- Offer Profile

-

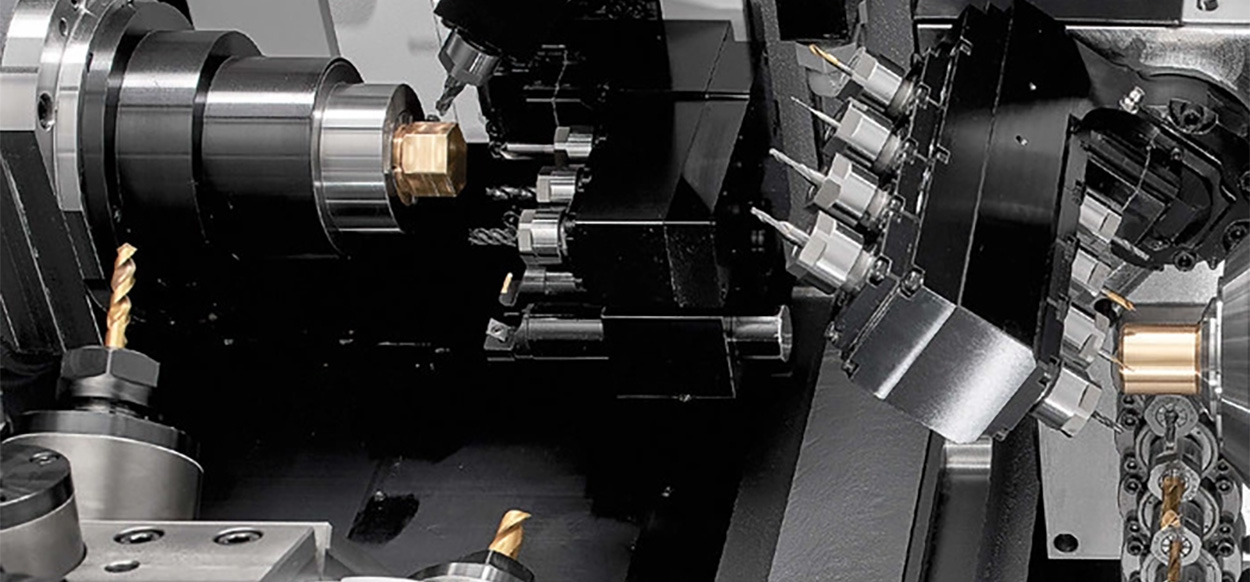

Citizen consolidates two worldwide leading CNC automatic lathe brands: the Cincom sliding head automatic lathes and the Miyano fixed head automatic lathes. Based on concentrated know-how and experience in metal cutting technology, we are able to offer customized solutions for machining on lathes, up to competent support and optimization of your manufacturing processes.

Cincom Sliding head automatic lathes

- The new generation of our new sliding head automatic lathes features maximum flexibility, excellent performance, and ease of operation.

Cincom A20-3F7N

-

Discover undreamt-of possibilities

Acclaimed for its excellent cost to performance ratio, the A20 has evolved as a 5-axis machine for 20 mm diameter applications with the advantage that it can be used with or without a guide bush. It can be used as a regular guide bush automatic lathe when machining long slender workpieces, and without a guide bush for shorter parts with minimal bar remnants. The guide bush can be quickly and simply mounted and removed.

The performance of the machine has been improved too. The high-speed 10,000 rpm spindle enables optimized machining operations on smaller-diameter bar material. The machining length per chucking is now extended to 200 mm enabling the number of re-chuckings and thus the cycle times to be reduced when machining long workpieces. As an option, bar material of up to Ø 25 mm can also be machined extending the range of workpieces even more.

Special Features:- Excellent price-performance ratio.

- Maximum precision and reliability.

- High operator convenience and good chip disposal.

- Short retooling times.

- Part removal: the finished part is transferred onto a workpiece conveyor belt via a chute.

Technical data:

- Number of axis (total) 5 + 2

- Main spindle Z1 + C1

- Gang tool post X1 / Y1

- Maximum machining Ø (mm) 20 / 25

- Maximum headstock stroke (mm) 200

- Maximum spindle speed (Rpm) 10000

- GBL- Specification Standard

- Motor Power (kW) 3,7

Cincom B12E-VI

-

Cincom’s B series ‘best seller’ model has been revamped. And the cost has been substantially reduced.

The B series, which has sold well worldwide for a long time, has been revamped. The B16 can handle diameters up to 16 mm, so the range of target workpieces has been expanded. The B series is renowned for its speed, accuracy and high reliability at extremely low running cost. This 4th generation model retains the same tool layout granting high-accuracy machining in the proven manner.

The rigidity of the back headstock has been improved. Preprocessing for shortest cycle time is supported by a simple on-machine program check function.

The standard specifications include a comprehensive range of NC functions.

Special Features:- Reduced thermal displacement.

- On-machine program check function.

- Full NC functions.

- Comprehensive range of optional accessories.

Technical data:

- Number of axis (total) 4

- Main spindle Z1

- Gang tool post X1 / Y1

- Maximum machining Ø (mm) 12

- Maximum headstock stroke (mm) 140 ( RGB = 62mm)

- Maximum spindle speed (Rpm) 12000 (RGB= 8000Rpm)

- GBL- Specification NA

- Motor Power (kW) 3,7

Cincom B16E-VI

-

The "bestseller" series Cincom B has been improved once again - and at a significantly lower cost

The B series, which has sold well worldwide for a long time, has been revamped with a significant price revision. The B16E can handle diameters up to φ16 mm, so the range of target workpieces has been expanded. The B series is renowned for itʼs speed, accuracy and high reliability at extremely low running cost. This 4th generation model retains the same tool layout which that brings high-accuracy machining. The rigidity of the back headstock has been improved. Preprocessing, for shortest cycle time is supported by an on-machine program check function for easy proveout. The standard specifications include a comprehensive range of NC functions.

Special Features:- Reduced thermal displacement.

- On-machine program check function.

- Full NC functions.

- Comprehensive range of optional accessories.

