- Offer Profile

-

Sill Optics is the specialist for quality and innovation in the field of photonics technologies. With regard to customized development as well as standard solutions we have established ourselves internationally and are one of the leading companies in this business. The company with more than 125 years of experience is located in Wendelstein.

Laser Optics

We offer lenses for various laser applications. Our product portfolio includes simple focusing lenses as well as beam expanders, standard ƒ-theta scan lenses and a variety of telecentric ƒ-theta scan lenses. These lenses are predominantly optimized for wavelengths in the range of 266 nm to 1090 nm.

Laser Optics from Sill Optics

-

You will love our laser optics

The product portfolio of Sill Optics ranges from simple collimation- and focusing optics to beam expanders to telecentric and non-telecentric scan lenses. We cover thereby the complete wavelength range from 193 nm to 1980 nm.

Mainly applications with solid state lasers around 1064 nm and its harmonic generations are covered. Furthermore, we provide lenses designed for disc lasers and fiber lasers in the range of 1030 nm to 1090 nm, as well as diode lasers from 800 nm to 980 nm or 900 nm to 1070 nm. Additionally many of our lenses, beam expanders and lens systems are optimized for the use with short pulse lasers (picosecond range) and ultra-short pulse lasers (femtosecond range). Lenses are also offered for very short wavelengths around 193 nm and 248 nm, but also for more long-wave radiation in the near and mid infrared regime (1550nm and 1980nm). A large selection of multispectral scan lenses allow monitoring through the used optics or use of multiple wavelengths and complete the range of our scan lens product range.

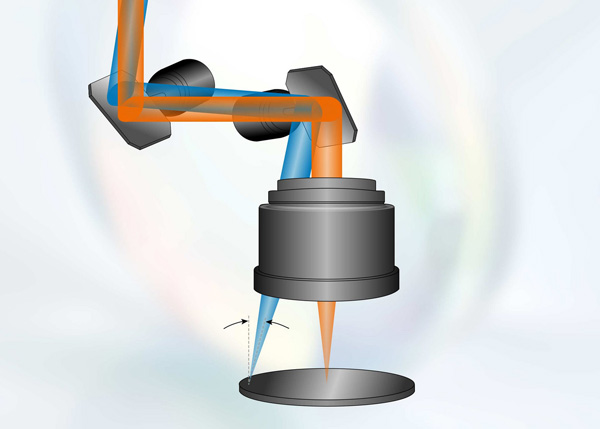

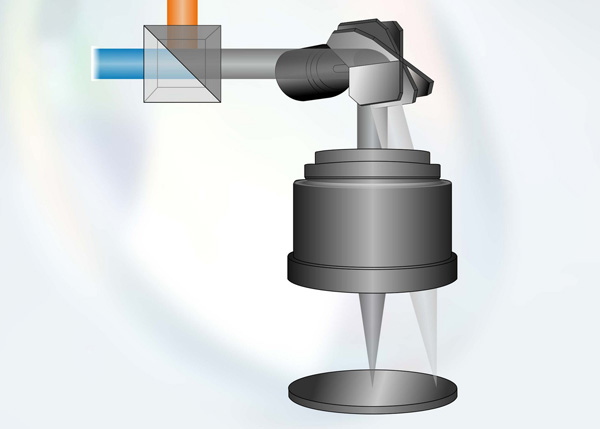

ƒ-Theta lenses

- ƒ-Theta objectives, also known as flat-field objectives or scan objectives, are used in many industries. While standard lenses display the laser beam on a spherical shell, but not on an even field, ƒ-Theta objectives have one major advantage: You can use them to position the laser focus on a level image field, while the focus size remains almost constant. The position of the focus point (image height) is proportional to the scanning angle.

OEM Products

-

Sill Optics has been a trusted partner for customized imaging lens solutions for many years. We specialize in various areas of application and offer a wide range of design types. With our extensive experience, we have successfully completed numerous projects involving customized optical designs and unique mechanical layouts. The key to our success lies in the close cooperation between our different internal departments, our vast manufacturing capabilities, and our commitment to high-quality production. These factors enable us to build your prototype in the shortest possible time.

