- Offer Profile

- Roosen BPL has been

developing and manufacturing high-quality handling systems for more than 30

years. The plastics industry, metal processing, chemicals, food industry,

logistics, packaging and automotive industry use our balancers worldwide.

We deliver the right handling system for every application – always comfortable, safe (including CE declaration) and effective. We design and manufacture your balancer on the basis of an extensive inventory and analysis of your local conditions, products and working methods.

LIFTING SOLUTIONS

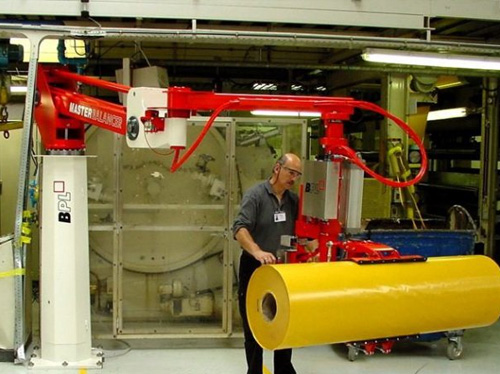

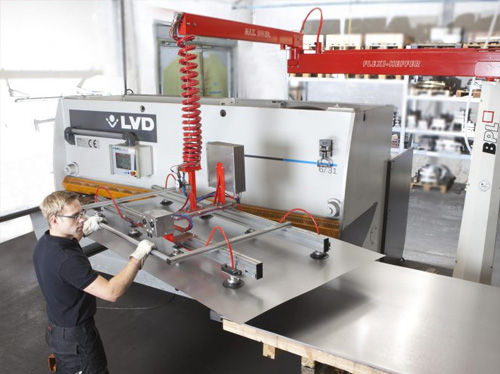

Roll Handling

-

- Roll weight up to 800 kg

- Roll width up to 5 meters

- Clamping on the outside, clamping in the role of a combination

- Vertical lifting, Horizontal lifting or a combination (tiltable during lifting)

- Lift multiple roles at the same time

- Standing on the floor, suspended from the ceiling or in a rail system

Lifting Aid Roll

- A lifting aid on a column and folding arms has a working area up to 12 meters (in a circle)

- A lifting aid in a rail system can reach a wider range, eg 5 x 9 meters

- Many integrated safety features make our systems extremely reliable

- The balancers operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Our designs need low maintenance

- All our appliances come with a CE declaration

Standard and Customer specific Manipulator

We have standard roller lifting aids that cover common roll handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

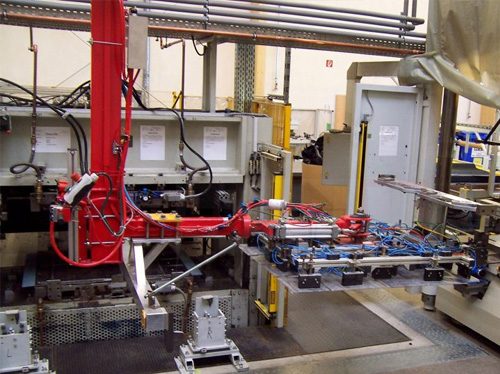

Shaft / Axis Handling

-

- Lifting weight up to 700 kg

- Shaft length up to 4 meters

- Lifting shafts in and out of the machine (e.g. printing, foil, packaging)

- Shafts lift and rotate eg cam shafts

- Through an interchangeable part in the clamp, different shaft diameters can be easily lifted

Shaft Lifting aid

- A lifting aid with column and folding arms has a working area of up to ∅ 8 meters

- A lifting aid with rail system can handle a greater range, for example 10×20 meters

- Many safety features make the system extremely reliable

- The handling systems operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Due to the design, maintenance is very low and simple

- All appliances are supplied with a CE declaration

Standard and Customer specific Manipulator

We have standard lifting aids for axles that cover the most common axle handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