Technical data:

- Number of axis (total) 4

- Main spindle Z1

- Gang tool post X1 / Y1

- Maximum machining Ø (mm) 12

- Maximum headstock stroke (mm) 140 ( RGB = 62mm)

- Maximum spindle speed (Rpm) 10000 (RGB= 8000Rpm)

- GBL- Specification NA

- Motor Power (kW) 3,7

Cincom D25-1M7

-

New innovative processing possibilities

New sliding headstock lathe with 2 vertical holders on the guide bush

The new sliding headstock lathe and short lathe impresses with its high drive power and its versatility for complex workpieces. It is particularly suitable for fast and productive machining. The innovative control follows the latest standards and is easy to operate.

Equipped with 2 vertical holders and a B-axis (type VIII), the D25 sliding headstock lathe guarantees fast machining times at the highest level of productivity. The large number of tools on the main and pick-up spindles keeps production costs low and offers multiple machining options.

And all this combined in one machine. Optionally, the machining

from bar material up to ø 25 mm possible. This further increases the variety of machinable workpieces.

Special Features:

- Up to 59 tools can be used.

- Ensures a fast machining time.

- High flexibility of machining on the main spindle due to the 2 vertical holders.

- Reduction of the cycle time by using several tools simultaneously.

Technical data:

- Number of axles (total) 9

- Main spindle Z1 + C1

- Vertical holder 2 independent aisle tool posts

- Maximum bar capacity (mm) 25

- Maximum part length (mm) 250

- Main spindle speed (rpm) 10000

- GBL- Function Standard

- Engine power (kW) 5,5

Cincom D25-1M8

-

New innovative processing possibilities

New sliding headstock lathe with 2 vertical holders on the guide bush

The new sliding headstock lathe and short lathe impresses with its high drive power and its versatility for complex workpieces. It is particularly suitable for fast and productive machining. The innovative control follows the latest standards and is easy to operate.

Equipped with 2 vertical holders and a B-axis (type VIII), the D25 sliding headstock lathe guarantees fast machining times at the highest level of productivity. The large number of tools on the main and pick-up spindles keeps production costs low and offers multiple machining options.

And all this combined in one machine. Optionally, the machining

from bar material up to ø 25 mm possible. This further increases the variety of machinable workpieces.

Special Features:

- Up to 59 tools can be used.

- Ensures a fast machining time.

- High flexibility of machining on the main spindle due to the 2 vertical holders.

- Reduction of the cycle time by using several tools simultaneously.

Technical data:

- Number of axles (total) 9

- Main spindle Z1 + C1

- Vertical holder 2 independent aisle tool posts

- Maximum bar capacity (mm) 25

- Maximum part length (mm) 250

- Main spindle speed (rpm) 10000

- GBL- Function Standard

- Engine power (kW) 5,5

Cincom L12-1M7

-

Machining of workpieces with small diameter with or without guide bush and high-speed spindle with 15,000 rpm.

It is a simple matter to fit or remove the guide bushing so that the machine configuration can be adapted to suit the workpiece to be machined.

As an automatic lathe that combines two roles in a single unit, it can be used to machine both long and short workpieces effectively. It also shows uncompromising performance as a machine for high-speed, small- diameter applications. It shortens cycle times with a front spindle capable of high-speed rotation of 15,000 rpm and 10,000 rpm rotary tools. The L series that has built Cincom’s history is now creating the new ‘standard’ in automatic lathes for function and performance.

Special Features:- Changeover between machining with or without guide bushing in ca. 30 minutes.

- Intuitive screen display – readable at a glance.

Technical data:

- Number of axis (total) 5 + 2

- Main spindle Z1 + C1

- Gang tool post X1 / Y1

- Maximum machining Ø (mm) 12

- Maximum headstock stroke (mm) 135

- Maximum spindle speed (Rpm) 15000

- GBL- Specification Standard

- Motor Power (kW) 3,7

Cincom L12-2M10

-

Machining of workpieces with small diameter with or without guide bush and high-speed spindle with 15,000 rpm.

It is a simple matter to fit or remove the guide bushing so that the machine configuration can be adapted to suit the workpiece to be machined.

As an automatic lathe that combines two roles in a single unit, it can be used to machine both long and short workpieces effectively. It also shows uncompromising performance as a machine for high-speed, small- diameter applications. It shortens cycle times with a front spindle capable of high-speed rotation of 15,000 rpm and 10,000 rpm rotary tools. The L series that has built Cincom’s history is now creating the new ‘standard’ in automatic lathes for function and performance.

Special Features:- Changeover between machining with or without guide bushing in ca. 30 minutes.

- Intuitive screen display – readable at a glance.

- Number of axis (total) 6 + 2

- Main spindle Z1 + C1

- Gang tool post X1 / Y1

- Maximum machining Ø (mm) 12 (16mm Optional)

- Maximum headstock stroke (mm) 135

- Maximum spindle speed (Rpm) 15000

- GBL- Specification Standard

- Motor Power (kW) 3,7

Cincom L20E-2M8

-

Our bestseller retreaded

A machine that stands for the history of the Cincom brand like no other has been made fit for the new age with 3 new models in modular design. From the 5-axis machine with an excellent price-performance ratio to the high-end model with B-axis and a counter spindle moving in the Y-axis. You have the choice and will find exactly the machine you need. The machine concept of the Cincom L20 stands for unparalleled versatility. Various vertical holders, drill holders for front and rear machining with and without driven tools are available, from which you can choose the most suitable types for the existing requirements.

Special Features::

- Individually selectable modules for maximum productivity and profitability.

- Modular tooling: versatile, reliable, powerful and highly productive.

- Shorter non-productive times and higher feed rates thanks to Cincom control, with significant reduction of cycle times.

Technical data:

- Number of axles (total) 5

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 20 / 25

- Maximum part length (mm) 200

- Main spindle speed (rpm) 10000

- GBL- Function Standard

- Engine power (kW) 3,7

Cincom L20E-2M10

-

Our bestseller retreaded

A machine that stands for the history of the Cincom brand like no other has been made fit for the new age with 3 new models in modular design. From the 5-axis machine with an excellent price-performance ratio to the high-end model with B-axis and a counter spindle moving in the Y-axis. You have the choice and will find exactly the machine you need. The machine concept of the Cincom L20 stands for unparalleled versatility. Various vertical holders, drill holders for front and rear machining with and without driven tools are available, from which you can choose the most suitable types for the existing requirements.

