- Offer Profile

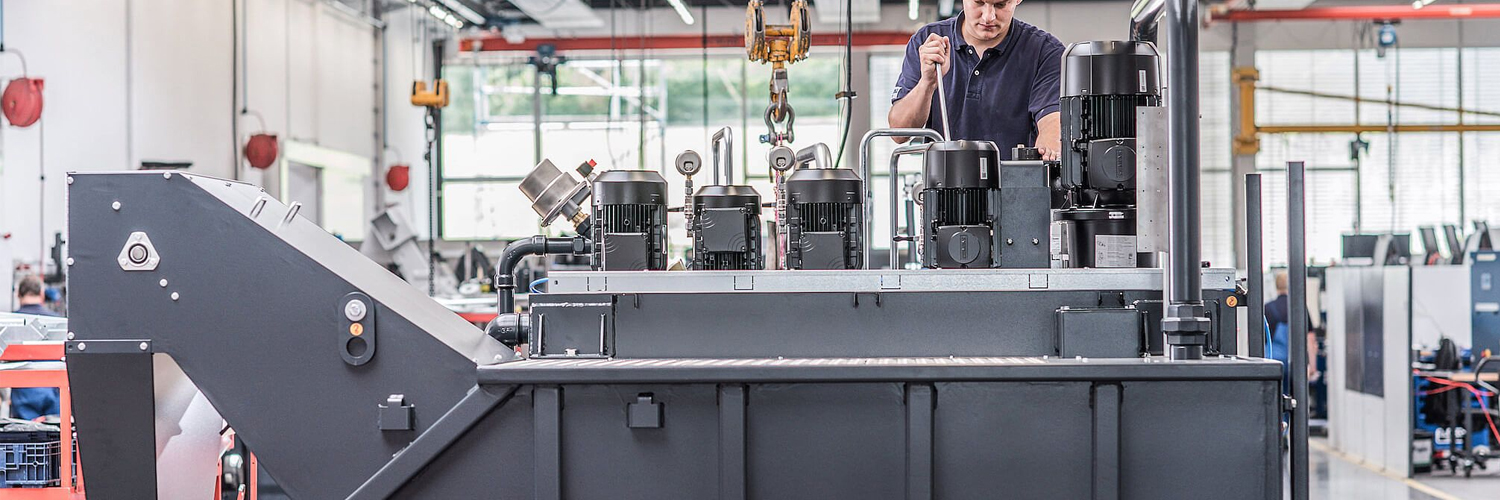

- KNOLL is the leading supplier of conveyor systems, filter systems, and pumps for metal processing. They transport and separate chips and cooling lubricants. For industries such as chemistry and food, the company offers special displacement pumps. Another division solves demanding logistics problems with assembly and transport systems.

Single Systems

- KNOLL single systems are accessories for machine tools or components of central systems. They serve to separate, transport and prepare chips and cooling lubricants. Many well-known machine-tool manufacturers and users in the field of metalworking put their money on KNOLL products when it comes to wet and dry machining. Whether it be chip conveyors, filters, or extraction or pump-back stations: KNOLL devotes all its efforts to customer requirements. From standard products individually tailored plants are created: Machine-integrated, positioned on the side or centrally positioned.

Transport systems

- KNOLL transport systems are ideally suited for use in logistics and assembly, even for heavy and very large parts. Because our systems are modularly structured mechanically, electrically, and in terms of their software, our specialists can implement custom-tailored solutions for you. Such systems guarantee a short amortization time and can be expanded nearly at will. The input-side visualization of the controller makes for easy operation.

Chip Conveyors

- KNOLL chip conveyors are available in various types, both machine integrated and centrally installed. Depending on chip type and transport route, screw conveyors and traction flap conveyors are used in addition to belt conveyors.

Scraper belt conveyor K

-

For short chips, small parts and sludge.

