- Offer Profile

- KELCH - Precision and

dynamics for your manufacturing

For more than 80 years, KELCH has made sure that their customers do not have to worry about their tools, but can fully concentrate on their production. To achieve this, we offer high precision, utmost reliable and practice-oriented solutions – from the individual tool up to the complete periphery for metal-cutting manufacturing. All based on the latest state-of-the-art technology and in outstanding quality.

As a subsidiary of the HMCT Group we were able to increase our investments in research and development, to achieve synergy effects and to improve our market position in international competition.

SALE on selected KELCH precision tools. Quality you can rely on!

-

For the highest manufacturing standards, we offer special conditions on three selected types of our precise and durable tools:

- SK-AD Sleeve for cylindrical shanks with lateral drive flat (Weldon) – reliable, stable, precisely manufactured

- SK-AD Collet Chuck for ER/ESX 25/32/40 collets with internal thread – maximum runout accuracy

- SK-AD Collet Chuck for ER/ESX 11/16 collets with internal thread – high repeatability and robust quality Detailed information can be found in the offer PDF or directly through our KELCH sales team. Reach out today!

Tool Presetters

-

It’s all a question of setting!

High-performance, precise tool setting is essential when the highest degree of manufacturing precision and maximum efficiency of production resources are required. We are convinced that you will find the most appropriate solution within our extensive range of KENOVA set line tool presetters. Tailored to every use and every budget. KELCH can offer you the widest range of vertical tool presetters. The portfolio ranges from the simplest entry-level models through to machines with multiple CNC axes.

Are you looking for special applications?

KELCH has them all.

