- Offer Profile

-

WE LOVE CHALLENGES

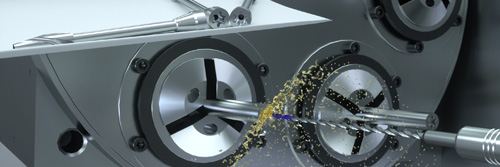

Tools are our passion, small dimensions are our specialty and hard-to-machine materials are our challenge. The everyday life of Mikron Tool is around these attributes.

Mikron Tool offers standardized tools of tungsten carbide for centering, chamfering and drilling, for milling and deburring in the diameter range from 0.1 to 6 mm (.004” to .236”).

In the area of customer-specific tools, the offer comprises the centering and chamfering, milling, turning, grinding or deburring and up to complex combination tools in the diameter range between 0.1 mm and 32 mm (.004” and 1.260”).

CUTTING SOLUTIONS FOR PROFESSIONALS

- Mikron Tool offers standardized tools of tungsten carbide for centering, chamfering and drilling, for milling and deburring in the diameter range from 0.1 to 6 mm (.004” to .236”).

In the area of customer-specific tools, the offer comprises the centering and chamfering, milling, turning, grinding or deburring and up to complex combination tools in the diameter range between 0.1 mm and 32 mm (.004” and 1.260”). CENTERING

MIQUDRILL CENTRO

-

FOR SMALL SERIES AND A RANGE OF VARIANTS

Whether centering, short drilling or precision drilling: with the MiquDrill family Mikron Tool offers three industrial minidrills for every application, provided you are dealing with the production of small and medium batch sizes or a large range of variants. The MiquDrill drilling program focuses on small diameters. All sizes are available from stock and in uncoated and coated versions. The major advantage: diameter increments at every 0.01 mm (.0004ˮ).

MiquDrill Centro starts the process by drilling and simultaneously creating a 90° or 120° chamfer. It prepares a precisely positioned follow-up hole in the diameter range of 0.1 mm to 6 mm (.0039ˮ to .236ˮ). It centers perfectly even for the smallest drilling diameters from 0.1 mm (.0039ˮ) and up. This best drill bit for steel (alloyed and unalloyed), cast iron, stainless steels, titanium and other nonferrous metals is universally applicable and is also the ideal partner of MiquDrill 210. MiquDrill Centro is available in diameters of 0.5 mm (.0197ˮ) (for follow-up drilling from a diameter of 0.1 mm (.0039ˮ)) to 6 mm (.236ˮ) in coated or uncoated versions.

CRAZYDRILL TWICENTER

-

A CENTERING DRILL WITH DOUBLE ADVANTAGE

CrazyDrill Twicenter from Mikron Tool is a unique tungsten carbide center drill with a double advantage. This drill with through-tool cooling is designed especially for the center drilling of difficult-to-machine materials. Customary centering drills wear out very quickly due to the strong heat buildup. Because of the through-tool cooling, CrazyDrill Twicenter keeps the machining temperature constantly low and lubricates the drill tip at the same time. The through-tool cooling shows its advantages even when drilling in difficult-to-access spots such as those with protruding edges. The cooling medium arrives at the right spot at all times. CrazyDrill Twicenter can also be used successfully with external cooling. The highest degree of position accuracy is guaranteed in each case.

The extremely short chisel edge and the "double tip" – in chamfers of 60° or 90° with an additional tip angle of 130° – ensure stability and good chip flow. The adapted high-performance coating guarantees longer tool life.

This centering drill, adapted for all types of drilling machines, machining centers and rotary transfer machines, is available from stock in diameters of 0.3 mm to 6 mm (.0118” to .236”) (center) or 1 mm to 10 mm (.0393” to .394”) (chamfer) and for chamfers of 60°, 90° or 120°.

CUSTOMER-SPECIFIC CENTER DRILLS

-

Mikron Tool produces tungsten carbide center drills according to your needs and requirements.

- You determines the operating conditions and the designated result and we define you a tool for you that matches them.

- You already know the tool you want? We will gladly accept this input as well and will grind the tool using your drawing.

- You've seen one of our center tools from the CrazyDrill family and you need it in a special length, in a special diameter or for the use of a special material? We will make you a tool with the geometry that suits you.

- You have a new project and you need tools for optimal machining of a part? We will support you in the design, definition of geometries and determining the best parameters.

SHORT DRILLING / PILOT DRILLING

MIQUDRILL 200

-

Executing finished short holes in one step or preparing deep holes, those are the strengths of MiquDrill 200. It is the ideal tool for the perfect execution of a short borehole between 1.4 x d and 2.4 x d. As a pilot drill it guarantees a high degree of position accuracy and accurate cylindrical guidance for the subsequent deep-hole tool. Its diameter range goes from 0.1 mm to 1.5 mm (.0039ˮ to .0591ˮ) and it is also available with coating starting from Ø 0.3 mm (.0118ˮ).

Very small diameter increments of 0.01 mm (.0004ˮ) are available from stock.