Areas of application

Transport of short broken metal chips and small pieces from machine tools. Installation possible as individual conveyor or interlinked system. Suitable for short steel chips, needle chips (e.g. brass), cast chips and cast abrasion, dry processing and wet processing.

Magnetic band conveyor M

-

For short, ferromagnetic chips and small parts (e.g. stampings).

Areas of application

Transport of short/broken ferromagnetic, with cooling lubricant afflicted chips and small pieces, e.g. stampings. Installation possible as individual conveyor or interlinked system.

Slat band conveyor P

-

For transporting metal chips and small parts.

Areas of application

KNOLL slat belt conveyors P are plants for transporting metal chips and small parts.- Decentral use on individual and interlinked machine tools

- Central use for waste disposal from machine groups and entire production areas

- Suitable for long chips, chip balls, wool chips (also in combination with short chips)

- Suitable for wet and dry processing

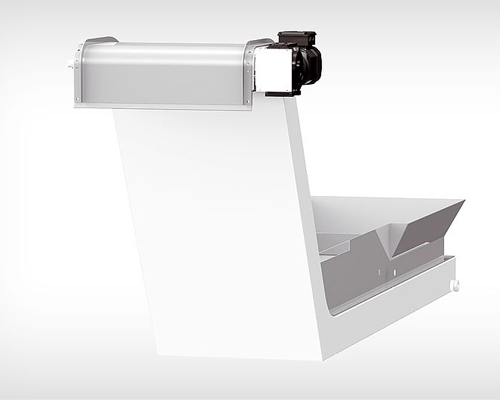

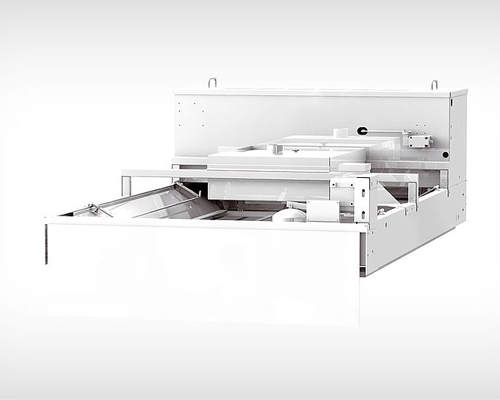

Return pumping station RIK

-

For integration into machine beds. With pump back tank, screw conveyor(s) and chip reducer (optional). For steel only suitable to a limited extent.

Properties- Fully automatic, unmanned chip transport

- Little space required, other than for the machine

- Low overall height, ideal for automation facilities

- Chip reducer may be retrofitted

- Hopper and screws adjustable at the machine tool

- All drives and maintenance areas are outside of the machine tool

Return pumping station RKR

-

For side installation on single units and transfer lines. With pump back tank, return pump(s) and chip reducer (optional).

Properties- Fully automatic, unmanned chip transport

- Little space required, other than for the machine

- Low overall height, ideal for automation facilities

- Chip reducer may be retrofitted

- Hopper and screws adjustable at the machine tool

- All drives and maintenance areas are outside of the machine tool

Return pumping station RSR

-

For side installation on machine tools which produce small amounts of chips, particularly grinders. With pump back tank and return pump(s).

Properties- Fully automatic, unmanned cooling lubricant and chip transport

- Simple, solid design

- Chip reducer cannot be retrofitted

- The cooling lubricant intake can be adapted to the machine (gravity inflow or pumping)

- All drives and maintenance areas are outside of the machine tool

Strap high conveyor S

-

For long chips, chip balls, wool chips and parts.

Areas of application

Transport of metal chips and small pieces from machine tools. Suitable for long steel chips, chip balls, wool chips, dry processing and wet processing. Installation possible as individual conveyor or interlinked system.

Scraper belt conveyor SF

-

For short chips and sludge.

Areas of application

Transport of short broken metal chips with small amounts of coolant. Suitable for wet processing with short steel chips, needle chips (e.g. brass), cast chips and cast abrasion and grinding sludge. Installation possible as individual conveyor or interlinked system.

