- Offer Profile

- In 1987, ILJIN Diamond was the first to develop industrial synthetic diamonds in Korea through an academy-industry cooperation with KIST (Korea Institute of Science and Technology). Since then, through continual reinvention of its technologies, we have firmly established our position as a globally leading industrial diamond maker.

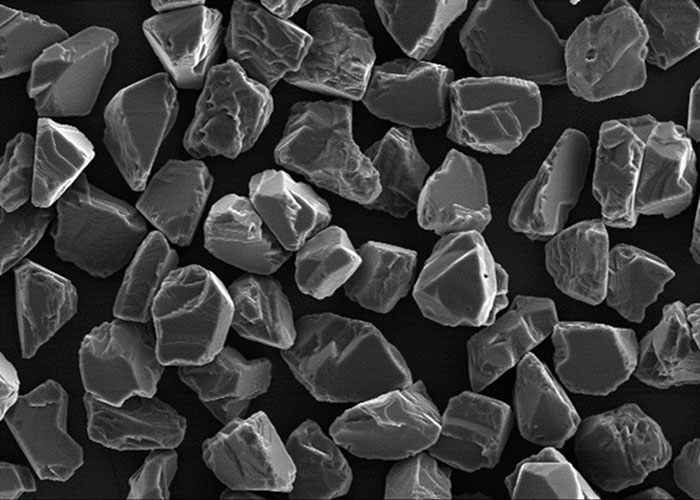

Diamond Powder

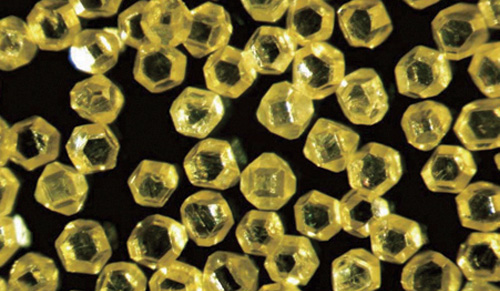

Synthetic Diamond

- ILJIN Synthetic Diamond (ISD) is used in saw blades,

cutters, core drill bits, etc. which are tools used to cut and process

construction and civil engineering materials such as stones, concrete and

asphalt. ISD made by ILJIN has the high durability and cutting force

essential in the construction and stone material fields, and is the result

of our continuous innovation and technology development to produce an

industrial diamond using HPHT technology.

Process

Sawing

Workpiece

Stone, Mining & Construction

Premium Synthetic Diamond

- ILJIN Premium Synthetic Diamond (IPD) was developed with ILJIN’s HPHT technology.

It has high hardness and high thermal stability, and a sharp cutting edge at forming surfaces. IPD has exceptional performance in harsh applications, such as mining bits and multi-wires to cut Granite. IPD’s high hardness and specific characteristics of edge and micro chipping properties of particles enable a reduction of processing load and increased cutting performance.

Process

Sawing

Workpiece

Stone, Mining & Construction

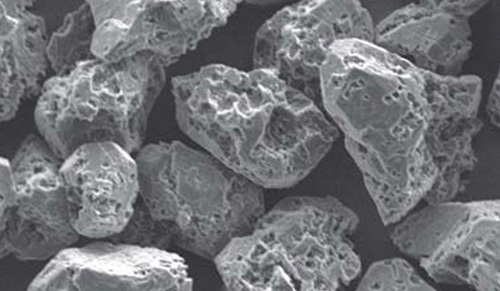

Metal Bond Diamond

- ILJIN Metal Bond Diamond (IMD) is a synthetic diamond

produced using a unique HPHT process of ILJIN, which offers outstanding

performance for the processing of nonferrous materials. IMD is used for a

range of applications, from Glass and Ferrite processing to CMP Pad

Conditioner.

IMD is designed to be suitable for various applications of Bond Systems thanks to its flexible coating options with excellent performance, and can realize a high material removal rate (MMR) and prominent surface finishing.

Continuous development is in progress to improve performance consistency and productivity for the end user.