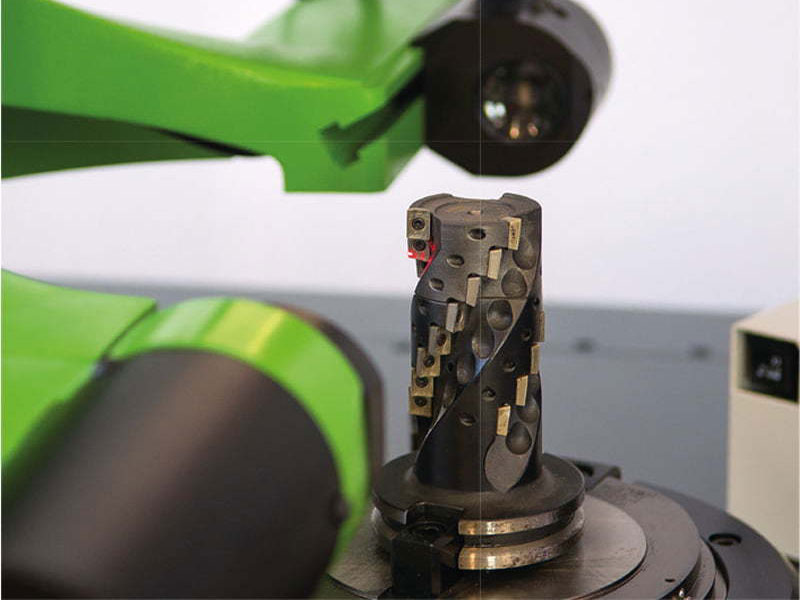

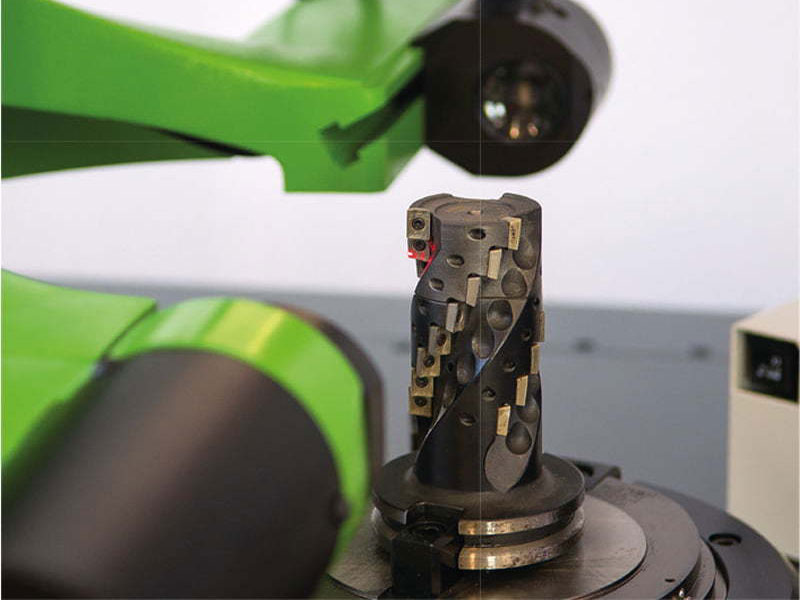

After all, it is precisely special solutions for out of the ordinary measuring tasks that differentiate a supplier of expertise. For example, our patented module monitoring system MoDetec automatically monitors whether the fitted insert module is the correct one for the adapter chosen in the control. It is now impossible to use an incorrect insert module! And as reference values are immediately available, there is instant assignment to adapters, machines and tools. BASIC line

-

Reliability pays off.

When it is a question of workpiece measurement and presetting, KELCH should be the first name you contact. For after all, KELCH has accumulated more than 75 years of experience in this sector. You will benefit from this experience, whether it is for the selection of materials or the correct combination of individual components. Our reliable and professional advice will ensure that you find the correct and appropriate device for for your needs. KELCH offers the widest range of presetters, in both vertical and horizontal designs. You can be sure that with KELCH you will find the right product for your requirements so that you will increase the quality of your production and therefore save money.

We place the highest possible value on high-grade components and high-precision mechanical machining. The overriding premise at KELCH is: “Accuracy comes from precise mechanics”. Where other companies rely on software corrections, we offer mechanical stability. Due to the stable grey cast iron, the base and the tower are considerably more resistant to temperature changes and machine vibrations. Furthermore, tools with a weight of up to 150 Kg can be measured on our devices without any problems. If heavier weights ever need to be measured, then we can also facilitate this using an additional

mechanical support.

A spindle of unsurpassed quality forms the first interface to the tool. An ergonomic one-hand operation of the optical carrier enables the fast placement of the tool in the cutting picture. Easy to use and clearly-structured software that delivers the results you need rounds off the package.

KENOVA set line V244

-

Setting and measuring tools without compressed air

Innovation meets efficiency. We proudly present our newest product, the tool setting device KENOVA set line V244. We understand the challenges posed by traditional tool setting equipment - the reliance on compressed air and the costs associated with it. That is why we have developed a groundbreaking solution: The KENOVA set line V244, the first tool setting device on the market that does not require compressed air.

Compact and robust, it is designed for tools with a diameter and length of up to 400 mm and a weight of up to 15 kg. Thanks to its flexibility and the possibility to place it in different locations, it becomes an indispensable auxiliary device directly at the machine tool, even in larger factories. Discover now the future of tool setting with KENOVA set line V244."

KENOVA set line V244 Basic:- X and Z axis with digital display and a resolution of 0.001 mm

- Measuring length X (Ø): 400 mm

- Measuring length Z: 400 mm

- Adapter sleeve available for all common taper sizes

- Cast iron base body

- Laser pointer

- 100 mm working distance

- Integrated image processing

- With control

- with Smart Pro IV software

- 0.3 MP CMOS camera

Accessories

-

Accessories for the BASIC line

Add to your tool presetter to meet your needs and

requirements and customise it with our accessories.

INDUSTRIAL line

-

Reliability pays off.

When it is a question of workpiece measurement and presetting, KELCH should be the first name you contact. For after all, KELCH has accumulated more than 75 years of experience in this sector. You will benefit from this experience, whether it is for the selection of materials or the correct combination of individual components. Our reliable and professional advice will ensure that you find the correct and appropriate device for for your needs. KELCH offers the widest range of presetters, in both vertical and horizontal designs. You can be sure that with KELCH you will find the right product for your requirements so that you will increase the quality of your production and therefore save money.