Special Features::

- Individually selectable modules for maximum productivity and profitability.

- Modular tooling: versatile, reliable, powerful and highly productive.

- Shorter non-productive times and higher feed rates thanks to Cincom control, with significant reduction of cycle times.

Technical data:

- Number of axles (total) 6

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 20 / 25

- Maximum part length (mm) 200

- Main spindle speed (rpm) 10000

- GBL- Function Standard

- Engine power (kW) 3,7

Cincom L20E-2M12

-

Our bestseller retreaded

A machine that stands for the history of the Cincom brand like no other has been made fit for the new age with 3 new models in modular design. From the 5-axis machine with an excellent price-performance ratio to the high-end model with B-axis and a counter spindle moving in the Y-axis. You have the choice and will find exactly the machine you need. The machine concept of the Cincom L20 stands for unparalleled versatility. Various vertical holders, drill holders for front and rear machining with and without driven tools are available, from which you can choose the most suitable types for the existing requirements.

Special Features::

- Individually selectable modules for maximum productivity and profitability.

- Modular tooling: versatile, reliable, powerful and highly productive.

- Shorter non-productive times and higher feed rates thanks to Cincom control, with significant reduction of cycle times.

Technical data:

- Number of axles (total) 7

- Main spindle Z1 + C1

- Vertical holder X1 / Y1 / B-axis

- Maximum bar capacity (mm) 20 / 25

- Maximum part length (mm) 200

- Main spindle speed (rpm) 10000

- GBL- Function Standard

- Engine power (kW) 3,7

Cincom L32-1M8

-

Now even more versatile and flexible

The Cincom L32, one of the best-selling Cincom machines, is available in the latest generation in 3 models in modular design. From the 5-axis machine with an excellent price-performance ratio to the high-end model with B-axis and Y-axis for backworking. Thanks to the wide range of modular tooling, the Cincom L32 is incredibly versatile and flexible and can be adapted to your specific future needs.

Special Features::

- Machining of a wide variety of workpieces: through quick changeover and easy operation.

- Modular tooling: versatile, reliable, powerful and highly productive.

- Can be converted to work with or without guide bushes.

Technical data:

- Number of axles (total) 5

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 32 / 38

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom L32-1M10

-

Now even more versatile and flexible

The Cincom L32, one of the best-selling Cincom machines, is available in the latest generation in 3 models in modular design. From the 5-axis machine with an excellent price-performance ratio to the high-end model with B-axis and Y-axis for backworking. Thanks to the wide range of modular tooling, the Cincom L32 is incredibly versatile and flexible and can be adapted to your specific future needs.

Special Features::

- Machining of a wide variety of workpieces: through quick changeover and easy operation.

- Modular tooling: versatile, reliable, powerful and highly productive.

- Can be converted to work with or without guide bushes.

Technical data:

- Number of axles (total) 6

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 32 / 38

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom L32-1M12

-

Now even more versatile and flexible

The Cincom L32, one of the best-selling Cincom machines, is available in the latest generation in 3 models in modular design. From the 5-axis machine with an excellent price-performance ratio to the high-end model with B-axis and Y-axis for backworking. Thanks to the wide range of modular tooling, the Cincom L32 is incredibly versatile and flexible and can be adapted to your specific future needs.

Special Features::

- Machining of a wide variety of workpieces: through quick changeover and easy operation.

- Modular tooling: versatile, reliable, powerful and highly productive.

- Can be converted to work with or without guide bushes.

Technical data:

- Number of axles (total) 7

- Main spindle Z1 + C1

- Vertical holder X1 / Y1 / B1

- Maximum bar capacity (mm) 32 / 38

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom M16-4M5

-

A top model for diameters up to ø 16 mm

Thanks to the B-axis function for driven tools on the vertical holder and Y-axis function on the tool holder for backworking, even the most complex machining operations can be carried out.

The M16 machines of type VIII are equipped with a B-axis function for the driven tools on the vertical holder. This allows inclined bores with various angles as well as complex milling operations to be carried out. The B-axis with a swivel angle of 135° can be used for front and rear machining. The tool holder for rear-side machining is designed with a Y-axis (type VIII) and can hold up to 9 tools. With all these advantages, we have not even mentioned the large number of controlled axes and clampable tools, not to mention the enormous rapid traverse speeds of up to 32 m/min, the high-speed machining with the latest CNC control, the maximum speeds of the main and counter spindles and the larger number of driven tools that can be fitted to the turret. No matter whether workpieces with small diameters are to be machined or small diameter drills/end mills are to be used. Machining always takes place under optimum conditions and maximum productivity is guaranteed.

Special Features::

- High speed and maximum ease of maintenance, combined with a significant increase in productivity.

- 32 m/min rapid traverse speed and reduction of non-productive time up to 30 %.

- Main spindle, guide bush and pick-up spindle are sealed with sealing air, so that neither coolant nor chips can penetrate.

- Optimum machining conditions for small complex parts thanks to high-speed spindles and tool spindles.

- Energy saving by switching off in idle speed.

Technical data:

- Number of axles (total) 8

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 16

- Maximum part length (mm) 200

- Main spindle speed (rpm) 12000

- Engine power (kW) 3,7

Cincom M16-4M8

-

A top model for diameters up to ø 16 mm

Thanks to the B-axis function for driven tools on the vertical holder and Y-axis function on the tool holder for backworking, even the most complex machining operations can be carried out.

The M16 machines of type VIII are equipped with a B-axis function for the driven tools on the vertical holder. This allows inclined bores with various angles as well as complex milling operations to be carried out. The B-axis with a swivel angle of 135° can be used for front and rear machining. The tool holder for rear-side machining is designed with a Y-axis (type VIII) and can hold up to 9 tools. With all these advantages, we have not even mentioned the large number of controlled axes and clampable tools, not to mention the enormous rapid traverse speeds of up to 32 m/min, the high-speed machining with the latest CNC control, the maximum speeds of the main and counter spindles and the larger number of driven tools that can be fitted to the turret. No matter whether workpieces with small diameters are to be machined or small diameter drills/end mills are to be used. Machining always takes place under optimum conditions and maximum productivity is guaranteed.