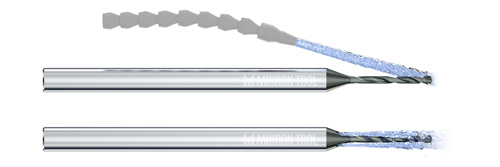

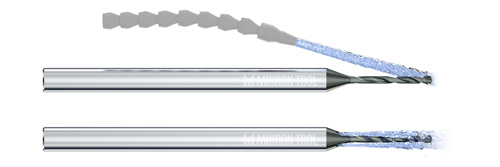

CRAZYDRILL FLEXPILOT

-

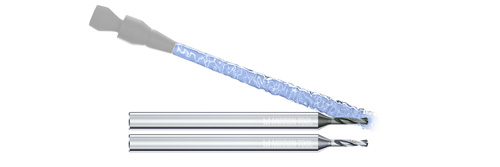

THE SMALLEST FLEXIBLE CARBIDE DRILL BIT

WITH INTEGRATED COOLINGCrazyDrill Flex of Mikron Tool makes the drilling within the diameter range from 0.1 to 1.2 mm (.004” to .047”) possible with versions for steel, titanium and stainless materials. The straight connecting element (neck) between the cutting body and the shaft gives the carbide drill CrazyDrill Flex the length required for drilling deep holes up to a bore depth of 50 x d and makes it very robust. Thanks to CrazyDrill Flex, small and deep holes can be drilled quickly, precisely and in a cost-efficient manner on machining centers, automatic lathes or rotary transfer machines (instead of using a gun drilling machine). In the case of deep and small drilled holes, this extra-long drill guarantees a significantly shorter drilling time compared to the single-lip drill, the electro-erosion (EDM) or the laser method.

The flexible tungsten carbide (VHM) drill is not actually a specially designed drill for plastic, but it can also be used as for certain thermoplastic materials and plexiglass.

Three types of drill bits can be selected: CrazyDrill Flex Steel,CrazyDrill Flex Titanium and CrazyDrill Flex SST-Inox.

CRAZYDRILL PILOT SST-INOX

-

EFFICIENT PILOT DRILLING IN STAINLESS STEEL

With CrazyDrill Pilot SST-Inox, Mikron Tool introduces a pilot and short drill for stainless steels, heat-resistant and CrCo alloys in the diameter range of 0.3 mm to 2.0 mm (.012” to .078”). This pilot drill is coated, has a cutting edge for 90° chamfer, integrated through-tool coolant channels in the shaft and a digressive helical flute. As pilot drill it is the ideal complement of the twist drill types CrazyDrill SST-Inox and CrazyDrill Flex SST-Inox and it is suitable as well for short drilling up to a drilling depth of 3 x d.

CRAZYDRILL PILOT

-

THE IDEAL PREPARATION OF DEEP HOLES

CrazyDrill Pilot, short drill, pilot drill and chamfer tool, is the perfect hole preparation for high-precision position accuracy in deep-hole drilling of lengths greater than 6 x d using twist drill types CrazyDrill Cool XL and CrazyDrill Cool.

With the coated pilot drill or center drill CrazyDrill Pilot from Mikron Tool, centering and pilot drilling up to 2 x d are done in one single step. The follow-up drill is guided cylindrically in the pilot hole and this translates to a high degree of straightness for the hole. The precise adjustment of the tip angle from pilot drill to follow-up drill protects cutting edges and ensures reliability. CrazyDrill Pilot is available from stock in diameters of 0.4 mm to 6.00 mm (.016” to .236”).

Its special high-performance geometry ensures high machining speed and the optimal coating increases tool life, and all of this while maintaining constant drilling precision.

CRAZYDRILL CROSSPILOT

-

FOR HOLES ON INCLINED, CONVEX

AND CONCAVE SURFACESThe coated tungsten carbide drill for steel, stainless steel materials, titanium and nonferrous metals (CrazyDrill Crosspilot from Mikron Tool) is a unique specialist for holes on inclined, convex and concave surfaces. It produces pilot holes directly in surfaces with up to a maximum inclined angle of 60°, which does not correspond to a DIN centering hole since no circular chamfer can be made on an inclined surface.

This means the solid carbide drill bit reduces the three steps needed up to now ( milling – centering – drilling) to two steps and simultaneously guarantees a higher degree of precision due to good guidance. Its compact and sturdy design provides for good position accuracy. Its geometry is designed for extreme applications. The 170° tip angle of the CrazyDrill Crosspilot affords the follow-up drill stability, thus preventing cutting edge breakage. The pilot drill can be supplied from stock in diameters of 0.4 mm to 6 mm (.016” to .236”), suitable for the existing CrazyDrill program.

CRAZYDRILL COOLPILOT

-

PILOT DRILLING WITH INNOVATIVE INTEGRATED COOLING

With CrazyDrill Coolpilot, Mikron Tool offers a pilot and short drill for stainless steels, heat-, acid-resistant and CrCo alloys in the diameter range of 1.0 to 6.0 mm (.039“ to .236“). This twist drill type is designed with internal helicoidally arranged cooling channels which bring up to four times more coolant volume to the drill tip. CrazyDrill Coolpilot is the perfect preparation for deep hole drilling with CrazyDrill Cool SST-Inox and realizes simultaneously, if requested, a 90° counter bore (countersink drill bit). It finds also a perfect application as an autonomous, precision short drill for depths of max. 3 x d.

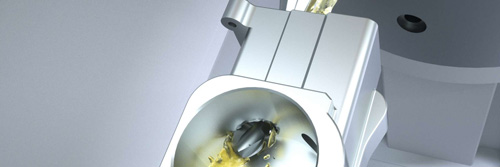

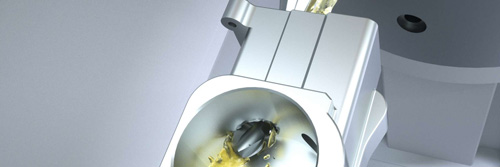

CRAZYDRILL HEXALOBE

-

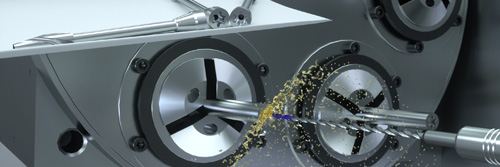

A DRILL, A MILLING CUTTER, AN ULTIMATE MACHINING STRATEGY

Most of medical screws are machined on lathes, on the main spindle the thread and on the sub-spindle the hex lobular socket. That particular operation is usually slower and defines the cycle time. With every second of time saving the manufacturer wins: time and money.