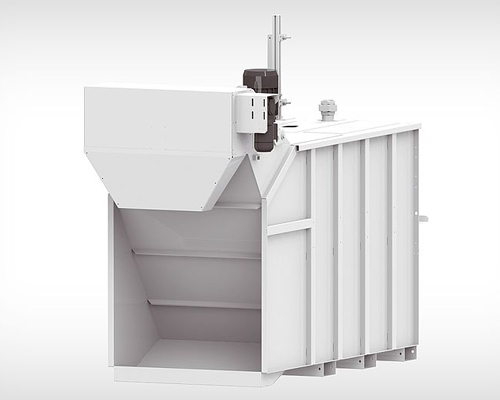

Traction flap conveyor ZK

-

For long and short broken metal chips.

Areas of application

Transport of long and short broken metal chips. Suitable for large conveying routes, long and short steel chips, needle chips (e.g. brass), dry processing and wet processing. Installation possible as individual conveyor or interlinked system.

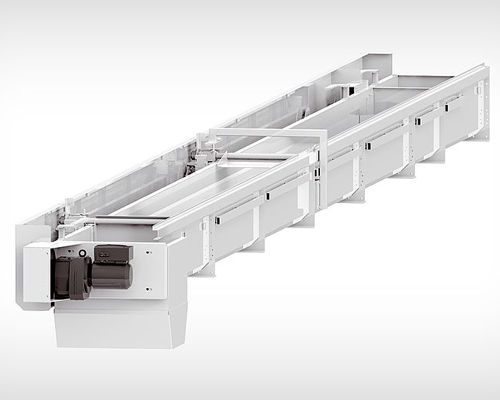

Scraper belt conveyor SR

-

For cutting off sedimenting short chips and sludge with a high coolant flow.

Areas of application

Collecting and cleaning of cooling lubricants with high coolant flow and large accumulation of sludge. Separating sedimentable solids from cooling lubricants. Installation as central plant for machine groups and entire production areas as well as individual plant for machines with large accumulation of sludge.

Filter Systems

- KNOLL filter systems clean coolant lubricants up to the very fine range, even without filter consumables. The filtration systems can be operated locally for standalone machines and centrally for machine groups or complete production areas.

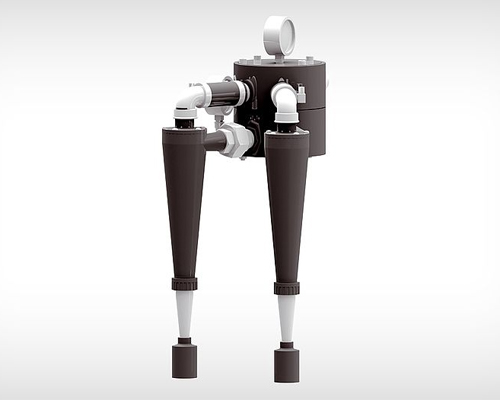

Hydroclone F60

-

Simple, modular centrifugal separator for separating sedimenting solids from low-viscosity liquids (e.g. emulsions) without filter consumables. Filter performance up to 90 l/min per module.

Areas of application

Removing sedimenting solids from liquids of low viscosity such as water and emulsions. Installation as independent cleaning unit on fine machining machine tools.

Fluid centrifuge CA 100

-

Automatic centrifugal separator for continuous ultrafine filtering of cooling lubricants and other industrial process fluids. Very good price-performance ratio. Max. filter output 120 l/min.

Properties- Very good price/performance ratio

- Short regeneration cycle thanks to mechanical brake system

- Frequency-controlled, wear-resistant direct drive via clutch

- Sound and oil-mist attenuation by shutter flap

- Electonic vibration monitoring with automatic stop function

- Separate speed monitoring of motor and drum

- Automatic flushing of rotor and centrifugal-force valves

- Flexible control console, can be erected on 2 sides

Superfine filter MicroPur®

-

Backflush filter for separating superfine impurities from oils and aqueous solutions. The ideal area of application is the tool grinding of hard metal and HSS. High filtration grade (1-3 µm). Filtration capacity up to 480 l/min.