Special Features::

- High speed and maximum ease of maintenance, combined with a significant increase in productivity.

- 32 m/min rapid traverse speed and reduction of non-productive time up to 30 %.

- Main spindle, guide bush and pick-up spindle are sealed with sealing air, so that neither coolant nor chips can penetrate.

- Optimum machining conditions for small complex parts thanks to high-speed spindles and tool spindles.

- Energy saving by switching off in idle speed.

Technical data:

- Number of axles (total) 8

- Main spindle Z1 + C1

- Vertical holder X1 / Y1 /B1

- Maximum bar capacity (mm) 16

- Maximum part length (mm) 200

- Main spindle speed (rpm) 12000

- Engine power (kW) 3,7

Cincom M32-4M5

-

The only long-turned man with a revolver

The M32 is known for its unique simultaneous machining with minimal floor space. The combination of the flexible tool system, large number of available tools combined with unrivalled user-friendliness makes the M32 our success story in this century. The new generation of the M32 allows simultaneous machining with 3 tools. This is achieved by the new Y3 axis on the tool carrier for backworking. This tool carrier can be equipped with up to 9 tools, of which 6 are driven and 3 are fixed tools. New improved features include a B-axis on the vertical holder, combined with simultaneous 4-axis control.

Special Features::

- Turret with 10 stations

- Wide range of tools for the machining of complex parts.

- Flexible tooling options

- Reduced cycle times with reduced power consumption

Technical data:

- Number of axles (total) 8

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 32 / 35

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom M32-4M8

-

The only long-turned man with a revolver

The M32 is known for its unique simultaneous machining with minimal floor space. The combination of the flexible tool system, large number of available tools combined with unrivalled user-friendliness makes the M32 our success story in this century. The new generation of the M32 allows simultaneous machining with 3 tools. This is achieved by the new Y3 axis on the tool carrier for backworking. This tool carrier can be equipped with up to 9 tools, of which 6 are driven and 3 are fixed tools. New improved features include a B-axis on the vertical holder, combined with simultaneous 4-axis control.

Special Features::

- Turret with 10 stations

- Wide range of tools for the machining of complex parts.

- Flexible tooling options

- Reduced cycle times with reduced power consumption

Technical data:

- Number of axles (total) 10

- Main spindle Z1 + C1+ B1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 32 / 35

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom M32-5M5

-

New born: The next generation M32

The redesigned cover improves accessibility and visibility, while the human-machine interface control panel optimizes the new NC control including touch panel, operations and monitoring.

Structural analysis has been used to develop a highly robust design that guarantees an optimum balance between force and weight, thus improving the stability required for machining. The tooling of the turret was changed from the ground up.

A single drive is now available for driven tools. For contour machining, the vertical holder can be equipped with up to five controlled axes including B-axis (type VIII). The tool holder for backworking has angle-adjustable driven tools (Type VII and VIII) and can thus handle complex machining tasks in combination with the Y axis.

By improving the backworking, the scope for process division has also been increased. A powerful 5.5/7.5 kW spindle motor is now used on the main and pick-up spindles. The machine can be converted to work with or without guide bush and can be optionally extended up to Ø 38 mm.

Special Features::

- Ultimate tool carrier + turret

- New, more modern design

- Backworking for the production of even more complex shapes

- New turret with individual drive

- More powerful spindle motor

Technical data:

- Number of axles (total) 8 + 2

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 32/38

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom M32-5M8

-

New born: The next generation M32

The redesigned cover improves accessibility and visibility, while the human-machine interface control panel optimizes the new NC control including touch panel, operations and monitoring.

Structural analysis has been used to develop a highly robust design that guarantees an optimum balance between force and weight, thus improving the stability required for machining. The tooling of the turret was changed from the ground up.

A single drive is now available for driven tools. For contour machining, the vertical holder can be equipped with up to five controlled axes including B-axis (type VIII). The tool holder for backworking has angle-adjustable driven tools (Type VII and VIII) and can thus handle complex machining tasks in combination with the Y axis.

By improving the backworking, the scope for process division has also been increased. A powerful 5.5/7.5 kW spindle motor is now used on the main and pick-up spindles. The machine can be converted to work with or without guide bush and can be optionally extended up to Ø 38 mm.

Special Features::

- Ultimate tool carrier + turret

- New, more modern design

- Backworking for the production of even more complex shapes

- New turret with individual drive

- More powerful spindle motor

Technical data:

- Number of axes (total) 10 + 2 (simultaneous 5-axis processing)

- Main spindle Z1 + C1 ( Pneumatic Clamping Sys.)

- vertical holder X1 / Y1 / B1

- Maximum bar capacity (mm) 32/38

- Maximum part length (mm) 320

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 7,5

Cincom R5 04-6

-

Cincom's answer to the demand for high-precision small and miniature parts

The R-series of sliding headstock automatic lathes, designed for ultra-precise production of small and very small parts, has evolved.

Whether for the efficient machining of watch parts, probe tips / pins, medical technology parts and other components with the smallest diameters, we have redesigned the machine design from the ground up in search of "the ideal machine" with "ingeniously simple operation". The high-speed spindle reaches the optimum speed for the workpiece at 20,000 rpm. In combination with linear and servo motors, the result is a total package that guarantees ultra-high precision, maximum compactness and low energy consumption.

Cincom's solution for the production of high-precision small and miniature parts is now available.

Special Features::

- Compact high-speed spindles:

- 25% more compact and lighter than previous model.

- Ceramic bearings improve stability at high speeds.

- Space-saving design. Reduced operating costs.

Technical data:

- Number of axles (total) 6

- Main spindle Z1 + C1

- Vertical holder X1 / Y1

- Maximum bar capacity (mm) 4

- Maximum part length (mm) 30

- Main spindle speed (rpm) 20000

- GBL function NA

- Engine power (kW) 0,75

Miyano Fixed head automatic lathes

- Our high-capacity fixed head automatic lathes boast high productivity and tremendous precision and speed.

