Lafert

- Offer Profile

- The Lafert Group is committed

to continuous growth by being the global leading manufacturer of customised

engineered Electric Motors and Drives with special focus on Energy Saving

and Industry Automation.

The Lafert Group will strive to be the ideal partner in the Electric Motors and Drives industry through focus on meeting specific customer demands.

Mutually beneficial partnerships are developed by continuous process improvements utilising state-of-the-art products and techniques by a skilled, motivated and professional workforce.

Product Portfolio

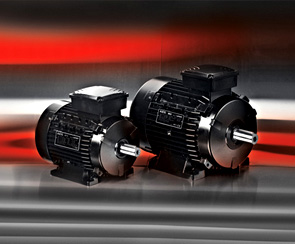

ENERGY EFFICIENT Motors

- High efficiency, energy saving

Energy, the range of asynchronous motors, has been developed to meet the increasing demand in high efficiency and highly reliable products.

Three-phase motors up to 200 kW meeting the requirements of IE1, IE2 and IE3 efficiency in accordance with IEC 60034-30;2008, with test method in accordance with IEC 60034-2-1;2007.

Standard Efficiency, IE1

- Efficiency values according to IEC 60034-30;2008

Efficiency testing method: IEC 60034-2-1;2007

Frame size 56 to 160, aluminium design

Output 0.09 - 22 kW

Frequency 50 - 60Hz

Polarity single - 2, 4, 6, 8 poles

double - 4/2, 8/4, 4/6, 6/8 poles

High Efficiency, IE2/cURus

- High Efficiency Motors, IE2 code

Efficiency values according to IEC 60034-30;2008.

Efficiency testing method: IEC 60034-2-1;2007

Frame size 71 - 160, aluminium design

180 - 315, cast iron design

Output 0.75 to 200 kW

Frequency 50Hz

Polarity single - 2, 4, 6 poles

High Efficiency Motors, IE2 code / cURus Energy

Efficiency values according to EPAct, Energy Policy Act. Verified by UL, Underwriters Laboratories Inc.

Frame size 90 - 160, aluminium design

Output 1.5 to 18.5 kW

Frequency 60Hz

Polarity single - 2, 4 poles

Premium Efficiency, IE3/EISA

- Premium Efficiency Motors - IE3 code

Efficiency values according to IEC 60034-30;2008.

Efficiency testing method: IEC 60034-2-1;2007

Frame size 90 - 160, aluminium design

Output 1.1 to 22 kW

Frequency 50Hz

Polarity single - 2, 4 poles

Premium Efficiency Motors - EISA

Efficiency values according to EISA Directive, Energy Independence and Security Act ,2007.

Verified by UL Environment.

Frame size 90 - 160, aluminium design

Output 1.1 to 22 kW

Frequency 60Hz

Polarity single - 2, 4 poles

CUSTOMISED Motors

- Our core business

Customised is a range of asynchronous motors up to 200 kW with special execution, in order to optimise electrical and mechanical design for particular markets or OEM specific demands.

A flexible family of products manufactured ad hoc according to the customer's demands. With a wide range of options we provide solutions to each individual industrial application.

Single-phase motors

- Wide range of standard and special executions to specific

demands.

Specific electrical design to grant low noise and low vibration level.

Totally enclosed capacitors and starting device.

AMM series: permanent capacitor design. Ideal for low inertia applications and the fan industry;

AMME series: cap start - cap run for high starting torque with electronic starting device. This range meets high starting torque requirements such as mixing machines and other machineries;

AMD series: Dual Voltage design (115/230 V).

Frame size 56 - 100

Output 0.09 to 2.2 kW

Polarity single - 2, 4, 6 poles

Options cURus certification, CSA certification

Brake motors

- Wide range of standard and special executions to specific

demands.

Different options available with AC or DC brake coil can fit any

applications.

