SPINEA

Videos

Loading the player ...

- Offer Profile

- SPINEA is a modern Slovak

engineering company, which deals with development, manufacture and sale of

high precision reduction gears, which are sold under trademark TwinSpin.

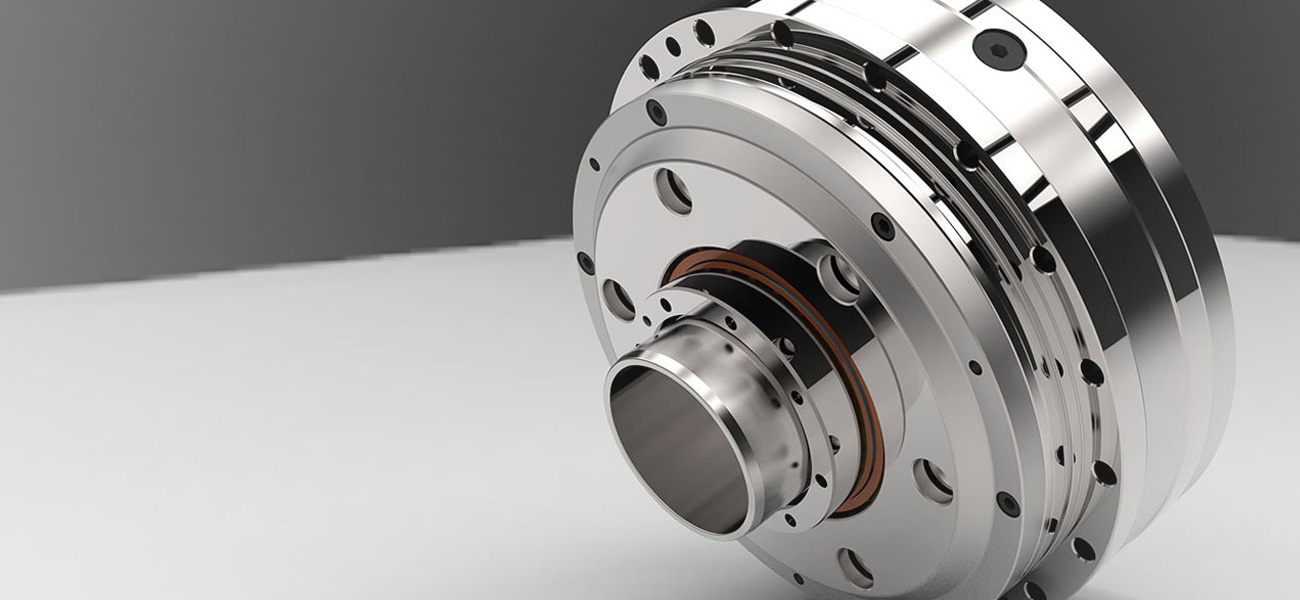

The company has been established in 1994. An invention of Slovak designer was an impulse for its establishment. The first world patent was awarded in 1995 and since 2001 TwinSpin reduction gears are manufactured serially. High precision reduction gear TwinSpin belongs in a category of HI-tech products and represents unique technical solution integrating radial-axial bearing with high precision reduction gear into one compact unit.

The products of the company are intended for applications, which require high reduction-gear ratio, high kinematic precision, clearanceless run, high speed-torque capacity, high rigidity, compact construction in a limited installation area as well as low weight. They are widely used in an automation and industrial robotics, in the field of machine tools manufacture, in navigation and camera equipments, medical technics and in many other fields.

Product Portfolio

Reduction Gears

-

TWINSPIN

The notion "high precision reduction gear" designates the full integration of high precision reduction gear and high precision radial-axial bearing in a single unit. TwinSpin high precision reduction gears are designed for applications requiring a high reduction ratio, high kinematic accurancy, low lost motion, high moment capacity and high stiffness of a compact design with a limited installation zone, and low mass. This new transmission concept allows the utilization of the reduction gear TwinSpin in robotics and automation, machine tools, measuring equipments, navigation systems, aircraft industry, military and medicine field, wood-working field, printers branch, machines for textile industry and glass treatment, filling machines, etc.