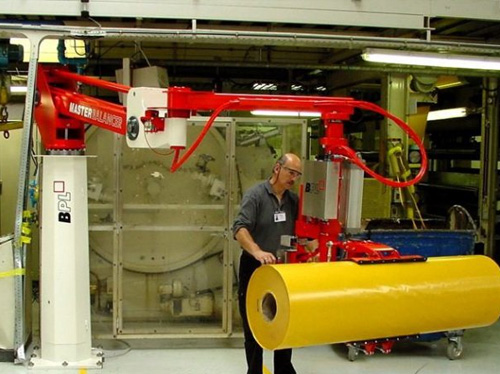

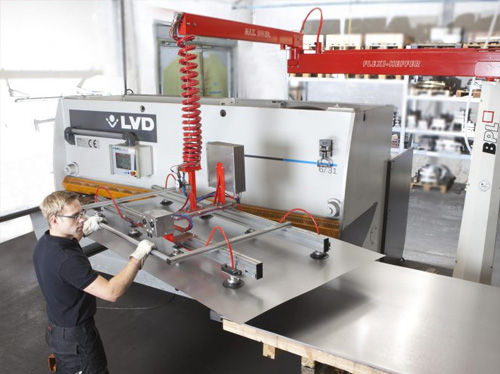

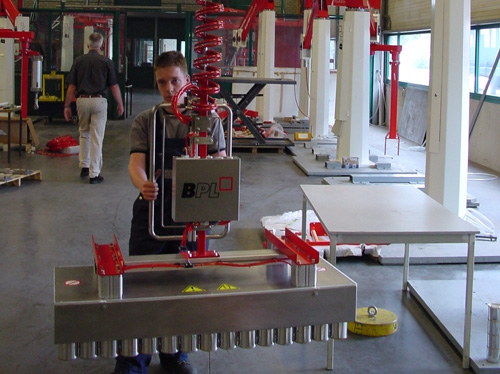

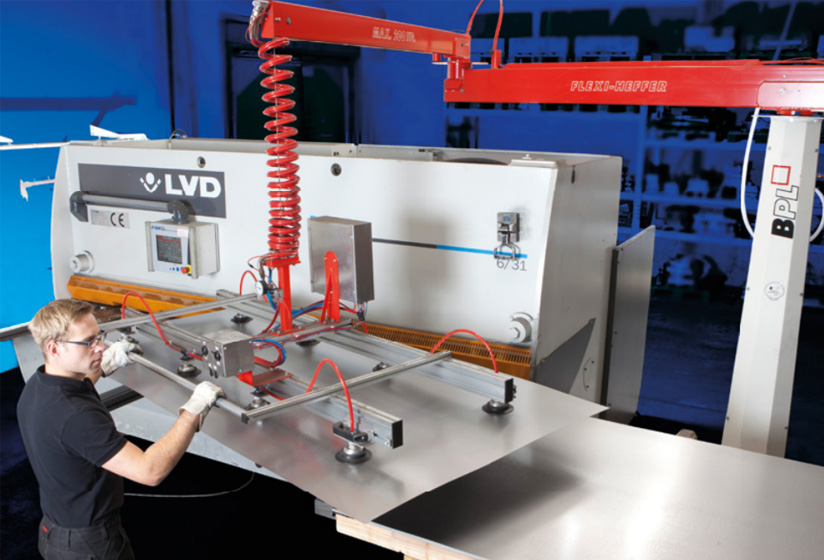

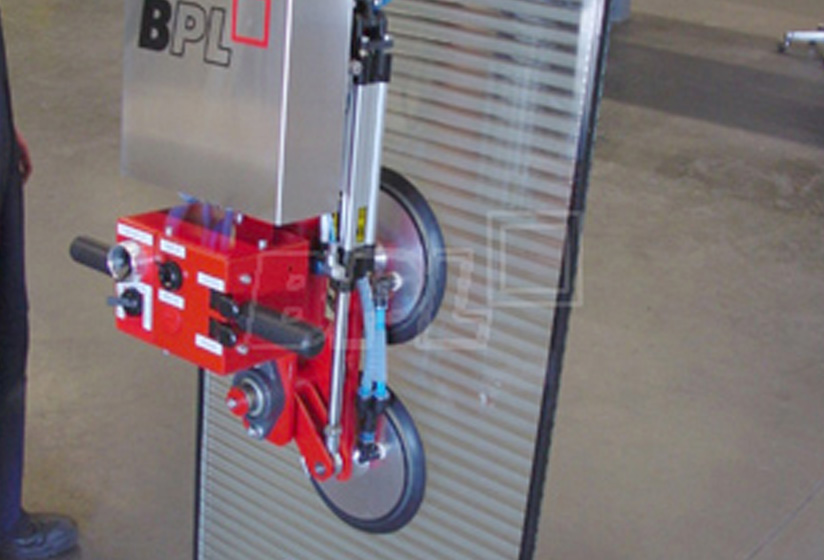

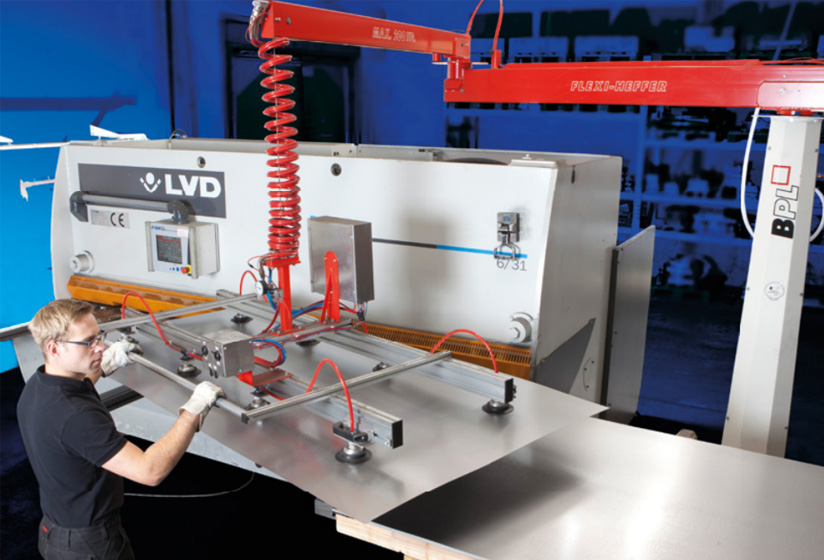

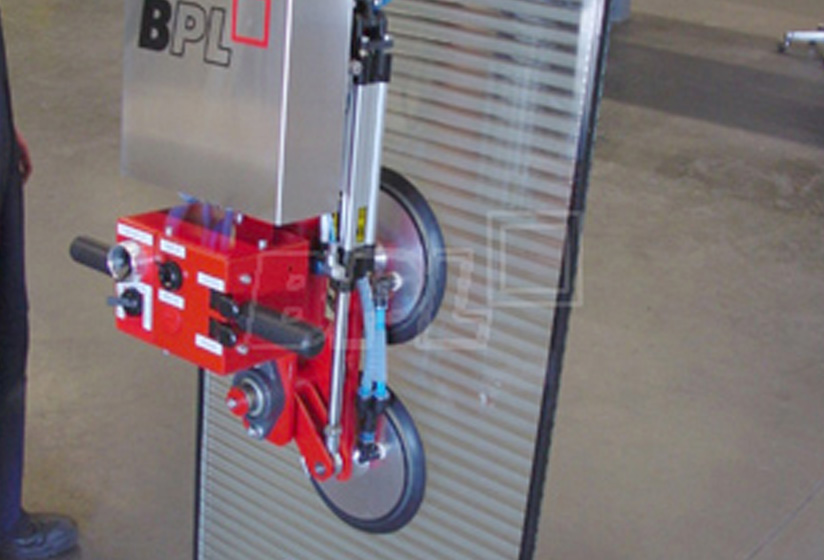

Plates & Panels Handling

-

- Lifting weight up to 400 kg

- Dimensions up to 3×6 meters

- Easily lift plates and panels with vacuum or by means of clamping

- Metal plates, diamond plates, glass plates

- Sandwich panels, solar panels, wooden panels

- Tilt 90 degrees or 180 degrees while lifting

Plates & Panels Lifting Aid

- A lifting aid with column and folding arms has a working area of up to ∅ 8 meters.

- A lifting aid with rail system can handle a greater range, for example 10×20 meters.

- Many safety features make the system extremely reliable.

- The handling systems operate at 6 bar air pressure – no electricity required.

- Stepless lifting and lowering speed.

- No need to set counter ballast weights.

- Due to the design, maintenance is very low and simple.

- All appliances are supplied with a CE declaration.

Standard and Customer specific Manipulator

We have standard lifting aids for plates and panels that cover common plate/panel handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

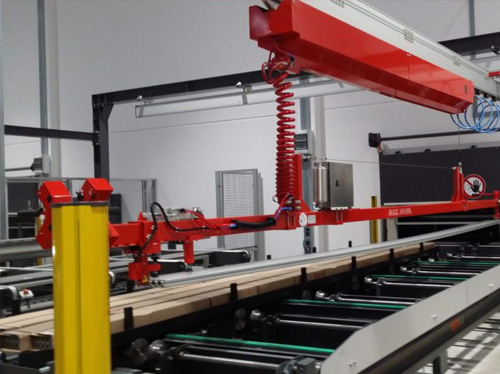

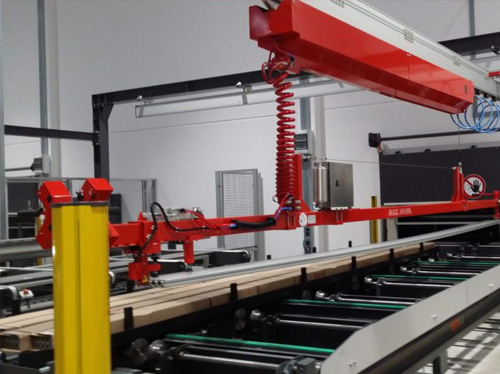

Tubes & Profiles Handling

-

- Lifting capacity up to 400 kg

- Lengths up to 14 meters

- Clamping on the outside, clamping in the tube / profile or a combination

- Lift several tubes / profiles at the same time

- Standing on the floor, suspended from the ceiling or in a rail system.

