- Offer Profile

- Baumüller is

one of the competent solution providers for automation, installation, drive

and control systems technology.

We offer you a wide range of drive solutions for all sectors of mechanical engineering.

Baumüller provides you with drive technology and know how.

Automation

- Control concepts for automation

The modularization of machinery is state of the art nowadays, and is based on the decentralization of the system’s intelligence

Baumüller is a full-range provider in the automation of decentralized, centralized and hybrid control architectures, whatever the application.

Baumüller Automation Solutions

- The Baumüller Group offers complete automation solutions for mechanical engineering. Our broad spectrum extends from components to integrated automation solutions, and our comprehensive services support you throughout the lifecycle of your machine.

Control concept b maXX-controllerPLC

- The b maXX-controllerPLC is the consistent link between the standard high performance PLC and the highly dynamic Motion Control PLC.

Control concept b maXX-drivePLC

- With a typical cycle time of 100 microseconds for 1000 lines of STL, the b maXX-drivePLC is one of the world’s fastest PLCs in a drive and is therefore suitable for both comprehensive control tasks and demanding Motion Control tasks.

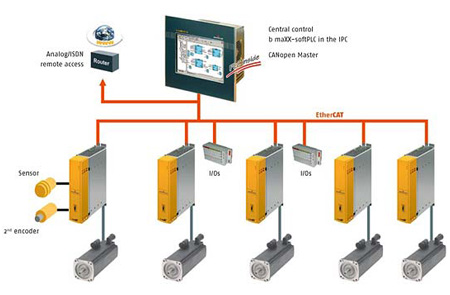

Control concepts b maXX-softPLC

- The b maXX-softPLC integrates automation tasks in the PC. Complex control tasks and automation requirements in large systems are easy to implement with the b maXX-softPLC.

Field bus systems

- Many different bus systems have established themselves in the field of industrial communication. Baumüller drive technology supports the six most popular field bus systems EtherCAT®, Sercos®, Ethernet, CANopen, CANsync and Profibus®.

b maXX HMI

- User orientation and operator convenience are characteristic of Baumüller operating and display products. All terminals in the HMI series are programmed using the same b maXX HMI Programmer programming tool.

I/O - Modules

- Baumüller I/O components provide users with a wide range of modules for adapting to requirements in the best possible way.

Drive electronics

- The new drive concept from Baumüller – b maXX 4000

modular – scalable – open.

Baumüller is setting standards with b maXX, its newest generation of drive.

This series of converters and controllers was developed to meet current and future automation technology requirements worldwide. b maXX serves as a basis for both simple and complex automation solutions.

b maXX 4000 - modular servo controller up to 300 kW

- b maXX has up to 11 drawers for plug-in modules and can therefore be individually adapted for special automation tasks. Special plug-in modules interface b maXX, including interface adaptors for most standard bus systems. The plug-in b maXX-drivePLC module provides integrated intelligent control.

Function and option modules for b maXX 4400

- With 20 function and option modules b maXX can easily be adopted in line with the individual tasks of the drive and automation solution.

The control unit b maXX-drivePLC

- With a typical cycle time of 100 microseconds for 1,000 lines of STL, b maXX-drivePLC is one of the fastest in-drive PLCs in the world and is therefore ideally suitable not only for sophisticated control tasks but also for demanding motion control tasks.

New approach for power modules

- Five cooling concepts for seven frame sizes allow you to select the optimal power modules for your requirements. To enhance diagnostics capability, the power modules are coupled with the drive controller via internal, serial communication.

b maXX 4100 – Rectifier and regenerative feedback unit

- It is often the case with electrical drives that energy costs make up almost 90% of the overall life-cycle costs. With this in mind, regenerative systems help to reduce the total cost of ownership

b maXX 3000 - Servo controller up to 10 kW

- The servo inverter b maXX 3400 was designed for low power ratings up to 10 kW. With the new series of dynamic DSD servomotors in frame sizes 28 to 100 and the linear motors, Baumüller offers a complete system for low power ratings for all applications.

b maXX 1000 - Frequency converter

- The b maXX 1000 is a frequency converter that provides for the highly efficient (vector) control of standard motors in three output gradations and in the power range 0.2 kW to 11 kW.

ProDrive: Operation and parameterization of b maXX

- WinBASS II is a tool that simplifies the commissioning, parameterization and operation of all b maXX controllers - for newcomers and advanced users.

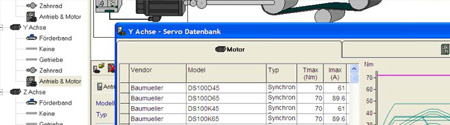

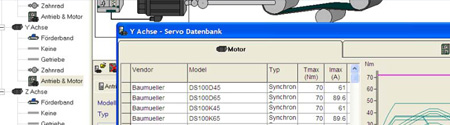

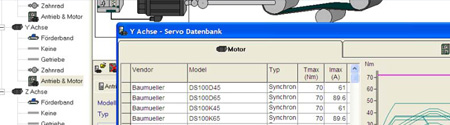

sizemaXX - Drive configuration made easy ********

- Baumüller developed a new software for drive dimensioning. The user can dimension up to six drives with sizemaXX.Users who are looking for new drives for their machines can access a helpful tool at www.baumueller.de, where sizemaXX is available in the download area.