We place the highest possible value on high-grade components and high-precision mechanical machining. The overriding premise at KELCH is: “Accuracy comes from precise mechanics”. Where other companies rely on software corrections, we offer mechanical stability. Due to the stable grey cast iron, the base and the tower are considerably more resistant to temperature changes and machine vibrations. Furthermore, tools with a weight of up to 150 Kg can be measured on our devices without any problems. If heavier weights ever need to be measured, then we can also facilitate this using an additional

mechanical support.

A spindle of unsurpassed quality forms the first interface to the tool. An ergonomic one-hand operation of the optical carrier enables the fast placement of the tool in the cutting picture. Easy to use and clearly-structured software that delivers the results you need rounds off the package.

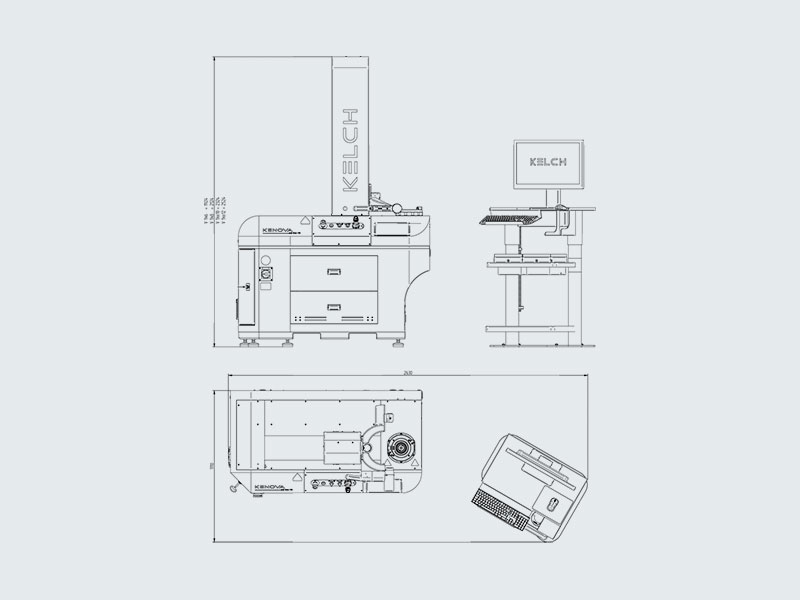

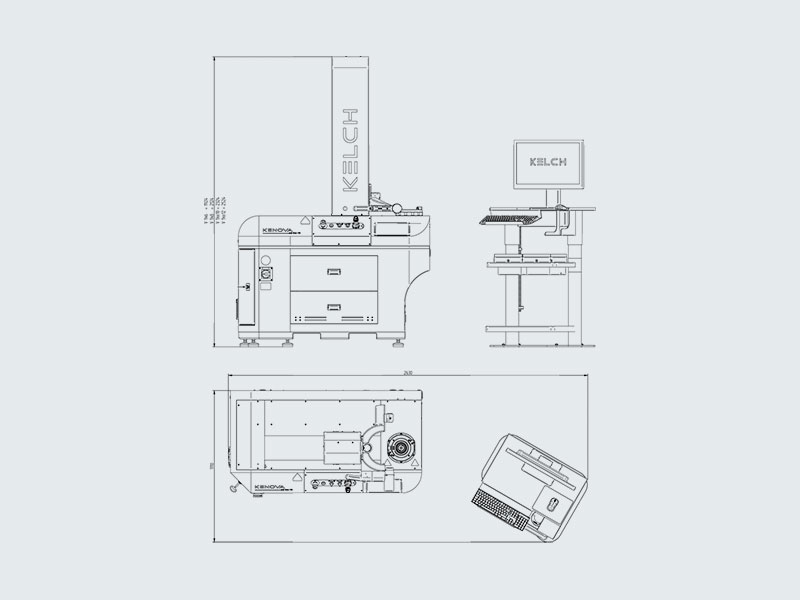

KENOVA set line V366

-

