- Offer Profile

- We design, produce and supply advanced rotary and linear motion sensors to meet growing global market demands. Our experience and knowledge combined with innovative ideas enable us to offer custom product solutions to match customer's needs.

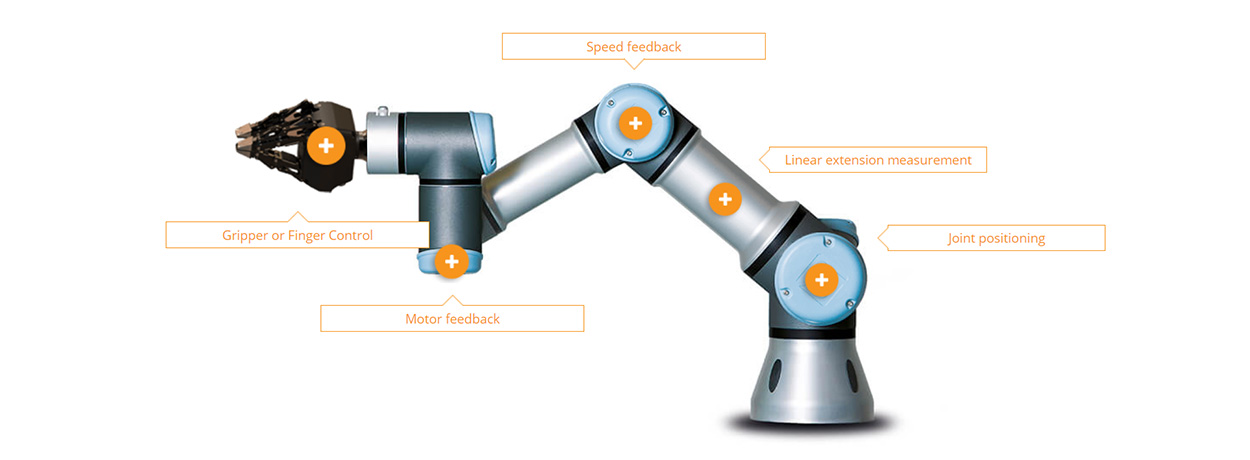

We Make Encoders For Robots

-

No matter how excellent the design, a robot still relies on the components used. Position encoders are one of the key components for robot's position, orientation and motion control.

RLS non-contact magnetic encoders offer outstanding performance, system safety and stability for robotic applications, such as motor feedback, joint position control, linear motion sensing, gripper and force feedback. The encoders come in a wide variety of shapes and sizes allowing a more flexible system design. Thanks to non-contact magnetic encoder technology RLS sensors bring reliable operation for years to come.

BENEFITS

-

- Good price performance

- Wide range of sizes and technologies available

- Wide range of resolutions

- Industry standard absolute or incremental output options

- High dynamic response

- High accuracy

- Wide installation tolerances

- High reliability

- Non-contact 360° rotary or linear position sensing

- Low power consumption

- Immune to external magnetic stray fields

APPLICATIONS

-

- Motor position feedback

- Joint position control

- Linear extension measurement

- Gripper/finger feedback

- Force feedback

- Miniature closed-loop position control

Rotary magnetic encoders

- A range of high-speed rotary magnetic encoders that bring reliable solutions to tough, hard-working applications including woodworking, stone-cutting, sawing, metalworking, textiles, packaging, plastics processing, automation and assembly systems, laser/flame/water-jet cutting, electronic assembly equipment etc.

Incremental encoders

LM10 rotary incremental magnetic encoder system

-

- Customer selectable resolutions

- High speed operation

- Excellent dirt immunity to IP68

- Integral set-up LED

- CE compliant, including RoHS -see Declaration of conformity

- High reliability from proven non-contact sensing technology

- Industry standard digital and analogue outputs

LM13 rotary incremental magnetic encoder system

-

- Compact readhead

- Resolutions from 1,280 to 327,680 counts per revolution

- High speed operation to 20,000 revolutions per minute

- Excellent dirt immunity

- Integral set-up LED

- High reliability from proven non-contact sensing technology

- Industry standard digital and analogue outputs

RoLin™ rotary incremental magnetic encoder system

-

- Incremental quadrature

- TTL output signals A, B and index Z

- Resolutions up to 622,592 cpr (76 pole ring)