Process

Grinding

Workpiece

Nonferrous Material

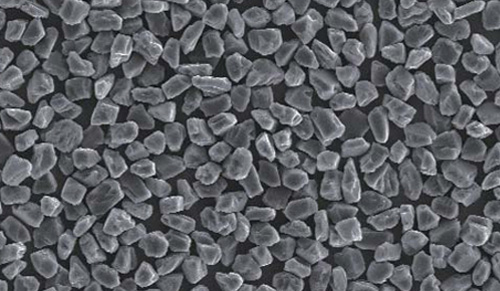

Resin & Vitrified Bond Diamond

- ILJIN Resin & Vitrified Bond Diamond (IRD) is a synthetic

diamond that is normally used to process nonferrous materials in the market,

particularly cemented Tungsten Carbides and Hard Ceramics.

Process

Grinding

Workpiece

Nonferrous Material

Micron Powder

- ILJIN Micron Powder (IMP) is a micron-sized synthetic

diamond and CBN powder that is widely used in a variety of manufacturing

processes such as Grinding, Polishing and Super Finishing in industries like

electronics, semiconductors and automobiles. Recently, it has been

spotlighted as a main material for PDC, PCD and PCBN which is

used to cut solar cell and LED materials.

ILJIN’s strict quality control ensures consistency of size and shape. We have sought a great deal of customer feedback in order to continuously improve this product to better suit our customers’ environments.

Process

Grinding

Workpiece

Semiconductor, Electronics, Solar

CBN

CNB Powder

-

ILJIN cBN Powder (IBN) is a highly effective and efficient material for processing various ferrous materials such as superalloy, bearing steel, and heat-treated steel. It improves the quality of surface finishing of processed materials, extends tool life, and lowers power consumption of processing equipment, enabling cost savings for end users.

In machining fields that require precise dimensions and quality, such as cam/crank shafts and CV joints among automobile parts, our IBN products provide consistent grinding results and extended tool life, helping to improve the productivity of end users.

IBN is used in a variety of bonds and can be surface treated and coated to suit each characteristic.Process

GrindingWorkpiece

Ferrous Metal

Micron cBN Powder

-

ILJIN Micron cBN Powder is a micron-sized cBN powder used in various processes such as grinding, polishing, and super finishing in the overall industries such as electronics, semiconductors, and automobiles. In addition, it is also used as a PCBN raw material.

We are maintaining strict quality checks, ensuring consistent size and shape conformity, while continuously seeking improvement by accommodating customer requests and offering technological advice tailored to customer needs and environments.Process

Grinding, PolishingWorkpiece

Ferrous Metal

PCD

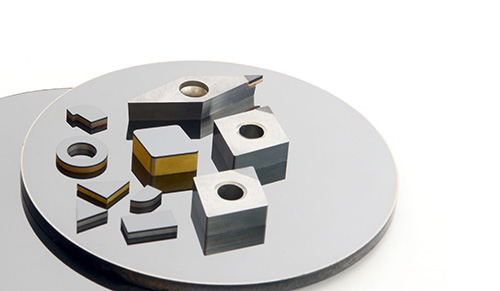

Polycrystalline Diamond

-

ILJIN Polycrystalline Diamond is a high-hardness tool material made by high-temperature and high-pressure sintering of synthetic diamond and binder. It is used as an essential material for machining all workpieces and difficult-to-cut materials such as non-ferrous materials - aluminum, ceramics, wood, silicon, carbide, CFRP, and copper in various fields, including automobiles and aerospace.

PCD grades are categorized based on diamond content and particle sizes.Process

CuttingWorkpiece

Nonferrous Material

PCBN

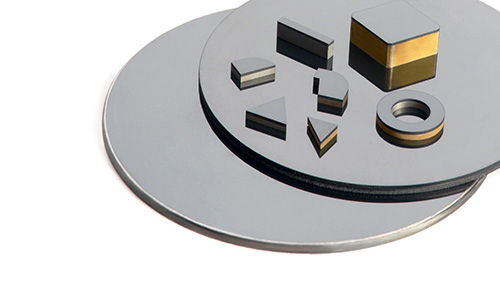

Polycrystalline Cubic Boron Nitride

-

ILJIN Polycrystalline Cubic Boron Nitride is a high-hardness tool material made by sintering CBN powder and ceramic binders under high temperature and high pressure.