CrazyDrill Hexalobe and CrazyMill Hexalobe are solutions developed by Mikron Tool to achieve a clear improvement of efficiency when machining medical screws made from Titanium(mainly Titanium Grade 5 ELI / TiAl6V4 ELI / 3.7165) or Stainless Steel (mainly 316LM / X2CrNiMo18-15-3 / 1.4441). Thanks to a perfect machining strategy and adapted parameters, the machining of hex lobular bone screws (better known as „Torx®“) is 50% faster, guaranteeing also a high degree of precision of the profile and achieving nearly burr-free results.

Pre-hole drilling with CrazyDrill Hexalobe, is available in the diameter range from T4 – T30 (0.9 to 3.8 mm, [.035“ - .150“]), or as customized combined drill.

Micro endmill CrazyMill Hexalobe, is available in the diameter range from T4 – T30 (0.2 to 1.0 mm, [.008“ - .039“]), for milling depths of 3.5 x d and 5 x d and, depending on diameter, with 3 or 4 flutes.

CUSTOMER-SPECIFIC SHORT / PILOT DRILLS

-

Mikron Tool produces carbide drilling tools according to your needs and requirements.

- You determines the operating conditions and the designated result and we define a matching tool for you.

- You already know what tool you want? We will gladly accept this input as well and grind the tool using your drawing.

- You've seen one of our drilling tools from the CrazyDrill family and you need it in a special length, in a special diameter or for the use of a special material? We will make you a tool with the geometry that meets your needs.

- You have a new project and you need tools for optimal machining of a part? We will help you with the design, definition of geometries and determining the best parameters.

DRILLING

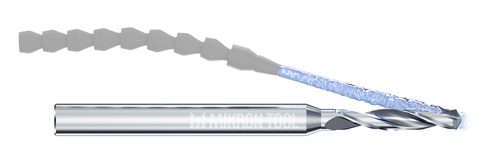

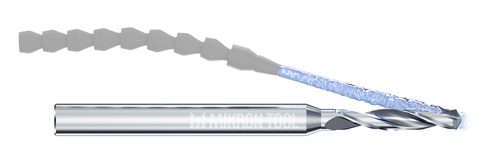

MIQUDRILL 210

-

FOR SMALL SERIES AND A RANGE OF VARIANTS

MiquDrill 210, the precision drill for micro-machining is available in diameters of 0.1 mm to 3 mm (.0039ˮ to .118ˮ) (drill Ø 0.1 mm to 0.29 mm (.0039ˮ to .0114”) uncoated, from drill Ø 0.3 mm (.0118”) also coated), usable lengths between 2.4 x d and 8.0 x d (depending on the diameter).

CRAZYDRILL STEEL

-

THE SMALL QUICK DRILL FOR STEEL

CrazyDrill Steel from Mikron Tool achieves the best results when machining challenging materials. Its self-centering, the extraordinary cutting speeds and the highest feed rates ensure the best hole quality, outstanding surface quality and excellent tool life. This guarantees optimal cost-effectiveness when drilling. The best drill bit for steel, CrazyDrill Steel, is available from stock in the diameter range of 0.4 mm to 6.0 mm (.016” to .236”). The standard drilling lengths are 4 x d, 6 x d and 7 x d.

CRAZYDRILL SST-INOX

-

SOLID CARBIDE DRILL BITS FOR STAINLESS,

ACID-RESISTANT AND HEAT-RESISTANT STEELWith CrazyDrill SST-Inox Mikron Tool offers two exclusive drill types for drilling in stainless steel up to 12 x d and in the diameter range of 0.3 to 2 mm (.012” to .079”): CrazyDrill SST-Inox type IN (8 x d / 12 x d) for drilling with external cooling and CrazyDrill SST-Inox type IK (8 x d / 12 x d) for drilling with integrated cooling.

Both variants of this best drill bits for stainless steel meet the challenge very well. A challenge which involves the machining of stainless steels, chromium-cobalt alloys, heat-resistant steels and even lead-free brass. They differ in their geometry significantly from other products available in the market today. For the first time in this drill size diameter range there is efficient cooling, an important factor for long tool life. Significant advances were also made in relation to cutting performance: a drilling process up to ten times quicker is possible.

As a perfect preparation for high-precision position accuracy, Mikron Tool recommends for CrazyDrill SST-Inox 12 x d the use of the pilot drill CrazyDrill Pilot SST-Inox with integrated cooling.

For drilling depths of up to 8 x d, CrazyDrill SST-Inox can be used on regular and straight surfaces without a centering or pilot hole. In case of irregular respectively rough surfaces we recommend the pilot drill CrazyDrill Pilot SST-Inox or the centering drill CrazyDrill Twicenter, both with internal cooling.

For both drilling types (8 x d / 12 x d) and on inclined surfaces, CrazyDrill Crosspilot is the perfect pilot drill.