Properties- High filter fineness (1-3 µm)

- Fast and effective regeneration cycle, low backflush volume

- Energy-efficient backflush without air

- Easy to maintain thanks to good accessibility and fast replacement of filter cartridges

- Inexpensive, back-flushable filter cartridges

- Energy-efficient, demand-controlled pump control

- Flexible modular system requiring minimal space

Reversible flow filter TURBO

-

Modular backflush filter for treatment of cooling lubricants without filter consumables, usually in combination with a sludge conveyor. Filter performance up to 250 l/min per unit.

Properties- Modular system

- Can be used with a wide range of plants

- Good expandability

- Simple, service-friendly design

- No filter aids are necessary

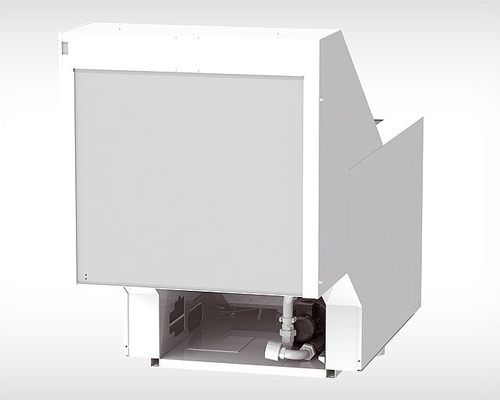

Vacuum rotation filter VRF

-

Backflush filter integrated in sludge conveyors for cleaning of cooling lubricants without filter consumables. Filter performance up to 1000 l/min per unit.

Areas of application

Cleaning of coolant lubricants, emulsions and cutting oils without filter residues. Installation on machine tools for individual machines, machine groups and central plants.

Gravity belt filter PF

-

Simple band filter in flat-bed design for cleaning of cooling lubricant with filter fleece. Filter performance up to 1000 l/min per unit.

Areas of application

Cleaning of cooling lubricants, emulsions, cutting oils and washing liquids. Installation as independent cleaning unit on machine tools as well as supplement to chip conveyors.

Compact band filter KF

-

Compact band filter in trough design for cleaning of cooling lubricant with filter fleece. Filter performance up to 2000 l/min per unit.

Properties- Compact design

- Good price-performance ratio

- Greater hydrostatic pressure as compared to flat-bed filters

- Sweeping strips and scraper

- Can be used universally for different working processes, materials, cooling lubricants, delivery rates and degrees of purity

Compact filter KF-E

-

Compact band filter in trough design for cleaning of cooling lubricant with endless filter belt. Filter performance up to 2000 l/min per unit.

Properties- Compact design

- Good price-performance ratio

- Greater hydrostatic pressure as compared to flat-bed filters

- Sweeping strips and scraper

- Endless filter belt

- No carrying of cooling lubricant by the filter fleece

Hydrostatic filter HL

-

Band filter in bevel design for cleaning of cooling lubricant with filter fleece. With simple vacuum technology. Filter performance up to 1000 l/min per unit.

