- Offer Profile

- JUARISTI is one of the

leading companies in the machine tool sector. With more than 75 years of

experience leading innovation and providing solutions to customers in the

most demanding industries, its specialty is the offer of premium Milling and

Boring solutions.

Quality, innovation, service commitment and delivery of taylor-made solutions to customer’s requests are the key factors that have allowed JUARISTI to reach the present level of development and customers satisfaction level.

Experience and market trends awareness, backed up by a flexible organisation, have resulted in the development of brand new series on boring, milling, 5-axis machining and turning solutions.

Our portfolio covers all the needs in relation to quality control systems, automation, digitalization and turnkey projects.

MILLING MACHINES

-

Milling machines adapt to all production plants

JUARISTI designs bed type or Floor type milling machines with lateral or central heads adapted to the needs of all industries.

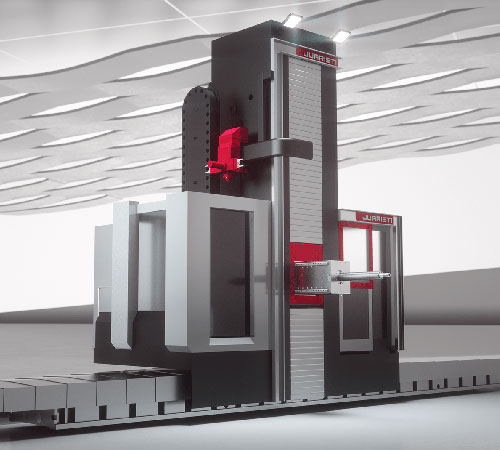

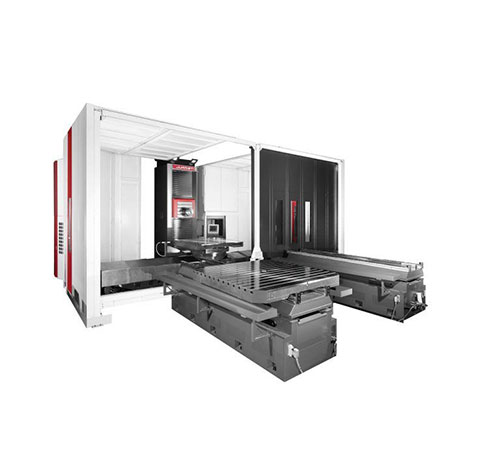

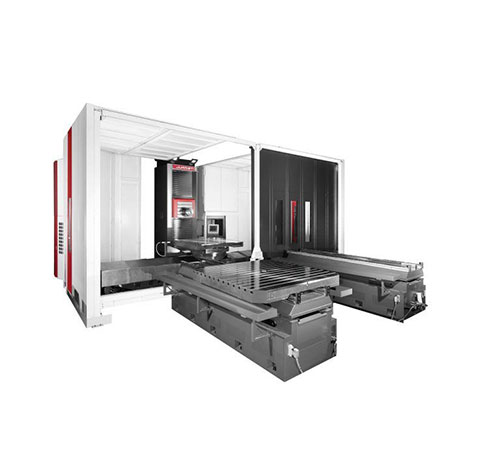

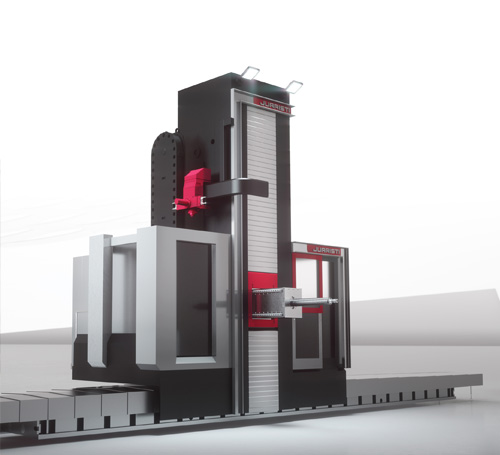

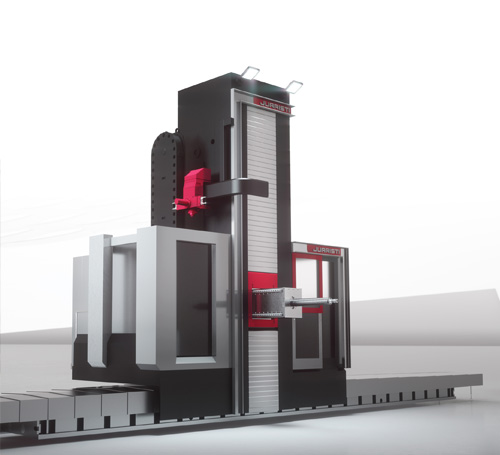

MX Series - Floor type milling machine with central head MX

-

Floor type milling machine with central head

The MX series is a premium solution featuring precision, rigidity and elevated dynamics, the result of more than 20 years of experience in designing this series.

The “box-in-box” concept introduced by JUARISTI for the first time on this type of machine, with a symmetrical column and completely closed central head, provides the machine with optimum rigidity, accuracy and dynamics.

- Maximum precision thanks to the box-in-box design

- Thermo-symmetric structure

- High dynamics (up to 30 m/min)

- Vertical head travel and RAM four-side guided

- Multiple multitasking options

STRUCTURAL ELEMENTS

- Reduced thermal deformation thanks to the thermo-symmetric column’s and central head’s design.

- Ergonomic operator platform with three independent movements in X-Y-Z directions.

- Machining up to 7 m high, 5 m wide parts.

HEADS AND TABLES

- Universal head ACD 60 kW Torque 2, 900 Nm – 3, 500 min-1| 40 kW Torque 1, 300 Nm – 6, 000 min-1.

- AV 4 Vertical Automatic Head 1ºx1º 60 kW 3,800 Nm 3,500 min-1.

- AOD Orthogonal Head 40 kW | 1,300 Nm | 5,000 min-1 | 60 kW | 2,900 Nm | 3,500 min-1.

- Rotary tables with 8 to 180 tonne capacity with up to 5,000 x 6,000 mm surface area.

- Can be supplied with turning and tilting table.

TECHNOLOGY AND AUTOMATION

- Double real-time geometrical compensation of the head + RAM centre of gravity and RAM flexion.

- Compatible with a wide range of automation systems (head and tool changer, measuring probes, etc.).

- ATC– Automatic Tool Changer (30-120 positions for chain type and 400 positions for robot type).

- Head/accessory magazines with up to 10 automatic change positions.

POWER AND PERFORMANCE

- High machining power and efficient thanks to the closed Column-Headstock design and four-sided guided RAM.

- High performance due to powerful, cooled gearbox transmission.

- High power (40 and 96 kW) and high machining torque (1,300 to 8,650 Nm).

ML Series - Floor type universal milling machine ML

-

Floor type universal milling machine

The ML Series models are the result of a design concept based on Value Analysis and offer high dynamics and precision with a reasonable investment.

It features many customisation options, its high-performance chip removal and its high productivity thanks to the various automation systems it includes.

It can be configured with different milling and boring heads and tools, making it a very versatile, desirable option.

- High performance in universal milling machines

- Dual RAM guiding: linear and hydrostatic

- Flexible configuration with milling and turning tables

- High dynamics and power and torque on spindle and motor torque

STRUCTURAL ELEMENTS

- Design focused on ergonomics and straightforward operations, based on 75 years of experience in the development of this type of machine.

- Option to operate in a mirrored position, which improves productivity by running operations simultaneously.

- High coaxial precision machining thanks to the automatic calibration cycle.

- Capability to carry out milling and turning operations with a single universal or orthogonal head.

HEADS AND TABLES

- 200 x 550 horizontal head.

- Universal head ACD 1º x 1º – 0.001º x 0.001º.

- Universal head ACD 2.5º x 2.5º – 1º x 1º – 0.001º x 0.001º.

- Compatible with various types of rotary tables from 8 to 100 tonnes, for both milling and turning.

- Table with double rotation system for turning and milling.

- Automatic lockable rotation for safe operation.

TECHNOLOGY AND AUTOMATION- AHC – Automatic Head Calibration.

- ATC – Automatic Tool Changer (30-120 tools).

POWER AND PERFORMANCE

- Good results for heights up to 3 metres.

- High performance chip removal and excellent finishes in large volume work pieces.

TX Series - Table-type milling centers TX

-

Highly stable and reliable multifunction centers

The TX series is one of the most recognisable emblems within the JUARISTI universe. We have a long track record of designing this type of solutions, which over the years have established themselves as one of the most sought after by our customers.

This involves a machine that can successfully carry out boring and milling operations. It is characterised by its symmetrical design with a centred head on the column, which provides a high degree of precision and dynamics.

- Thermo-symmetric design with centered head.

- Oversized cast iron structural components.

- Hydrostatic rotary table with double pinion anti-blacklash.

- High-precision and rigid linear guides.

- Multiple customisation and automation options.

STRUCTURAL ELEMENTS

- Minimal thermal distortion guaranteed thanks to the thermo-symmetric column with central head.

- Oversized cast iron structure.

- Maximum rigidity with 4 vertical guides (TX3 and TX7).

- Linear guide with high precision bearings.

- Vertical stroke up to 2,500 mm (TX1), 3,000 mm (TX3) and 4,000 mm (TX7).

HEADS AND TABLES

- Universal head ACD 1º x 1º | 0.001º x 0.001º | 40 kW | 6,000 min-1 | 60 kW | 3,000 Nm.

- AOD Orthogonal Head 1º x 1º | 40 kW | 5,000 min-1.

- Compact ISO 50 vertical head 1ºx1º.

- Hydrostatic rotary table with a capacity of 8 tonnes (TX1) to 60 tonnes (TX7).

- Ample working space of 1,600 x 2,000 mm (TX1), 2,000 x 2,500 mm (TX3) and 3,000 x 2,500 mm (TX7).

TECHNOLOGY AND AUTOMATION

- Thermal sensors for real-time temperature control.

- ATC chain type 30-160 positions.

- ATC robot type up to 400 positions.

- Automatic head changer.

- Customisable with full enclosure with automatic doors, roof and fume extraction system.

- Ergonomic operator platform: vertical and crosswise motion.

- Central maintenance cabinet including all hydraulic, lubrication and pneumatic units.

POWER AND PERFORMANCE

- High machining power thanks to the closed Column-Headstock design and four-sided guided RAM.

- High performance due to powerful, cooled gearbox transmission.

- High spindle power and torque.

MULTITASKING CENTERS - TH SERIES

-

High Productivity CNC Machining Centers

JUARISTI's multifunction centres have been designed with a focus on versatility, enabling a wide range of machining operations: milling, boring, turning and high-precision work on large parts. They are characterised by the extreme rigidity and high precision resulting from their thermo-symmetric structure.

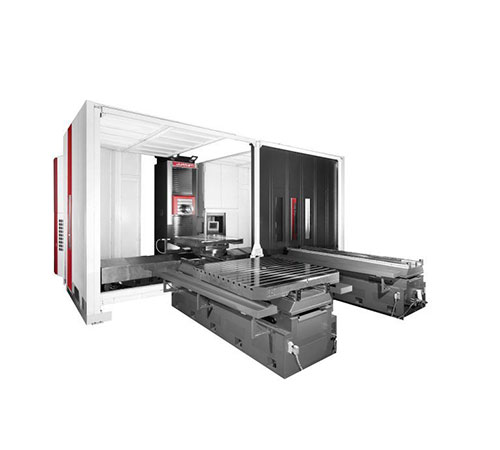

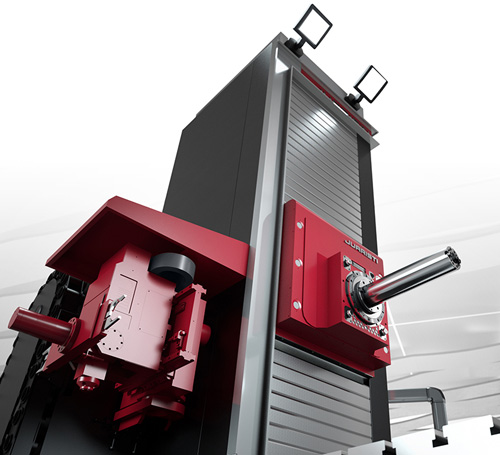

TH Series - Universal and 5-axis machining centers

-

High productivity multitasking centers for milling, boring or turning

The TH series is optimised for multitasking. Its symmetrical design with central head and 4 vertical guides (two front and two rear) and its oversized structural elements provide great robustness and stability.

It stands out for its powerful chip removal, with feeds of up to 40 m/min and a 3 m/s2 acceleration.

It is capable of working large, complex work pieces thanks to its wide axis stroke (4,000 – 2,500 – 2,500 mm XYZ) and its compatibility with up to 12-tonne rotary tables.

- High dynamics in a large machining centre

- Thermo-symmetric structure

- Multifunctionality

- High customisation and automation capacity options.

STRUCTURAL ELEMENTS

- Unbeatable thermal and mechanical performance thanks to its symmetrical design with central head and 4 vertical guides.

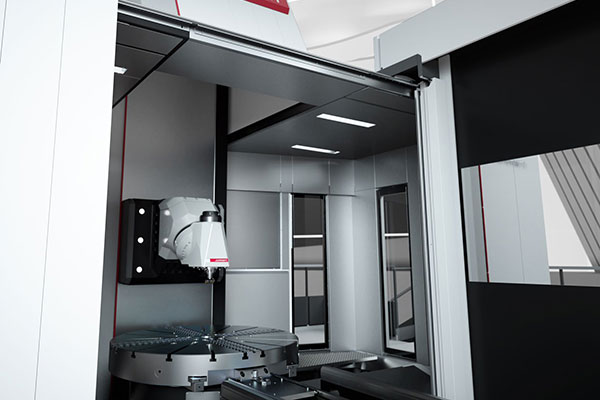

- Strokes of up to 4,000, 2,500 and 2,500 mm on the XYZ axes.

- Closed design that integrates a protective cabinet with chip conveyor and allows the complete collection of chips and cutting fluids without contaminating the workspace.

- Automatic doors for loading/unloading pallets, ceilings with lights and parts cleaning systems with coolant jets.

HEADS AND TABLES

- 5-axis continuous rotary head

- Universal head ACD 2.5º x 2.5º – 1º x 1º – 0.001º x 0.001º.

- Compatible with boring bar and fixed horizontal spindle.

- Large working space of up to 2,000 x 2,500 mm and simple working of complex parts with rotary tables.

TECHNOLOGY AND AUTOMATION

- Automatic turning, milling and boring head changes.

- Automatic pallet change with FMS system.

- Automatic tool change ATC chain type (up to 160 positions), matrix or robot type (up to 400).

- Preloaded double pinion rotation system to save time with more efficient movements.

- BT-50 or HSK-A100 tool cones.

POWER AND PERFORMANCE

- Rapid feeds of up to 40 m/min and 3 m/s2 acceleration.

- High performance chip removal and excellent finishes in large volume work pieces.

TABLE TYPE BORING CENTERS

Table-type milling-boring center TX-RAM

-

Table-type milling-boring center

Horizontal boring-milling centersThe TX series is one of the most recognisable symbols in the JUARISTI universe. We have a long track record of designing this type of solutions, which over the years have become one of the most sought after by our customers. This machine can successfully carry out boring and milling operations. Its thermo-symmetrical structure provides high rigidity and precision. The JUARISTI TX-RAM stands out for its reliability and unbeatable performance.

- Box-in-box concept: head centred on the thermo-symmetric column and RAM centred on the headstock with four-sided guidance.

- High performance and vibration-free even under extreme conditions.

- Precision machining and long service life.

- Large part machining capacity: work area that allows turning of parts up to 5,000 mm long and weighing 60 t.

Table-type milling-boring center TX-S

-

Table-type milling-boring center

High rigidity and precision thanks to its thermo-symmetrical structure. It stands out for its reliability and unbeatable performance.

The TX series is one of the most recognisable symbols in the JUARISTI universe. We have a long track record of designing this type of solutions, which over the years have become one of the most sought after by our customers. This machine can successfully carry out boring and milling operations.

- Thermo-symmetric design with central head.

- Oversized cast iron structural components.

- Hydrostatic rotary table with double pinion system to eliminate blacklash.

- High-precision and high-rigidity linear guides.

- Multiple customisation and automation options.

FLOOR TYPE BORING MACHINES

-

High roughing power on premium boring machines

One of the hallmarks of JUARISTI. The travelling column boring machines are solutions with a high-tech element that distinguish it as the best machine tool producers.

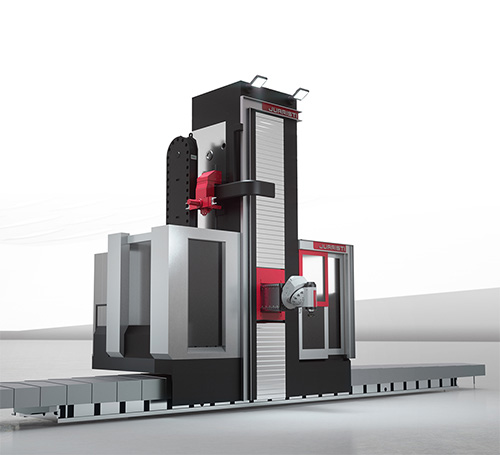

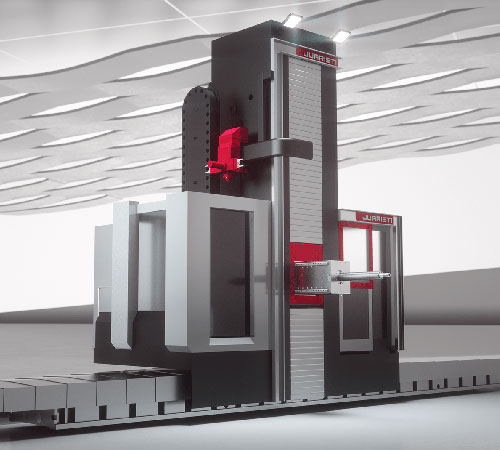

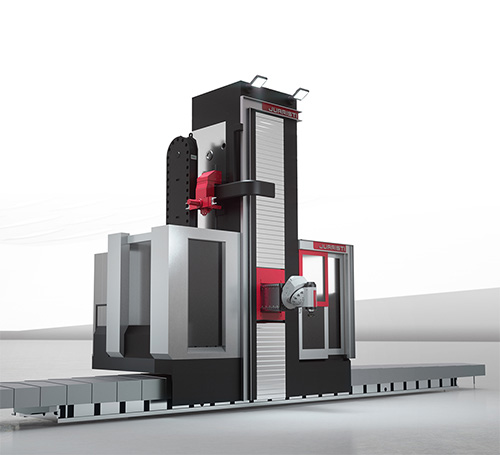

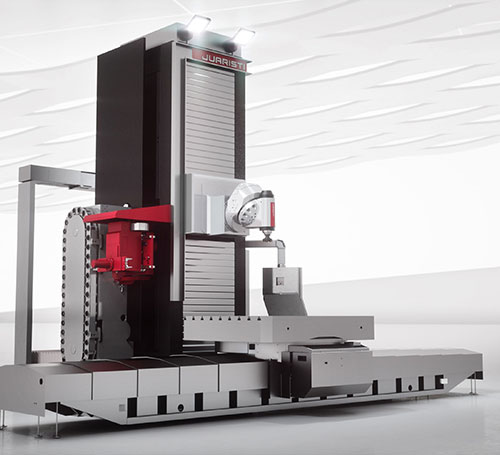

MP-RAM Series

-

Travelling column machine with hidrostatic guiding for unsurpassed accuracy

The MP travelling column boring center is at the pinnacle of the JUARISTI series. Unbeatable results, guarantee of the highest precision and very high machining power thanks to hydrostatic technology. Designed to meet the demands of the most complex, critical parts down to the last millimetre over a long service life.

The hydrostatic guiding allows extraordinarily smooth movements. The triple automatic compensation system seamlessly blends with the hydrostatic technology, taking the stability of the entire system to the next level.

This floor type boring center guarantees maximum rigidity in the heaviest machining jobs.

- Premium solution with the best available technologies.

- Unbeatable cutting capacity.

- Extremely smooth movements and perfect finishes.

- Long service life due to reduced vibrations.

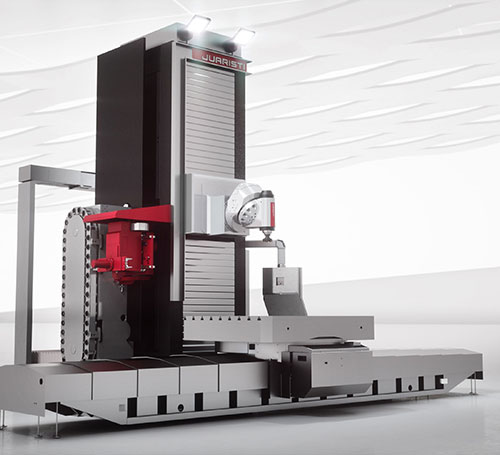

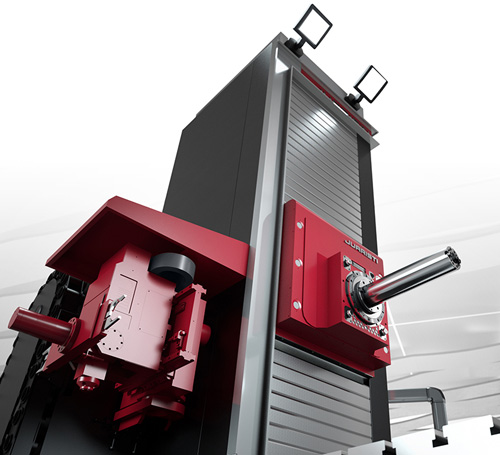

MX-RAM Series

-

Travelling column boring centers with exclusive design

The MX series is a premium solution featuring precision, rigidity and dynamism, the result of more than 20 years of experience in designing this series.

The “box in box” concept introduced for the first time by JUARISTI on this type of machine, with a symmetrical column and completely closed central head, provides the machine with optimum rigidity, accuracy and dynamics.

- Maximum precision thanks to the box-in-box design.

- Thermo-symmetric structure.

- 4-sided RAM and vertical stroke guiding.

- High dynamics (up to 30 m/min).

- Multiple multitasking options.