Tubes & Profiles Lifting aid

- A lifting aid with column and folding arms has a working area of up to Ø 8 meters

- A lifting aid with rail system can handle a greater range, for example 10×20 meters

- Many safety features make the system extremely reliable

- The handling systems operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Due to the design, maintenance is very low and simple

- All appliances are supplied with a CE declaration

Standard and Customer specific Manipulator

We have standard lifting aids for tubes and profiles that cover common handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

Metal Products Lifting Aid

-

- Product weight up to 700 kg

- Lifting the product by means of. magnets, slings, fork or with a clamp mount

- Vertical lifting, Horizontal lifting or a combination (tiltable during lifting)

- Lift multiple products at the same time

- Standing on the floor, suspended from the ceiling or in a rail system

Metal Products Lifting Aid

- A lifting aid on a column and folding arms has a working area up to 12 meters (in a circle)

- A lifting aid in a rail system can reach a wider range, eg 5 x 9 meters

- Many integrated safety features make our systems extremely reliable

- The balancers operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Our designs need low maintenance

- All our appliances come with a CE declaration

Standard and Customer specific Manipulator

We have standard lifting aids for metal products that cover common handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

Pallet Handling – 90 degree tilting

-

Tilt pallets easily and safely 90 degrees. This can be done in a stand alone solution and directly in the production line

- max. 1.500 KG – bin (lxbxh) 1200 x 1200 x 1200 mm

- max. 2.000 KG – bin (lxbxh) 1500 x 1500 x 1500 mm

- Suitable for various pallet sizes including Euro and Block pallets.

- Also possible to place directly in the (production) line.

- With CE certification

Pallet Handling – 180 degree turning

Easily change pallets or turn over your products, with this stand-alone solution it is safe and very simple.

- Max. 2.000 KG – bin (lxbxh) 1250 x 1200 x 600~2080 mm

- Suitable for Block and Euro pallets and others

- Low maintenance and CE certified

Pallet Handling – Dumpster

Easy to dump (lift and tilt) pallets. This can be done directly in the production line or as a stand-alone solution.

- Suitable for various pallet sizes including Euro and Block pallets.

- Also possible to place directly in the (production) line.

- The dumpers are supplied with a CE declaration

Bins & Crates Handling

-

- Lifting weight up to 800 kg

- Many variations in containers and crates possible

- Clamping on the outside, lifting with vacuum or with a fork

- Vertical lifting with a possibility for a tilt function (dumping)

- Multiple bins / crates at the same time

- Standing on the floor, suspended from the ceiling or in a rail system

Bins & Crates Lifting aid

- A lifting aid with column and folding arms has a working area of up to Ø 8 meters

- A lifting aid with rail system can handle a greater range, for example 10×20 meters

- Many safety features make the system extremely reliable

- The handling systems operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Due to the design, maintenance is very low and simple

- All appliances are supplied with a CE declaration

Standard and Customer specific Manipulator

We have standard roller lifting aids that cover common roll handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

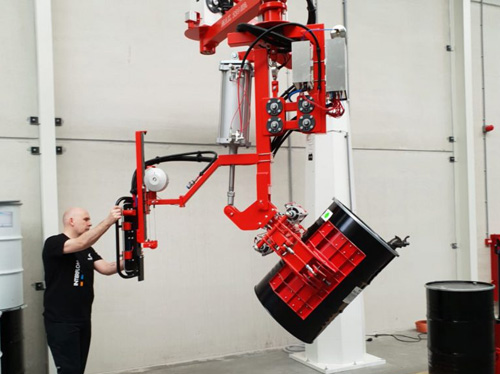

Drums & Barrels Handling

-

These products are often difficult to lift and move due to their weight, shape and size.

- Lifting capacity up to 500 kg

- Clamping on the outside or clamping at the top

- Vertical lifting, Horizontal lifting or a combination (tiltable during lifting)

- Lift several barrels / barrels / jugs at the same time

- Standing on the floor, suspended from the ceiling or in a rail system

Drums & Barrels Lifting Aid

- A lifting aid with column and folding arms has a working area of up to Ø 8 meters

- A lifting aid with rail system can handle a greater range, for example 10×20 meters

- Many safety features make the system extremely reliable

- The handling systems operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Due to the design, maintenance is very low and simple

- All appliances are supplied with a CE declaration

Standard and Customer specific Manipulator

We have standard lifting aids for barrels and barrels that cover common handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

Box Handling

-

- Lifting weight up to 200 kg

- Many box variants possible – material, measurement, thickness, etc.

- Lift with vacuum, a clamp or a combination

- Vertical lifting, horizontal lifting or a combination (tiltable during lifting)

- Lift multiple boxes at the same time

- Standing on the floor, suspended from the ceiling or in a rail system.

Box Lifting Aid

- A lifting aid with column and folding arms has a working area of up to Ø 8 meters

- A lifting aid with rail system can handle a greater range, for example 10×20 meters

- Many safety features make the system extremely reliable

- The handling systems operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Due to the design, maintenance is very low and simple

- All appliances are supplied with a CE declaration

Standard and Customer specific Manipulator

We have standard box lifting aids that cover common box handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

Bag Handling

-

- Bag weight up to 500 kg (big bags)

- Lifting by Vacuum, Clamping or a combination

- Lift several bags at the same time

- Standing on the floor, hanging from the ceiling or in a rail system

Bags Lifting Aid

- A lifting aid on a column and folding arms has a working area up to 12 meters (in a circle)

- A lifting aid in a rail system can reach a wider range, eg 5 x 9 meters

- Many integrated safety features make our systems extremely reliable

- The balancers operate at 6 bar air pressure – no electricity required

- Stepless lifting and lowering speed

- No need to set counter ballast weights

- Our designs need low maintenance

- All our appliances come with a CE declaration

Standard and Customer specific Manipulator

We have Standard bag lifting aids that cover common bag handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

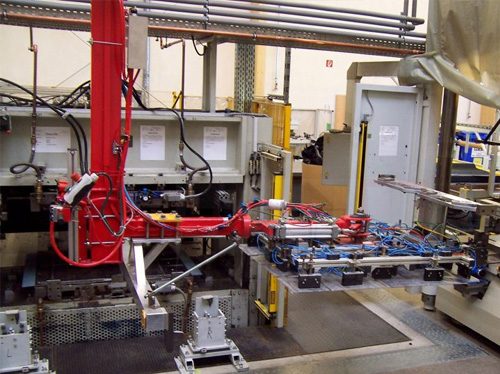

Others Balancers

-

Optimization of your Handling

Our custom solutions are tailored to your work situation, variety and dimensions of your products, any special wishes and requirements, which we inventory and record together with you.