Energy efficient drive systems

- Baumüller is placing increasing value on energy-efficient drives and the consideration of their lifecycle costs. Its servo motors and converters have for many years been rated as both meeting and exceeding the criteria of the highest efficiency class, EFF1.

Motors and servo drives

- Baumüller offers a wide range of servo motors and servo drives. From linear drives and disc motors up to dynamic servo motors, servo drives and powerful High-Torque Motors.

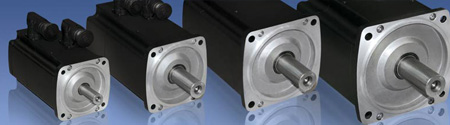

DSD - Dynamic servo motors

- The six installation sizes for the DSD-range of Baumüller offer a suitable solution for almost every application in the automation. The servo motors for highly dynamic applications with the highest requirements of acceleration capacity and the best start-stop qualities.

DS/DA - General purpose servo motors

- With a shaft height from 45 to 280 Baumüller offers the largest product range of synchronous and asynchronous motors. The servo motor for dynamic applications with highest requirements of energy efficiency.

DSC - Compact servo motors

- With its new DSC servo motors, Baumüller is making the torque motorservo-ready. This series focuses on improving ratings in order to achieve a higher torque density while also drastically reducing the volume of the device.

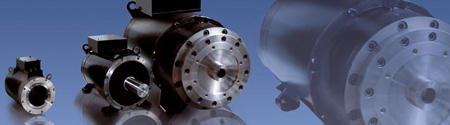

DST Powerful high torque motors

- Baumüller offers the DST-range up to 13500 Nm torque and herewith provides the maximum dynamic in the direct drive technology. The high-torque synchronous motors for application with maximum torque requirements.

DSL - Three-Phase Synchronous Linear Actuator

- With its two variants the DSL 56 ensures optimal linear motions. As a roller screw assembly for high forces and high velocities or as a ball screw assembly in simple applications for low-cost linear drives.

DSD-IPG Three-Phase Synchronous Geared Motor

- The geared motor from Baumüller, the DSD-IPG, is distinguished by its high torque and excellent dynamic response qualities. Thanks to the integrated planetary gearing, the DSD IPG is ideal for high torque applications that require a high dynamic response.

BPx - Baumüller Planetary Gearing Range

- In connection with our standard DS/DSD servo drives, the BPx – planetary gear range is optimally suitable for applications that require maximum standards of torque and dynamics.

Linear motors

- The know-how used to develop and manufacture rotary motors has been applied by Baumüller to linear motors.

Disc motors

- The main strength of these motors are that they are small and compact. In its shortest design, motor type GDM 12 N, only 39,5 mm of axial space is required.

sizemaXX - Drive configuration made easy ********

- Baumüller developed a new software for drive dimensioning. The user can dimension up to six drives with sizemaXX.Users who are looking for new drives for their machines can access a helpful tool at www.baumueller.de, where sizemaXX is available in the download are

Energy efficient drive systems

- Baumüller is placing increasing value on energy-efficient

drives and the consideration of their lifecycle costs. Its servo motors and

converters have for many years been rated as both meeting and exceeding the

criteria of the highest efficiency class, EFF1.

Software

- Parameterization, programming and software for

drive dimensioning

An engineering tool that guarantees continuous software compatibility is available for programming the three control concepts with PROPROGwt II in accordance with the IEC 61131 standard, whereby it does not matter which hardware the application was originally developed for.

Baumüller developed a new software for drive dimensioning. The user can dimension up to six drives with sizemaXX

sizemaXX - Drive configuration made easy

- Baumüller developed a new software for drive dimensioning. The user can dimension up to six drives with sizemaXX.Users who are looking for new drives for their machines can access a helpful tool at www.baumueller.de, where sizemaXX is available in the download area.

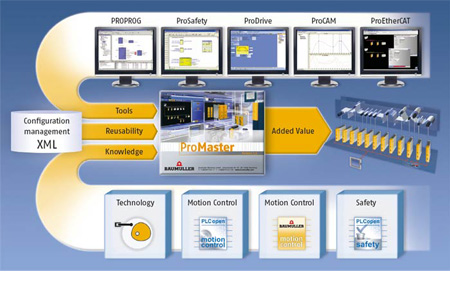

Engineering Framework ProMaster

- Due to their flexible and modular construction, modern automation solutions contain an ever-increasing amount of software. This increases the complexity of the entire machine. To keep the programming expenditure of the user as low as possible, however, Baumüller has developed the ProMaster Engineering Framework.

PROPROGwtII ************

- The powerful PROPROGwt II tool is available for programming in accordance with IEC 61131. Support for multi-resourcing in PROPROGwt II puts the user in a position to also handle complex projects with a large number of decentralized controls.

Automation solutions

- Baumüller is one of the competent solution providers

for automation, installation, drive and control systems technology.