The basic parts of TwinSpin high precision reduction gear are:- case - incoporates the high capacity, precision radial-axial output bearings integrated in the reduction gear

- output sealling - on the output flange side, it prevents internal contamination and lubricant leakage from the reduction gear

- flanges - input and output flanges are fixed together by fitted bolts, and rotate at reduced speed in the radial-axial output bearing relative to the case

- shaft - high-speed member of the reduction mechanism carried by roller bearings in the flanges. Bearing raceways are ground directly on the shaft and the flangers. The shaft eccentrics rotationally support the trochoidal gears via roller bearings

- trochoidal gearing - their trochoidal profile wih almost 50% simultaneous meshing ensures transmission of the high torque and backlash-free performance of the reduction gear

- transformation member - transforms the planetary motion of the trochoidal gears to the rotary motion of a pair of flanges

T Series

-

The T series represents a wide range of TwinSpin high precision reduction gears with a cylindrical shaped case. The T series high precision reduction gears comprise an accurate reduction mechanism and high-capacity radial and axial cylindrical roller bearings. This design of reduction gears allows the mounting of the load directly on the output flange or the case without a need of additional bearings. The T series high precision reduction gears are characterized by a modular design, which allows the mounting of your desirable type of motor to the reduction gear by means of a motor connection flange. The T series includes TwinSpin high precision reduction gears that are not completely sealed; an inlet flange and a gasket kit have to be used for the sealing. Upon the customer’s request, SPINEA is able to supply a completely sealed reduction gear with a flange according to the customer’s motor.

Advantages- zero-backlash reduction gears

- high moment capacity

- excellent positioning accuracy and positioning repeatibility

- high torsional and tilting stiffness

- small dimensions and weight

- high reduction ratios

- high effeciency

- long lifetime

- easy assembly

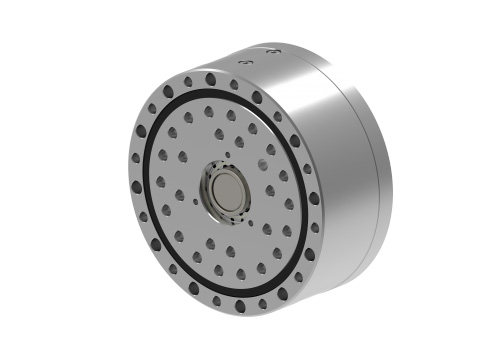

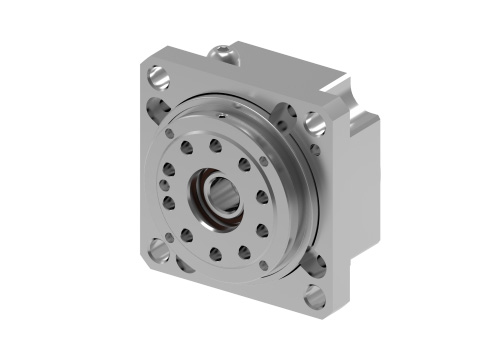

E Series

-

The E series represents a wide range of TwinSpin high precision reduction gears with a flange shaped case. The E series high precision reduction gears comprise an accurate reduction mechanism and high-capacity radial and axial cylindrical bearings. This design of reduction gears allows the mounting of the load directly on the output flange or the case without a need of additional bearings. The E series high precision reduction gears are characterized by a modular design, which allows the mounting of your desirable type of motor to the reduction gear by means of a motor connection flange. The E series includes TwinSpin high precision reduction gears that are not completely sealed; an inlet flange and a gasket kit have to be used for the sealing. Upon the customer’s request, SPINEA is able to supply a completely sealed reduction gear with a flange according to the customer’s motor.