The result: the ideal solution for your workplace. Whether you need a flexible, rigid, standing or hanging balancer, perhaps a rail system or a movable version, we are happy to offer it, from simple to special. Everything to handle your products safely and repetitively.

Lifting aid – achieve a lot with little

- Increase work safety

- Reduce sickleaves

- Comply to the Occupational health and safety legislation

- Increase efficiency

- Relieve employees

- Increase work rate

- Eliminate lifting and handling damage

- Increase job satisfaction

Standard and Customer specific Manipulator

We have several standard lifting aids with which apply to common handling issues.

Is a standard device not sufficient?

Then our experienced Engineers can translate your wishes into a customer-specific lifting solution.

EASY SERIE

- Our standard product line for many handling situations e.g. platehandling, rollhandling and pallethandling.

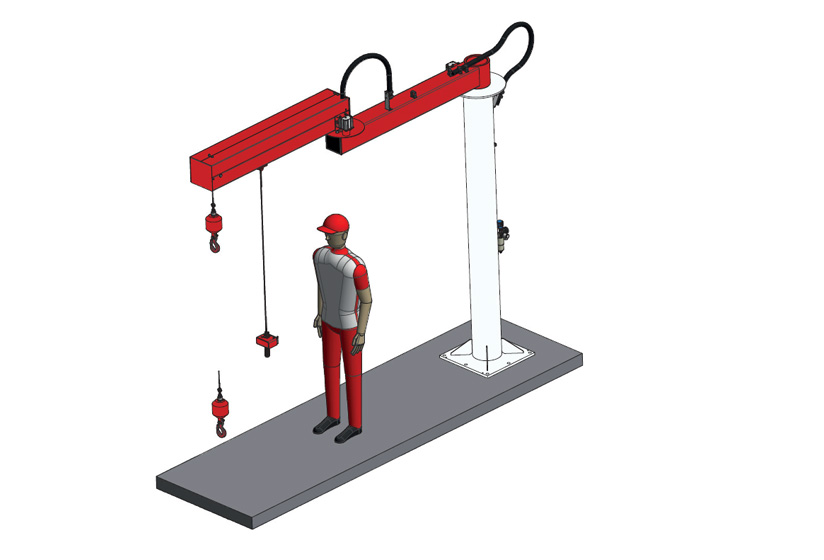

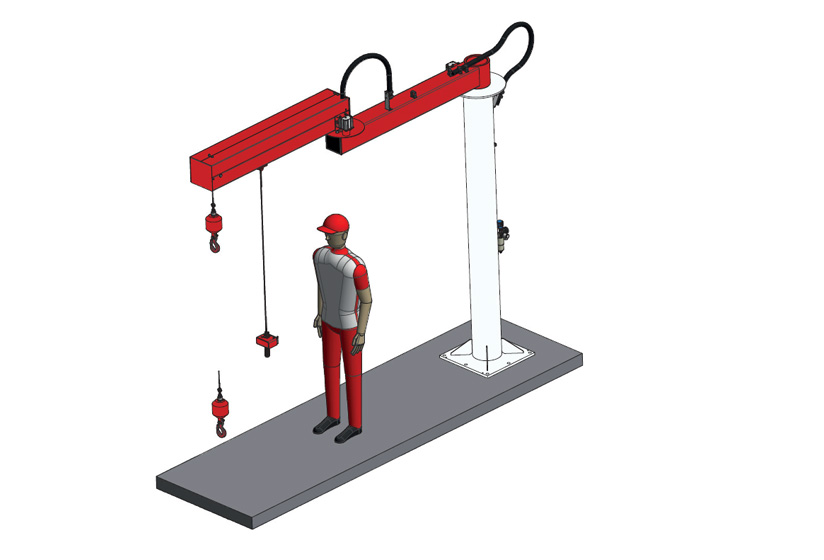

EASY-UP

-

The pneumatic EASY-UP is an ergonomic balancer equipped with a user-friendly one-hand controller and a safety hook as load-bearing device, making this a multifunctional lifting aid.

WHY THE EASY-UP?

Advantages of this EASY-UP compared to a column slewing or overhead crane:

- High lifting and lowering speed

- Knee arms for easy and light movement

- Easy positioning

- Parking brakes on the pivot points

- Fully pneumatic

- Easy to install yourself

- Delivery including mounting materials

COLUMN PLACEMENT

To be fixed with chemical anchors on a non-cracked concrete floor with a minimum thickness of 150 mm. In case of a thinner concrete floor, the column can be mounted on a steel intermediate plate (optional).

MOVABLE

The EASY-UP can (optionally) be executed on a steel forklift base, 1500x1500x50 mm. This makes the device easy to move. Total mass including forklift base approx. 1100 kg

STEEL CABLE

The steel cable must be replaced at a maximum of 50,000 lifting cycles or at least once a year.

In addition to the EASY-UP, we also offer standard solutions for, among other things, roll, axle and plate handling. Roosen BPL is a specialist in customer-specific lifting aids. We are happy to solve your handling issue!