Properties- Minimum residual moisture in fleece and waste discharge, resulting in less cooling lubricant loss and reduction of disposal costs

- Low fleece consumption

- High filter fineness

- Trouble-free removal of chips, including light alloy

- All-purpose filter for different machining procedures, materials and coolant lubricants

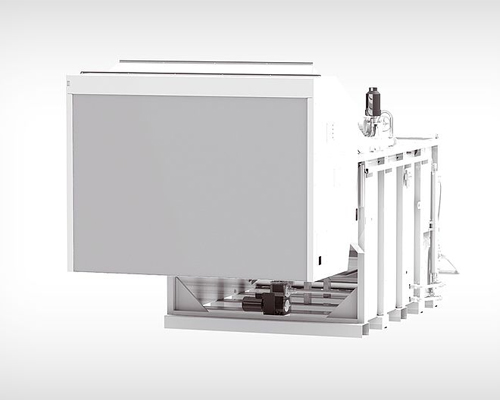

Vacuum filter VL

-

High performance band filter in bevel design for fine cleaning of cooling lubricant without filter consumables. With extended vacuum technology, optionally with precoating system or filter fleece. Filter performance up to 1500 l/min per unit.

Properties- Production of pure concentrate with low residual moisture as standard without filter aids

- Optimised filter capacity, filter quality and energy efficiency thanks to a flawless control system

- Continuous filter process without reverse flushing intteruption

- Forced degasification of coolant lubricants in the filter

- Can be used for different machining processes, materials and coolant lubricants

- Problem-free removal of light metal chips

Vacuum filter VLO

-

High performance band filter for cleaning of cooling lubricant without filter consumables, for example profile grinding with processing oil. Filter performance up to 900 l/min per unit.

Properties- Pure concentrate with low residual moisture

- Continuous filter process without reverse flushing interruption

- Scaling of filter capacities from 300 to 900 l/min (oil) with the same floor space possible

- Subsequent extension of the unit possible

- Redundant design of the filter modules possible

- Different filter qualities per filter module possible

Vacuum filter VLX

-

The vacuum filter VLX is a high performance band filter for cleaning of cooling lubricant, machining operations, in particular for grinding processes.

Properties- Production of pure concentrate with lower residual moisture without filter media

- Optimised filter capacity, filter quality and energy efficiency thanks to the intelligent control system

- Problem-free chip and light alloy discharge

- Almost constant filter quality without outlier

- Continuous filter process without reserve flushing interruption

- Forced degasification of coolant lubricants in the filter, optionally supported by the overhead tank system

- Can be used for different machining processes, materials and coolant lubricants

Pumps

- Ever since the company was founded, KNOLL has been developing and producing pumps for its internal requirements. Over the years, innovative technology has helped positive-displacement machines in particular to become very popular with external customers in industries such as mechanical engineering and process technology. KNOLL also produces pumps which are suitable for high-viscosity, contaminated or non-lubricating media. As well as their reliability, long service life and ease of servicing, customers also appreciate the quick availability of the products and spare parts.

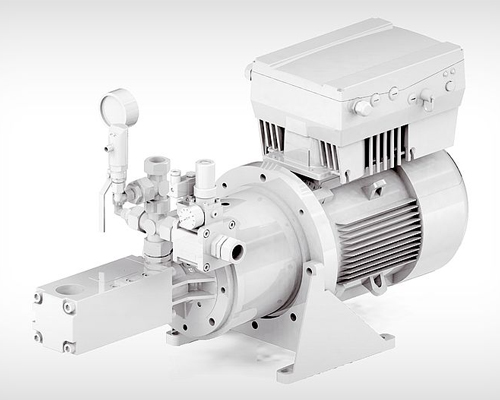

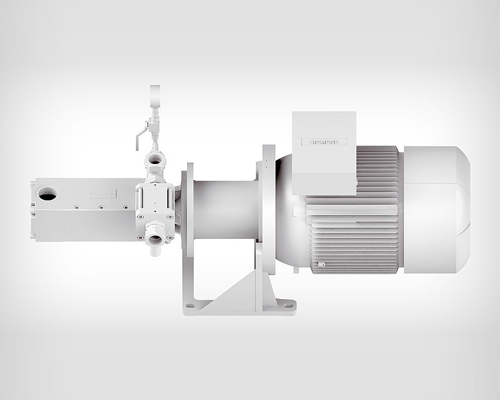

Screw pump KTS

-

Dry and wet installed high-pressure pump for cleaned cooling lubricants, optionally in a highly wear-resistant version. Volumetric flow up to 900 l/min, pressure up to 150 bar.