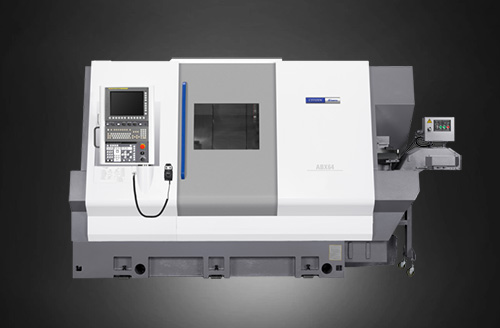

Miyano ABX-51SYY2

-

High-performance turning center with long strokes as well as independent upper and lower turrets and Y axes.

The ABX-51/64SYY features shortened cutting times by simultaneous machining at left and right with two Y axes. The ability to machine simultaneously at the left and right spindles using the upper and lower turrets, both featuring a Y-axis function, means that complete front and back machining of products with complex shapes can be accomplished simply and in a short time.

Special Features:- Thermal displacement compensation for 100 % precision around the clock.

- High-rigidity 12-station turret. Hand-scraped slideways for heavy cutting.

- Optional for 80 mm available.

- Max. turning dia. (mm) 210

- Distance between Spindle (mm) 749

- Max. turning length (mm) 514

- Max. bar capacity Ø (mm) 51

- Chuck size SP1 (mm) 210 (8")

- Chuck size SP2 (mm) 169 (6")

Miyano ABX-51THY2

-

The perfect turning center with three Y axes.

Right and left upper turrets equipped with Y axis and a lower turret also with Y-axis provides free and direct access to both spindles.

Special Features:- Three Y axes grant high efficiency and high productivity.

- High rigidity and high torque with 40 Nm rotary tools.

- Optional for 80 mm available.

- Max. turning dia. (mm) 210

- Distance between Spindle (mm) 749

- Max. turning length (mm) 514

- Max. bar capacity Ø (mm) 51

- Chuck size SP1 (mm) 210 (8")

- Chuck size SP2 (mm) 169 (6")

Miyano ABX-64SYY2

-

High-performance turning center with long strokes as well as independent upper and lower turrets and Y axes.

The ABX-51/64SYY features shortened cutting times by simultaneous machining at left and right with two Y axes. The ability to machine simultaneously at the left and right spindles using the upper and lower turrets, both featuring a Y-axis function, means that complete front and back machining of products with complex shapes can be accomplished simply and in a short time.

Special Features:- Thermal displacement compensation for 100 % precision around the clock.

- High-rigidity 12-station turret. Hand-scraped slideways for heavy cutting.

- Optional for 80 mm available.

- Max. turning dia. (mm) 210

- Distance between Spindle (mm) 749

- Max. turning length (mm) 514

- Max. bar capacity Ø (mm) 64

- Chuck size SP1 (mm) 210 (8")

- Chuck size SP2 (mm) 169 (6")

Miyano ABX-64THY2

-

The perfect turning center with three Y axes.

Right and left upper turrets equipped with Y axis and a lower turret also with Y-axis provides free and direct access to both spindles.

Special Features:- Three Y axes grant high efficiency and high productivity.

- High rigidity and high torque with 40 Nm rotary tools.

- Optional for 80 mm available.

- Max. turning dia. (mm) 210

- Distance between Spindle (mm) 749

- Max. turning length (mm) 514

- Max. bar capacity Ø (mm) 64

- Chuck size SP1 (mm) 210 (8")

- Chuck size SP2 (mm) 169 (6")

Miyano BNA-42CY5

-

Two models of the BNA series with improved basic functions

Type SY with improved performance for efficient processing of bar material.

Type CY allows use as automatic feeder.

Special Features::

- Extended tooling.

- Highly rigid spindle.

- SY: Front and rear machining.

- SY: Equipped with a 12-station turret and a Y-axis. SY: Temporary increase of the nominal power of the main spindle.

Technical data:

- Turning diameter max. (mm) 505

- Distance between collet chuck (mm) 300

- Turning length max. (mm) 285

- Spindle passage Ø (mm) 42

- Chuck diameter SP1 (mm) 135 ( 5")

Miyano ANX-42SYY

-

The BNA series stands for evolution and innovation

The machine BNA-DHY is characterized by compact design and numerous high performance and precision features as well as 2 turrets and Y-axis. All features for which Miyano is rightly known. This makes it extremely flexible.

Special Features::

- Compact design.

- Numerous high performance and precision features.

2 turrets and Y-axis. - Reduced machining time thanks to overlap machining. Wide range of tool loading options.

Technical data:

- Turning diameter max. (mm) 80

- Distance between collet chuck (mm) 360

- Turning length max. (mm) 235

- Spindle passage Ø (mm) 42

- Chuck diameter SP1 (mm) 135 ( 5")

- Chuck diameter SP2 (mm) 100 (4")

Miyano BNA-42DHY3

-

The BNA series is a synonym for evolution and innovation.

The BNA-DHY distinguishes itself by a compact structure and numerous high-performance and accuracy features as well as 2 turrets and one Y-axis. All features for which Miyano has rightly been renowned by our demanding customers. This makes the BNA-DHY an extremely flexible machine.

Special Features:- Compact design.

- Numerous high-performance and precision features.

- Two turrets with Y-axis.

- More versatile tooling options.

- Cycle time shortened by superimposition control.

- Max. turning dia. (mm) 80

- Distance between Spindle (mm) 360

- Max. turning length (mm) 235

- Max. bar capacity Ø (mm) 42

- Chuck size SP1 (mm) 135 ( 5")

- Chuck size SP2 (mm) 100 (4")

Miyano BNA-42GTY

-

Even faster with concistently high precision.

Hand scraped slideways offering maximum stability and rigidity are used to achieve the renowned “Miyano accuracy“. These slideways excel at extraordinarily high rigidity as well as excellent damping characteristics thus contributing to powerful machining and extended tool life. The main components of the machine, like spindles and tool slides, are installed on the stable cast bed. The machine is designed in a way that mounting faces are not distorted by the effects of heat. Even if the units are subject to thermal expansion, they are all displaced in the same direction (perpendicular to their mounting faces). This minimizes relative deviations between the workpice and cutting tools.