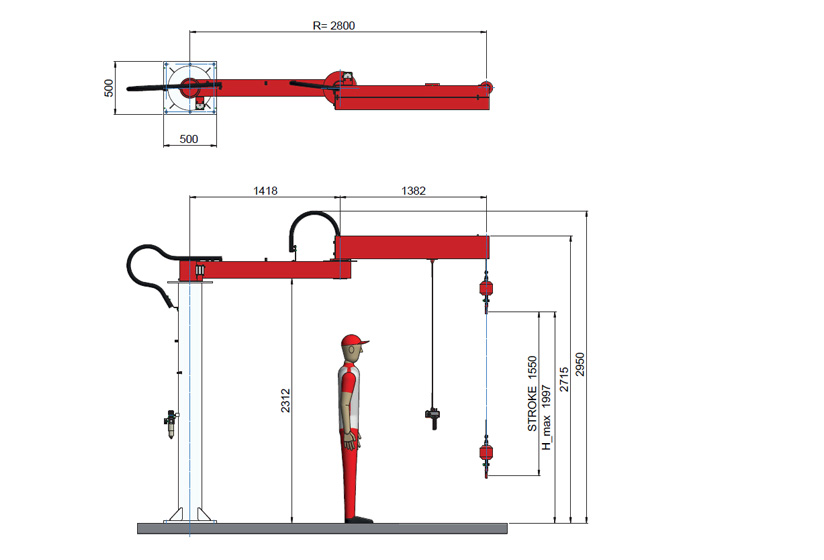

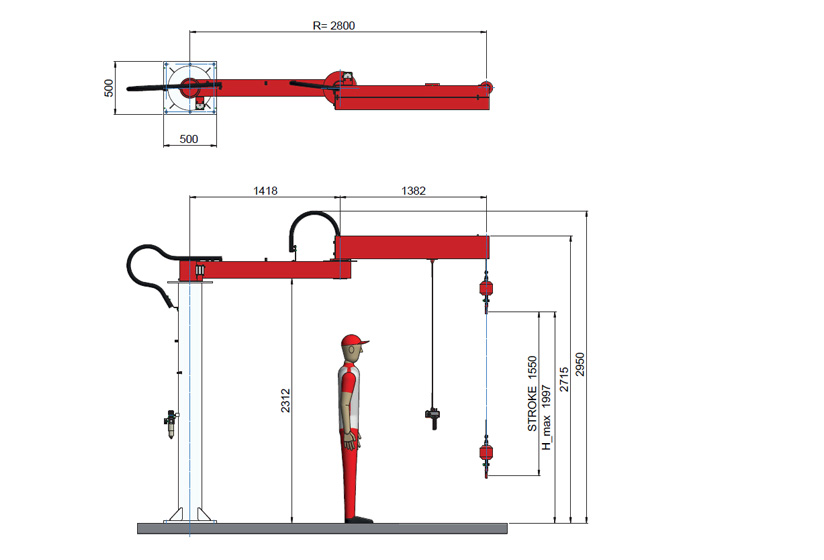

TECHNICAL SPECIFICATIONS- Lifting capacity : max. 125 kg

- Radius range : min. 500 mm, max. 2800 mm

- Device height : 2950 mm

- Installation height : min. 3000 mm

- Compressed air supply : min. 6 bar – clean and dry compressed air

- Air consumption : approx. 50 Nl / cycle

- Includes CE declaration

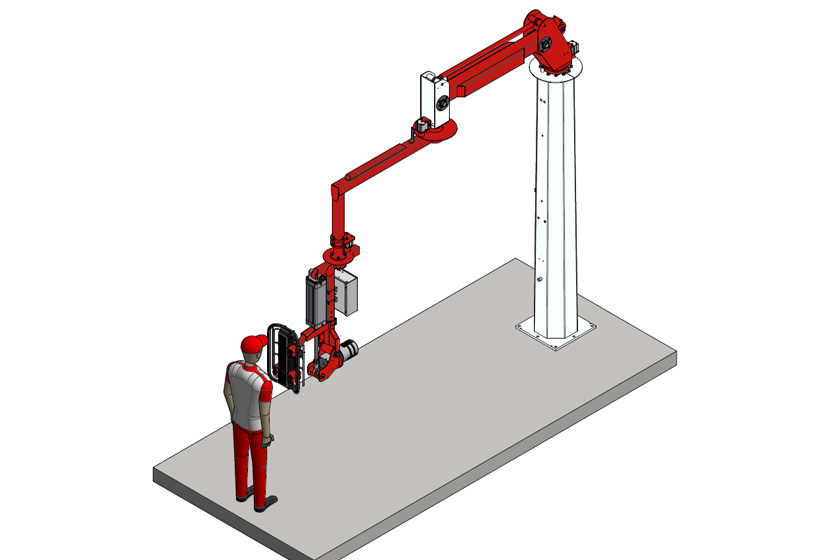

EASY-ROLL

-

The fully pneumatic EASY-ROLL lifts and tilts rolls up to 200 kg and 500 kg respectively, depending on the version. It is unique in its construction and works without ballast weight. The Ergo operation makes the lifting aid user-friendly for every employee. The well thought-out clamping mandrel and other safety features make the EASY-ROLL your ideal reel handling aid.

WHY THE EASY-ROLL?

- Safe & reliable

- Stepless lifting and lowering speed

- No weight adjustment necessary

- Easy positioning with parking brakes on the pivot points

- Stand-by without air consumption

- Delivery including mounting material

- Possibly to assemble yourself

COLUMN PLACEMENT

To be fixed with chemical anchors on a non-cracked concrete floor with a minimum thickness of 150 mm and 190 mm respectively. In case of a thinner concrete floor, the column can be mounted on a steel intermediate plate (optional).

MOVABLE

The EASY-ROLL is (optional) available on a steel forklift base, 1500×1500 mm. This makes the device easy to move and use at multiple workplaces.

OPTIONAL

- 6 ”Adapter

- Pneumatic anti-telescoping unit

In addition to the EASY-ROLL, we also offer standard solutions for sheet, axle and pallet handling, among other things. Do you have other wishes than the technical specifications mentioned on the right? Roosen BPL is the specialist in customer-specific lifting aids. We are happy to solve your handling issue!

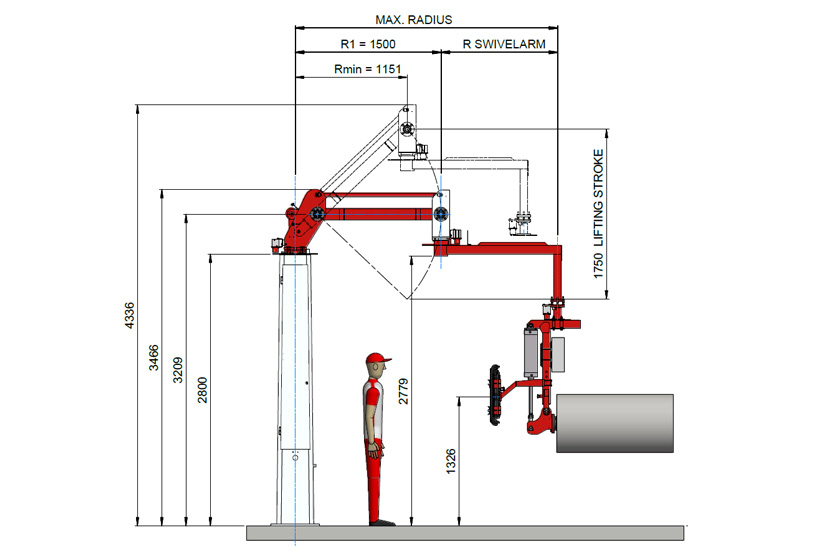

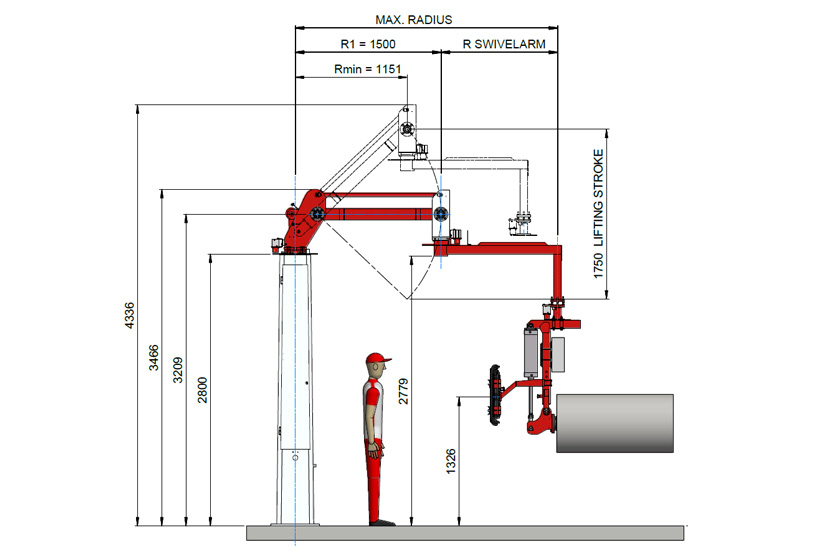

TECHNICAL SPECIFICATIONS- Lifting capacity: max. 300 kg resp. 500 kg (XL)