Advantages:

- Long durability thanks to high wear resistance

- Low pulsation

- High temperature resistance

- Low noise generation

- Gentle liquid conveyance

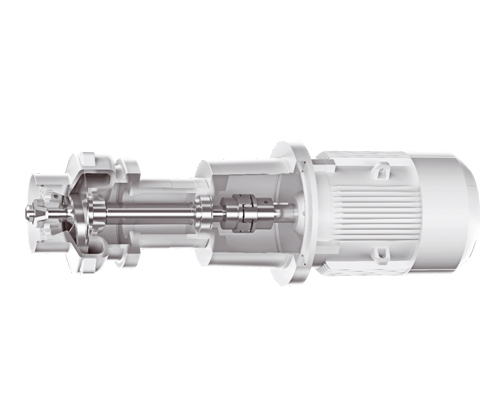

Screw spindle pump KTSV

-

Extremely wear-resistant high-pressure pump for conveying and dosing free-flowing to high-viscosity media in process engineering. Volumetric flow up to 50 m³/h, pressure up to 200 bar.

Advantages:

- Long service life thanks to high resistance to wear

- Low pulsation

- Extremely temperature-resistant

- Minimal noise generation

- Gentle fluid delivery

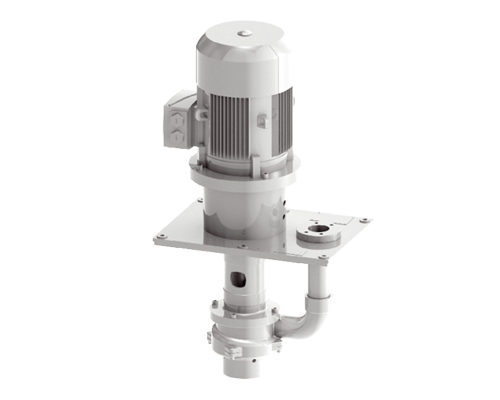

Centrifugal pump

-

KNOLL centrifugal pumps are available as submersible- or block pumps. These flow machines are used primarily on machine tools to convey cooling lubricants.

As return pumps, they transport the chips/cooling lubricant mixture to filters/separators. They then supply the machines again with the cleaned cooling lubricant. Thanks to their solid and robust design, the KNOLL coolant pumps have a high load capacity and a long durability.Types:

- Block pumps

- Clean coolant pumps

- Dirt coolant pumps

- Shredder pumps

Shredder pump TSC

-

KNOLL shredder pumps TSC are cooling lubricant pumps with an integrated shredder for aluminum chips. These pumps are able to shred long aluminum chips into pump-appropriate size and to convey them to the central preparation station with the help of cooling lubricant. Therefore, an additional chip reducer is not necessary.

Properties:

- Flexible design with standard motor

- Energy efficient in conjunction with frequency converter

- Bearing is protected by shaft seal ring

- Rigid shaft through bearing of the cutting head in a ceramic precision bearing

- Durable and low-maintenance due to hardened hydraulic and reducer

components - Semi-open radial impeller

- Impeller material ST

Block pump BS

-

Self priming KNOLL block pumps of the BS series are pumps which transport

contaminated cooling lubricant with high air content. Thanks to the solid and

robust design, KNOLL block pumps are extremely reliable and have a long

durability. Volumetric flow up to 340 l/min, pressure up to 2.3 bar, particle size up

to 10 mm.Properties:

- Dry installation

- Self priming

- Flexible design with standard motor

- Energy efficient in conjunction with frequency converter

- Flow-optimized housing with impeller

- High-quality and wear-resistant mechanical seal

- Rapid suction time

- Variable connection possibilities for pressure side piping

High-pressure units

- KNOLL high pressure systems serve as suppliers for machine tools such as machining centers and turning machines. High pressure pumps provide the correct supply-pipe pressure for the different consumers.