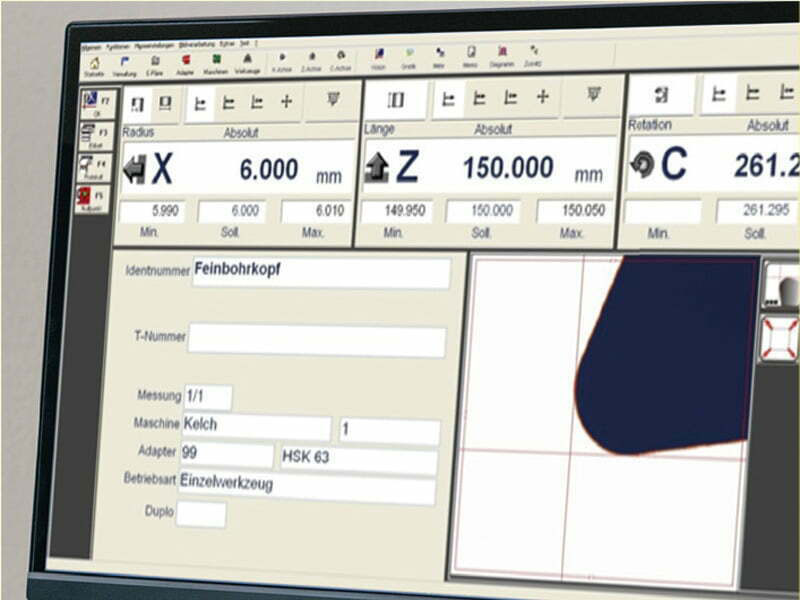

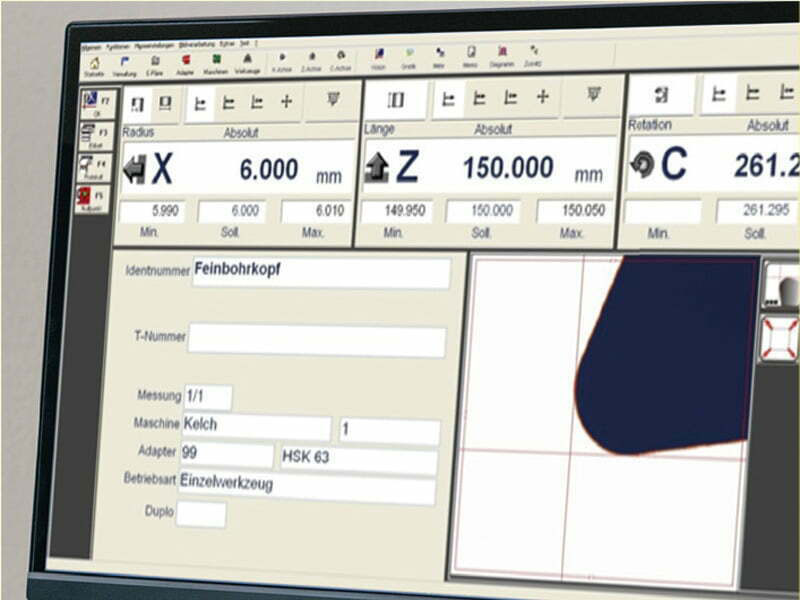

Connected production systems in machining companies only enhance quality when maximum precision is guaranteed. The new KELCH KENOVA set line V3 tool presetter with kOne software and TeamViewer IoT equips production lines for Industry 4.0 and IoT. TeamViewer IoT is optionally available. More information on TeamViewer IoT.

- Compact grey cast iron design for use in confined spaces.

WxDxH (mm): 1300 x 540 x 1300 (excluding TUL rack IV) - Convenient axis positioning by pneumatically released rough adjustment. Also features hand wheels for fine adjustment.

- Ultra-precise tool spindle with direct SK 50 interface and integrated calibration balls. Optionally with pneumatic tool clamping.

- CMOS camera with precise optics and lighting for ± 2 μm repeatability.

- KENOVA set line V3xx is available in three versions:

1. Manual

2. Manual with CNC spindle (Autofocus)

3. Fully CNC

- Compact grey cast iron design for use in confined spaces.