- Radius range: 2600 mm resp. 3000 mm (XL)

- Device height: 4336 mm resp. 4512 mm (XL)

- Installation height: 4500 mm resp. 4650 mm (XL)

- Compressed air supply: min. 6 bar – clean and dry compressed air

- Air consumption: 200 NI / cycle Includes

- CE declaration

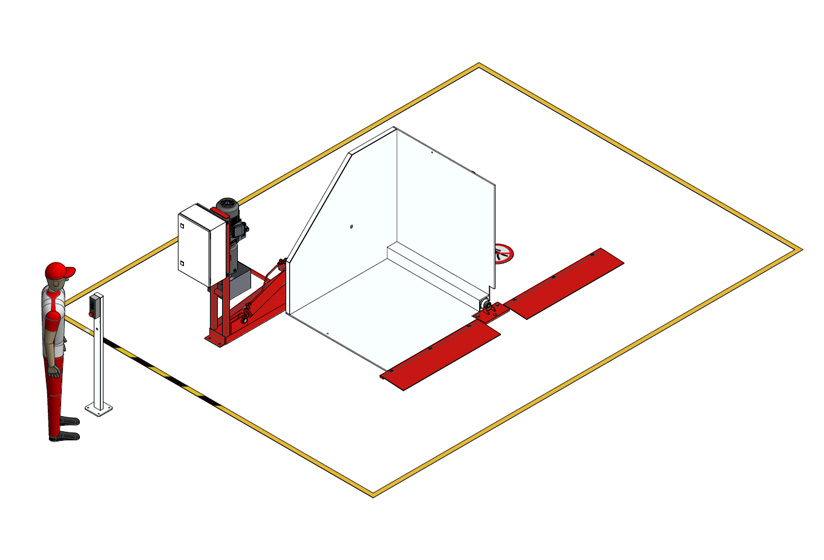

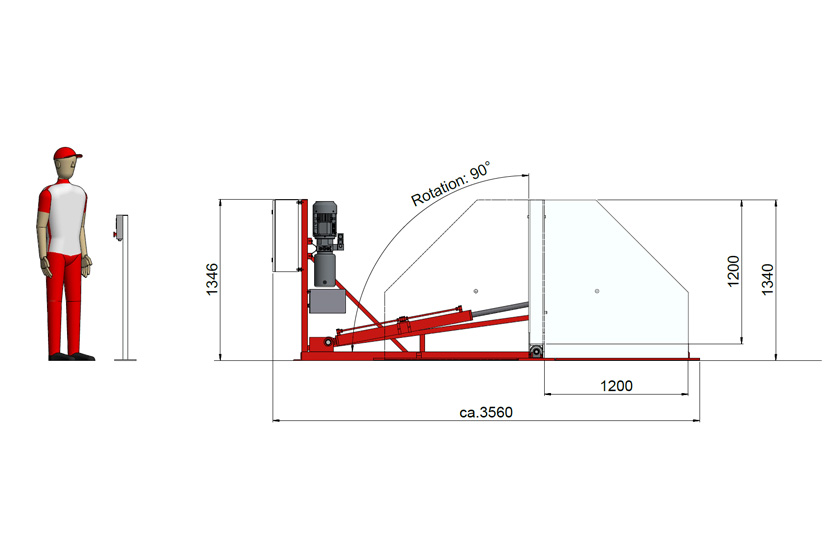

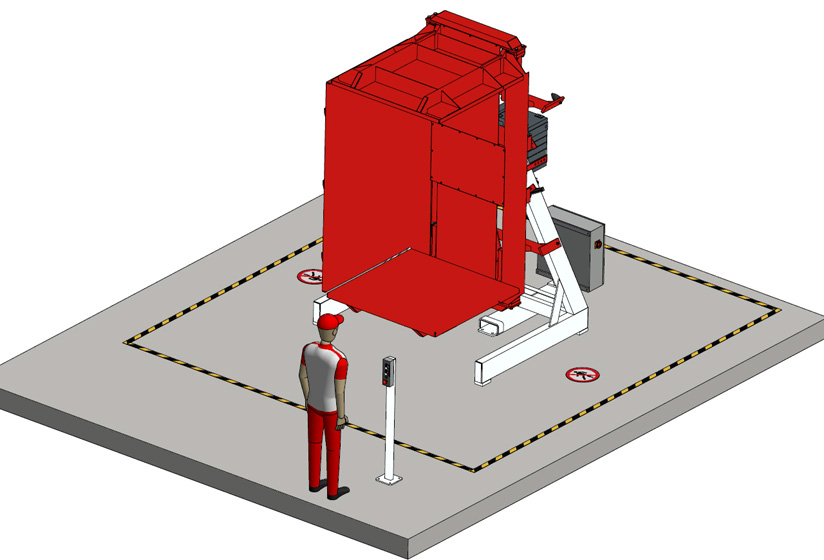

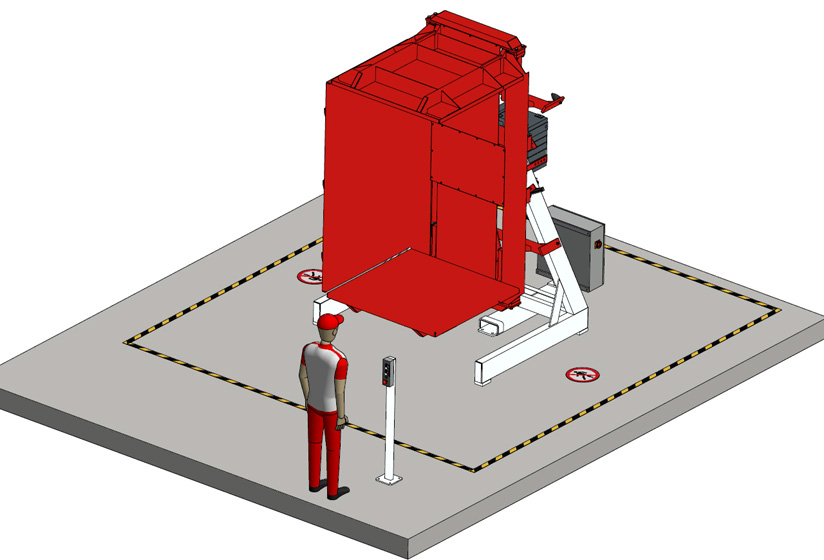

EASY-TIPPER

-

With our 90 degree pallet tipper you can easily tilt large and heavy products such as rolls and packaged goods safely and controlled. Loading and unloading of this EASY-TIPPER can be done by means of a hand pallet or forklift truck.

