heavy vibration conditions

- Reduced sensitivity to shape deformations in the mouonting structure

- Higher static load capacity than similar designed Cross Roller Slewings Rings

- Catalog series with outside diameters from 180 to 2,971 mm

- Often designed as special versions according to customer requirements (outside diameters more than 6,000 mm)

- Frequently used in wind energy turbines, cranes, construction machinery, mechanical enginnering and special purpose machinery.

Double Axial Slewing Rings

-

- Double row design with large supporting balls and smaller retainings balls

- Ball diameters 20 to 80 mm

- Both raceway in two point geometry

- Standard series with outside diameters more than 6,000 mm

- Used in cranes and as replacement parts for existing equipment

- Special design can be supplied

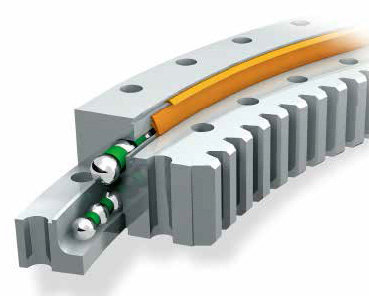

Roller / Ball Combination Slewing Rings

-

- Roller raceway to take up the axial body

- Ball raceway provides support for radial loads. All parts are retained together as a unit during fitting

- Ball diameters 25 to 80 mm, roller diameters up to 100 mm

- Used in applications with a dominant axial force and low radial load / tilting moments

- Standards series with outside diameters more than 6,000 mm

- Frequently produced as special designs according to customer requirements

- Typical apllications: Bulk material handling, stacker reclaimers, bucket wheel excavators, machine tools.

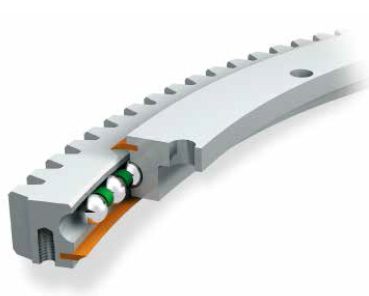

Roller Slewing rings

-

- Triple Row Roller Slewing Rings

- Roller diameters 10 to 100 mm

- Plastic, steel or brass cage segments according to loads (can also be supplied with closed cage)

- Designed to provide the combination of the highest capacity in the smallest configuration

- Greater static and dynamic laod capacity higher rigidity and constant friction torque comapred with all other Slewing ring designs (with the same raceway diameter)

- High requirement on the rigidity and precision of the mounting structure

- Standard series with outside diametrers from 1,462 to 5,179 mm

- Mostly supplied as customer specific designs

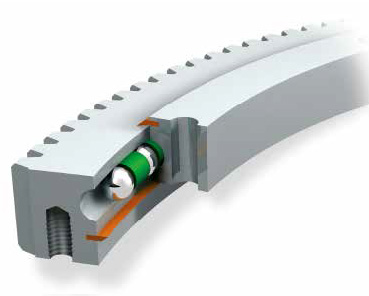

Cross Roller Slewing Rings

-

- Single Row raceway under 45 degrees

- Roller diameters 12 to 60 mm

- Alternately arranged rolling elements

- Constant friction torque with different loads

- Higher dynamic service life than similar Ball Slewing rings designs

- Higher demands on the rigidity and precision of the mounting structure in comparison with Ball Slewing Rings

- Applications: Robots, antennas, medical technology, positioning devices, machine tools

- Can be supported to special customer requirements

Slew Drives

-

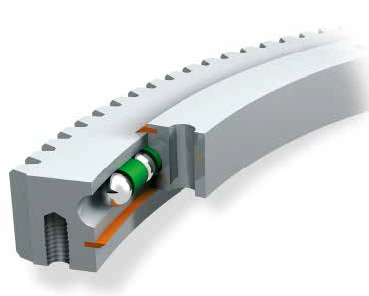

Worm or pinion driven IMO Slew Drives consists of a ball or roller slewing ring, a drive train, and a completely enclosed and sealed housing.

These convenient, ready-to-install systems can replace complex systems with multiple parts to reduce design and assembly time.

They are used around the world for steering in equipment such as gantry cranes and heavy-duty transporters, as well as rotating, tilting,

and positioning in machinery, including construction equipment and slew drilling rings. IMO Slew Drives are also used within the renewable energy industry in small wind trubines,

solar trackser and solar thermal tower plants.

- Ready-to-Install system with integrated Slewing Ring (please see column on the left)

- Available with flanges for all standard electric, hydraulic motors and/or planetary gearboxes

- Worm or pinion driven

- Sealed raceway system

- Housing which completely encloses the gearing (grease reservoir, protection against contamination and contact)

WD Series

WD-L Series

-

Ball Slewing Ring

- Single or double raceway design

- Outer ring with toothed worm gear

Motor- Hydraulic or electric motor driven

- With or without gearbox

- Can be delivered without a motor

- Industry standard motor connection

Worm drive- High torque transmission

- Complete Toothed worm gear

- Maximum load capacity and extended life

- Reduced backlash

- Self-locking and non-self-locking models

Connection point for potentiometer, permanent brake or manual turning- Intergrated self-locking brake system provides reliable, safe and smooth operation

- No stick/slip or sudden lurching when starting movement

- Easy access to hex connection allows quick emergency manual operation.

WD-H series

-

Roller Slewing Ring

- High torque transmission

- Complete toothed worm gear

- Maximum load capacity7extended life

- Reduced blacklash

- Single and doubled-lead worm

- Self-locking and non-self-locking models

Worm drive:- High torque transmission

- Complete toothed worm gear

- Maximum load capacity/extended life

- Reduced backlash

- Single and doubled-lead worm

- Self-locking and non-self-locking models

Motor:- Single or twin motors (standard or double torque capacity)

- Hydraulic or electric

- Can be delivered without a motor

- Industry standard motor connection

- Connection point for attachments

- Brakes

- Feedback sensors / potentiometer

SP Series

SP-I

-

SP-I, intermediate series

- Mounting hole patterns and height identical to IMO Ball Sleing Ring

- series 120

- ball diameter 20 mm

- module 4 mm

- Direct drive

- Mounting hole patterns and height identical to IMO Ball Sleing Ring

SP-M

-

SP-M, Medium series

- Mounting hole patterns identical to IMO Ball Slewing Ring Series 120

- height increased by base plate thickness of 15 mm

- ball diameter 20 mm

- module 6 mm

- One or multistage planetary gearbox

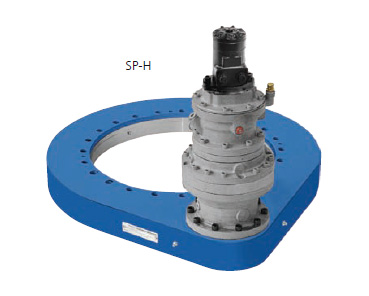

SP-H

-

SP-H, Heavy series

- Mounting hole patterns identical to IMO ball Slewing rings series 125

- height increased by base palte thickmess of 15 mm

- ball diameters 25 mm

- module 8 mm

- One or multisatge planetary gearbox