As the market leader for customized optics for laser applications, individual development projects are the main part of our business. We participate in public research projects and respond to specific requests from our customers. Our expertise is particularly useful in laser material processing, additive manufacturing and electrical engineering, but also in laboratory applications and the automotive sector, for example. We pride ourselves on providing you with customized solutions for your specific requirements.

F-THETA LENSES

-

Multi-element lens systems minimize the imaging errors of single lenses and provide precision focusing for non-scanning applications.

Besides our portfolio and customized optics, we also offer a variety of F-Theta lenses and Beam Expanders from our former portfolio with outstanding specifications upon request. This also includes lenses for different lens markets, applications and specifications.

BEAM EXPANDERS

- Sill Optics has been manufacturing high-quality laser optics for almost 40 years. These lenses are specifically designed for laser material processing applications of industrial mechanical engineering. They are specially designed for applications in CE, automotive, semiconductor, additive or solar cell manufacturing. In addition to medical and biotech applications (confocal microscopy, ophthalmology) and science and research. The design and the quality of the optical components play a key role in the lens performance. Many of our Beam Expanders can also be used in reverse direction. Using a Beam Expander reverse may the result in increased divergence and possibly other disadvantages as the Beam Expanders are usually designed to magnify beams. Therefore, please feel free to contact our technical support if you have any questions.

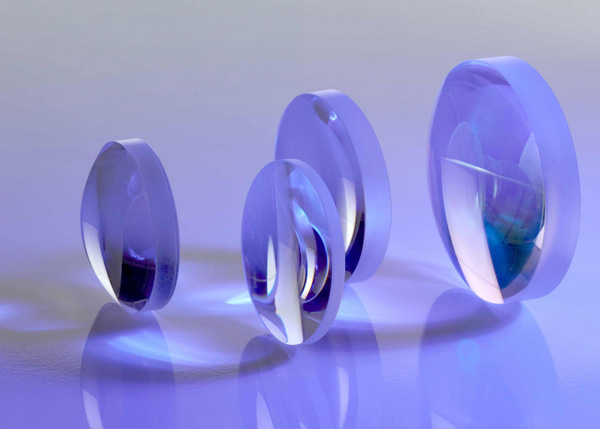

ASPHERIC LENSES

- The use of aspheric lenses in optical systems is increasing. Aspheric lenses enable an enhancement of resolution especially for optical systems with a high numerical aperture. The aspheric deviation of the high end series is smaller than 0.05 μm RMSi. Aspheres offer the great advantage to accomplish monochromatic imaging tasks with one optical element where multiple lens elements would otherwise be needed. Main advantages of aspheres are less spherical aberrations, less weight, increased transmission and no internal ghosts.

TRAPPED ION LENSES

- Trapped (cold) ions are a research topic with increasing interest over the last few years because of their possibility to store Qubits (quantum bits) and the related use for quantum computers. To make the qubits usable under certain conditions, we must observe and study their behaviour in detailed experiments first. Sill Optics has designed lenses both, for just observation and observation combined with laser focusing for these experiments. Those lenses are exceptional for their high NA and adjustment to specific wavelengths (UV to IR). As the vacuum cryostats differ in dimension (e.g. the window thickness) every lens has to be designed specifically for the existing conditions.

Portfolio lenses

-

Lenses that are used in combination with XY galvanometer scanners or polygon scanners are known as ƒ-theta lenses, flat field lenses or simply scan lenses. Our scan lenses are used in a variety of applications, such as industrial material processing (e.g. structuring, drilling, welding, cutting, etc.), in medical technology and biotechnology (confocal microscopy, ophthalmology) and in science and research. The design and quality of the optical components play a decisive role.