WHY THE EASY-TIPPER?

- Easy loading and unloading

- Easy to operate

- Hold-to-Run operation

- Easy to self-install

- Delivery including 2 ramps

PLACEMENT

The pallet turner is placed separately or as a customer-specific version integrated into a transport system. Optionally, this tipper can be equipped with transport rollers or product carriers to further optimize product handling

SAFETY

The minimum safety distance around the appliance is 1200 mm. The EASY-TIPPER can (optionally) be equipped with fencing and / or safety light curtains and / or fully automatic.

In addition to the EASY-TIPPER, we also offer standard solutions for, among other things, roll, axle and plate handling. Roosen BPL is a specialist in customer-specific lifting aids. We are happy to solve your handling issue!

TECHNICAL SPECIFICATIONS- Lifting capacity: max. 1000 kg

- Tilting tray dimension (lxwxh): 1200 x 1200 x 1200 mm

- Tilt angle: 90 degrees

- Height of the appliance: 1340 mm

- Electrical supply: 3x 400 V / 3 kW

- Includes CE declaration

EASY-SHEET

-

The pneumatic EASY-SHEET is an ergonomic balancer equipped with a user-friendly one-hand operation. The lifting aid is equipped with a vacuum load pick-up, making it ideal for handling sheet material.

WHY THE EASY-SHEET?

- Safe & reliable

- High lifting and lowering speed

- Simple positioning

- Parking brakes on the pivot points

- Stand-by without air consumption

- Low noise

- Delivery including mounting material

- Possibly to assemble yourself

COLUMN PLACEMENT

To be fixed with chemical anchors on a non-cracked concrete floor with a minimum thickness of 150 mm. In case of a thinner concrete floor, the column can be mounted on a steel intermediate plate (optional).

MOVABLE

The EASY-UP can (optionally) be executed on a steel forklift base, 1500x1500x50 mm. This makes the device easy to move. Total mass including forklift base approx. 1100 kg

STEEL CABLE

The steel cable must be replaced at a maximum of 50,000 lifting cycles or at least once a year.

In addition to the EASY-UP, we also offer standard solutions for, among other things, roll, axle and plate handling. Roosen BPL is a specialist in customer-specific lifting aids. We are happy to solve your handling issue!

TECHNICAL SPECIFICATIONS- Lifting capacity : max. 220 kg

- Radius range : 3000 mm

- Device height : 3238 mm

- Installation height : min. 3473 mm

- Compressed air supply : min. 6 bar – clean and dry compressed air

- Air consumption : approx. 250 Nl / cycle

- Includes CE declaration

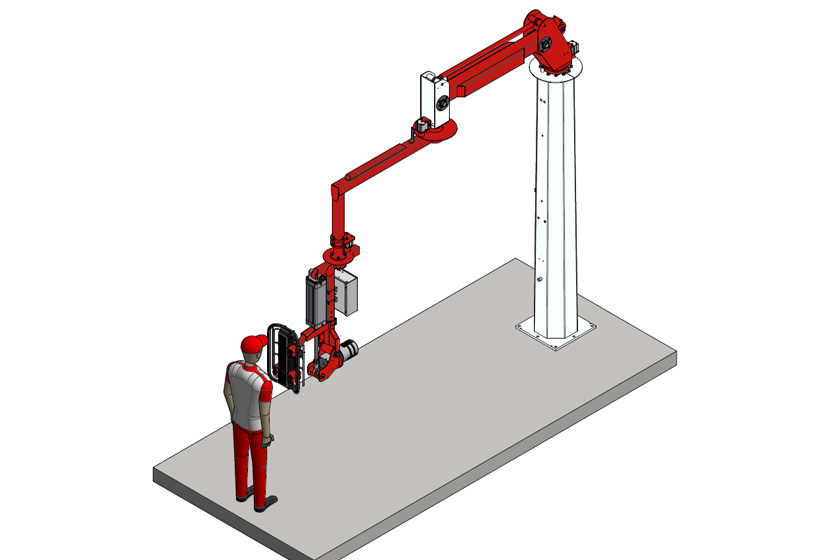

EASY-SHAFT

- The fully pneumatic EASY-SHAFT lifts shafts horizontally and clamps them on 1 side of the shaft. It is unique in its construction and works without ballast weight. The ergo operation makes the lifting aid user-friendly for every employee. The well thought-out clamping fixture and other safety features make the EASY-SHAFT your ideal tool for handling shafts.

- Safe & reliable

- High lifting and lowering speed

- No weight adjustment necessary

- Easy positioning with parking brakes

- Stand-by without air consumption

- Delivery including mounting material

- Possibly to assemble yourself

COLUMN PLACEMENT

To be fixed with chemical anchors on a non-cracked concrete floor with a minimum thickness of 150mm and 190mm respectively. In case of a thinner concrete floor, the column can be mounted on a steel intermediate plate (optional).

MOVABLE

The EASY-SHAFT can (optionally) be executed on a steel forklift base, 1500 x 1500mm. This makes the device easy to move and use at multiple workplaces.

THE CLAMP MOUNT

The clamp mount is standard for a shaft diameter of 6 Inch. On request, this clamp holder can be replaced free of charge for a size smaller than 6 inches. Optionally, it is possible to supply multiple adapters if smaller than 6 inches.

Do you have other wishes than the technical specifications mentioned on the right? Roosen BPL is the specialist in customer-specific lifting aids. We are happy to solve your handling issue!

