- Offer Profile

- Our drive is your success. We have been a major supplier of High Precision gear solutions to international companies in the robotics, machinery and automation industries for over 35 years. From our headquarters in Hamelin, Germany, we develop, produce, assemble and test innovative precision gearboxes for the global market.

Gearboxes from Melior Motion: Precise, durable, efficient

-

We build innovative gear boxes for industrial automation applications to ensure your success. Our broad product portfolio ranges from standard gearboxes through application-specific adapted products to custom-made special gearboxes. Your individual requirements are always at the forefront.

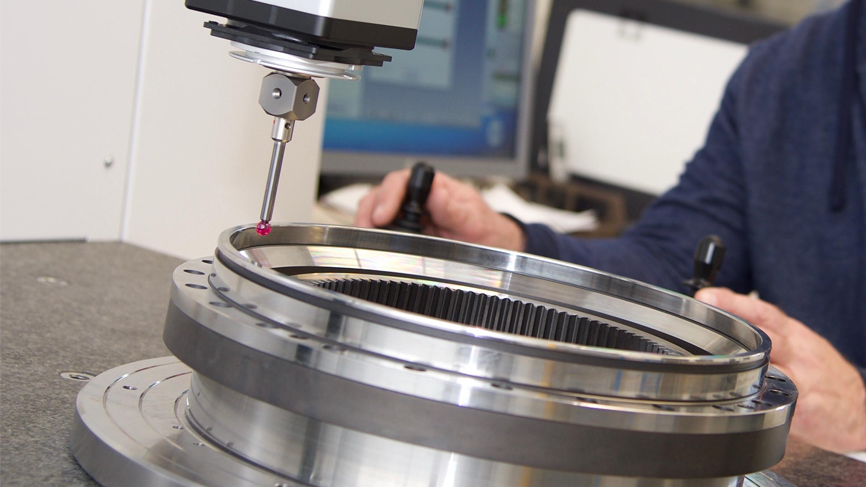

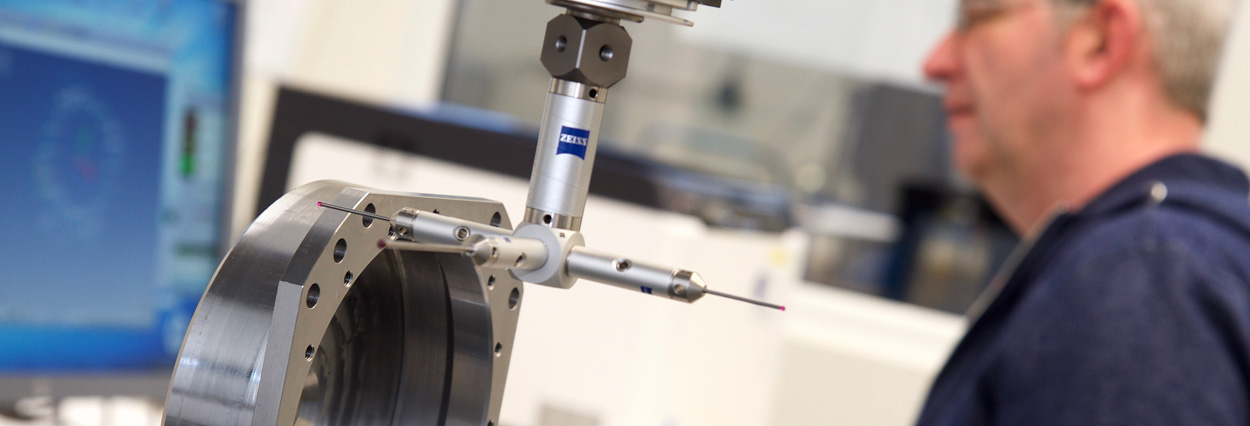

Our precision gearboxes are considered to be backlash-free with a backlash of ≤ 0.1 arcmin. They benefit from our reliability: thanks to a patented solution for wear compensation, the backlash of the gearboxes remains unchanged over the entire service life. This gives you maximum security for your applications. High-precision Melior Motion® gearboxes