Advantages- zero-backlash reduction gears

- high moment capacity

- excellent positioning accuracy and positioning repeatibility

- high torsional and tilting stiffness

- small dimensions and weight

- high reduction ratios

- high effeciency

- long lifetime

- easy assembly

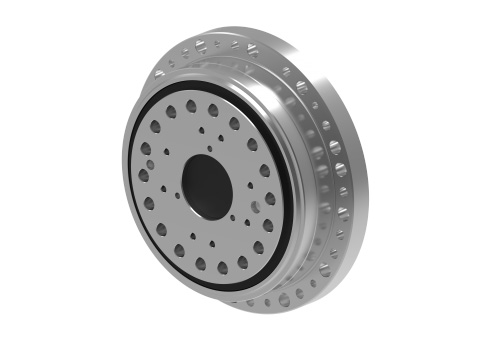

H Series

-

The H series represents TwinSpin high precision reduction gears with through-holes in the shafts, also known as the hollow-shaft version. Cables, tubes with compressed air, drive shafts etc. can be led through the hole in the shaft of the gear. The H series is completely sealed and filled with grease for lifetime. The H series high precision reduction gears comprise an accurate reduction mechanism and high-capacity radial and axial cylindrical bearings. This design of the reduction gears allows the mounting of the load directly on the output flange or case without a need of additional bearings.

Advantages- large input shaft diameter

- fully sealed

- zero-backlash reduction gears

- high moment capacity

- excellent positioning accuracy and positioning repeatibility

- high torsional and tilting stiffness

- small dimensions and weight

- high reduction ratios

- high effeciency

- long lifetime

- easy assembly

M Series

-

The M series represents TwinSpin high precision reduction gears of mini sizes. The first representative of the series is the size TS 50, and in the near future we plan to introduce even smaller TwinSpin gears that will widen the M series. The M series has retained all the qualities of the larger SPINEA gears. We can proudly say that, in their category, they represent the best gears on the market. The M series is filled with grease for lifetime. The sealing of the M series reduction gears is secured by sealed (2RS) ball bearings, which are used as output bearings of the reduction gear, and they are also used for the housing of the input shaft of the reduction gear. (Slight leakage of the lubricant is allowed). Upon the customer’s request, SPINEA is able to supply a completely sealed reduction gear. This design of the reduction gears allows the mounting of the load directly on the output flange or case without a need of additional bearings.

Advantages- small dimensions and compact design

- fully sealed by 2RS ball bearings

- simple installation

- zero-backlash reduction gear

- very low mass

- very high power density

- output deep groove ball output bearing with very low friction

- high performance of the reduction gear

- high precision

- high torsion rigidity

- high linearity of torsion chracteristics

- very low input inertia

- very low friction and high efficiency

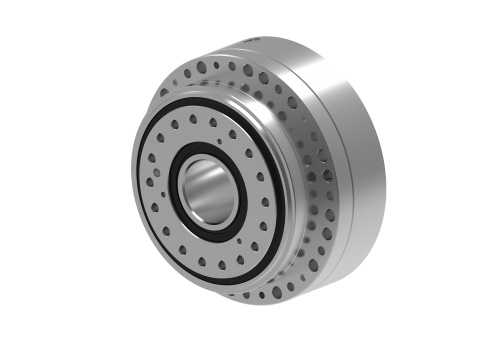

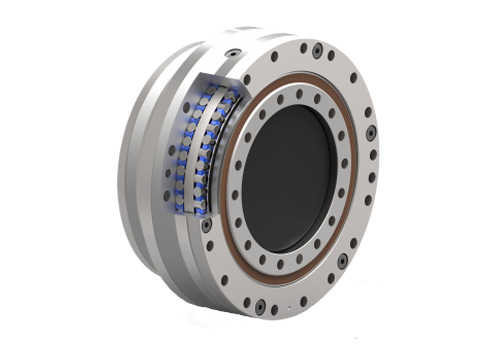

G Series

-

New genration of TwinSpin high precision reduction gears with a new design of the main bearing and improved performance for the most demanding applications. It comes in two variants, with sealed output only or as a fully sealed gear for direct connection with

a motor. In the new generation, we have concentrated the results of several years of the development of the reduction gears design, together with the implementation of the latest manufacturing processes and technologies.