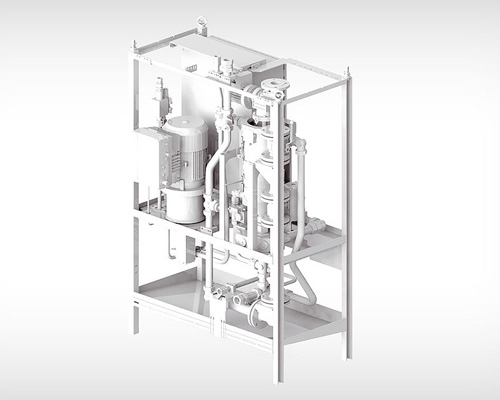

High pressure unit LubiCool®-M

-

The KNOLL high pressure unit LubiCool®-M is a mobile high pressure unit for machine tools, particulary fixed- and sliding headstock automatic lathes. The system cleans the CL and provides the machine with high pressure.

It is suitable for

- demanding machining processes

- deep hole drilling in one move

- processing with difficult materials (e.g. high-alloyed steel, titanium, copper, bronze)

- original equipment and retrofitting

Properties- Compact and mobile

- Plug-and-Play

- High pressure up to 150 bar

- Effective filtration via belt filter

- Wear-resistant screw spindle pump

- Demand-driven pump control

- Attractive price-performance ratio

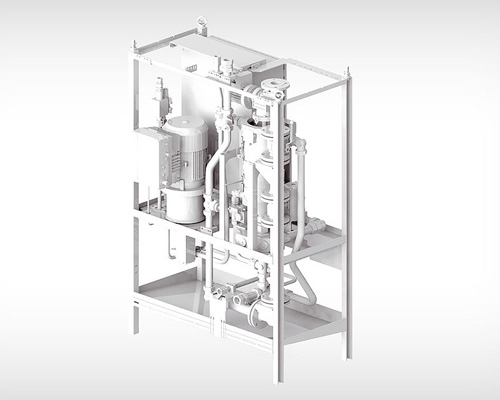

High pressure unit LubiCool®-L

-

The KNOLL high pressure unit LubiCool®-L is a compact high pressure unit for machine tools, particulary for small and medium machining centers and lathes. The system cleans the CL and provides the machine with high pressure.

It is suitable for

- Demanding machining processes

- Machining difficult materials (e.g. high-alloy steels, titanium, copper)

- High pressure requirements with increased volume of CL

- Additional flushing requirements

- Original equipment and retrofitting

Properties- Compact and mobile

- Plug-and-Play

- High pressure up to 150 bar

- Effective filtration via belt filter

- Wear-resistant screw spindle pump

- Demand-driven pump control

- Attractive price-performance ratio

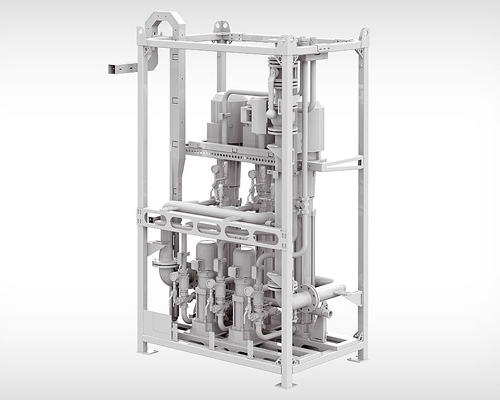

Pressure booster DHS

- The pressure booster DHS serves to supply machine tools with cooling lubricant. For this, low and/or high pressure pump(s) increase the supply pressure of a central plant. They supply all consumers of a machine tool with the necessary quantity of cooling lubricant. Examples are internally cooled tools and flushing.