-

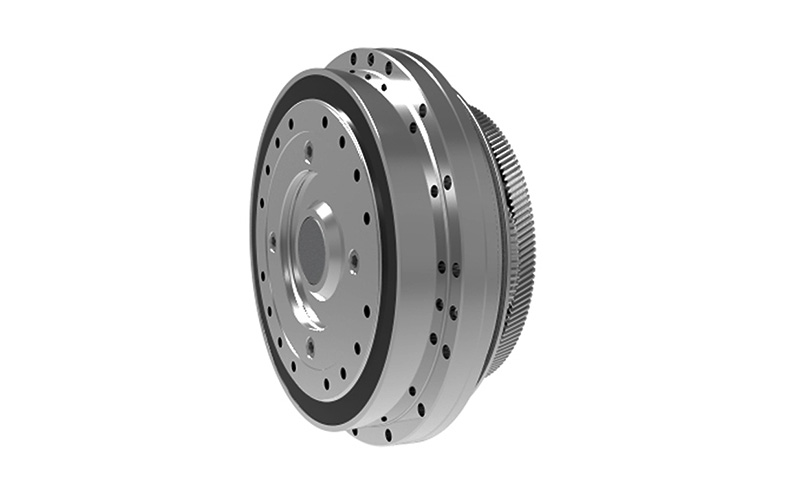

Our precision Melior Motion® gearboxes of the standard PSC series are available in seven sizes – in solid and hollow shaft versions. The entire series is characterized by a long service life and a high efficiency of ≥ 90%.

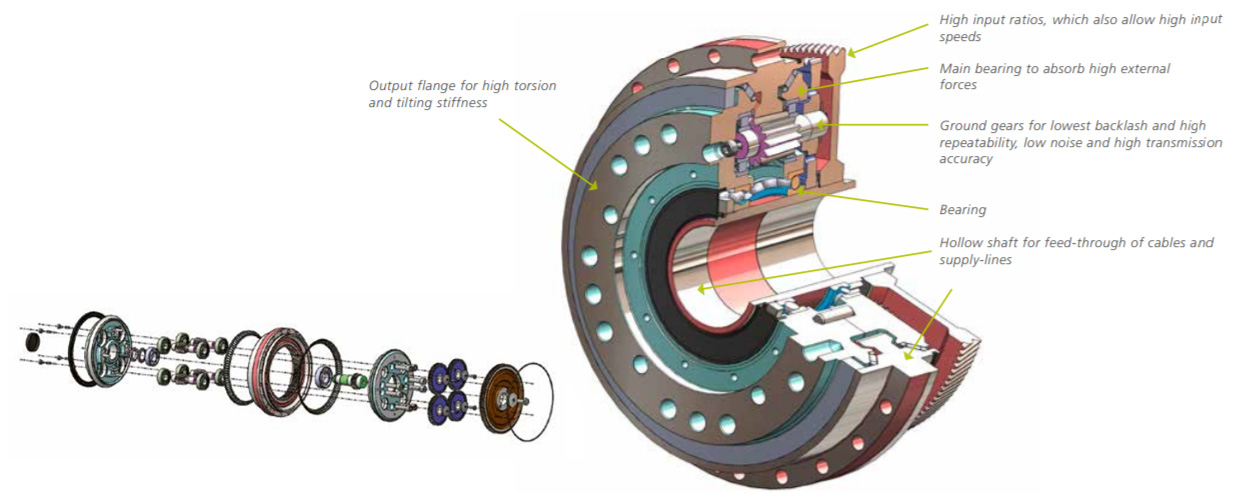

The gearboxes are a patented planetary design with an integrated helical gear stage.

High torques, together with high tilting and torsional stiffness, allow precise positioning at all times. All sizes are available as sub-assemblies or fully enclosed gearbox units, with motor adaption.