Advantages- zero-backlash reduction gears

- high-moment capacity

- excellent positioning accuracy and positioning repeatibility

- high torsional and tilting stiffness

- small dimensions and weight

- high reduction ratios

- high effeciency

- long lifetime

- easy assembly

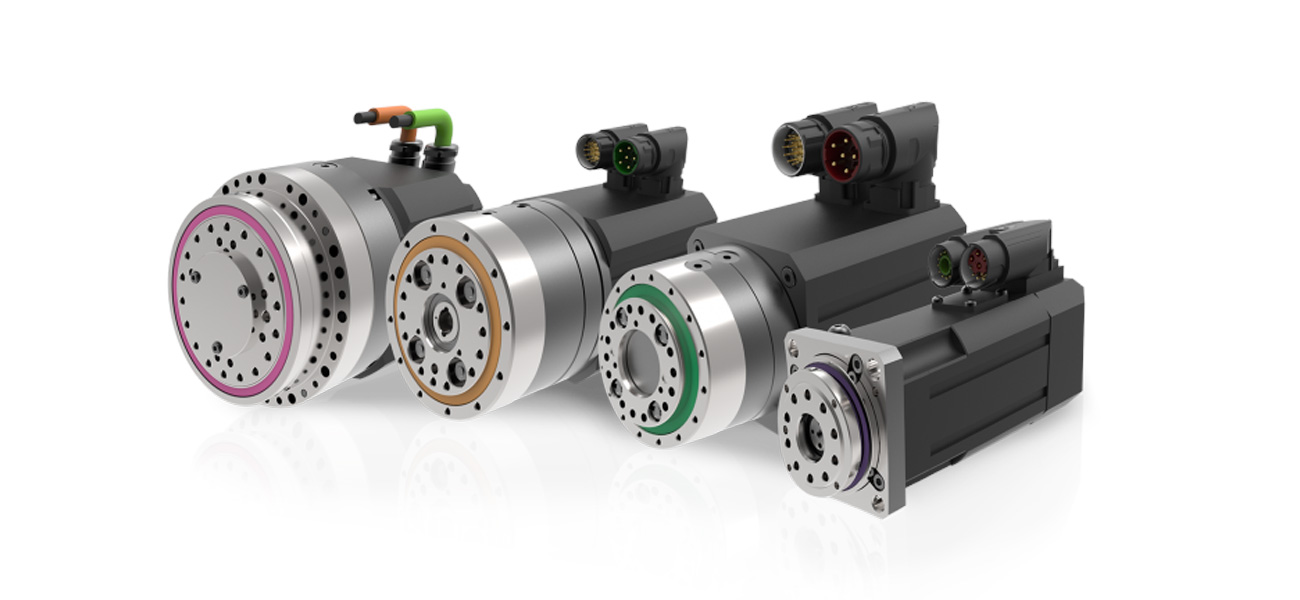

Actuators

-

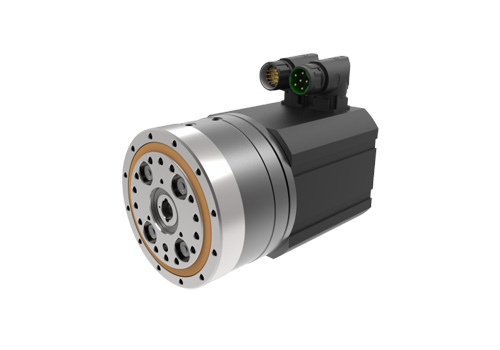

DRIVESPIN

The actuators of the DriveSpin series combine optimised servomotors and TwinSpin gears resulting in a dynamic, high- performance and very compact servo actuator with high tilting torque capacity with integrated bearing. Main characteristics of DriveSpin are compact design, zero backlash, high dynamic performance, high torsional and tillting stiffness, small size, low mass, simple installation, high load capacity of radial-axial output bearing and maintenance free.