- High speed operation

- Bi-directional reference mark

- High reliability from proven non-contact sensing technology

- Pin / Flex options

- RoHS compliant

Absolute encoders

AksIM™ off-axis rotary absolute encoder

-

- True absolute

- Single track

- Resolution to 20 bits

- No hysteresis

- Non contact

- High speed

- Low profile

- Custom ASIC based magnetic sensor

- Built-in self-monitoring

- Integrated status LED

- BiSS, SSI, PWM, USB, SPI and serial RS422

- Corrosion resistant magnetic ring

AksIM-2™ off-axis rotary absolute encoder

-

- True absolute system

- Custom magnetic sensor ASIC

- Self-calibration option

- No hysteresis

- Resolutions up to 20 bits

- Multiturn counter option

- High speed operation

- 9 kHz bandwidth, 44 kHz refresh rate

- Low profile, non-contact

- Built-in self-monitoring

- Integrated status LED

- BiSS, Asynchronous serial (UART), PWM or SSI

- Corrosion resistant magnetic ring

- Up to 600 bar pressure

Orbis™ absolute rotary encoder

-

- True absolute encoder

- 14 bit resolution

- 8 proprietary Hall sensor ASICs

- Through-hole design enables its mounting anywhere along the shaft

- Self-calibration after assembly

- No magnetic hysteresis

- Built-in self-diagnostics

- Status LED

- SPI, SSI, BiSS-C, PWM, and asynchronous serial communication

Linear magnetic encoders

-

A range of high-speed linear magnetic encoders designed for use in harsh environments, such as woodworking, stone-cutting, sawing, metalworking, textiles, packaging, plastics processing, automation and assembly systems, laser/flame/water-jet cutting, electronic chip/board production etc. The linear magnetic encoder system consists of a readhead and self-adhesive magnetic scale. As the readhead moves along the scale it detects the magnetic signature of the magnetised scale and processes these signals to the required output.

Incremental encoders

LM10 linear incremental magnetic encoder system

-

- Customer selectable resolutions

- Stick-on reference mark

- Distance coded reference and periodic reference mark option

- High speed operation

- Excellent dirt immunity to IP68

- Integral set-up LED

- Axis lengths of up to 100 m

- High reliability from proven non-contact sensing technology

- Industry standard incremental digital and analogue output options

LM13 linear incremental magnetic encoder system

-

- Compact readhead

- Resolutions from 250 µm to 1 µm

- Stick-on reference mark

- High speed operation

- Excellent dirt immunity

- Integral set-up LED

- High reliability from proven non-contact sensing technology

- Industry standard digital output options

- Repeatability inside resolution

- Suitable for partial arc applications

- TRS track system compatible

- Distance coded reference mark compatible

LM15 linear incremental magnetic encoder system

-

- Easy to install with wide installation tolerances

- Ride height from 0.1 mm to 4 mm

- Resolutions from 625 µm to 5 µm

- High speed operation

- Excellent dirt immunity

- Integral set-up LED

- Axis lengths of up to 100 m

- Industry standard digital outputs

- Bidirectional reference mark

- TRS track system compatible

- Distance coded reference mark compatible

Absolute encoders

LA11 absolute magnetic encoder system

-

- True absolute system

- Suitable for highly dynamic control loops

- Small footprint

- High accuracy

- Resolutions up to 0.244 µm

- Axis lengths up to 16.3 m

- Speeds up to 7 m/s at 0.977 µm resolution

- Integral status LED

- Synchronous (SSI, SPI, BiSS) communication protocols available

- Parallel incremental output (analogue or digital)

- Double shielded, drag-chain compatible cable

- Simple and fast installation

- Robust measuring principle

- Excellent degree of protection to IP68

LinACE™ absolute linear shaft encoder

- True absolute system

- RLS InAxis™ measuring technology

- Custom ASIC based magnetic sensor

- No hysteresis

- Resolution to 0.5 μm

- Length up to 500 mm (320 mm for shaft diameter 4 mm)

- Speed up to 5 m/s

- Built-in self-monitoring

- Suitable for high dynamic control loops

- Integrated status LED

- CAN, SSI, PWM and serial RS422

- Corrosion resistant, non-magnetised chrome plated shaft

- Insensitive to stray magnetic fields

OnAxis encoders

-

Each magnetic encoder contains an integrated circuit that senses the angular position. The IC senses the angular position of a permanent magnet placed above it. The permanent magnet is diametrically polarized and of cylindrical shape. Hall sensor technology detects the magnetic flux density distribution at the surface of the silicon. Hall sensors placed in a circular array around the center of the IC deliver a voltage representation of magnetic field distribution. The sine and cosine voltage outputs from the sensor array vary with magnet position. The sine and cosine signals are then converted to absolute angle position with a fast flash interpolator. This basic sensing technology can then be combined with further electronics to produce a wide range of output formats. Resolutions of up to 13 bit absolute (8192 counts per revolution incremental) are achieved with internal interpolation. The ability of the encoder system to operate with a gap between the magnetic actuator and the encoder chip allows its incorporation into designs that need isolation of the moving elements.