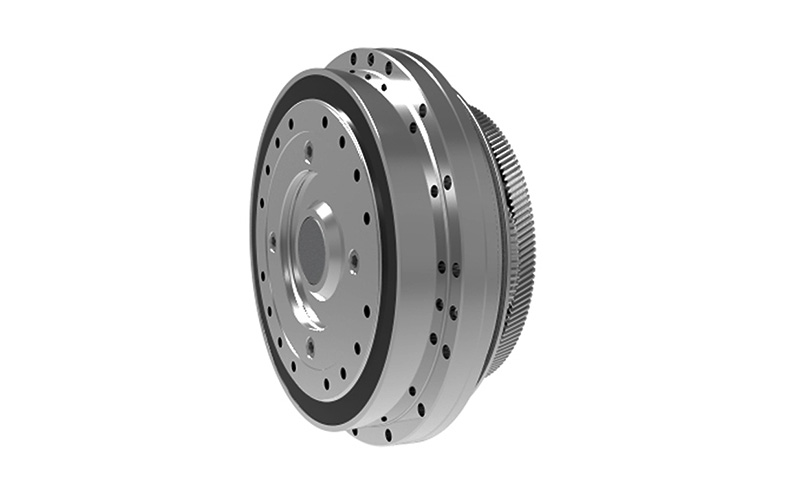

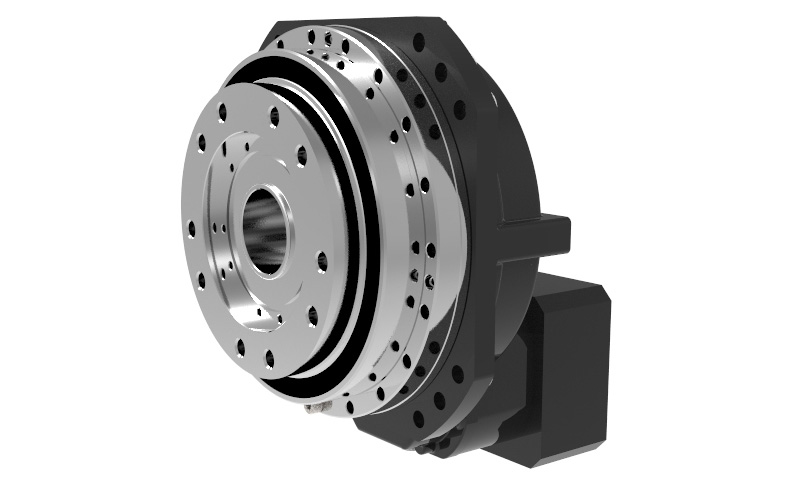

Sub-assemblies PSC-V / H-E

-

Low backlash precision gearboxes:

Sub-assemblies PSC-V / H-E of the meliormotion®seriesMelior Motion offers high precision gearboxes, which with a backlash of ≤ 0.1 arcmin are considered backlash-free. With our patented solution for wear regulation, we ensure that this does not change over the entire service life.

Low-backlash precision gearboxes – efficient and durable

More safety for your application is offered by low-backlash gearboxes thanks to high output, acceleration and emergency stop moments. Our gearbox series has exceptionally high tilting and torsional stiffness. These ensure precise positioning straight-to-the-point.

Gearboxes and drive elements

Our low-backlash precision gearboxes achieve a particularly high performance level thanks to multiple simultaneous teeth engagement (sun gear, planetary gears and ring gear). The efficiency of> 90% and the extremely low breakaway torque ensure outstanding energy efficiency. Thanks to the high efficiency, the transmission temperature remains consistently low, extending the operational life of the oil seals, transmission components and lubrication.

The result is an impressive life of 20,000 hours. This is much more than is possible with other designs of precision gearboxes and has been verified in numerous tests.

At the same time, the unique design of our low-backlash precision gearbox ensures extremely quiet operation. The noise in the work environment is thus reduced.

Not only quiet but also precise, the sub-assemblies even work effectively at low torque, allowing small movements to be precisely controlled.