We offer you a wide range of drive solutions for all sectors of mechanical engineering.

Baumüller provides you with drive technology and know how.

Automation solutions for Mechanical Engineering

- The Baumüller Group offers complete automation

solutions for mechanical engineering. Our broad spectrum extends from

components to integrated automation solutions, and our comprehensive

services support you throughout the lifecycle of your machine.

Machines and systems are increasingly built on a modular basis, allowing the use of centralized, decentralized, and hybrid automation concepts. Manufacturing processes that operate with continuous rapid cycles (such as the web processing of paper, foils, or textiles) represent particular challenges to the real-time capability of drive, control, and fieldbus technologies.

With its b maXX-drivePLC, b maXX-controller PLC, and b maXX-softPLC controls and its b maXX HMI solutions - from the text-oriented terminal to the touch panel – Baumüller supports decentralized, centralized, and hybrid control architectures – based on the requirements of the application.

Automation concepts

- The modularization of machinery is state of the art

nowadays, and is based on the decentralization of the system’s intelligence.

A modular machine architecture provides flexible expansion capability and

increases the availability of the system. Baumüller provides forward-looking

solutions for modular and decentralized concepts. As a system partner,

Baumüller can solve any automation problem using central and decentralized

control architecture. The IEC 61131 programming standard is an important

prerequisite for modular automation concepts.

Modular design is being used in an ever-increasing number of machines and systems, and is based on an automation concept with decentralized control and drive technology. The modularization of machinery with manufacturing processes that operate with continuous rapid cycles (such as the processing of paper, film or textile webs) represents a particular challenge to the real-time capability of drive, control and field bus technology. Baumüller provides automation solutions with central or decentralized control architecture and solutionsfor dynamic processes that require proper real-time processing.

Flexible topologies in automation

- There is an increasing trend towards modular

configuration of machines and plants in mechanical engineering. In order to

achieve this, not only centralized or decentralized automation concepts are

used but also hybrid ones.

As a system partner for automation and plant technology, Baumüller has set itself the goal to reduce the complexity of plants and therefore offers integrated complete solutions – tailored to the needs of the customer.

Software solutions

Motion Control

- The Motion Control concept puts the main focus on

the user’s manufacturing process

The Motion Control concept from Baumüller puts the main focus on the user’s manufacturing process. Machine functions can be planned without functional knowledge of the system using Motion Control modules that comply with PLCopen and the IEC 61131 programming standard.

This gives machine constructors the freedom to use their core competency more effectively for the further development of machine concepts. The amount of engineering that is required for the automation and drive system is minimized.The Baumüller Motion Control concept

Baumüller’s Motion Control concept reduces the complexity and the development cost of automation software in mechanical engineering. It puts the main focus on the user’s processes and machine functionality. This concept allows the machine manufacturer to concentrate on machine-specific future technologies and the continuous further development of their machine functionality in the software – and increasing the manufacturer’s competitive edge.

The planning of Single Axis and Multi Axis functionality in accordance with “PLCopen Motion Control” is only carried out using the relevant function module libraries from a technological point of view

Engineering Framework ProMaster

- Due to their flexible and modular construction, modern

automation solutions contain an ever-increasing amount of software. This

increases the complexity of the entire machine. To keep the programming

expenditure of the user as low as possible, however, Baumüller has developed

the ProMaster Engineering Framework. By this means, the user can implement

his or her machine configuration and the configuration and programming of

individual machine modules, devices and components easily and intuitively.

ProMaster – A framework for any automation task.

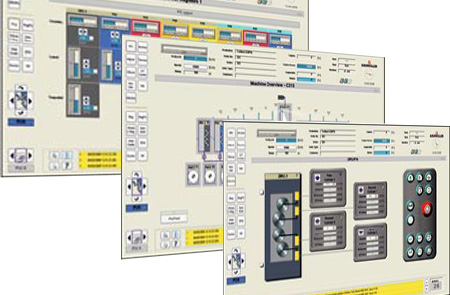

Baumüller process control system - BPLS

-

- A control center for the visualization and management of production and machine parameters for the graphic arts industry

- Convenient, simple, self-explanatory and ergonomically correct operation

- Preparation for subsequent production step while production is taking place is possible, which translates to faster conversion

- Presetting of color zones by importing CIP3 data is possible

- PC-based, which makes it ideal for the replacement of discontinued hardware components

- Control center provides interfaces to subsystems from other manufacturers, e.g. for the integration of color density regulation or connection to ERP systems

- Increase in productivity, reliability and availability, including for older printing machines, thanks to the use of the BPLS

- Complete solutions for new machines and retrofit solutions, from the controller to the drive to the control center.

BAUDIS Diagnostic and remote monitoring system

- Platform-independent architecture and Internet-based

operation

- System diagnostics via intranet and internet

- Easy integration into system-dependent control centers

- Platform - independent presentation of diagnostic data

Modular construction with libraries

- Expandability and flexible adaptation to the needs of other industries

- Easy and quick creation of overviews for system diagnosis

- Drive-integrated diagnostics to PC-based diagnostics