TECHNICAL SPECIFICATIONS- Radius range: 2800 mm (clamp)

- Device height: 4336 mm resp. 4512 mm

- Installation height: 4500 mm resp. 4650 mm

- Compressed air supply: min. 6 bar – clean and dry compressed air

- Air consumption: approx. 200 Nl / cycle

- CE declaration

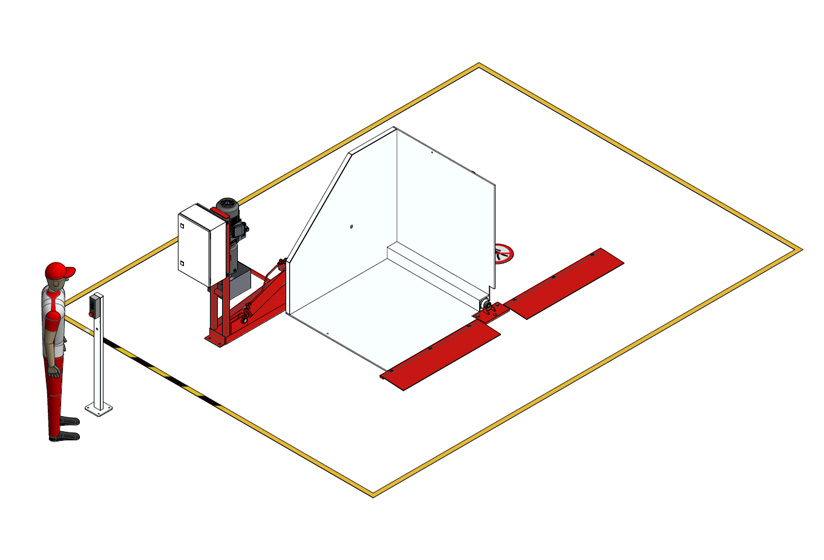

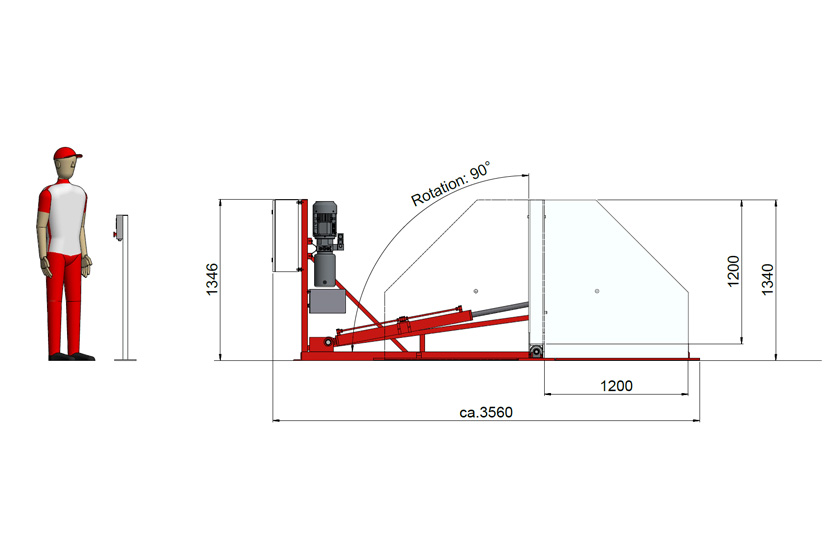

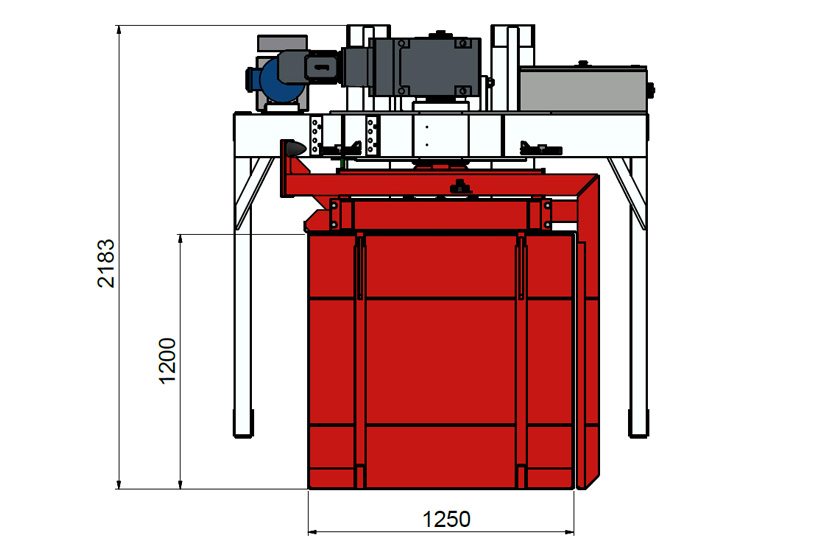

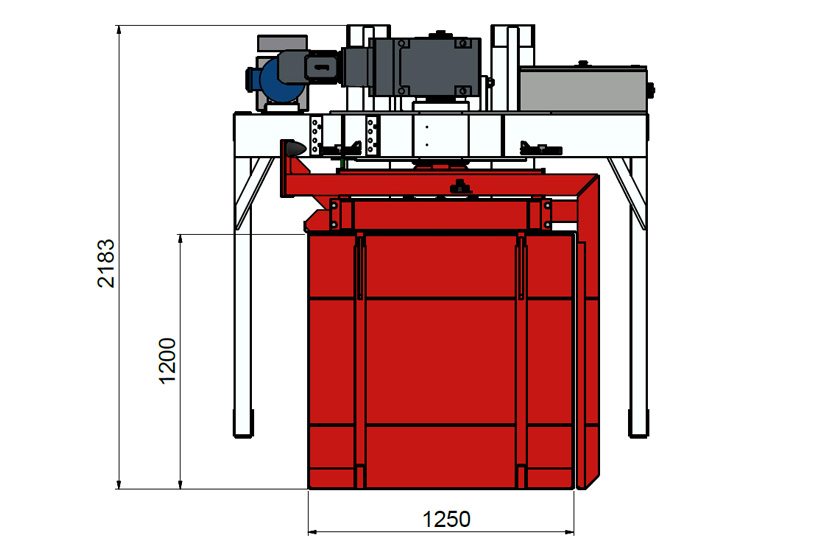

EASY-INVERTER

-

You can quickly and easily change pallets or rotate your products 180 degrees with this pallet turner. The EASY inverter is suitable for all standard pallet sizes and can be designed according to customer and product specifications.

WHY THE EASY-INVERTER?

- Easy loading and unloading

- Loading with forklift

- Robust and low maintenance

- Safe and controlled tilting

- Plug – & – Play

PLACEMENT

Placing or relocating the EASY-INVERTER is easy with a forklift truck through the tubular profiles in the construction. The pallet turner is placed separately or integrated into a transport system as a customer-specific version.

SAFETY

The minimum safety distance around the appliance is 1200 mm. The EASY-INVERTER can (optionally) be fitted with fencing and / or safety light curtains.

In addition to the EASY-INVERTER, we also offer standard solutions for, among other things, roll, axle and plate handling. Roosen BPL is a specialist in customer-specific lifting aids. We are happy to solve your handling issue!

TECHNICAL SPECIFICATIONS- Lifting capacity:; max. 2000 kg

- Tilting container size (lxw): 1250 x 1200 mm

- Clamping range (h): min. 600 mm, max. 2080 mm

- Height of the appliance: 2963 mm

- Electrical power supply: 3x 400 V / 2,2 kW

- CE declaration