Hollow shaft gearboxes for cable routing

Hollow shafts with a diameter of up to 75 mm allow, for example, the feed-through of data or supply lines.

The gear design of our products allows for the use of standard transmission oils, and are also suitable for use with food-compatible lubrication.

The PSC-V / H-E sub-assemblies are also suitable as high precision gear units with output flange for your highly specialised applications.- Torque range 400 – 4500 Nm

- Outer diameter 180 – 329 mm

- Scope of ratios: 35: 1 – 200: 1

Sub-assemblies PSC-V / H-E

Integrated DesignThe application of PSC sub-assemblies is commonly used in robotics, where the connection to the motor can be incorporated into the design of the robot arm, to optimise space and cost.

Further applications for this design option can be found in automation, machine tools, printing industry, packaging machines, rotary tables, medical technology, and more.

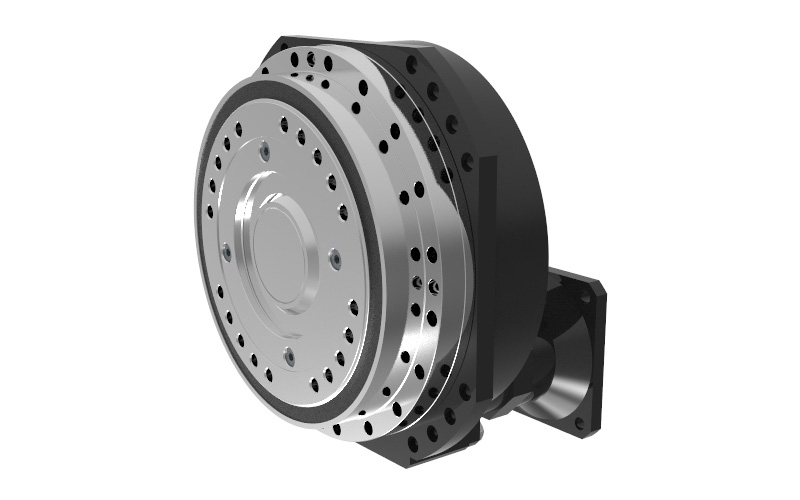

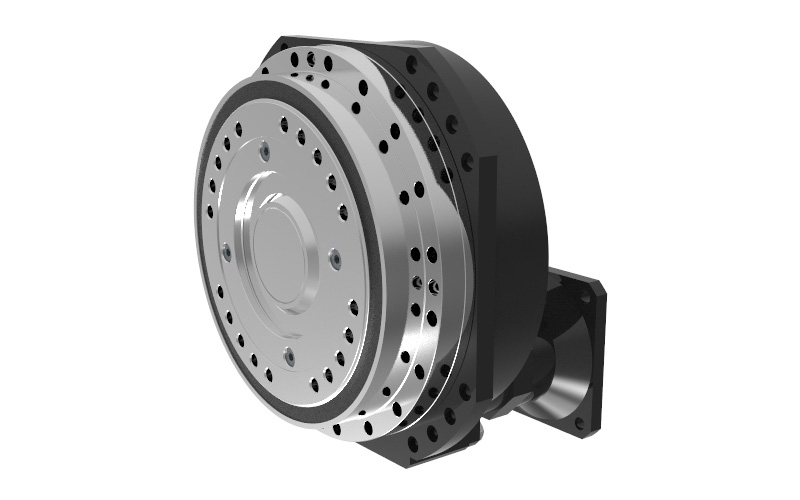

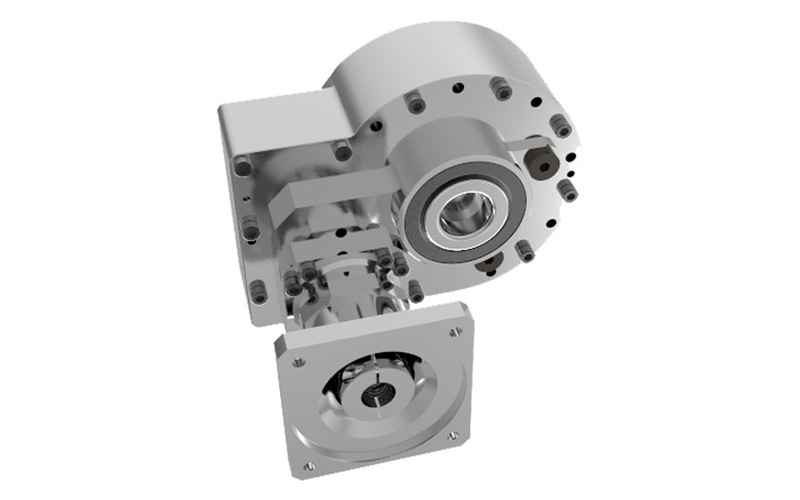

Fully enclosed gearboxes PSC-V / H-B

-

Planetary gear unit with integrated bevel gear stage: The PSC-B fully enclosed gearboxes.

Our PSC-B range of planetary gearboxes are ready-to-mount. They are filled as standard with a mineral-based oil. The most common servomotors are easily adapted via different interfaces. A fully developed arrangement of the planets around the sun gear and an integrated helical gear stage ensure that the teeth are immediately engaged. The breakaway torque is therefore extremely low. This results in a better controllability of the system.

Precise and compact: meliormotion® PSC fully enclosed gearbox units