Special Features:- Easy to use tooling system.

- Simultaneous machining with 3 tools.

- Maximum productivity hand in hand with very short cycle times. The renowned “Miyano accuracy“.

- Highly flexible tool configuration.

- Excellent machining output and efficiency.

- Cycle time shortened by superimposition control.

- LFV Technology.

- Max. turning dia. (mm) 42

- Distance between Spindle (mm) 390

- Max. turning length (mm) 110

- Max. bar capacity Ø (mm) 42

- Chuck size SP1 (mm) 42

- Chuck size SP2 (mm) 34

Miyano BNA-42MSY2

-

Sets the new standard in bar machining.

We proudly introduce: Model BNA-42MSY – CNC turning center with 2 spindles and 1 turret. The turret features a Y axis and half-indexing, expanding the machining possibilities. The machine is equipped with the largest spindle motor in the series, enabling powerful cutting.

The X2 axis at the back spindle allows for the simultaneous machining at the front and back of the workpiece. This model combines the advantages of a double turret machine and the lower purchase price of a machine with just one turret. The unique control improves productivity and cycle times.

Special Features:- Maximum rigidity and stability for powerful cutting.

- Cycle time shortened by superimposition control.

- Substantial reduction in non-cutting time.

- Easy to use tooling system.

- Convenient operation.

- Max. turning dia. (mm) 80

- Distance between Spindle (mm) 360

- Max. turning length (mm) 235

- Max. bar capacity Ø (mm) 42

- Chuck size SP1 (mm) 135 ( 5")

- Chuck size SP2 (mm) 100 (4")

Miyano BNA-42S2

-

Two models of the BNA series with improved basic functions

Type SY with improved performance for efficient processing of bar material.

Type CY allows use as automatic feeder.

Special Features::

- Extended tooling.

- Highly rigid spindle.

- SY: Front and rear machining.

- SY: Equipped with a 12-station turret and a Y-axis. SY: Temporary increase of the nominal power of the main spindle.

Technical data:

- Turning diameter max. (mm) 505

- Distance between collet chuck (mm) 300

- Turning length max. (mm) 285

- Spindle passage Ø (mm) 42

- Chuck diameter SP1 (mm) 135 ( 5")

- Chuck diameter SP2 (mm) 100 (4")

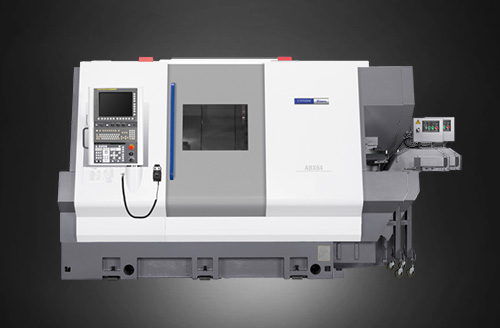

Miyano BNA-42SY5

-

Ideal for the precise machining of complex parts

BND51 SY, a short turning machine with a pick-up spindle and a Y-axis for machining bar stock up to 51 mm diameter.

The design of the machine features precision-scraped box guides for maximum stability and excellent vibration dampening properties and a solid 30° inclined bed in platform design with intelligently arranged stiffening ribs, resulting in very good thermal stability and minimal dimensional deviations. In other words: A total package for consistently high machining precision over long operating periods.

Special Features::

- Stable, highly rigid construction.

- Wide range of complex manufacturing tasks thanks to driven tools.

- NC operator menu: 'One-touch' functions for faster setup.

Technical data:

- Turning diameter max. (mm) 175

- Distance between collet chuck (mm) 454

- Turning length max. (mm) 414

- Spindle passage Ø (mm) 51

- Chuck diameter SP1 (mm) 250 (10")

- Chuck diameter SP2 (mm) 120 (5")

Miyano BND-51SY2

-

With additional X axis, for more simultaneous machining

The BNE series is known for its high stability, high-performance cutting and outstanding precision. The MSY model extends the performance spectrum of the BNE series by using the X3 axis on the pick-up spindle (SP2) as well as synchronous/superimposed control for simultaneous machining with 3 tools. The results are faster cycle times, extremely simple operation and the ability to machine complex workpieces.

Special Features::

- Highest stability for precise machining.

- User-friendly operation.

- Simultaneous machining with up to 3 tools simultaneously.

- Optional up to 65 mm passage.

Technical data:

- Max. turning diameter (mm) 165

- Distance between collet chuck (mm) 432

- Turning length max. (mm) 380

- Spindle passage Ø (mm) 51

- Chuck diameter SP1 (mm) 165 (6")

- Chuck diameter SP2 (mm) 165 (6")

Miyano BNE-51MSY

-

Equipped with double Y-Axis.

Our two new BNE Series models, developed from the BNE51 and BNE65 (with machining diameters of 51 and 65 mm respectively) have inherited the characteristics of high rigidity and precision for which the BNE Series has been greatly praised.

The upper and lower turrets of the BNE51MYY and BNE65MYY are equipped with a Y axis. Operating with the same capabilities, these two 12-station turrets provide even more flexible tooling due to optimal process allocation that is not restricted by machining balance limitations.

Special Features:- Double Y-Axis.

- These new models have inherited the slide structure that makes it easy to clean away chips.

- New design and an innovative touch panel.

- Max. machining diameter of 51 mm.

Miyano BNE-51MYY

-

For more demanding production of complex high-precision parts from bar stock

The BNE series is specially designed for today's increasingly demanding production of complex high-precision parts from bar stock. Simultaneous machining with several tools means that even complex shapes can now be machined ultra-fast and economically. Type S allows simultaneous multiple tooling in L- and R-spindle. Type SY with Y-axis slide for the upper turret is similar to a machining center in its functionality and efficiently machines complex workpieces.

Special Features::

- Highly stable precision shaved box guides.

- Powerful tools.

- Simple operation.

- Optional up to 65 mm passage.