Properties- State-of-the-art screw pumps, valve and control

- technology

- High and low pressure supply in a compact frame

- Demand-controlled pump control

- Modular toolbox system

- Customer-specific design

Chip reducers

-

KNOLL chip reducers cut metal and plastic chips to bulk material quality. The reducers can be installed on machine tools or at central collecting points. Depending on model, horizontal or vertical chip feed is possible, together with faulty part ejection in some applications.

Properties- Suitable for different types of chips

- Wide, insensitive cutter

- Intake behavior regardless of the chip form

- Flexible, changeable toolbox system

- Easy, robust, and service-friendly layout

- Intelligent control

- Multiple sealing of the bearing units

- Low energy requirement

Central systems

- If chips and/or cooling lubricants are transported completely automatically to a central point and should be treated there, system solutions are required. These are individual systems and components that are linked to form one system. KNOLL can offer you all required services, from planning to production to start-up, all from a single source. Then our customer service ensures safe and economical operation. And if the system should be expanded or reconfigured, KNOLL is the right partner for you.

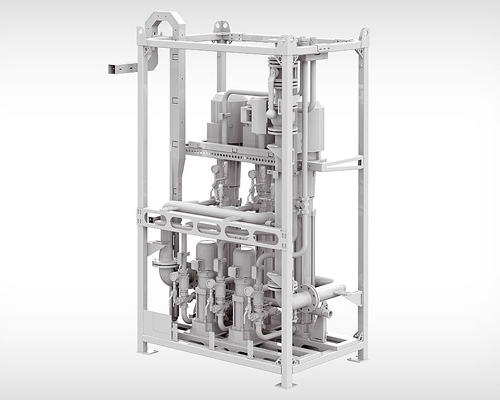

Systems with pump technology

-

A conveyor and filter system with pump technology is suitable for fully-automatic chip transport from several processing machines to a central filter system. Cooling lubricant serves as the carrier medium. This system is especially advantageous in production areas with a large machine park. It is constructed to save space and be flexible with regard to its overall height. The user has many possibilities for expanding and converting his machine park. Little maintenance and service is required.

Properties:

- High flexibility in the erection or changeover of the machine train

- Low space requirement due to above-floor pipelines

- No plant components within the hall floors

- Low maintenance and upkeep

Systems with extraction technology

-

A conveyor system with extraction technology is suitable for fully-automatic chip transport from several processing machines to a central collection point. Room air serves as the carrier medium. It can transport dry or slightly damp chips across a distance of up to 560 m. With the use of modern fans and control technology, the system requires little energy. It is also space-saving and offers great flexibility for the setup or conversion of the machine park.

Properties- High flexibility in the erection or changeover of the machine train

- Low energy requirement thanks to the use of modern blowers and control technology

- Easy routing and low space requirement of above-floor pipelines

- Safe, fast and clean transportation with long service life

- Low maintenance and upkeep

- Material mix (e.g. aluminium, steel or cast iron) possible with one system

Systems with collecting conveyors

-

Collecting conveyor systems are required to bring metal chips and small parts from production to a central collection point. Initially, integrated systems convey the chips from the machine tool. They transfer their freight to collecting conveyors. If the distances are large, transfer stations and appropriate control technology is required. Depending on spatial and production-technical circumstances, individually customizable underfloor, overfloor or on-the-floor solutions are available.

Properties- High flexibility in the erection or changeover of the machine train

- Simple technology

- Low planning

Systems for chip processing

-

The treatment of chips has many advantages: they are dry and separated by type, so disposal costs are low. Depending on the material, it may even be possible to sell the chips. A system for chip treatment includes different components depending on the requirements: conveyor and collection devices, magnetic separator technology, filter and volume-reducing briquetting presses. And containers or chip silos are also required. The components can be linked to one another and operated completely automatically.

Properties:

- Chip drying is essential to ensuring safe transportation on public routes

- Volume reduction reduces storage and transportation cost

- Recovery of chips and cooling lubricant protects the environment and reduces

costs