RM44/RM58 - up to 13 bit encoder base unit

-

- Easy to install - with self locating design

- Low cost for OEM integration

- Fully sealed to IP68

- High reliability from proven non-contact sensing technology

- Available with 5 V or 24 V power supply

- RoHS compliant (lead free)

RMC22 commutation and incremental encoder

-

- Incremental resolution up to 4,096 cpr

- Simple installation and setup

- U, V, W commutation signals with up to 16 poles

- Industry standard incremental outputs (RS422)

- Operating speed to 30,000 rpm

- Compact - 22 mm diameter body

- Non-contact, frictionless design

- Low inertia

RMB28 rotary magnetic module

-

- 28 mm square module

- Low cost for OEM integration

- 24 V and 5 V power supply versions

- High speed operation to 60,000 rpm

- Absolute - to 13 bit resolution (8,192 counts per revolution)

- Industry standard absolute, incremental, analogue and linear output formats

- Accuracy to ±0.5°

- RoHS compliant (lead free)

Rings

-

The robust RLS magnetic rings consist of a vulcanised elastoferrite layer securely attached to a steel hub. They are compatible with RLS standard LM family or component level RoLin readheads, which bring reliable solutions to surveilance, transportation, industrial automation, renewable energy and other tough, hard-working motion control applications.

Radial magnetic rings

-

- Radial rings

- Excellent dirt immunity

- Bi-directional reference mark

- High reliability from proven noncontact sensing technology

- Industry standard digital outputs

Axial magnetic rings

-

- Axial rings

- Excellent dirt immunity

- Bi-directional reference mark

- High reliability from proven noncontact sensing technology

- Industry standard digital outputs

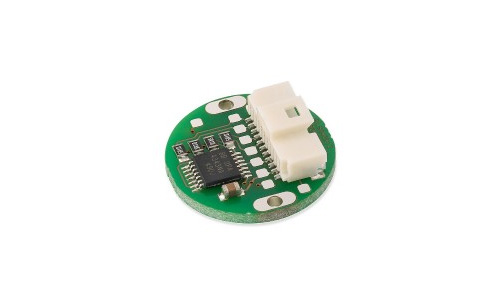

Miniature encoders

-

RLS announces the launch of high performance miniature encoder sensors for embedded OEM motion control applications. With their miniature and lightweight design they are perfect for medical applications, optics positioning, robot control, 3D printers, gimbals and hand held devices. The miniature sensors come in different shapes and offer linear and rotary performances at resolutions to 0.244 μm for linear and to 753,664 cpr for rotary applications. The encoders consist of a miniature sensor and a magnetic scale or a ring. The sensors are available either in a potted housing or as PCB board level sensors. The position information is output in incremental quadrature TTL or RS422 and parallel in SSI and BiSS-C formats with the option of a unique or periodic reference mark. The proven RLS non-contact sensing technology brings high reliability and performance in harsh applications.

RM08 super small non-contact rotary encoder

-

- Super small size – 8 mm diameter body

- Non-contact, frictionless design

- 3.3 V or 5 V power supply versions

- High speed operation to 30,000 rpm

- Industry standard analogue sinusoidal, incremental, SSI and linear voltage output formats

- Accuracy to ±0.3°

- RoHS compliant (lead free)

RLB rotary miniature PCB level incremental magnetic encoder

-

- Miniature design

- Incremental quadrature TTL output signals A, B, Z

- Periodic, bidirectional index impulse

- Resolutions up to 622,592 cpr for rotary applications (76 pole ring)

- High speed operation

- Flex cable connection

- RoHS compliant

RMB20 rotary magnetic module

-

- 20 mm diameter circular module

- 5 V power supply

- High speed operation to 30,000 rpm

- Absolute - to 13 bit resolution (8,192 counts per revolution)

- Industry standard absolute, incremental, analogue and linear output formats

- Accuracy to ±0.5°

- RoHS compliant (lead free)