AMBY series: high torque DC brake

Main applications: automation with smooth intervention, elevation/cranes, packaging machinery

AMBZ series: high torque AC brake

Main applications: automation with high intervention frequency, gearmotors, lifting and handling

AMS series: low torque DC brake - reduced overall dimensions

Main applications: wherever a very soft and gradual braking is required, cutting machinery for food industry, wood working machineries.

Frame size 63 - 160

Output 0.12 to 22 kW

Polarity single - 2, 4, 6, 8 poles

Rectifier standard supply:

230V - 50/60Hz (other on request)

Options cURus certification

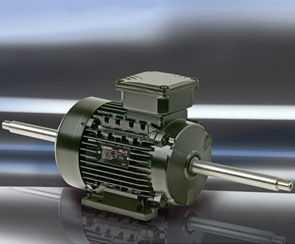

Special executions

- Lafert specializes in customized solutions for

non-standard motor applications. We are considered as a market leader in

this field and have built a reputation for excellence for this core activity

over the past 45 years.

The range of specials includes both electrical and mechanical variants:

- extended stainless steel shafts for the fan industry

- motors for pumping applications

- complete tailor-made designs

- customized flange and shaft for gear motors

- electrical design to meet specific duty requests

- specific wound motors for worldwide electrical supply (208V - 60 Hz ... 575V - 60 Hz)

- motor design to meet special environments (smoke and heat exhaust ventilation, Dust Ignition for Zone 22, Non Sparking Exn).

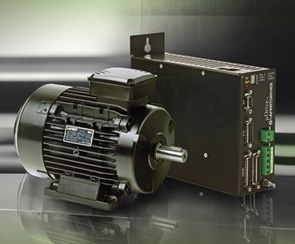

HIGH PERFORMANCE Motors

- Reduced energy

costs

High Performance is a range of synchronous motors 0.37 kW to 22 kW, with variable speed and equipped with sensorless drives it is specifically designed for its energy saving potential and renewable energy applications.

Permanent magnet technology, very high efficiency, compact design, reduced weight, low operating temperature and limited costs make them the ideal product to enter a new era of design for industrial machines.

PM motors - integral drive

- Motor Specifications

Frame size 71 - 90 - 112 -132

Power rating 0.55 to 22 kW

(single-phase 200-240V, three-phase 380-480V)

Torque 2 Nm to 100 Nm

Speed 1 rpm to 6000 rpmDrive Specifications

Supply Frequency 48 - 62 Hz

Supply Voltage 3x380/480V ± 10%

Output rated current 100% continuously @ 40°C

Overload capacity 150% for 60 sec

Programmable digital input 4

PM motors - stand alone motor

- Frame size 71 - 90 - 112 -132

Output 0.55 to 22 kW

(single-phase 200-240V, 50/60Hz to 2.2 kW)

three-phase 380-480V, 50/60Hz)

Torque 2 Nm to 100 Nm

Speed 1 rpm to 6000 rpm

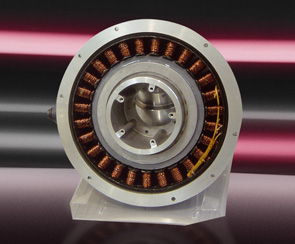

SERVO Motors & Drives

- Best in

industrial automation

The range of Lafert brushless servomotors is one of the most complete available on the market, with nominal torques ranging from 0.30 Nm to 150 Nm. Direct Drive is a range covering torques from 8 Nm to 1000 Nm.

The family of drives and speciality electronics are particularly versatile to provide the perfect partner when designing automated industrial machines.

Brushless servo motors

- Among the few independent manufacturers of servo motors

in the market, Lafert can supply a wide range of standard and tailor made

products for Industrial Automation.

The whole manufacturing process is integrated within Lafert manufacturing facilities, giving an excellent flexibility to specific market demands, as well as a high level of cost-efficiency.