KENOVA set line H3

-

The compact entry-level tool presetter for horizontal tool measurement.

Thanks to its compact design, the horizontal tool presetter is ideal for small and medium-sized businesses. Do you have a clear need for tool measurement and require a stable and precise measuring system?

KELCH offers this option with the innovative development of the KENOVA set line H3. A further benefit includes possible connection to tool management systems. The unit is therefore suitable for use with Industry 4.0 applications

- Fine adjustment in both axes

For μm-precise fine adjustment in the X and Z direction - Table layout

Versatile table layouts with tool holders and spindles. - Possible set up

with three tool holders and one CNC spindle - Ergonomic handle

Quick adjustment of the axes ensures ergonomic working - Software EASY

(Optional CoVis) - Optional

optics carrier with turning centre camera

- Fine adjustment in both axes

PREMIUM line

-

Reliability pays off.

When it is a question of workpiece measurement and presetting, KELCH should be the first name you contact. For after all, KELCH has accumulated more than 75 years of experience in this sector. You will benefit from this experience, whether it is for the selection of materials or the correct combination of individual components. Our reliable and professional advice will ensure that you find the correct and appropriate device for for your needs. KELCH offers the widest range of presetters, in both vertical and horizontal designs. You can be sure that with KELCH you will find the right product for your requirements so that you will increase the quality of your production and therefore save money.

We place the highest possible value on high-grade components and high-precision mechanical machining. The overriding premise at KELCH is: “Accuracy comes from precise mechanics”. Where other companies rely on software corrections, we offer mechanical stability. Due to the stable grey cast iron, the base and the tower are considerably more resistant to temperature changes and machine vibrations. Furthermore, tools with a weight of up to 150 Kg can be measured on our devices without any problems. If heavier weights ever need to be measured, then we can also facilitate this using an additional

mechanical support.

A spindle of unsurpassed quality forms the first interface to the tool. An ergonomic one-hand operation of the optical carrier enables the fast placement of the tool in the cutting picture. Easy to use and clearly-structured software that delivers the results you need rounds off the package.