Applications:- Robotics: 6-axis robots, gantry robots and manipulators

- Machines: CNC machine, grinding machine, lathe machine

- Special machines: bending machine

- Medicine equipment

- Aerospace applications

- Flight simulators

- Defense industry

- Semiconductor industry

- Radar and monitoring systems

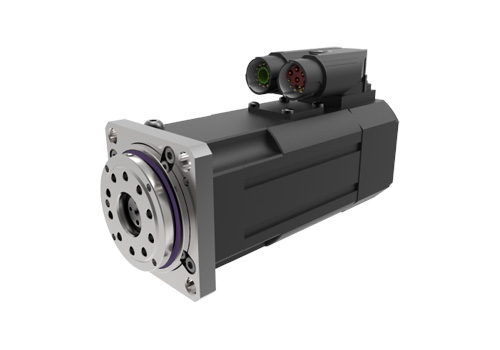

DS/DSH/DSM 50

-

The high precision DriveSpin DS 050 actuators represent the smallest serially produced member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Main design performance and advantages- small size gearbox with TwinSpin transformation mechanisms

- design with simple installation possibilities and as device for large ambient temperature range

- fully sealed design with possibility to select type of seals

- gearbox transformation members (crosses) in preloaded linear bearings

- design with possibility to select type of actuator performance and gearbox output bearings

- high linearity of torsion characteristics with respect to non-linearity in competition systems

- higher torsion rigidity with respect to small size competition gearboxes

- very high torque capacity, higher (at least twice) then in small size competition gearboxes

- low angular transmisson error and high mechanical positioning perfomance

- oscillation at higher natural frequency and lower amplitude

Applications- Robotics & general automation

- Manipulation and transport systems

- Aerospace applications

- Radar, navigation, pan&tilt, optical, camera and monitoring systems

- Defence applications

DS 050

The DriveSpin electric rotary actuators, as the basic type of actuators, provide rotary motion and the transfer of output torque with a high radial-axial load capacity and are the most accurate and precise solution in their category. The DS actuators are characterized by high dynamics, guaranteed by an AC servomotor, and high robustness and overload capacity of their reduction gears. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSH 050

The DSH electric actuators are characterized by the possibility to use a through hole for routing cables, pipes, and drive shafts while maintaining the radial-axial and torque load capacity and the characteristic high overload capacity of the reduction gear and of the AC servomotor, featuring high dynamics. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSM 050

The DSM modular rotary positioning modules provide controlled rotary motion and transfer of torque with a high positioning accuracy and precision. The output flange of the module allows to capture both radial and axial forces. The modules feature a special design of the case, which allows versatile connections, also without additional devices. The good design integration ability and small dimensions allow to create kinematic assemblies from DSM modules for end effectors, but also for additional devices and positioners. The selection of a module size depends on the required load-carrying capacity and the number of degrees of freedom of the motion axis.

DS/DSH/DSM 70

-

The high precision DriveSpin DS 070 actuators represent the medium-size serially produced member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Advantages- low lost motion

- low moment of inertia

- high reduction ratio

- high kinematic accuracy

- high moment overload capacity

- high capatity of the integrated radial-axial output bearings

- high dynamic performance

DS 070

The DriveSpin electric rotary actuators, as the basic type of actuators, provide rotary motion and the transfer of output torque with a high radial-axial load capacity and are the most accurate and precise solution in their category. The DS actuators are characterized by high dynamics, guaranteed by an AC servomotor, and high robustness and overload capacity of their reduction gears. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSH 070

The DSH electric actuators are characterized by the possibility to use a through hole for routing cables, pipes, and drive shafts while maintaining the radial-axial and torque load capacity and the characteristic high overload capacity of the reduction gear and of the AC servomotor, featuring high dynamics. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSM 070

The DSM modular rotary positioning modules provide controlled rotary motion and transfer of torque with a high positioning accuracy and precision. The output flange of the module allows to capture both radial and axial forces. The modules feature a special design of the case, which allows versatile connections, also without additional devices. The good design integration ability and small dimensions allow to create kinematic assemblies from DSM modules for end effectors, but also for additional devices and positioners. The selection of a module size depends on the required load-carrying capacity and the number of degrees of freedom of the motion axis.