- Rated torque from 0.3 to 150 Nm

- High peak torque, low cogging torque

- Low or high inertia

- Compact design: high ratio between power/weight

- Standard and special executions

- Precision in movement and positioning

- Wide range of feedback systems

- Reliability to the highest dV/dt produced by the new generation of electronic switch.

Direct drive motors

- Motor Specifications

- Rated torque from 8 to 1000 Nm

- High peak torque, low cogging torque

- Very high torque density

- No blacklash compensation

- High dynamic performance and stiffness

- Compact design, high reliability

- On request, water cooling; frameless executions.

Servo drives

- Standard Drives 230/480 Vac:

Micro Drive Series: output currents up to 15/30 Arms-drive 4 to 24 Nm

Power Box Series: output currents up to 15/30 Arms-drive 8 to 24 Nm

Maxi Drive Series: output currents up to 60/100 Arms-drive 40 to 80 Nm

Battery-powered Drives:

started out as the result of a specific customer's need to drive motors inside radio-operated motor vehicles, monorail cars and most common applications powered by standard battery voltage (48Vdc, 72Vdc, 96 Vdc). Such drives allow the controlling of low-voltage brushless motors and coupling 2 drives in closed speed/position loop.

Customised Drives:

with particular hardware and software personalization that integrates complex and performing functions inside.

LIFT Motors

- Gearless

machines

The LIFT range allows the manufacturing of systems where the traction machine is inside the elevator shaft, so there is no need for a machine room, with obvious space and cost savings and a more rational layout of the all components.

LIFT is permanent-magnet gearless synchronous machine with torque up to 660 Nm for systems up to 1,275 kg.

The compact and heavy-duty motor comes with the following features:

* Very small dimensions

* High Efficiency

* High comfort

* No maintenance

* Low noise level

Range M24S/T24S - M24/T24 - T24L up to 630 Kg

- For mains voltage 230 V (single-phase) and 380-400

(three-phase) 50/60 Hz

Range M24S/T24S - up to 320 Kg

Max payload: 240 kg - 320 Kg

Traction sheave Ø: 210 mm - 240 mm

Speed: 0,6 m/s - 1,0 m/s

Rated torque: 140 Nm

Max braking torque: 2x150 Nm - 2x280 Nm

Range M24/T24 - up to 550 Kg

Max payload: 320 kg - 480 Kg - 550 Kg

Traction sheave Ø: 210 mm - 240 mm

Speed: 0,6 m/s - 1,0 m/s

Rated torque: 200 Nm

Max braking torque: 2x280 Nm

For mains voltage 380-400 (three-phase) 50/60 Hz

Range T24L - up to 630 Kg

Max payload: 320 Kg - 400 kg - 630 Kg

Traction sheave Ø: 240 mm - 320 mm

Speed: 1,0 m/s - 1,6 m/s

Rated torque: 330 Nm

Max braking torque: 2x350 Nm

Range T32S - T32 - T32L - up to 1275 Kg

- For mains voltage 380-400 (three-phase) 50/60 Hz

Range T32S - up to 800 Kg

Max payload: 320 kg - 450 Kg - 630 Kg - 800 Kg

Traction sheave Ø: 240 mm - 320 mm

Speed: 1,0 m/s - 1,6 m/s

Rated torque: 330 Nm

Max braking torque: 2x350 Nm

Range T32 - up to 1000 Kg

Max payload: 320 kg - 480 Kg - 630 Kg - 800 Kg - 1000 kg

Traction sheave Ø: 240 mm - 320 mm

Speed: 1,0 m/s - 1,6 m/s

Rated torque: 480 Nm

Max braking torque: 2x450 Nm

Range T32L - up to 1275Kg

Max payload: 600 Kg - 800 Kg - 1000 kg - 1250 kg - 1275 kg

Traction sheave Ø: 240 mm - 320 mm

Speed: 1,0 m/s - 1,6 m/s

Rated torque: 660 Nm

Max braking torque: 2x700 Nm