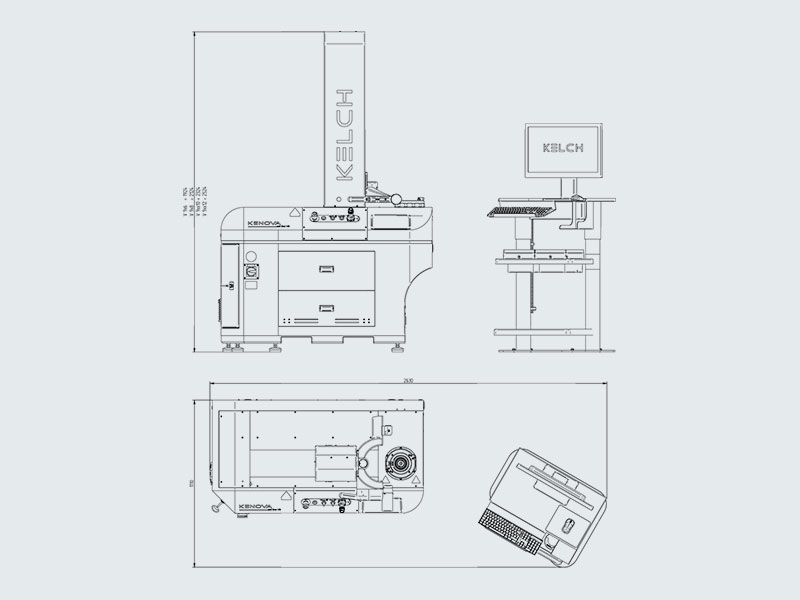

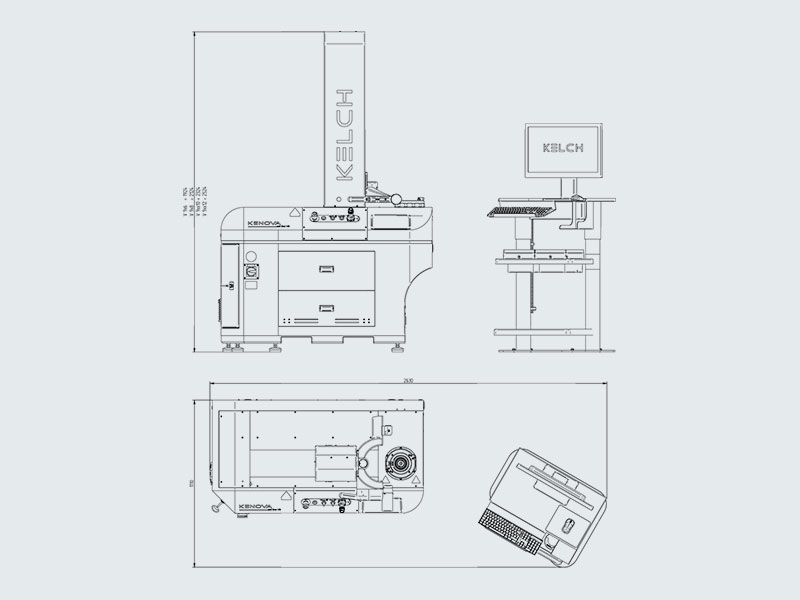

KENOVA set line V6xx

-

The new compact premium tool presetter for

maximum precision in the most compact spaces

The KENOVA set line V6 series guarantees fast, easy and precise measurements coupled with maximum possible process reliability

from patented systems.

The compact PREMIUM line system can be integrated very easily

into an ergonomic workplace design, leaving plenty of space for

tools and materials.- Modular precision spindle the most stable and

precise tool holder spindle. - Control panel with joystick to move the CNC axes.

-

Optics carrier including CCD camera and pneumatic

quick adjustment. Optional laser pointer for

detection of the cutting edge. - MoDeTec

Optional patented MoDeTec module monitoring system. - EASY software intuitively operated.

- Optional additional tool monitor.

- Modular precision spindle the most stable and

KENOVA set line V9xx / V9xx-S

-

The revolution in tool presetting.

Ease of use coupled with maximum precision. This range is modern, ergonomically designed and unique in its design. With its mineral cast base, cast in one piece from the guideway to the floor, KELCH is setting new

benchmarks in the design of tool presetters. This design promises durable and consistent mechanical KELCH quality.

Product features of mineral cast:- Environmentally-friendly manufacture thanks to cold casting process

- Sustainable recycling is possible

- Vibration-damping

- Insensitive to temperature fluctuations thanks to thermal inertia

- Precise measurement due to robust structure

Precision Tools

-

Do you know the difference between KELCH

and a precision tool? Precisely, there is none.

Precise simply remains precise.

For optimum machining results it is not only necessary to have efficient machinery and tools but also the corresponding interface. In this area we offer innovative solutions which guarantee the highest precision and stability:

For example i-tec®, the leading system for inductive shrinking technologies, but also ISO, HSK and PSK tool holders as well as useful accessories. Workshop Logistics

-

The most efficient way of transporting tools and having them available is provided by the flexible. KELCH transport and storage system. Our sophisticated solutions in the workshop logistics area make sure that the right tool will be available at the right place and at the right time. You name it: all-purpose tool carriers, transport and storage trolleys or work- shop equipment – KELCH products get your production moving and bring order to your tools.

TUL carriers are the perfect transport and storage unit for your tools. VariTUL offers variable solutions for flexible transportation and storage, so that tools are readily available, or so that the equipment in question will get to the right destination.

Measuring equipment

-

Double standards when measuring? Not with KELCH. Our answer is precision.

What is a manufacturing process without controls? Basically, it isn’t worth a penny. That’s why we go with the saying “Control is good – measuring with KELCH is better“. With our measuring equipment, users and customers are on the safe side.

We offer a wide range of products for production- related measuring and testing technology, so that the desired quality targets can be met. The KELCH production program ranges from manual dial indicators and callipers, gauges for the measurement of HSK tools and spindle tapers up to our electronic pull-back power measuring device for machine tool spindles, called ”SAFECONTROL“. Safecontrol 4.0

- With Safecontrol 4.0, you digitally and precisely measure the pull-in forces of machine tool spindles as well as extensions, reducers and zero point clamping systems.