CRAZYDRILL ALU

-

SMALL DRILL FOR ALUMINUM

FOR HIGHEST DEGREE OF PERFORMANCE

AND COST-EFFECTIVENESSOptimal chip removal, extraordinary tool life, high productivity and simultaneously excellent surface quality – all of these requirements are met by CrazyDrill Alu from Mikron Tool. The tungsten carbide drill for aluminum guarantees that its user enjoys maximum profitability. Due to its three-flute geometry it is self-centering.

CrazyDrill Alu is available from stock in the diameter range of 0.4 mm to 3 mm (.016” to .118”) and in the usable lengths of 5 x d and 10 x d.

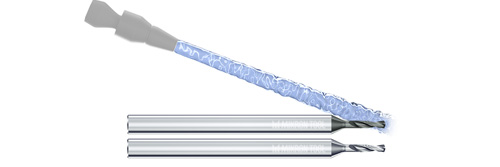

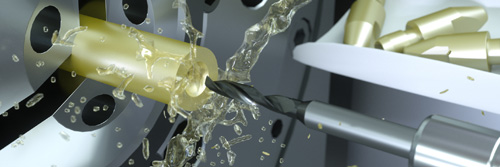

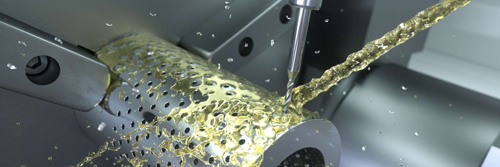

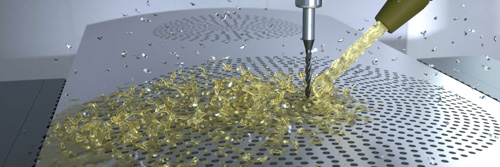

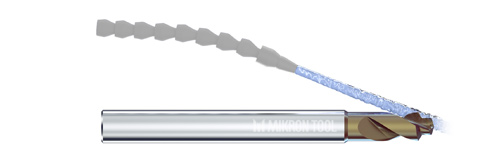

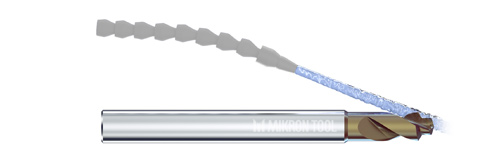

CRAZYDRILL COOL SST-INOX

-

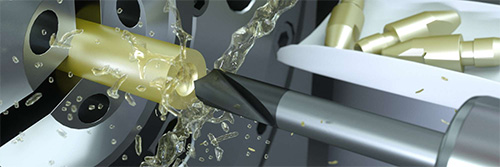

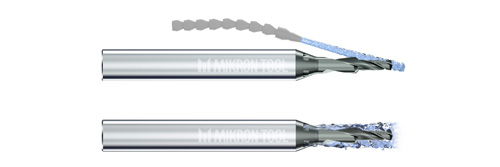

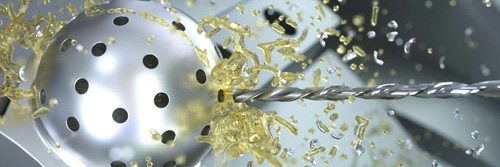

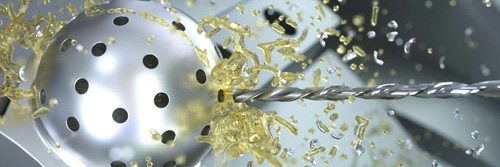

THE REVOLUTIONARY DRILL IN TERMS OF

GEOMETRY AND COOLING CONCEPTWith CrazyDrill Cool SST-Inox, Mikron Tool introduces a twist drill type for stainless steels, heat- and acid-resistant steels and CrCo alloys in the diameter range from 1 up to 6 mm (.039“ up to .236“) and for drilling depths from 6 x d to 40 x d. The tungsten carbide drill is designed with internal helicoidally arranged cooling channels which bring up to four times more coolant volume to the drill tip. The new cooling system, the new design of tip and flute as well as the innovative coating enabledrilling in one single step up to a drilling depth of 40 x d with high performance in terms of quality, tool life and machining time.

CRAZYDRILL COOL

-

CRAZYDRILL COOL FOR DRILLING DEEP HOLES

AND CHALLENGING MACHINING CONDITIONSThe small drill with through-tool cooling CrazyDrill Cool from Mikron Tool also resolves drilling problems in difficult-to-machine materials. The combined use of a pilot drill (solid carbide drill bits CrazyDrill Pilot or CrazyDrill Crosspilot) and the small drill with through-tool cooling CrazyDrill Cool allows drilling depths of up to 15 x d (other standard lengths: 6 x d and 10 x d) and this in drill size diameter ranges of 0.75 mm to 6 mm (.030” - .236”). A shaft-integrated power chamber (up to a drill diameter of 2.95 mm / .116”) allows a more efficient coolant supply directly to the drill tip results in higher drilling speeds and tool life. A double advantage! In addition, the drilling concept of the CrazyDrill Cool is an alternative to the long and costly deep-hole drilling methods using single-lip drills (gundrill).