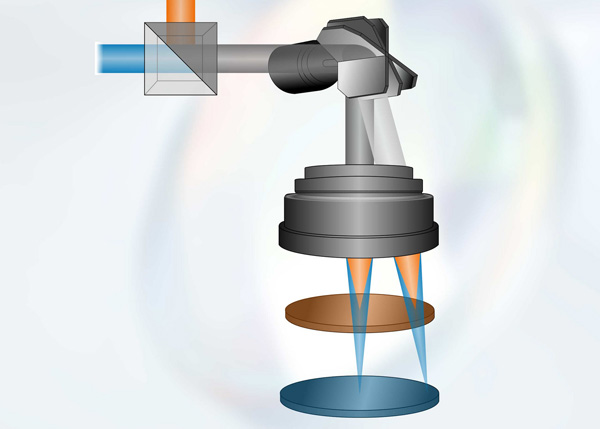

Color corrected scan lenses

- While the dispersion in material can be neglected when using femtosecond pulses, the color error due to the spectral width of the pulse plays an important role. The spectral width of the pulse increases rapidly with shorter pulses and longer wavelengths. This results in a color error that has a different axial and lateral image position for different wavelengths. Our range includes scan lenses specifically for use with femtosecond lasers, which are designed to correct this color error and thus guarantee uniform beam quality across the processing field.

Optical glasses vs. fused silica

- Short pulse lasers and ultra-short pulse lasers, but also lasers with high average power issue a exceptional challenge for lenses. Processed are strongly influenced by the characteristics of regular optical glasses. For instance thermal effects change both the beam shape and the working distance. At this point fused silica presents its crucial advantage by lower sensitivity to thermal effects in comparison to optical glasses and is therefore highly recommended for the use with the named laser sources above.

Telecentricity

- While the dispersion in the material can neglected for fs-pulses, the color error caused by the spectral width of the pulse plays a decisive role. The spectral width of the pulse is increasing rapidly by shorter pulse durations and for longer wavelengths. This results in a color error where the axial and lateral position of a focused beam varies for different colors. The amount of deviation of the resulting spot depends on the focal length and the wavelength. Sill offers ƒ-theta lenses which are especially designed for the use with femtosecond lasers and correct this color error leading to a consistent beam shape over the complete scan area.

Color corrected ƒ-theta lenses

- While the dispersion in the material can neglected for fs-pulses, the color error caused by the spectral width of the pulse plays a decisive role. The spectral width of the pulse is increasing rapidly by shorter pulse durations and for longer wavelengths. This results in a color error where the axial and lateral position of a focused beam varies for different colors. The amount of deviation of the resulting spot depends on the focal length and the wavelength. Sill offers ƒ-theta lenses which are especially designed for the use with femtosecond lasers and correct this color error leading to a consistent beam shape over the complete scan area.

Multispectral ƒ-theta lenses

-

For online inspection systems we successfully introduced color corrected ƒ-theta lenses for 1064 nm and 532 nm to the market. Color correction offers usage of one lens for several manufacturing steps at the same time.

In addition, we offer color corrected ƒ-theta lenses designed for confocal microscopy applications optimized for a wavelength range from 450 nm to 650 nm and a lens optimized for 355 nm and 1064 nm. The focal lengths and working distances are identical for several wavelengths, resulting in identical image fields for the laser and inspection wavelength respectively for a whole wavelength range.

Beam expanders

- Beam expanders are optical systems used to increase or decrease the beam diameter. The product of beam diameter and divergence of the laser beam is a constant and therefore remains unchanged, i.e. increasing the beam diameter means reducing the divergence of the beam to the same degree. This is true for the expanders with fixed expansion factor as well as for the zoom expanders, where the magnification is variable. Each type of our beam expanders offers a manual or motorized divergence adjustability.

Beam expanders

-

All optical elements of beam expanders consist of fused silica and provide stable and reliable performance even with high average power or laser with high peak power. Because of the high power density (especially at the entrance lens element) we advise our low absorption coating as standard product.

For each magnification ratio, at least one beam expander without internal ghost is available offering stable working conditions even at high power and small entrance beam diameter.