- Robust basic device with simple operation

- Measured value indication via display with position orientation integrated in the handle - for better readability and identification of the spindle to be measured

- App for 100% process reliability

- Fast, trouble-free and reliable measurement immediately after the clamping process in the machine spindle

- High measuring accuracy (0.5 % of full scale)

- Large measuring range (0-100 kN)

- One basic device suitable for all adapters (HSK, PSC and SK/BT)

- Data display on tablet PC via Bluetooth transmission

- Calibration and repair service

Cleaners

RoWi II

-

3 rotating brushes gently clean external tapers and flat surfaces. To be used with and without cleaning agents. Chips, oil and coolant residue, as well as resinificated dirt are removed.

- Modular cleaning device for cleaning various tool holder tapers

- Robust housing with integrated time switch, to avoid continuous operation of the device

- Ergonomic design for safe and easy operation

- Resistant to rust and cooling lubricants

- Fast, gentle and reliable cleaning of extremely dirty or resinified tool holders

RoWi III

-

Discover the breakthrough cleaning performance of KELCH RoWi III today and optimize your manufacturing processes. Welcome to KELCH RoWi III - your solution for ultimate mold accuracy and efficiency. Our innovative product revolutionizes tool preparation and sets new standards in precision.

Learn how KELCH RoWi III optimizes your manufacturing processes and takes your productivity to a new level. Act now and experience the difference!

- Modular cleaning device in the new Design for cleaning different Tool holding taper

- Adjustable timer

- Newly designed clamping principle for even more ergonomics and combined System for DIN and MAS BT steep tapers

- Fully compatible with the RoWi2 system

- Ergonomic design for safe and easy operation

- Resistance to rust and Cooling lubricants

- Fast, gentle and reliable Cleaning of heavily soiled or gummed up tool holders

Automatic cone cleaner

Cleans the tool holders in the machine tool.

- Automated cone cleaning

- Cleaning intervals programmable

- Cleaning of the tool holder during the machining process

- Compact design, especially suitable for tight spaces

- Individual adaptation to the machine tool

- Resistant to rust and cooling lubricants

- Cleans dirty tool holders reliably, quickly and gently

- Standard unit available for all common taper sizes HSK, PSC and SK

Shrinking Technology

i-tec® M

-

Advantages

- Effortless adapter and test item change

- Modular design

Individual expansion and configuration options of the basic shrink fit machine into a premium shrink fit machine - Efficient heating up within seconds

Powerful induction coil for efficient shrinking in

shrinking in seconds of HM- (ø 3 - 32 mm)

and HSS (ø 6 - 32 mm) tools. The induction power of the coil can even reach 13KW for a short time. - Wide range of applications

Shrinking of tools with a taper size up to max. SK 60 / HSK 160 / PSC 100 and a total length up to max. 650 mm (with tower extension: 1400 mm). - Gentle, long-lasting & safe shrinking

For a long service life of your shrink fit chucks, overheating of the shrink fit chucks is specifically excluded. - Ergonomic work area with large tray

Ergonomically arranged work area with generous storage space for tools and shrink accessories for convenient and safe working. - Simple and intuitive operation

Shrinking can be done quickly and easily in just a few steps. LED indicators on the coil signal whether the coil is heating or not. - Patented contact cooling technology

Contact cooling achieves uniform, gentle and dry cooling of shrink fit chucks without additional costs for emulsion or compressed air.