CRAZYDRILL COOL XL

-

QUICK AND ACCURATE

WITH DEEP-HOLE DRILL

CRAZYDRILL COOL XLThe coated small drill CrazyDrill Cool XL from Mikron Tool (in the diameter range of 1 mm to 6 mm / .039” to .236”) is available in drilling lengths of 15, 20 and 30 x d for drilling diameters of 1 mm (.039”) and up and up to 40 x d for diameters of 2 mm (.078”) and up. Thanks to its newly developed geometry it meets the very challenging conditions of drilling a deep hole perfectly and is an ideal alternative to a gundrill. The outcome: an outstanding tungsten carbide drill for steel that produces short chips in all steel alloys. This is an essential requirement for smooth chip removal in drilling depths of up to 40 x d. The tool is designed so that holes up to the maximum depths can be produced in one step without chip removal, and this at the highest cutting speeds and feed rates. The through-coolant supply contributes to this and guarantees good cooling at the tip and hence outstanding tool life.

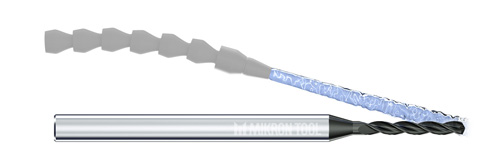

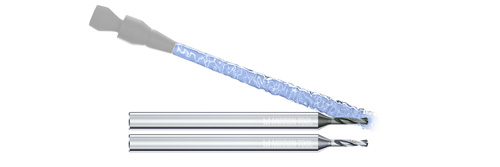

CRAZYDRILL FLEX

-

THE SMALLEST FLEXIBLE CARBIDE DRILL BIT

WITH INTEGRATED COOLINGCrazyDrill Flex of Mikron Tool makes the drilling within the diameter range from 0.1 to 1.2 mm (.004” to .047”) possible with versions for steel, titanium and stainless materials. The straight connecting element (neck) between the cutting body and the shaft gives the carbide drill CrazyDrill Flex the length required for drilling deep holes up to a bore depth of 50 x d and makes it very robust. Thanks to CrazyDrill Flex, small and deep holes can be drilled quickly, precisely and in a cost-efficient manner on machining centers, automatic lathes or rotary transfer machines (instead of using a gun drilling machine). In the case of deep and small drilled holes, this extra-long drill guarantees a significantly shorter drilling time compared to the single-lip drill, the electro-erosion (EDM) or the laser method.

The flexible tungsten carbide (VHM) drill is not actually a specially designed drill for plastic, but it can also be used as for certain thermoplastic materials and plexiglass.

CUSTOMER-SPECIFIC DRILLS

-

Mikron Tool produces solid carbide drills and step drills according to your needs and requirements

- You determines the operating conditions and the designated result and we define a matching tool for you.

- You already know what tool you want? We will gladly accept this input as well and grind the tool using your drawing.

- You've seen one of our drilling tools from the CrazyDrill family and you need it in a special length, in a special diameter or for the use of a special material? We will make you a tool with the geometry that meets your needs.

- You have a new project and you need tools for optimal machining of a part? We will help you with the design, definition of geometries and determining the best parameters.

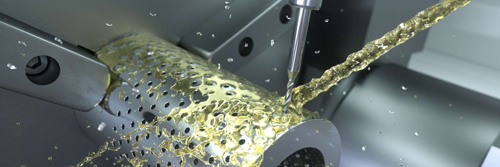

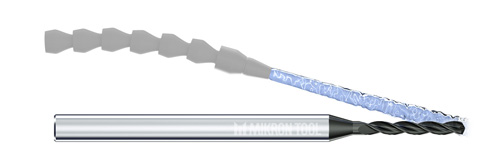

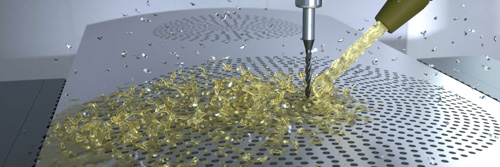

MILLING

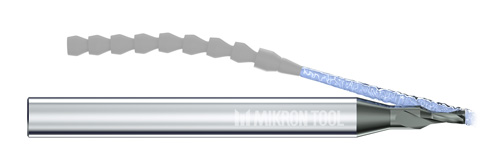

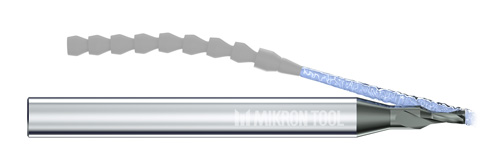

CRAZYMILL COOL SQUARE&CORNER RADIUS Z4

-

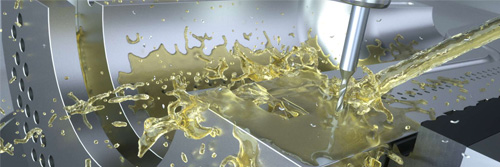

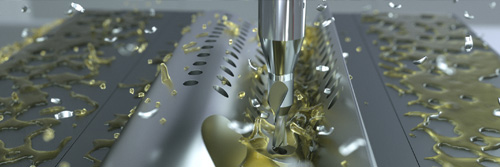

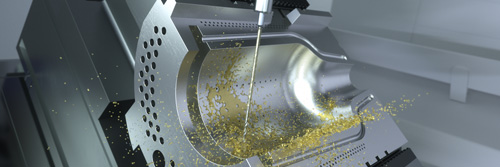

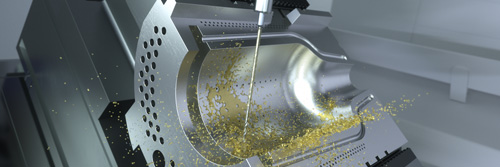

NEW DIMENSIONS WHEN MILLING

DIFFICULT-TO-MACHINE MATERIALSCrazyMill Cool Square / Corner radius with four flutes and integrated cooling channels in the shaft is an innovative end mill, developed by Mikron Tool, for pre-machining and finishing of stainless steel, titanium alloys, CrCo and super alloys. It’s specially adapted for the milling of pockets and walls in linear ramping or helical interpolation. Its strengths are, on the one hand, high removal rates, on the other hand high precision (perpendicularity) and surface quality.