DS/DSH/DSM 110

-

The high precision DriveSpin DS 110 actuators currently represent the largest serially produced member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Advantages- low lost motion

- low moment of inertia

- high reduction ratio

- high kinematic accuracy

- high moment overload capacity

- high capatity of the integrated radial-axial output bearings

- high dynamic performance

DS 110

The DriveSpin electric rotary actuators, as the basic type of actuators, provide rotary motion and the transfer of output torque with a high radial-axial load capacity and are the most accurate and precise solution in their category. The DS actuators are characterized by high dynamics, guaranteed by an AC servomotor, and high robustness and overload capacity of their reduction gears. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSH 110

The DSH electric actuators are characterized by the possibility to use a through hole for routing cables, pipes, and drive shafts while maintaining the radial-axial and torque load capacity and the characteristic high overload capacity of the reduction gear and of the AC servomotor, featuring high dynamics. The voltage and feedback variability will widely satisfy all of customers’ requirements.

DSM 110

The DSM modular rotary positioning modules provide controlled rotary motion and transfer of torque with a high positioning accuracy and precision. The output flange of the module allows to capture both radial and axial forces. The modules feature a special design of the case, which allows versatile connections, also without additional devices. The good design integration ability and small dimensions allow to create kinematic assemblies from DSM modules for end effectors, but also for additional devices and positioners. The selection of a module size depends on the required load-carrying capacity and the number of degrees of freedom of the motion axis.

DS/DSH/DSM 140

-

The high precision DriveSpin DS 140 actuators represent the new largest member of the DriveSpin product range, meeting even the most demanding requirements of customers from all industries. With their optimal price/performance ratio, they reliably provide parameters such as high accuracy and precision, high tilting and torsional stiffness, low weight, compactness, low vibrations, and a wide range of suitable technical solutions.

Advantages- low lost motion

- low moment of inertia

- high reduction ratio

- high kinematic accuracy

- high moment overload capacity

- high capatity of the integrated radial-axial output bearings

- high dynamic performance

DSH 155

-

Inline Series H represents new hollowshaft „Inline“ series of rotary actuators DriveSpin.

All components of actuator are arranged in the axis with new TwinSpin G serie hollowsaft reduction gear. Static tube enables customer to lead wires, other shaft or different mechatronic distribution system through non-rotating hole of actuator and protects it from possible damage by rotation of input shaft. Designed arrangement of components aims to provide solution with the shortest axial lenght hand in hand with the largest hollowshaft. Series is also intended to fullfill special demands of customers with variety

of sensors, brake options and electrical connection types.

Advantages- largest hollow shaft in class

- short axial length

- high torsional and tilting stiffness

- high torque

- high repetitive precision

- optimal design solution

Positioners

-

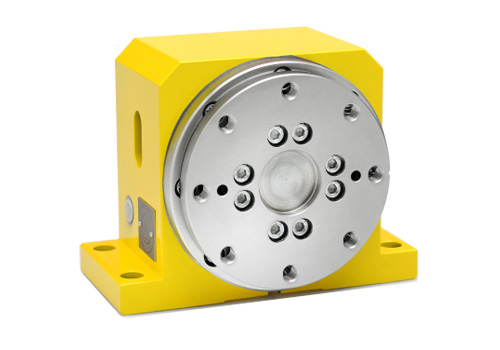

ROTOSPIN

The product RotoSpin rotary module serves for the construction of facilities which are characterized in the rotary motion, speed reduction and the tilting moment transmission. RotoSpin is installed by the highly precise TwinSpin reductor, which ensures the rotary motion without backlash, high torsional and tilting stiffness. The construction of RotoSpin ensures easy connection to the frame and comfortable clamping of movable parts to the output flange. The modularity of construction enables to connect different types of servomotors. Therefore these modules are normally produced without the drive, but with such special-purpose connecting equipment that is required by a customer for a given type of engine.