Balancing machine

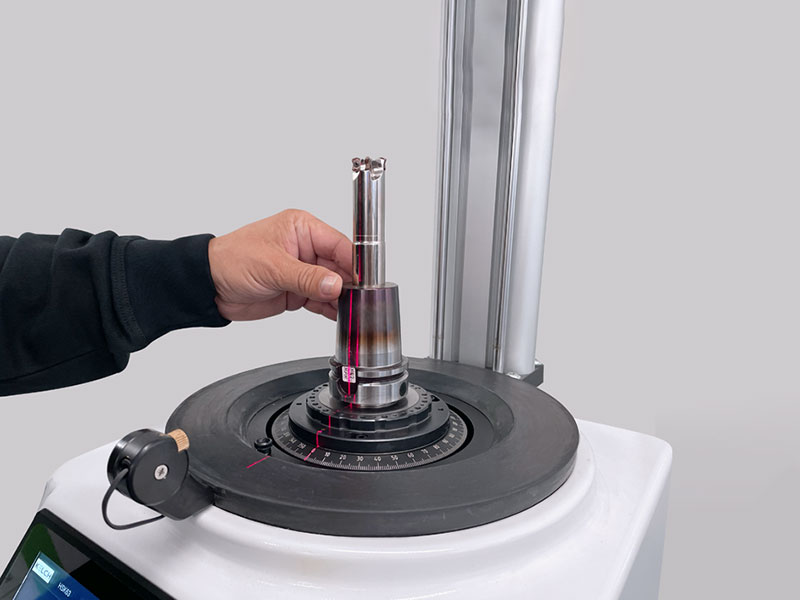

KELCH TB 100

- Increase the quality of your products with the vertical balancing machine KELCH TB 100 for balancing tools and rotary workpieces, for single and serial parts.

- Effortless adapter and test piece change

- Highest measuring accuracy with

- simplest operation

- Protocol at the push of a button with your printer

- Usable with your IT-compatible computer and notebook

- Available in all spindle versions

- Compact and space-saving

- Dimensions WxDxH (mm): 458x591x775 Balancing machine without base frame

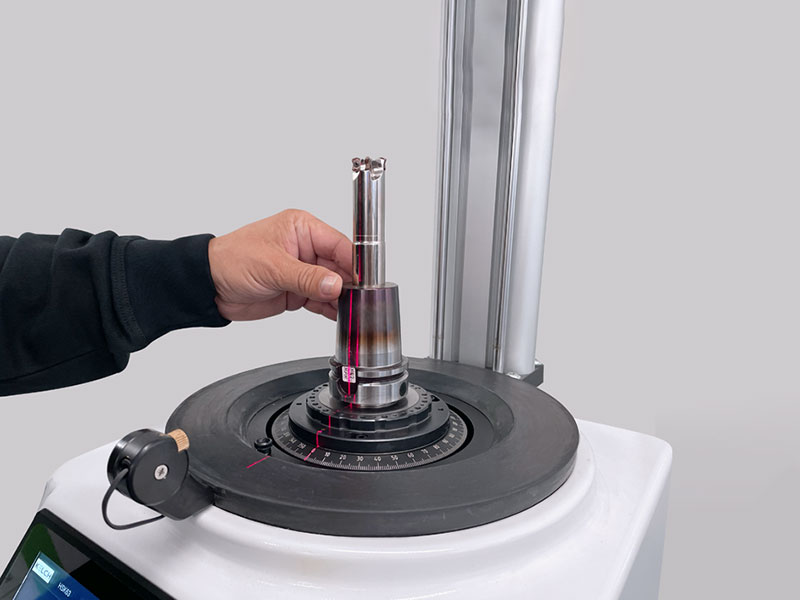

KELCH TB 200

-

Discover the future of tool balance control with KELCH's TB 200 - your solution for unsurpassed precision and efficiency. Increase the quality of your products with the Stand Alone KELCH Balancing Station TB 200 incl. automatic clamping device.

Learn more about its features and how it can optimize your manufacturing processes. Welcome to the world of innovation at KELCH!

- For balancing tools and rotary workpieces, for single and series parts

- Effortless adapter and test item change

- Highest balancing accuracy at the best price

- Protocol at the touch of a button on your printer

- Available in all spindle versions

- For 1 and 2 plane balancing

- Compact and space-saving with 6 balancing methods gram, spread angle, fixed location, drilling axial, drilling radial, milling.

- Dimensions WxDxH (mm): 460 x 790 x 590

- 10" operating panel, visual operator guidance