Technical data:

- Max. turning diameter (mm) 165

- Distance between collet chuck (mm) 432

- Turning length max. (mm) 380

- Spindle passage Ø (mm) 51

- Chuck diameter SP1 (mm) 165 (6")

- Chuck diameter SP2 (mm) 135 (5")

Miyano BNE-51S6

-

For more demanding production of complex high-precision parts from bar stock

The BNE series is specially designed for today's increasingly demanding production of complex high-precision parts from bar stock. Simultaneous machining with several tools means that even complex shapes can now be machined ultra-fast and economically. Type S allows simultaneous multiple tooling in L- and R-spindle. Type SY with Y-axis slide for the upper turret is similar to a machining center in its functionality and efficiently machines complex workpieces.

Special Features::

- Highly stable precision shaved box guides.

- Powerful tools.

- Simple operation.

- Optional up to 65 mm passage.

Technical data:

- Max. turning diameter (mm) 165

- Distance between collet chuck (mm) 432

- Turning length max. (mm) 380

- Spindle passage Ø (mm) 51

- Chuck diameter SP1 (mm) 165 (6")

- Chuck diameter SP2 (mm) 135 (5")

Miyano BNE-51SY6

-

Economical and powerful through simultaneous machining

Turret No. 2 has 8 tool stations instead of the 6 stations of the previous machines; thus the number of tools has been increased and driven tools can also be accommodated.

The milling processes that were previously only possible with turret no. 1 can now be carried out with both turrets no. 1 and no. 2, which considerably reduces cycle times and also makes it possible to machine complex workpieces.

Special Features::

- Significantly improved operability.

- Collision protection (rapid traverse only).

- Reduced machining time through simultaneous machining left & right. Combination machining with the Y axis.

- Reduced machining time thanks to overlap control.

- Optional up to 64 mm passage.

Technical data:

- Max. turning diameter (mm) 165

- Distance between collet chuck (mm) 555

- Turning length max. (mm) 246

- Spindle passage Ø (mm) 42

- Chuck diameter SP1 (mm) 160 (6")

- Chuck diameter SP2 (mm) 120 (5")

Miyano BNJ-42SY6

-

Economical, efficient and powerful thanks to simultaneous machining.

Turret No. 2 now has 8 tool mounting stations instead of 6 on the previous machines, so the number of tools has been increased and also rotary tools may be mounted. The milling processes that were handled using turret No. 1 alone can now be shared with turret No. 2, making it possible so substantially shorten cycle times and deal with workpieces that require complex machining.

Special Features:- Considerably improved operability.

- Collision protection (rapid feed only).

- Machining time shortened by simultaneous machining at left and right. Combined Machining with the Y-axis.

- Machining time shortened through superimposition machining. Optional for 64 mm available.

- Max. turning dia. (mm) 165

- Distance between Spindle (mm) 555

- Max. turning length (mm) 246

- Max. bar capacity Ø (mm) 42

- Chuck size SP1 (mm) 120 (5")

- Chuck size SP2 (mm) 120 (5")

Miyano BNJ-51SY6

-

Economical, efficient and powerful thanks to simultaneous machining.

Turret No. 2 now has 8 tool mounting stations instead of 6 on the previous machines, so the number of tools has been increased and also rotary tools may be mounted. The milling processes that were handled using turret No. 1 alone can now be shared with turret No. 2, making it possible so substantially shorten cycle times and deal with workpieces that require complex machining.

Special Features:- Considerably improved operability.

- Collision protection (rapid feed only).

- Machining time shortened by simultaneous machining at left and right. Combined Machining with the Y-axis.

- Machining time shortened through superimposition machining. Optional for 64 mm available.

- Max. turning dia. (mm) 165

- Distance between Spindle (mm) 555

- Max. turning length (mm) 246

- Max. bar capacity Ø (mm) 51

- Chuck size SP1 (mm) 160 (6")

- Chuck size SP2 (mm) 120 (5")

Miyano BNE-65MYY

-

Equipped with double Y-Axis.

Our two new BNE Series models, developed from the BNE51 and BNE65 (with machining diameters of 51 and 65 mm respectively) have inherited the characteristics of high rigidity and precision for which the BNE Series has been greatly praised.

The upper and lower turrets of the BNE51MYY and BNE65MYY are equipped with a Y axis. Operating with the same capabilities, these two 12-station turrets provide even more flexible tooling due to optimal process allocation that is not restricted by machining balance limitations.

Special Features:- Double Y-Axis.

- These new models have inherited the slide structure that makes it easy to clean away chips.

- New design and an innovative touch panel.

- Max. machining diameter of 65 mm.

- Max. turning dia. (mm) 160

- Distance between Spindle (mm) 740

- Max. turning length (mm) 380

- Max. bar capacity Ø (mm) 65

- Chuck size SP1 (mm) 169 (6")

- Chuck size SP2 (mm) 169 (6")

Highprecision machines

- Our high-performance automatic short turning machines stand for high productivity as well as enormous precision and speed.

Miyano GN-3200

-

Productive and space saving, with traditional accuracy

This machine is designed for high throughput machining of small parts and has a fixed spindle in wing shape, installed on a thermally symmetric machine bed, for minimum heat influence and maximum thermal stability. The design concept for highest precision has also been integrated into this machine from the ground up, as is traditional for the high-precision series. The guideways offer excellent damping properties and are precision scraped by experienced specialists. With these design features, the user receives a package designed for outstanding machining precision in terms of dimensional accuracy and roundness. Workpieces can, of course, also be loaded/unloaded manually, but the machine also offers flexible automation possibilities by using fast gantry loaders and robots. This allows dimensionally accurate production to be made even more efficient.

Special Features::

- High-precision lathe.

- Loading and unloading takes only 3.5 seconds.

- High/improved efficiency through space-saving design.

- Highly accurate positioning and exceptional precision.

- Intelligent stable construction without any thermal deformation.

- Stable construction for highest precision.