Four versions of cylindric (small protection phase of 45°) and toric (corner radius) micromills with four teeth are available in the diameter range from 1.0 – 8.0 mm (.039“ – .315“, fractional inches available) and for milling depths up to 2 x d, 3 x d, 4 x d and 5 x d.

CRAZYMILL HEXALOBE

-

A MILLING CUTTER, A DRILL, AN ULTIMATE MACHINING STRATEGY

ost of medical screws are machined on lathes, on the main spindle the thread and on the sub-spindle the hex lobular socket. That particular operation is usually slower and defines the cycle time. With every second of time saving the manufacturer wins: time and money.

CrazyMill Hexalobe and CrazyDrill Hexalobe are solutions developed by Mikron Tool to achieve a clear improvement of efficiency when machining medical screws made from Titanium (mainly Titanium Grade 5 ELI / TiAl6V4 ELI / 3.7165) or Stainless Steel (mainly 316LM / X2CrNiMo18-15-3 / 1.4441). Thanks to a perfect machining strategy and adapted parameters, the machining of hex lobular bone screws (better known as „Torx®“) is 50% faster, guaranteeing also a high degree of precision of the profile and achieving nearly burr-free results.

Micro endmill CrazyMill Hexalobe, is available in the diameter range from T4 – T30 (0.2 to 1.0 mm, [.008“ - .039“]), for milling depths of 3.5 x d and 5 x d and, depending on diameter, with 3 or 4 flutes.

Pre-hole drilling with CrazyDrill Hexalobe, is available in the diameter range from T4 – T30 (0.9 to 3.8 mm, [.035“ - .150“]), or as customized combined drill.

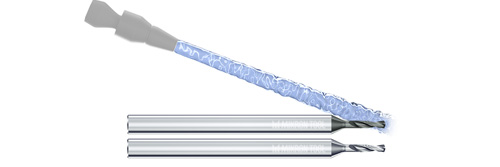

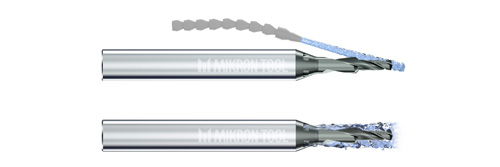

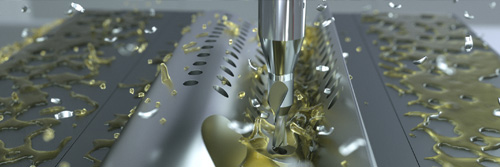

CRAZYMILL COOL SQUARE&CORNER RADIUS Z2

-

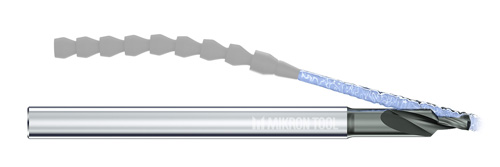

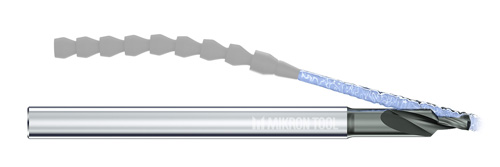

QUANTUM LEAP IN THE MILLING OF STAINLESS STEEL

With CrazyMill Cool Z2, Mikron Tool has made a quantum leap in the milling of stainless steel, titanium, chromium-cobalt-alloys and superalloys.

The newly designed roughing and finishing cutter improves current results many times over and in every aspect. From now on new standards apply to the milling of grooves, pockets and walls in relation to cutting speeds, performance, tool life and surface quality. It combines HSC (high-speed cutting) and HPC (high-performance cutting), thus becoming an HSPC (high-speed performance cutting) milling tool.

Everything is new: the tungsten carbide, the geometry, the coating and especially the coolant supply through the shank which ensures perfect cooling on the cutting edges and removes chips effectively from the work area.

Three versions of cylindrical (small protection phase of 45°) and toric (corner radius) micro-milling tools are available in standard milling sizes of diameter 0.3  6.35 mm (.0118" - .250", fractional inches available): a short one for maximum milling depths of up to 1.5 x d, a medium one up to 3 x d and a long one up to 5 x d. The cutting length for all three is 1.5 x d.

CRAZYMILL COOL BALL Z2

-

QUANTUM LEAP IN BALL MILLING

OF STAINLESS STEELWith CrazyMill Cool Ball Z2, Mikron Tool has made a quantum leap in the milling of stainless steel, titanium, chromium-cobalt-alloys and superalloys.

The newly designed roughing and finishing cutter improves current results extremely and in every aspect. From now on new standards apply to copy and side milling in relation to cutting speeds, performance, tool life and surface quality. It combines HSC (high-speed cutting) and HPC (high-performance cutting), thus becoming an HSPC (high-speed performance cutting) milling tool.

Everything is new: the tungsten carbide, the geometry, the coating and especially the coolant supply through the shank which ensures perfect cooling on the cutting edges and removes chips effectively from the work area.

The micro-milling tool CrazyMill Cool Ball with two teeth is available in standard milling sizes of diameter 0.3 – 8 mm (.0118” - .315”) and for three milling depths: a short one for maximum milling depths of up to 2 x d, a medium one up to 3 x d and a long one up to 5 x d. The cutting length for all end mill cutters is

2 x d.