Main parts

The module RotoSpin is built on basis of the bearing reducer TwinSpin. The module can be delivered without a servomotor, with demanded connecting dimensions or with a servomotor, according to particular requirements of the client. For handling with long components the module RS-A is used in connection with the suspensory module RS-C that can be equiped by a rotary pneumatic or electrical wiring for welding currents, controlling signals.

ROTOSPIN A

-

The RotoSpin rotary modules with type designation A are called flange ones. They feature a flange design, which allows the module’s attachment and building into a structure with a circular hole. According to their size, RotoSpins A are manufactured in four size categories with load capacities of 60, 250, 500, and 1000 kg respectively.

Due to their small dimensions and low weight, the RS-A modules are used mainly in moving parts of positioning devices. If the RS modules are loaded with a higher than allowed tilting moment or shock load, we use them in combination with a support bearing.

Maintenance

The rotary module does not require any special maintenance. When installing the rotary modul, observe the respective dimensional and positional tolerances of the centering diameters. The rotary module is a high-precision product, therefore it requires careful manipulation, installation, and dismounting.

Delivery Conditions

The rotary module is delivered completely assembled, without fixing screws, grease lubricated, and in a protective package.

Each rotary modul is identified with an identification plate, including the following data:- manufacturer

- production type and size

- reduction ratio

- model

- manufacturing number

Advantages- Possibility to build into circular holes

- Low weigh and small dimensions

- Wide area of use

- Easy attachment

ROTOSPIN B

-

The modules with the identification "B", so-called footing modules are of casing construction that enables simple and safe fitting of the module to the base frame. RotoSpin B is characterized in a casing shape, which enables its easy and safe connection to a frame.

Maintenance

The rotary module does not require any special maintenance. When installing the rotary modul, observe the respective dimensional and positional tolerances of the centering diameters. The rotary module is a high-precision product, therefore it requires careful manipulation, installation, and dismounting.

Delivery Conditions

The rotary module is delivered completely assembled, without fixing screws, grease lubricated, and in a protective package.

Each rotary modul is identified with an identification plate, including the following data:- manufacturer

- production type and size

- reduction ratio

- model

- manufacturing number

ROTOSPIN C

-

The RotoSpin C rotary (support) module is used for the capturing of tilting moments during the welding of large spatial parts, for the transmission of welding current, compressed air, electrical signals, etc. The RS-C module consists of a frame, a rotary flange, a hollow shaft, a tilt bearing and a rotary welding current distribution unit. The hollow shaft allows to route compressed air and electric signal distribution lines.

Versions

The RS-C module is normally supplied with a rotary electric distribution unit for the welding current od 500 A. Upon an agreement with the manufacturer, the rotary distribution unit can be modified, or the module can be supplied without a distribution unit. The module is supplied in two versions, with feet or with a flange. The RS-C module for the horizontal or vertical axis of rotation is used as complement to the RS-A or RS-B module.

Maintenance

The rotary module does not require any special maintenance. When installing the rotary modul, observe the respective dimensional and positional tolerances of the centering diameters. The rotary module is a high-precision product, therefore it requires careful manipulation, installation, and dismounting.

Delivery Conditions

The rotary module is delivered completely assembled, without fixing screws, grease lubricated, and in a protective package.

Each rotary modul is identified with an identification plate, including the following data:- manufacturer

- production type and size

- reduction ratio

- model

- manufacturing number