Our planetary gears are characterised by high output, acceleration and emergency stop torques. This gives the application more security. An enormous tilting and torsional stiffness enables precise positioning.

Long lifetime of gearbox units PSC-V/H-B

A long service life of all components and lubricants of 20,000 hours is very important for our customers.

In addition, the high efficiency of> 90%, ensures that the temperature in the gearbox remains constant at a particularly low level.Planetary gears for highest precision in your application

The gearbox units PSC-V/H-B are available in solid and hollow shaft design and once lubricated, do not require further oil changes throughout their lifetime, providing lowest possible operating costs.

Data or supply lines can be routed through the hollow shafts of up to 75 mm diameter. If desired, we can offer additional right angle solutions. Our planetary gearboxes are used in many applications including; automation, machine tools, printing and packaging machines, rotary tables and medical technology, amongst others.- Torque range 400 – 4500 Nm

- Outer diameter 180 – 329 mm

- Scope of ratios: 35: 1 – 200: 1

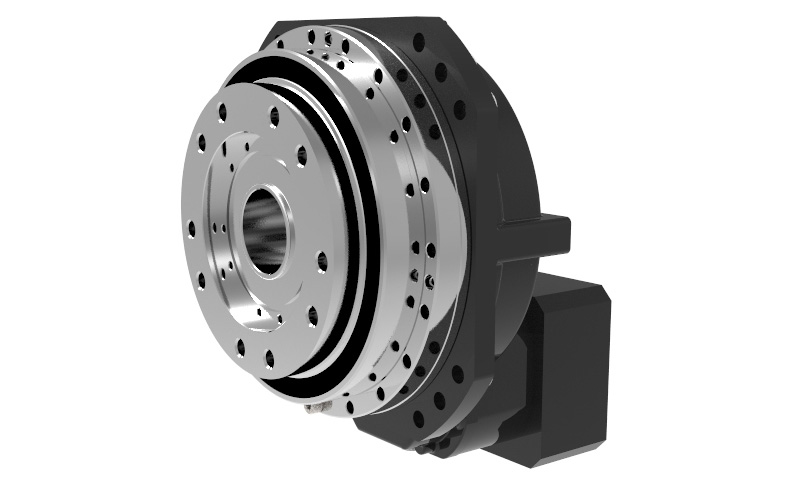

Special gearbox PSD

-

Robotic gearboxes for special applications

This special robotic gearbox was originally developed for use in Delta robots. Today our special and robotic gearboxes are used in nearly all areas with very specific requirements. They combine the highest precision with fast reverse movements. The precision gearbox PSD can easily be adjusted with varying product weights and different pick & place paths. Our customers can expect high cycle numbers and short, fast reverse movements with a simultaneous high duty cycle.