Technical data:

- Turning diameter max. (mm) 45

- Turning length max. (mm) 50

- Chuck diameter SP1 (mm) 152.4

Miyano GN-3200W

-

Productive and space saving, with traditional accuracy

This machine is designed for high throughput machining of small parts and has a fixed spindle in wing shape, installed on a thermally symmetric machine bed, for minimum heat influence and maximum thermal stability. The design concept for highest precision has also been integrated into this machine from the ground up, as is traditional for the high-precision series. The guideways offer excellent damping properties and are precision scraped by experienced specialists. With these design features, the user receives a package designed for outstanding machining precision in terms of dimensional accuracy and roundness. Workpieces can, of course, also be loaded/unloaded manually, but the machine also offers flexible automation possibilities by using fast gantry loaders and robots. This allows dimensionally accurate production to be made even more efficient.

Special Features::

- High-precision lathe.

- Loading and unloading takes only 3.5 seconds.

- High/improved efficiency through space-saving design.

- Highly accurate positioning and exceptional precision.

- Intelligent stable construction without any thermal deformation.

- Stable construction for highest precision.

Technical data:

- Turning diameter max. (mm) 45

- Turning length max. (mm) 50

- Chuck diameter SP1 (mm) 152.4

- Chuck diameter SP2 (mm) 152.4

Miyano GN-4200

-

GN 4200 Highest precision through hand-scraped guides and precision spindle

This machine is designed for high throughput machining of small parts and has a fixed spindle in wing shape for minimum heat influence and maximum thermal stability, which in turn is installed on a thermally symmetrical machine base. The design concept for highest precision has also been integrated into this machine from the ground up, as is traditional for the high-precision series. The guideways offer excellent damping characteristics and are precision-scraped by experienced specialists. With these design features, the user receives a package designed for outstanding machining precision in terms of dimensional accuracy and roundness. Workpieces can, of course, also be loaded/unloaded manually, but the machine also offers flexible automation possibilities through the use of fast gantry loaders and robots. This makes dimensionally accurate production even more efficient.

Special Features::

- Highest precision due to hand-scraped guides and precision spindle. Higher speed for higher machining performance.

- Extreme machining accuracy.

- Program-controlled lubrication of the guideway.

- Loading and unloading system.

Technical data:

- Turning diameter max. (mm) 45

- Turning length max. (mm) 80

- Chuck diameter SP1 (mm) 152.4

Miyano LX08-C

-

Powerful with high stiffness

We introduce: An 8" chuck lathe which, after careful analysis, has been specially designed to meet the basic performance requirements of a machine tool. The highly stable turret uses precision-scraped box ways with excellent vibration damping properties, the highly rigid spindle rests in double row cylindrical roller bearings as well as angular contact ball bearings and the massive 30° inclined bed in platform design serves quasi as a table to accommodate the turret and spindle. The machine reliably produces a high basic output and thus ensures consistently high machining accuracy.

Special Features::

- Outstanding thermal stability thanks to smooth chip removal.

- Minimal dimensional changes.High rigidity, inclined bed and turret with 10 stations for powerful machining.

- Simple operation. Machining accuracy for hard turning.

Technical data:

- Turning diameter max. (mm) 210

- Distance between collet chuck (mm) 320

- Turning length max. (mm) 320

- Spindle passage Ø (mm) 52

- Chuck diameter SP1 (mm) 210 (8")

Miyano LZ-01 R2

-

Fast loading through movable spindle and automation

This series are high-precision automatic chuck lathes, equipped with a universal machine-internal loading head. Due to the coordinated operation of the loading head and spindle, the loading time is drastically reduced.

The design of the turret with a single slide only in Y-axis direction (01RY) and the assignment of the X- and Z-axis running in linear guides to the spindle not only gives the machine high stability and rigidity but also allows high traversing speeds. The extended system configuration based on the loader head adapts flexibly to the most varied and demanding automation requirements.

Special Features::

- Roundness.

- Dimensional accuracy.

- Highly stable turret and highly rigid spindle.

- Machining of complex parts.

Technical data:

- Turning diameter max (mm) 70

- Turning length max. (mm) 80

- Chuck diameter SP1 (mm) 152.4

Miyano LZ-01 RY2

-

Fast loading through movable spindle and automation

This series are high-precision automatic chuck lathes, equipped with a universal machine-internal loading head. Due to the coordinated operation of the loading head and spindle, the loading time is drastically reduced.

The design of the turret with a single slide only in Y-axis direction (01RY) and the assignment of the X- and Z-axis running in linear guides to the spindle not only gives the machine high stability and rigidity but also allows high traversing speeds. The extended system configuration based on the loader head adapts flexibly to the most varied and demanding automation requirements.

Special Features::

- Roundness.

- Dimensional accuracy.

- Highly stable turret and highly rigid spindle.

- Machining of complex parts.

Technical data:

- Turning diameter max (mm) 70

- Turning length max. (mm) 80

- Chuck diameter SP1 (mm) 152.4

Cincom MC20-III

-

Processing cell with several stations enables individualized mass production (mass customization)

By combining three machining modules in a multi-station configuration, the MC20 supports a wide range of machining layouts and reaches completely new dimensions in terms of productivity and performance. In addition, machining processes can be optimized with the dynamic Cincom control software; this control supports highly flexible operations, making individualized mass customization a reality.

Special Features::

- Workpiece transfer between spindles and machine-internal loading system.

- Optimization of machining processes. Accuracy.

- High ease of use through intuitive use of several functions.

Technical data:

- Number of axles (total) 10

- Main spindle Z1/ C1 + Z3/C3

- Vertical holder X1/Y1 + X3/Y3

- Maximum bar capacity (mm) 45

- Maximum part length (mm) 470

- Main spindle speed (rpm) 8000

- GBL- Function Standard

- Engine power (kW) 3,7

- Number of modules 3

Miyano VC03-II

-

The space-saving high-precision lathe designed for ultra-fine machining in the micro range

This machine is specially designed for high-precision machining and is used, for example, in the watch industry. There it effortlessly turns the smallest hands and movement screws in the 0.1 mm range. Combined with the basic concept "machine design for high precision", which has been adopted from the GN series, this opens up completely new possibilities in machining technology.

Special Features::

- High-precision lathe.

- Variety of possible geometries.

- Machine design for high precision.

- Compact footprint.

Technical data:

- Turning diameter max. (mm) 45

- Turning length max. (mm) 50

- Chuck diameter SP1 (mm) 152.4