CRAZYMILL COOL BALL Z4

-

A MILLING CUTTER

FOR PERFECT SURFACE FINISHES

IN STAINLESS STEELS & CO.CrazyMill Cool Ball Z4, the newly designed four teeth Finishing Milling Cutter joins perfectly the already existing tungsten carbide milling cutters of the CrazyMill Cool family. This milling cutter also improves current results drastically in all materials. From now on new standards apply to semi-finishing and finishing in relation to cutting speeds, performance, tool life and surface quality. It combines HSC (high-speed cutting) and HPC (high-performance cutting), thus becoming an HSPC (high-speed performance cutting) milling tool.

Everything is new compared to conventional finishing milling cutters: the geometry, the coating, the tungsten carbide and especially the coolant supply through the shank.

The micro-milling tool CrazyMill Cool Ball with four teeth is available in standard milling sizes of diameter 1 – 8 mm (.039“ - .315“) and for five milling depths: a short one for maximum milling depths of up to 2 x d, a medium one up to 3 x d and a long one up to 5 x d. The cutting length for these end mill cutters is 2 x d. Additionally two more versions with progressive flute-angle and milling depths of up to 3.5 x d resp. 4.5 x d are available. These ones with cutting length of 3.5 x d resp. 4.5 x d.

CRAZYMILL COOL P&S SQUARE&CORNER RADIUS Z3

-

A MILLING CUTTER

FOR SLOTS AND POCKETS

IN SMALLEST SPACESCrazyMill Cool P&S is an innovative, 3-flute mill with in the shank integrated coolant supply ducts which Mikron Tool developed specially for rough and finish milling of stainless steels, titanium, super alloys and CrCo alloys. It is also very well adapted for other materials such as steels up to max. 40 HRC, cast iron, non-ferrous metals and plastics. Based on its ability to plunge directly with up to 1 x d vertically into material, it becomes a “plunge-mill” i.e. “drill-mill” or “milling drill” for metal and is especially suitable to mill grooves, pockets and faces in smallest spaces in general and specifically for keyways (feather keys) as found in drive shafts for example.

This solid carbide shaft endmill is available in diameters from 1 – 6 mm (.039” - .236”) and for depths up to 2.5 x d.

CUSTOMER-SPECIFIC MILLING CUTTERS

-

Mikron Tool produces tungsten carbide milling cutters according to your needs and requirements.

- You determines the operating conditions and the designated result and we define you a tool for you that matches them.

- You already know the tool you want? We will gladly accept this input as well and will grind the tool using your drawing.

- You've seen one of our milling tools with standard milling sizes from the CrazyMill family and you need it in a special length, in a special diameter or for the use of a special material? We will make you a tool with the geometry that suits you.

- You have a new project and you need tools for optimal machining of a part? We will support you in the design, definition of geometries and determining the best parameters.

CUSTOMER-SPECIFIC PROFILE MILLING CUTTERS

-

Mikron Tool produces tungsten carbide profile milling cutters according to your needs and requirements.

- You determines the operating conditions and the designated result and we define you a tool for you that matches them.

- You already know the tool you want? We will gladly accept this input as well and will grind the tool using your drawing.

- You have a new project and you need tools for optimal machining of a part? We will support you in the design, definition of geometries and determining the best parameters.

CHAMFERING

CRAZYMILL CHAMFER

-

FOR A CLEAN MACHINED FINISH

The tungsten carbide deburring tools from Mikron Tool reach top-level performance when it comes to chamfering and deburring in small dimensions, difficult materials and hard-to-reach locations. CrazyMill Frontchamfer in the diameter range of 1.0 mm to 6.0 mm (.0393" to .236") reaches even difficult-to-access locations because of its ingenious geometry and exhibits a constant, positive cutting behavior over the entire cutting edge. CrazyMill Backchamfer in diameters of 0.36 mm to 5.7 mm (.0142" to .224") for back edge deburring or hole deburring even in the smallest dimensions without unclamping the part (alternative process to thermal deburring). With CrazyMill Doublechamfer in the diameters of 0.9 mm to 5.7 mm (.0354" to .224") you can deburr edges and difficult-to-access locations front and rear with one single tool. The universally applicable CrazyMill Radiuschamfer in the diameter range of 1 mm to 6 mm (.0393" to .236") is suitable for front and back chamfering as well as for all possible internal and external contours and intersections of holes and milling procedures.

All four models have the same quality features: They are suitable for use in small-scale machining in a wide variety of materials, can be utilized at high feed rates and result in first-class surface quality.

CUSTOMIZED CHAMFER AND DEBURRING TOOLS

-

Mikron Tool produces tungsten carbide chamfer and deburring tools according to your needs and requirements.

- You determines the operating conditions and the designated result and we define you a tool for you that matches them.

- You already know the tool you want? We will gladly accept this input as well and will grind the tool using your drawing.

- You've seen one of our chamfer and deburring tools from the CrazyMill Chamfer family and you need it in a special length, in a special diameter or for the use of a special material? We will make you a tool with the geometry that suits you.

- You have a new project and you need tools for optimal machining of a part? We will support you in the design, definition of geometries and determining the best parameters.