Our beam expanders are available in diverse variation

-

Our beam expanders are available in diverse variations and additional special functions. Please note the following listing as an overview:

- fixed magnification

- fixed magnification for large beam diameters

- compact beam expanders with fixed magnification

- fixed magnification with motorized divergence adjustment

- variable magnification (zoom beam expander)

- motorized variable magnification

- combined motorized magnification and divergence adjustmen

Aspheres

-

Aspheres offer the great advantage to accomplish imaging tasks with one optical element where lens systems were needed otherwise.

Main advantages of aspheres are:

- less spherical aberrations

- less weight

- increased transmission

- no internal ghosts

The combination of high purity fused silica and low absorption coatings decreases the thermal induced shift of focal length and working distance.

Another application of an asphere is beam shaping with respect to the intensity distribution or the phase. A typical conversion is the change of a Gaussian profile into a top-hat profile. For material processing, this form has the advantage of a more homogeneous removal of surface material, steeper borders between removal zone and surrounding material and a resulting smaller heat affected zone (HAZ).

Production of aspheres up to diameter 200 mm

-

The capability of Sill Optics MRF machines allows production of aspheres up to diameter 200 mm. Measurement setup (interferometric wavefront test, tactile and optical 3D profi lometry) enables us to

ensure a surface quality of 0.15 μm PV(fWD) and RMSi < 0.025 μm depending on geometry. Even sagittal heights z(r) up to 21 mm are measurable enabling the production and test of very steep radii at certain diameters.Our range of products covers unmounted and mounted precision aspheres out of fused silica with focal lengths from 20 mm to 400 mm, which are usable for focusing and collimation.

Special forms and customized versions are available on request.

Our technological possibilites

-

- Diameter: 12 - 200mm

- Diameter tolerance: ±0.01mm

- Thickness tolerance: ±0.01mm

- Concave radius of curvature (local): > 35mm

- Sagittal deviation (PV): < 0.5fr (= 0.137µ )

- Irregularity (PV): < 0.5fr (= 0.137µ )

- Rotaional invariant irregularity (PV): < 0.2fr (= 0.055µ )

- RMSi (PV): < 0.1fr (= 0.025µ )

- Centration (tilt angle between surfaces): < 1arcmin

- Cleanliness / imperfections: 3x0.04 (S/D:10/5)

Materials:

- all fused silica types (Corning, Heareus, Nikon, Ohara)

- optical glasses (CDGM, Hoya, Nikon, Ohara, Schott,...)

Metrology:

- tactical 2D measurement

- 2D / 3D profilometry via white light interferometry

- interferometric wavefront measurement (632.8 nm)

Focusing lenses

- Multi-element lens systems minimize the imaging errors of single lenses and provide precision focusing for non-scanning applications. You have to distinguish between monochromatic and achromatic systems.

Monochromatic systems are only corrected for a specific wavelength. So they are most suitable for laser applications. Especially fused silica lenses in air-spaced design are preferably chosen for collimation or focusing of high power laser. Mounted air spaced multi element systems in fused silica andoptical glass

- Our laser optics run at peak performance with the right equipment. For example, with an objective holder that makes the calibration of optical components in a laser path as easy as 1, 2, 3. Or with a telephoto lens for precise, impressive camera images. We also provide special equipment to suit your needs – simply let us know!

Accessories

Telephoto lens

- These lenses are designed for observing the process by a camera system through the scan lens. The field of view is defined by the ratio of the focal lengths of the scan lens and of the camera lens. An integrated illumination system through the camera lens is recommended, which concentrates the light exactly onto the required field of view.

Lens mount

- The adjustment of optical components into a laser beam is often a challenge. Many commercial holders realize tilt or an axial offset by a fine adjustment only. The holder of Sill Optics realizes both: a tilt (+/-0.5°) and a lateral shift (in X and Y of +/-1.5 mm) in one mechanical component. This developed holder has an additional remarkable advantage: It tilts the optical system in reference to the optical and not in terms of a lateral shifted axis. Therefore it is not necessary to track the lateral components while angular adjustment. The holder can be mounted in two positions, 0° and 45° or can be integrated directly into a mechanical holder without the base also.