Robotic gearboxes from Melior Motion: Constantly high precision

The unique and patented gear design allows very low backlash of ≤ 0.5 arcmin, this also remains constant throughout the lifetime of the gearbox. Input speeds of up to 6,000 rpm are achieved and an extremely high precision of the gearbox is possible, even in the range of low torques and small movements. The range of ratio offered is 20:1 … 50:1.

The gears are precision ground. The housing is made of a high-quality aluminum alloy. This contributes to the low gearbox weight of 7.5 kilograms. In order to ensure the highest possible quality, we use exclusively high-quality bearings .

The advantages of the special PSD gearbox – your added value

The compact design of our special PSD gearbox enables a smart system design. The operating noise level is <70 dB (A), reducing noise pollution in the workplace:

The motor mounting is carried out individually via a variable interface, thus enabling simple adaptation of the common servomotors. Maintenance is not required due to life-time lubrication. Cables and supply-lines can be routed through the hollow shaft. Alternatively it is also available in solid shaft version.The characteristics and advantages of the PSD range

CHARACTERISTICS ADVANTAGES Very low backlash Constant precision throughout the entire service life Compact design Smart environment design Low noise Low noise pollution in the work environment Low friction Higher energy efficiency High stiffness Allows precise positioning High efficiency Reduced energy consumption Gearbox with hollow shaft For feed-through of supply lines or for centering Motor assembly via motor flange and coupling Simple motor adaption of common servomotors Special gear design ensures fast change of directions S1 Operation is possible Life-time lubrication No maintenance required

Customised gearboxes

-

Precision gearboxes made to measure

We also develop and manufacture high precision automation gearboxes individually according to customer requirements – consisting of a planetary gear stage, helical gear stage or bevel gear stage. Our project and development teams consistently implement innovative concepts. This gives our customers tailor-made automation drives for their individual applications – with safety through controlled and established development, verification and production processes.

Special precision gear units for industrial applications

Also for customer specific solutions, we offer especially low backlash gearboxes. This is demonstrated by our examples for robotic applications: Our SP191 special gearbox is a robotic gearbox with very low backlash which remains constant at ≤ 0.1 arcmin. The gearbox with a hollow shaft of 80 mm diameter is ideally suited for carrying data or supply lines. The maximum torque is 2,000 Nm.

We adapt the gearbox size individually to the specific customer requirements. This is, of course, not only for robotic gearboxes, but for all customer-specific gearboxes. Another example: the positioning drive SP224. The positioning accuracy is +/- 0.03 mm. This gearbox also has a particularly low backlash of ≤ 0.1 arcmin over the entire service life.Gearboxes for linear axis

Another highly specialized example is our gearbox for linear movements, which are equipped with output pinions for rack-and-pinion applications. The ratio is 10: 1. The solid shaft gearbox has a backlash of <4 arcmin.

In this way, robots and workpieces reliably reach their goal. And, of course, our customer-specific automation gearboxes are characterized by high dynamics and high precision. Combined with a long service life, they are suitable for all applications, such as pick & place applications in handling technology.

Our customer-specific precision gearboxes – your advantages at a glance

- Best fit of service offer to your function

- Safety thanks to established and continuously improved development, verification and production processes

- Reliability through a variety of references in numerous industries

- Speed in project implementation ensures your competitive edge

Applications

-

Precision is required in many industries. We have the right solution.

Should you not find yourself here, ask us. We will face your challenge. ROBOTICS

- Industrial robots of all kinds; robots for linear axis

AUTOMATION

- Handling systems, pick and place applications, automation systems, transport systems

MACHINE TOOLS

- Tool changers, feed systems, rack and pinion applications

PACKAGING TECHNOLOGY

- Palletising systems, pick and place applications, handling, transport systems

WELDING

- Rotary tables, positioners

MEDICAL SYSTEMS

- MRT-, CT devices