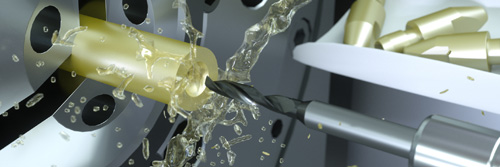

TURNING

CUSTOMER-SPECIFIC FORM TURNING TOOLS

-

Mikron Tool offers its "customer-specific form turning tools" within the following range:

- Shaft that can be turned: 0.3 - 12.0 mm (.0118” - .472”)

- Form tolerance max.: ± 0.5 µm (.00002”)

- Number of cutting edges: 1

- Cutting direction: right hand cutting or left hand cutting

- Material for form turning tool: tungsten carbide, grade selection depending on application

- Material to be machined: steel, corrosion resistant steels, i.e. stainless steels, titanium / titanium alloys, super alloys i.e. heat resistant alloys such as Inconel or Hastelloy, Cr-Co alloys, drills for hardened steel up to 55HRC, aluminum / aluminum alloys, brass, copper, cast materials, etc.

- Cooling:

- Form turning tools for external coolant supply

- Tool holding:

- Clamping face for turning tools

- Other types on request

- Coatings: Various, choice according to application

- Treatment: Cutting edge preparation

CUSTOMER-SPECIFIC GROOVING TOOLS

-

Mikron Tool offers its "customer-specific grooving tools" within the following range:

MikronTool-Customized-Grooving-Tools-Drawing

Tool offers its “customer-specific grooving tools” within the following range:- Diameter of shaft that can be turned: 0.3 - 12.0 mm (.0118” - .472”)

- Form tolerance max.: ± 0.5 µm (.00002”)

- Number of cutting edges: 1

- Cutting direction: right hand cutting or left hand cutting

- Material for grooving tool: tungsten carbide, grade selection depending on application

- Material to be machined: steel, corrosion resistant steels, i.e. stainless steels, titanium / titanium alloys, super alloys i.e. heat resistant alloys such as Inconel or Hastelloy, Cr-Co alloys, drills for hardened steel up to 55HRC, aluminum / aluminum alloys, brass, copper, cast materials, etc.

- Cooling:

Grooving tools for external coolant supply - Tool holding:

By means of clamping face for turning tools

Others upon request - Coatings: Various, choice according to application

- Treatments: Cutting edge preparation

REAMING

CUSTOMER-SPECIFIC REAMERS

-

Mikron Tool offers its “customer-specific reamers” within the following range:

- Reamer with 1-diameter

- Reamer with different diameters

- Surface quality n5 can be obtained depending on cutting / coolant medium, machine tool equipment, spindle, tool holder (concentricity), material to be removed

Characteristics:

- Diameter min: 0.4 mm (.0157“)

- Diameter max: 32.0 mm (1.260”), bigger following specific request

- Maximum tool length: 330 mm (12.992“)

- Tool diameter tolerance max.: ± 0.5 µm (.00002”)

- Concentricity with shaft max.: 2 µm (.00008”)

- Number of cutting edges: 1 up to 16

- Cutting direction: right hand cutting or left hand cutting

- Form of flutes: Straight flutes left hand helix, right hand helix

- Division of teeth: regular or irregular

- Shape of cutting edges: various

- Reamer material: Tungsten carbide, grade selection depending on application

- Material to be machined: reamer for steel, corrosion resistant steels, i.e. stainless steels, titanium / titanium alloys, super alloys i.e. heat resistant alloys such as Inconel or Hastelloy, Cr-Co alloys, hardened steel up to 55HRC, aluminum / aluminum alloys, brass, copper, cast materials, etc.

- Cooling:

- Reaming tools with straight internal cooling channels in the shaft

- Reaming tools with internal cooling channels, special exits, for example in the flutes

- Reaming tool for external coolant supply

- Type of shaft:

- Cylindrical as per DIN 6535 HA

- Cylindrical as per DIN 6535 HB (Weldon)

- Other types upon request

- Coatings: Various choice according to application

- Finishing: Cutting edge preparation, polishing of flutes

MULTIFUNCTIONAL TOOLS

CUSTOMER-SPECIFIC MULTIFUNCTIONAL TOOLS

-

Mikron Tool offers its “customer-specific multifunctional tools” within the following range:

- Various operations can be combined in one tool for example:

- Tool for centering + drilling

- Tool for centering + drilling + reaming

- Tool for drilling + reaming

- Drill + Form Drill

- Tool for milling + deburring

- Diameter min: 1.0 mm (.0394")

- Diameter max: 32.0 mm (1.260”), bigger following specific requests

- Maximum tool length: 330 mm (12.992")

- Tolerance of tool diameters max.: ± 0.5 µm (.00002")

- Concentricity between shaft and cutting diameters.: 2 µm (.00008")

- Number of cutting edges: 2 - 8

- Cutting direction: right hand cutting or left hand cutting

- Tool material: tungsten carbide, grade selection depending on application

- Material to be machined: tools for steel, corrosion resistant steels, i.e. stainless steels, titanium / titanium alloys, super alloys i.e. heat resistant alloys such as Inconel or Hastelloy, Cr-Co alloys, hardened steel up to 55HRC, aluminum / aluminum alloys, brass, copper, cast materials, etc.

- Cooling:

- Tools with internal helix shaped cooling channels up to the tip of the tool

- Tools with straight internal cooling channels in the shaft

- Tools to be used with external coolant supply

- Type of shaft:

- Cylindrical as per DIN 6535 HA

- Cylindrical as per DIN 6535 HE (Whistle Notch)

- Cylindrical as per DIN 6535 HB (Weldon)

- Others upon request

- Coatings: Various, choice according to application

- Treatments: Cutting edge preparation, polishing of flutes

Characteristics: