- Offer Profile

-

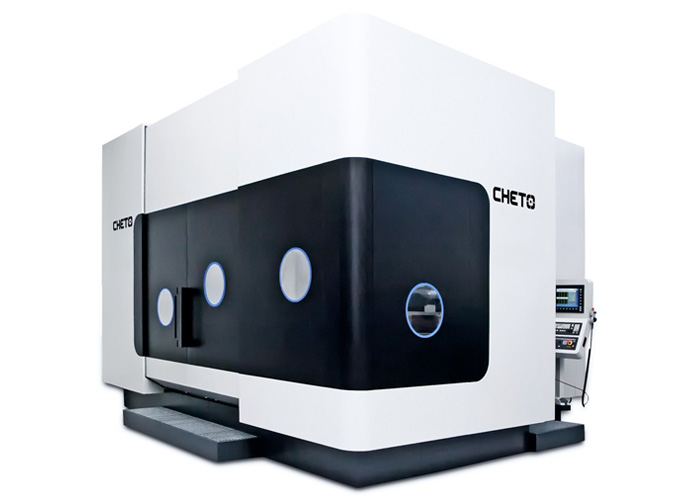

Officially established in the late 90s, CHETO project is the result of more than 30 years of moldmaking experience.

Since then, a continuous improvement and attention to the market’s specific needs set the development path for our machines. Optimizing the process is our goal and CHETO machines are able to perform several operations with a single setup and the highest levels of precision. We build time saving machines so our customers reduce their manufacturing costs.

Today, the market recognizes CHETO machines as a world renowned brand for Deep Hole Drilling. With machines sold in four continents, it is our goal to keep improving and innovating our products.

The brand new products!

CSHI CHETO SMART HOLE INSPECTION

-

Designed to improve and assist during the assembly process of injection molds.

FUNCTIONALITIES

CHETO Smart Hole Inspection allows: testing of tightness, checking of flow rates, possible leakages and strangulations inside the cooling channels.- Inspection, cleaning and maintenance of the cooling channels;

- Automatic testing with an acuracy of 95%;

- Tightness and leakage tests up to 10bar of pressure;

- Flow tests from 0.5l/min (excellent for conformal cooling);

- Report certified, protected and with instant translation to 5 languages

- Versions with 40L and 90L pump;

- Tank with capacity up to 80 liters;

- Connectivity to the i4.0 with a built-in API;

- Three-phase power supply with USB/Wi-fi and LAN connectivity (addictional hdmi/vga and usb available);

- CE Certification.

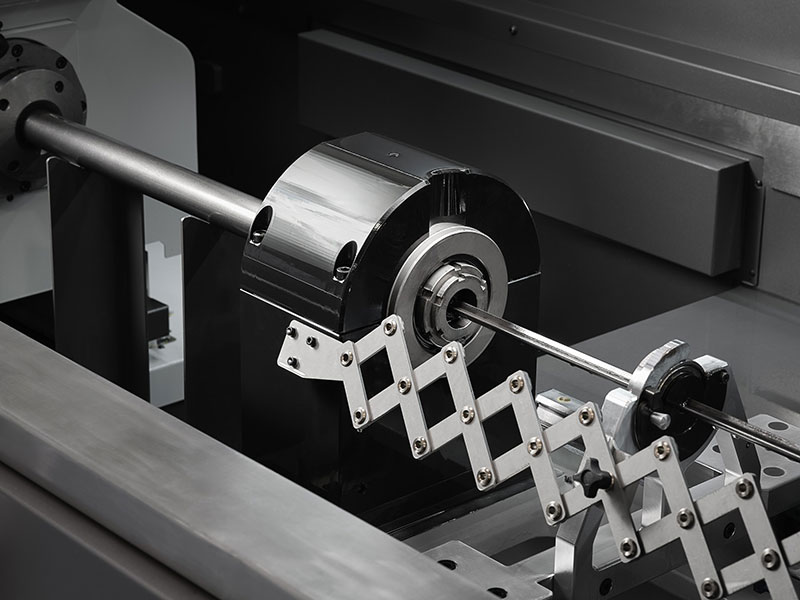

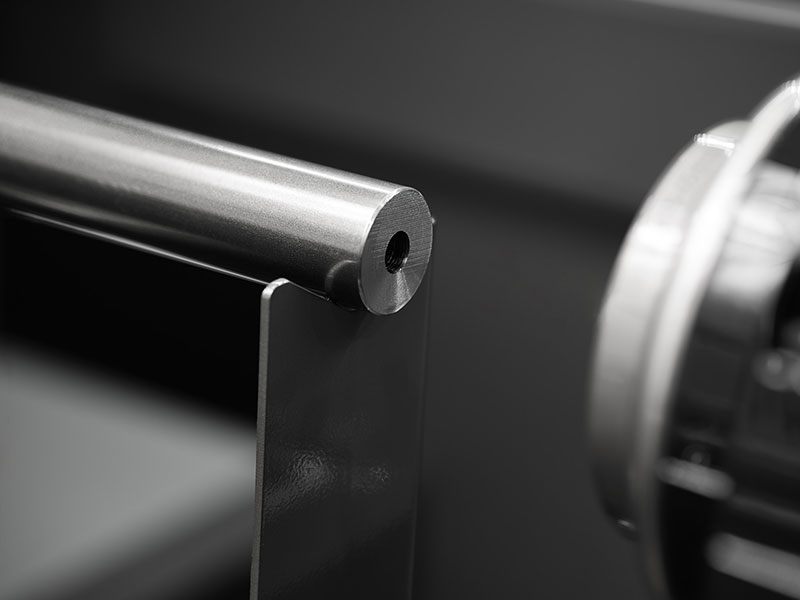

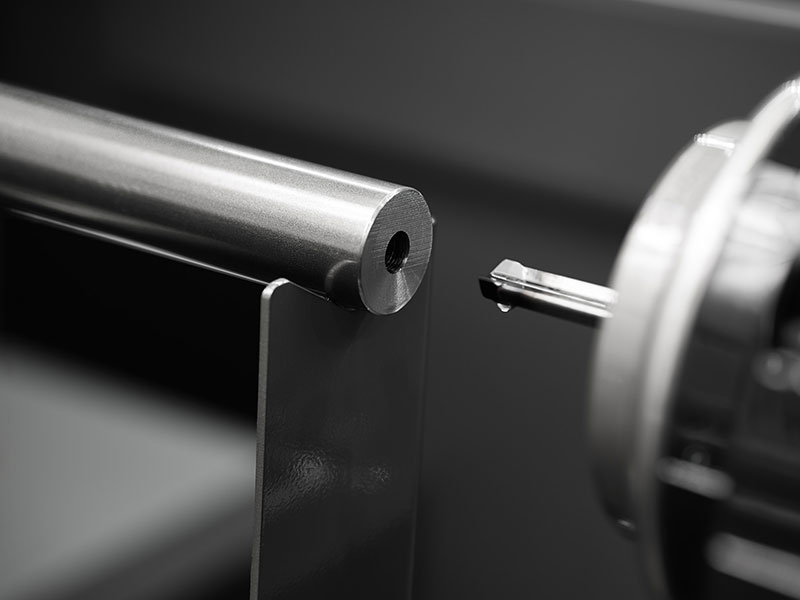

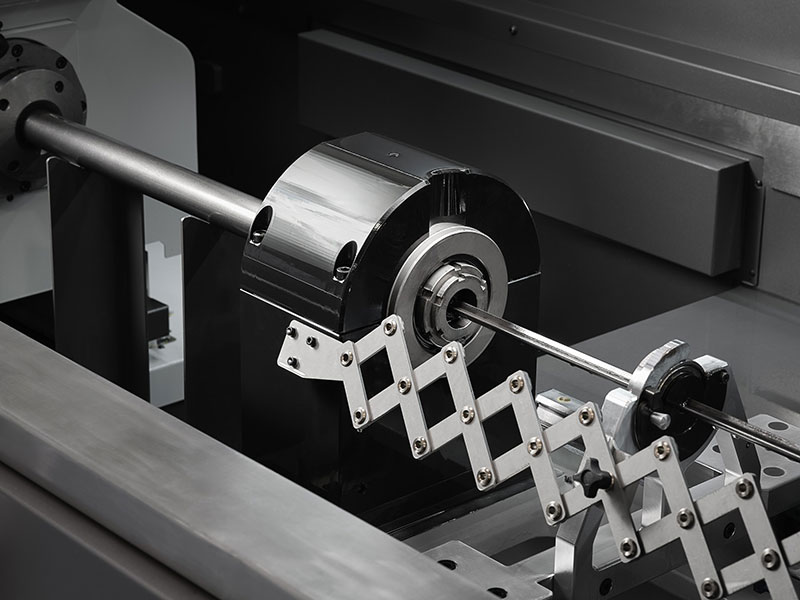

INL Deep Hole Drilling: INL BTA and GUNDRILL

-

Dedicated to the production of round bars, this machine allows you to use in parts up to 6 meters. It is possible to equip this model with dedicated sensors, using artificial intelligence, allowing an exhaustive machine learning process.

Technical Data:

- DRILLIING CAPACITY (Solid drill in steel): BTA ø18-32 mm | ø0.7-1.3 in; BTA ø18-55 mm | ø0.7-2.2 in; GUNDRILL ø5-25 mm | ø0.2-1.0 in

- DRILLING UNIT (Number of spindles): BTA 1; GUNDRILL 1 to 6

- DRILLING UNIT (Depth): BTA 150-3000 mm | 5.9-118.1 in; BTA 150-3000 mm | 5.9-118.1 in; GUNDRILL 150-3000 mm | 5.9-118.1 in

- CONTROL (reference): BECKOFF

- SPINDLE (Power): BTA 25 kW / 34 hp; BTA 37 kW | 50 hp; GUNDRILLl 8 kW | 11 hp

- max. Torque: BTA 272 Nm / 201 ft-lbs; BTA 330 Nm | 243 ft-lbs; GUNDRILL 44 Nm | 32 ft-lbs

- Rapid feed: 5000 mm/min

- Max. Speed Spindle: BTA 0-2300 rpm; GUNDRILL 0-6000 rpm

- COOLANT SYSTEM (Volume): BTA 3000L; BTA 4000L; GUNDRILL 1500L

- Pump capacity: BTA 160-280 l/min; GUNDRILL 100 l/min

- Max. coolant pressure: BTA 50-30 bar; GUNDRILL 8 0bar

- Layout Dimensions: Dimensions of the machine according to the depth

- BTA or GUNDRILL System

- Temperature of the oil and level of the tank monitoring

- Automatic Chip Conveyor

- Coolant tank with automatic filtering

- Pressure and flow monitoring of drilling fluid

- Easy determination of workpiece origin

- Remote diagnosis

- Clamping cones set

- NC tailstock

- Automatic doors

- SIEMENS CONTROL

- X asis

- Tailstock

- Pack Connectivity i4.0

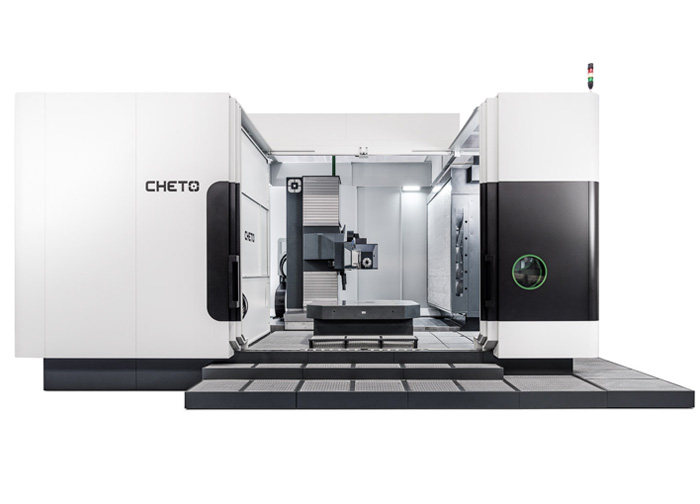

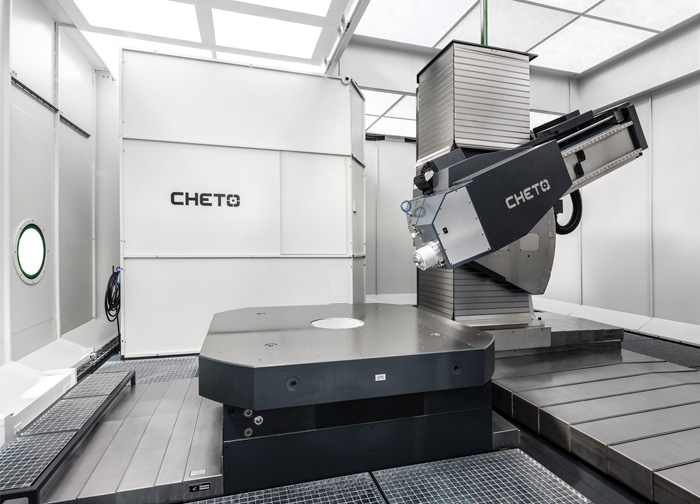

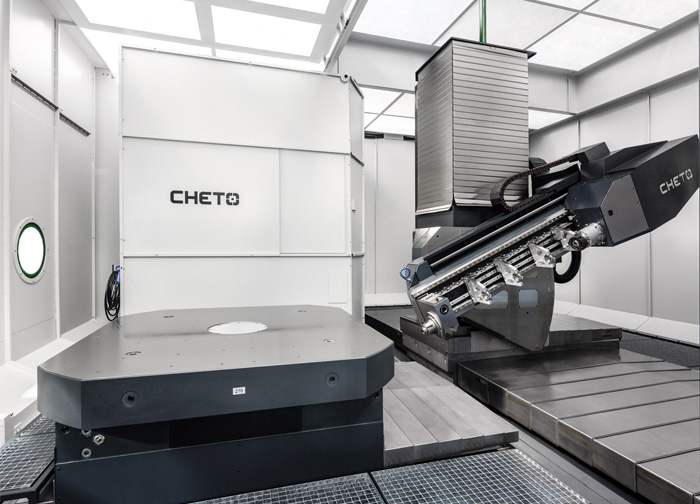

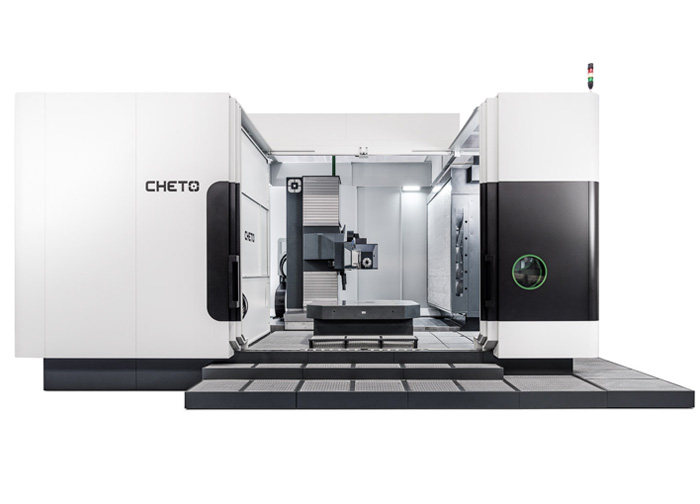

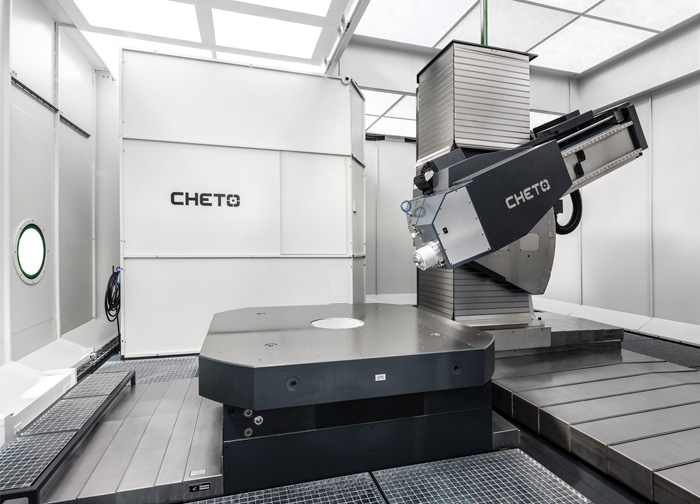

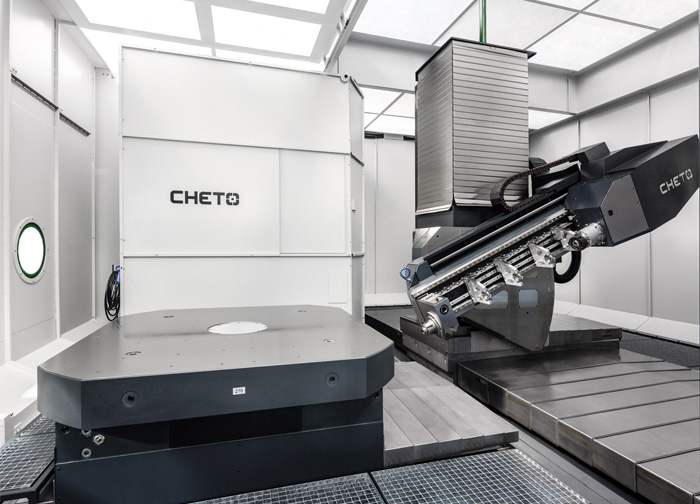

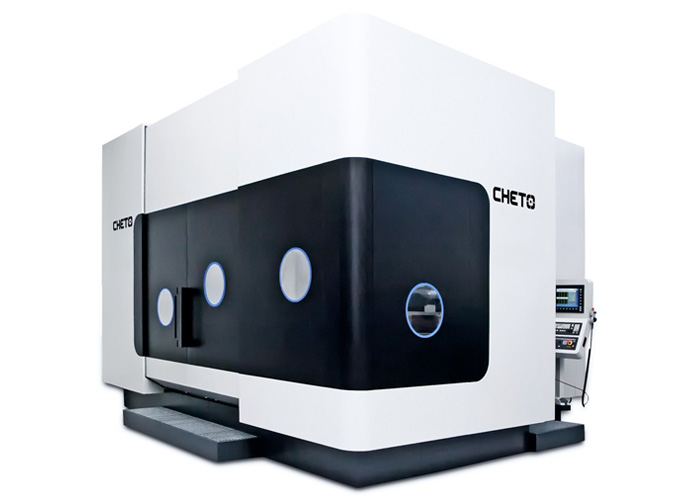

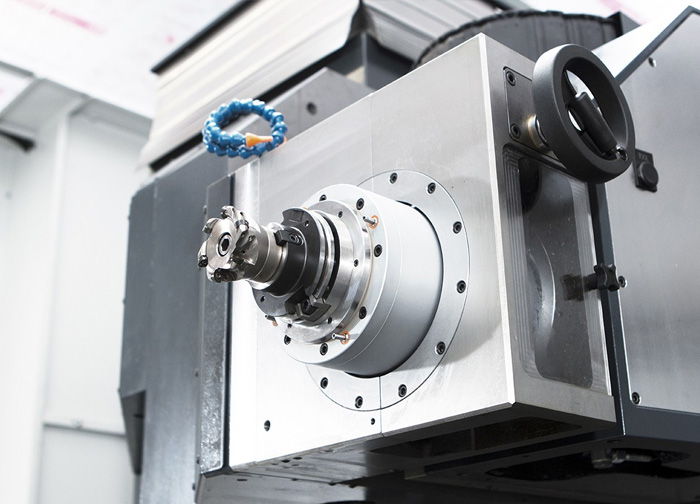

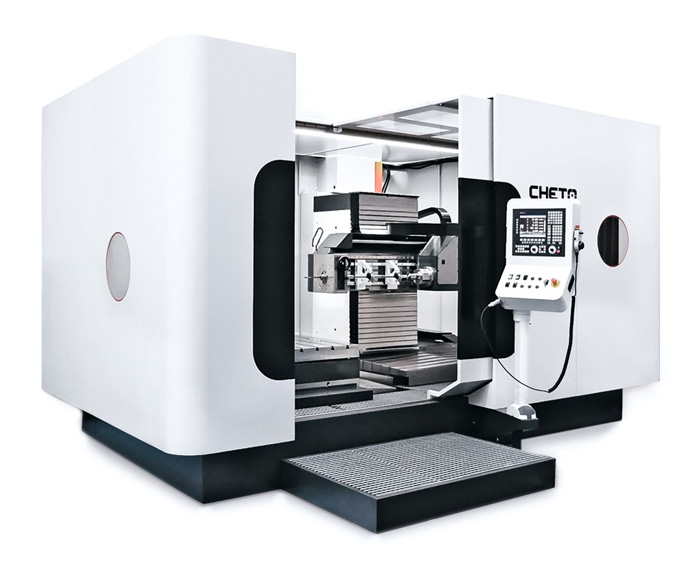

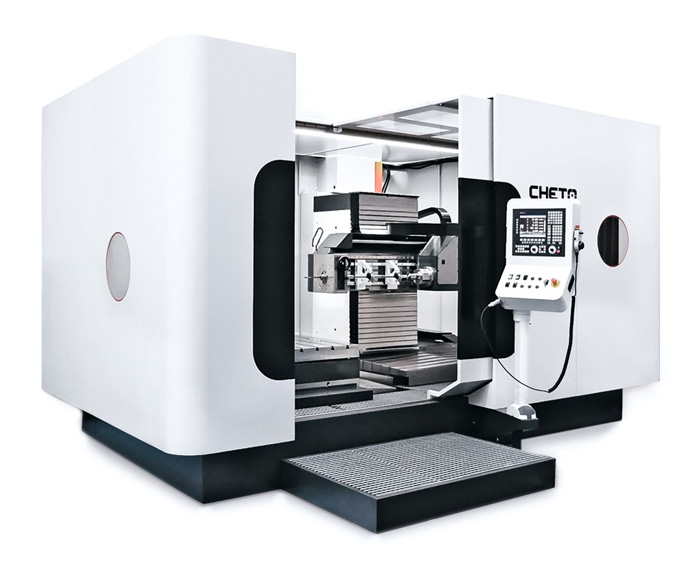

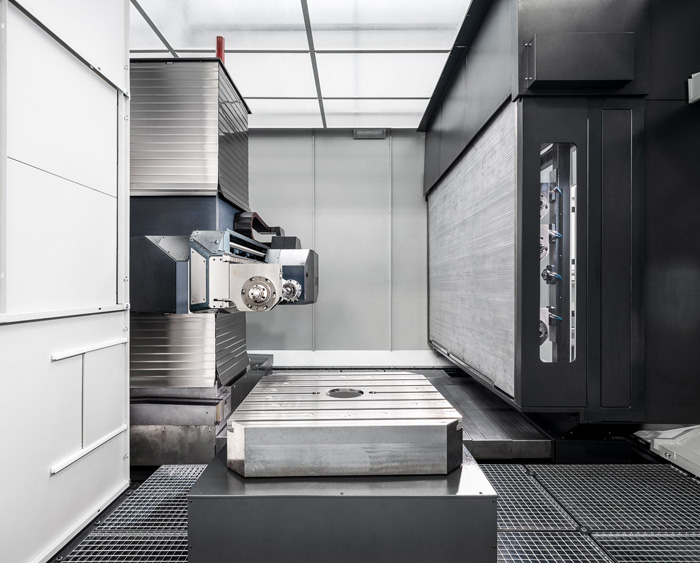

CHETO CONCEPT - ALL IN ONE

CHETO ALL IN ONE

-

Working all around the part in a single setup (mold industry)

5 MACHINES IN 1

1.DEEP HOLE DRILLING MACHINE

2.RADIAL DRILLING MACHINE

3.DILLING MACHINE

4.TAPPING MACHINE

5.BORING MACHINEWHY CHOOSE CHETO?

- Innovative concept for moldmakers and service companies;

- Deep hole drilling, standard drilling, milling, tapping, boring in a single machine;

- Eliminates setup operations in mold manufacturing;

- Excellent quality/price ratio;

- Reduction of time and costs;

- Embedded drilling and machining processes, minimizing human errors;

- Brand of excellence, internationally recognized in the mold industry;

- CHETO machines represent an excellent investment for their multitasking features that otherwise were directed at other machines less specific and less adequate to the needs and requirements of the mold manufacturing and other services.

ADVANTAGES

- 60% reduction in drilling time

- 40% reduction in setup time

- 20% reduction in mold delivery time

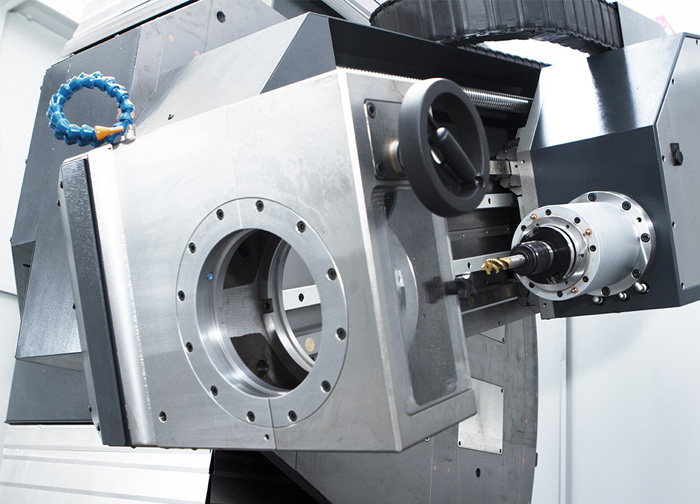

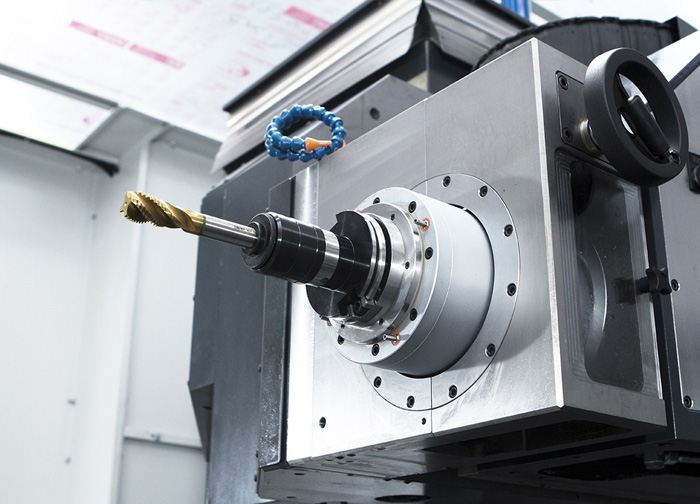

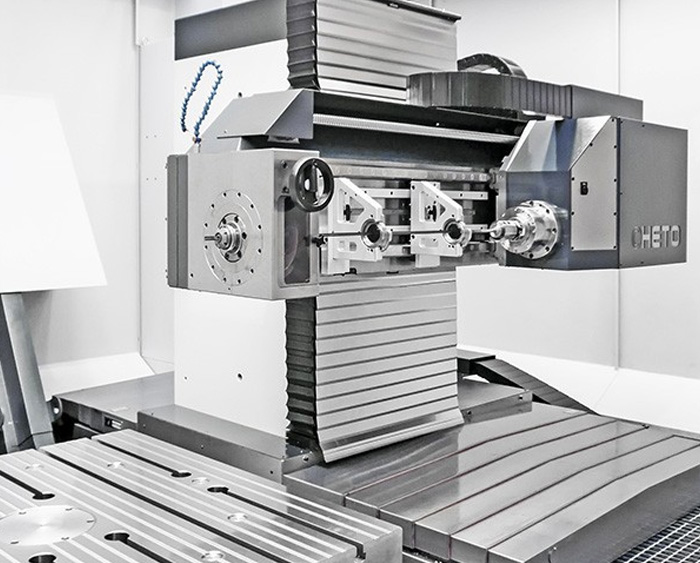

MAIN FEATURES

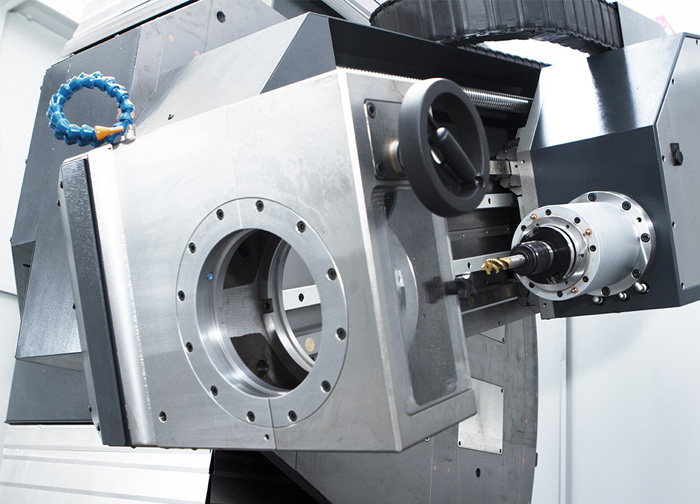

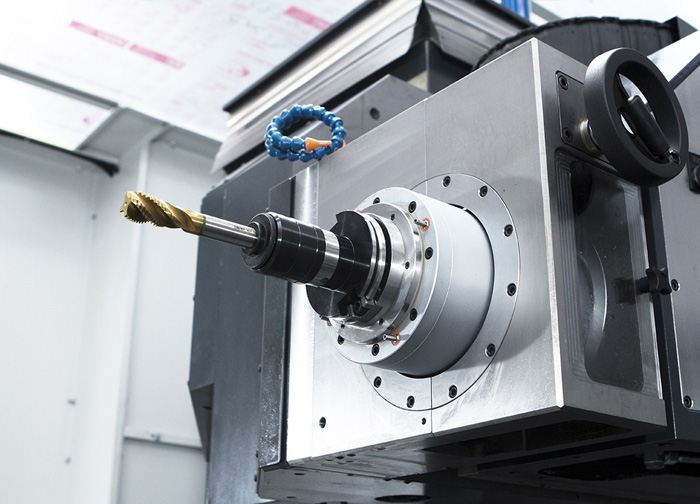

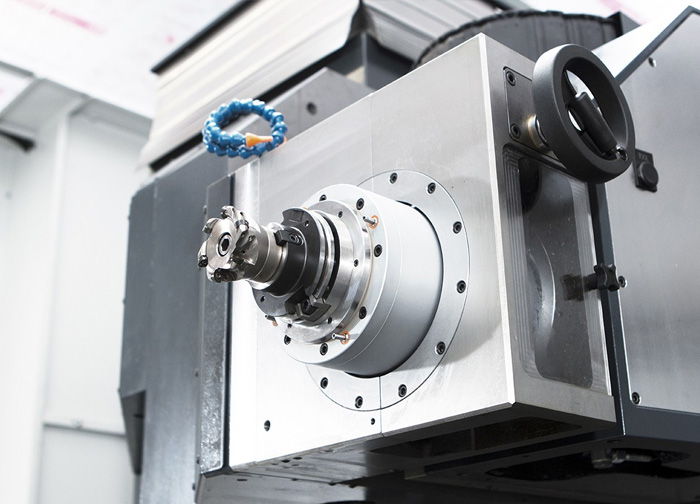

- Tool changing systems to rapidly and easily exchange between deep hole drilling and milling processes;

- Customized structure to increase milling capacity (chip removal rate);

- Active control software dedicated to deep hole drilling, tapping and milling;

- Ability to, in a single click, translate and rotate coordinates;

- Latest generation of numerical controls, digital servo-drives, linear slides and high-precision roller guides;

- Filtering and cooling the cutting fluid;

- Pressure and flow adjustment to meet the tools requirements;

- Deep hole drilling with gundrills at high pressure;

- Smart and online control system with remote access;

- Rapid and precise machining;

- Self-compensation of the machine’s dimensional parameters in relation/dependent of operating conditions, namely temperature, humidity, vibration, etc.;

- Optimized life cycle, safety and energy efficiency;

- Easy reconfiguration and adaptation to new production/manufacturing realities;

- User-level safety and environmental efficiency.

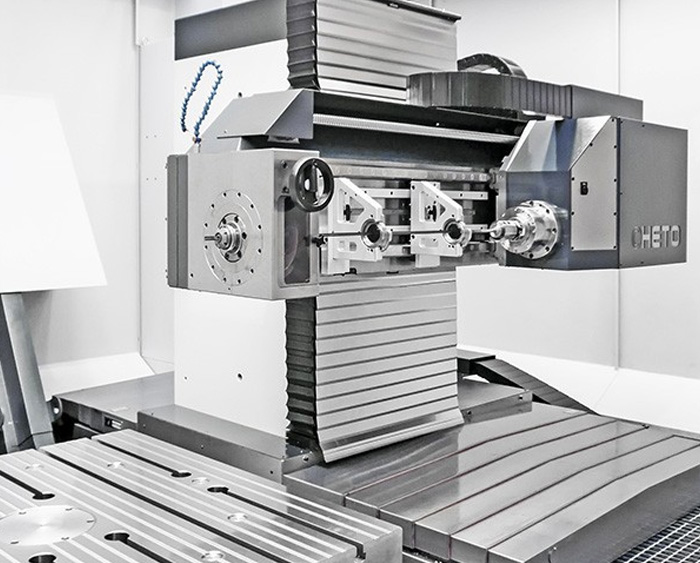

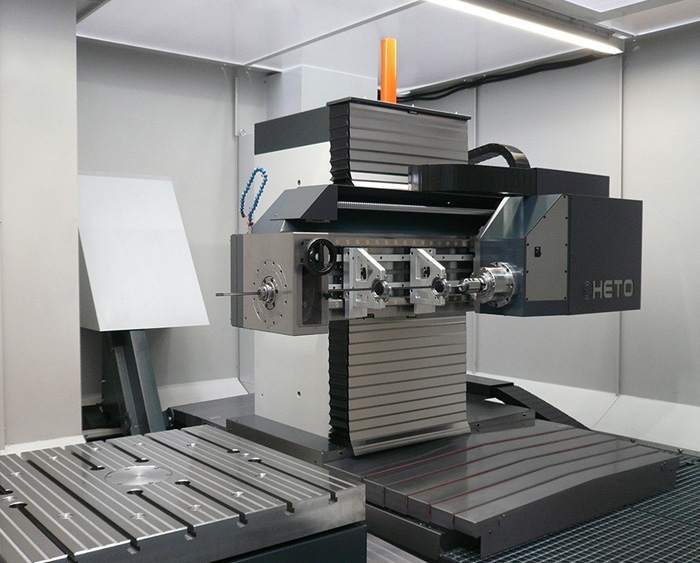

6/7 AXIS

IXN 1000 I 2000 I 3000 6/7 AXIS

-

1000 2000 3000 CNC AXIS X longitudinal travel: 1000 mm | 39.4 in 2000 mm | 78.7 in 3000 mm | 118.1 in Y vertical travel 1000 mm | 39.4 in 1200 mm | 47.2 in 1200 mm | 47.2 in Z cross travel 800 mm | 31.5 in 800 mm | 31.5 in 800 mm | 31.5 in Z1 cross travel 700 mm | 27.6 in 700 mm | 27.6 in 700 mm | 27.6 in *option W drilling one stroke 1630 mm | 64.2 in 1630 mm | 64.2 in 1630 mm | 64.2 in B table rotation 360,000 pos. 360,000 pos. 360,000 pos. A tilting rotation +25º/-15º +25º/-15º +25º/-15º STANDARD EQUIPMENT

- CNC FAGOR 8065

- Electronic handwheel

- Digital drives

- Nitrogen double counterweight

- Nitrogen double counterweight

- Absolute linear encoders in AXIS X, Y and Z

- Absolute angular encoders in AXIS A and B

- Telescopic covers in all AXIS (except drilling axis)

- Kinematics / RTCP

- Rigid tapping

- Quick change between drilling/milling

- Coolant tank with automatic filtering

- Submerged pumps for oil recirculation

- High-pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

- Automatic chip conveyor-

- Complete cover with doors, laminated glass windows and acrylic ceiling

OPTIONAL EQUIPMENT- CNC HEIDENHAIN TNC640

- ATC automatic tool changer up to 250 tools

- ATC gun drill up to 5 tools

- Upgrade size option for AXIS Y and W

- Upgrade table size options up to 2000x2000 mm | 78.7x78.7 in

- Z1 axis = 700 mm | 27.6 in

- Tilting rotation +25º/-25º

- Spindle motor power upgrade

- Wise software system

- AC for electrical cabinet

- Immersion chiller for oil/emulsion

- Air cleaning unit

- High pressure pump 100 bar

- BLUM MCA7 Laser measuring system

- BLUM TC60 Electric probe

- Machine preparation for automation

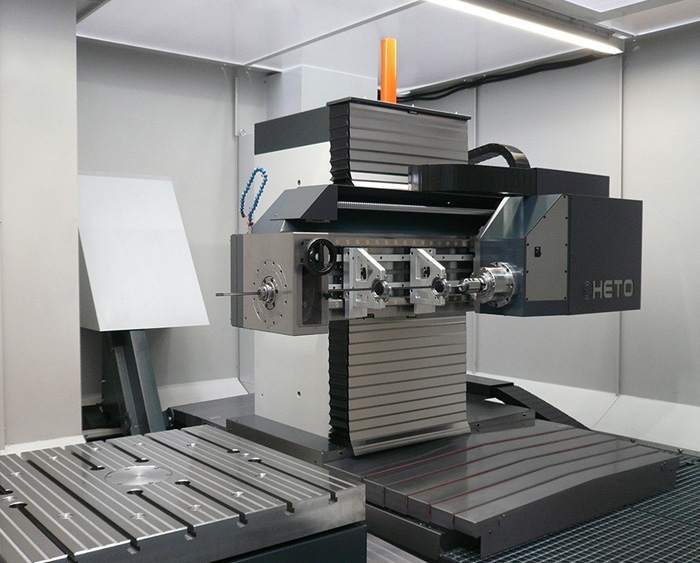

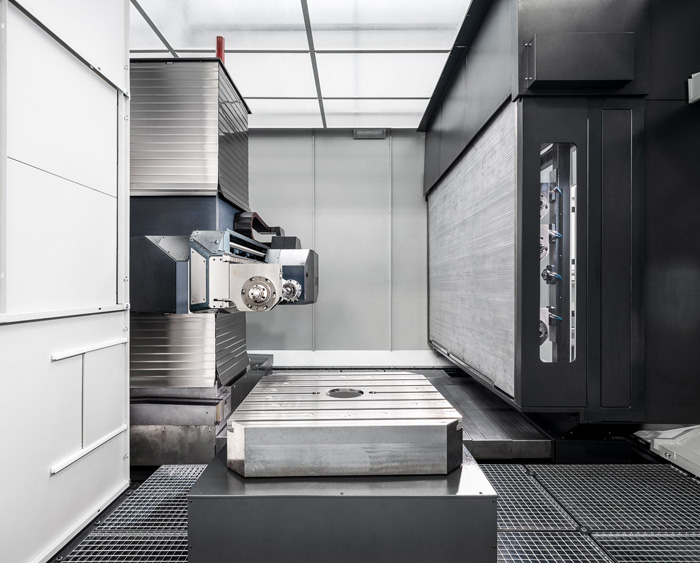

MT 1500 I 2500 6 AXIS

-

1500 2500 CNC AXIS X longitudinal travel: 1500 mm | 59.1 in 2500 mm | 98.4 in Y vertical travel 1000 mm | 39.4 in 1200 mm | 47.2 in Z cross travel 650 mm | 25.6 in 650 mm | 25.6 in W drilling one stroke 1630 mm | 64.2 in 1630 mm | 64.2 in B table rotation 360,000 pos. 360,000 pos. A tilting rotation +25º/-15º +25º/-15º STANDARD EQUIPMENT

- CNC FAGOR

- Communication ethernet/USB

- Electronic handwheel

- Digital optical drives

- SERCOS

- Remote I/Os

- Nitrogen double counter weight

- Linear roller guideways

- Glass scales in all AXIS except W axis

- RTCP to tool (A axis)

- RTCP function for piece origin (B axis)

- Rigid tapping

- Quick change between drilling/milling

- High pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

- Coolant tank with automatic filtering

- Carter submerge pump for oil recirculation

- Automatic chip conveyo

- rComplete covering with movable doors

OPTIONAL EQUIPMENT- ATC automatic tool change (40 or 24 tools)

- Spindle with 6,000 rpm

- Wise software system

- AC for electrical cabinet Immersion chiller for oil/emulsion

- Table size 2000x2000 mm | 78.7x78.7 in

- Mirror Version

- Y axis = 1500 mm | 59.1 in

- W axis = 2000 mm | 78.7 in

SIC 650 6 AXIS

-

1000 CNC AXIS X longitudinal travel: 650 mm | 25.6 in Y vertical travel '840 mm | 33.1 in Z cross travel 500 mm | 19.6 in W drilling one stroke 1120 mm | 44.0 in B table rotation 360,000 A tilting rotation +90°/-45° STANDARD EQUIPMENT

- CNC FAGOR 8065

- Electronic handwheel

- Digital drives

- Absolute linear encoders in AXIS X, Y and Z

- Absolute angular encoders in AXIS A and B

- Kinematics RTCP

- Rigid tapping

- Quick change between drilling/milling

- Coolant tank with automatic filtering

- Submerged pumps for oil recirculation

- High-pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

- Automatic chip conveyor

- Complete cover with doors, laminated glass windows and acrylic ceiling

OPTIONAL EQUIPMENT- CNC HEIDENHAIN TNC 640

- ATC automatic tool changer up to 112 tools

- Wise software system

- Independent refrigerator unit for the coolant

- Air cleaning unit

- High pressure pump 100 bar

- BLUM MC A7/2 Laser measuring system

- BLUM TC60 Electric probe

- Immersion chiller for oil/emulsion

- Table with zero clamping system prepared for automation with automatic frontal door

5 AXIS

CC 1000

-

1000 CNC AXIS X longitudinal travel: 1000 mm | 39.4 in Y vertical travel 600 mm | 23.6 in Z cross travel 500 mm | 19.7 in W drilling one stroke 1550 mm | 61.0 in B table rotation 360,000 pos.

STANDARD EQUIPMENT- CNC FAGOR 8055i Power

- Communication ethernet/USB

- Electronic handwheel

- Digital optical drives SERCOS

- Remote I/Os

- Nitrogen double counterweight

- Linear roller guideways

- Kinematics RTCP

- Rigid tapping

- Quick change between drilling/milling

- High pressure pump 70 bar, 90 l/min | 1,015 psi, 23.8 gal/min

- Coolant tank with automatic filtering

- Automatic chip conveyor

- Complete covering with movable doors

OPTIONAL EQUIPMENT- CNC FAGOR 8060-M

- ATC automatic tool changer up to 40 tools

- Spindle motor power upgrade

- Wise software system

- AC for electrical cabinet

- Immersion chiller for oil/emulsion

- Air cleaning unit

- High pressure pump 100 bar

- BLUM MCA7 Laser measuring system

- BLUM TC60 Electric probe

PWN 1000,2000,3000

-

1000 2000 3000 CNC AXIS X longitudinal travel: 1000 mm | 39.4 in 2000 mm | 78.7 in 3000 mm | 118.1 in Y vertical travel 1000 mm | 39.4 in 1200 mm | 47.2 in 1200 mm | 47.2 in Z cross travel 800 mm | 31.5 in 800 mm | 31.5 in 800 mm | 31.5 in W drilling one stroke 1630 mm | 64.2 in 1630 mm | 64.2 in 1630 mm | 64.2 in B table rotation 360,000 pos. 360,000 pos. 360,000 pos.

STANDARD EQUIPMENT- CNC FAGOR 8065

- Electronic handwheel

- Digital drives

- Nitrogen double counterweight

- Absolute angular encoders in axis B

- Telescopic covers in all AXIS (except drilling axis)

- Kinematics RTCP

- Rigid tapping

- Quick change between drilling/milling

- Coolant tank with automatic filtering

- Submerged pumps for oil recirculation

- High-pressure pump 80 bar, 100 l/min | 1,160 psi, 26.5 gal/min

- Automatic chip conveyor

- Complete cover with doors, laminated glass windows and acrylic ceiling

OPTIONAL EQUIPMENT- CNC HEIDENHAIN TNC640

- ATC automatic tool changer up to 250 tools

- ATC gun drill up to 5 tools

- Glass scales in all AXIS except W axis

- Upgrade size option for AXIS Y and W

- Upgrade table size options up to 2000x2000 mm | 78.7x78.7 in

- Spindle motor power upgrade

- Wise software system

- AC for electrical cabinet

- Immersion chiller for oil/emulsion

- Air cleaning unit

- High pressure pump 100 bar

- BLUM MCA7 Laser measuring system

- BLUM TC60 Electric probe

- Machine preparation for automation