We enable the machining of ferrous materials, which are difficult to process with PCD, making it an essential material in various fields, including automotive, aerospace, and other industries working with ferrous materials such as carbon steel, cast iron, heat-treated steel, sintered metal, superalloys, and more.

And PCBN is divided into low content and high content depending on the CBN content and binder properties.Process

CuttingWorkpiece

Ferrous Metal

Tungsten Carbide

Tungsten Carbide Rod

-

ILJIN's Tungsten Carbide Rod is divided into general drills, end mill tools, PCB board processing routers, and micro drills depending on the area of use, and is applied to the processing of various workpieces in the automotive, aviation, energy, IT, and medical fields that require carbide cutting.

Grades are classified according to cobalt content, work material hardness, and application.Process

Drilling & Endmilling

Tungsten Carbide Roll

-

ILJIN's Tungsten Carbide Roll is used in the rolling processes of steel companies for rebar, wire rod, and round bar. Recently, we are able to design and assemble composite rolls that use carbide rings and shafts to roll products of various sizes simultaneously, expanding the application of ILJIN carbide rolls to various customer lines.

According to customer requests, we have single binder grades using only cobalt and multi-binder materials using Co+Ni.Process

RollingWorkpiece

Steel Bar

PDC

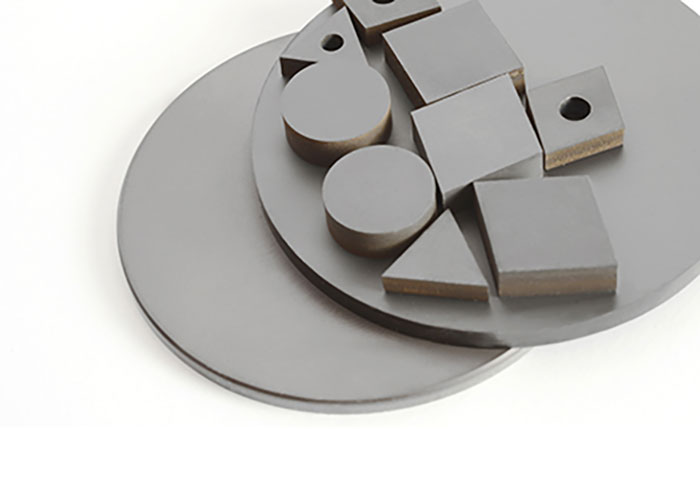

Polycrystalline Diamond Compact

-

ILJIN Diamond's PDC products have excellent durability, wear resistance, impact resistance, and heat resistance, saving overall drilling time and increasing drilling efficiency, contributing greatly to cost reduction and productivity improvement in the Oil & Gas industry.

Process

DrillingWorkpiece

Downhole (Oil & Gas)

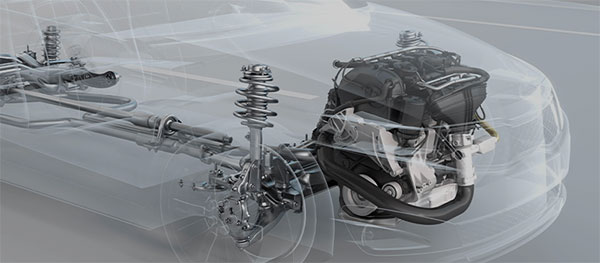

Application

Automotive / Aerospace

- Workpiece materials in the automotive/aerospace fields are gradually becoming lighter and more difficult to machine along with electrification.

For a long time, we’ve been involved in the research and manufacturing of ultra-hard materials aimed at enhancing production efficiency and enabling high-precision, high-speed machining. Drawing from this experience, we contribute to industrial development by recommending materials suitable for user conditions and developing new material types.

We will continue to lead the development and expansion of applications of ultra-hard materials.

Semiconductor

- High-quality micron-sized diamond materials are essential for semiconductor wafer processing, and ILJIN provides micron-sized diamond powder whose shape, particle size, and surface condition are thoroughly controlled.

In the wafer and semiconductor fields, harder workpiece materials are being developed every year, and difficult machining and high efficiency are required. In addition, the heat-conducting properties of ultra-superhard materials are also gaining attention for the thermal management of semiconductor chips.

For a long time, we’ve been engaged in the research and manufacturing of ultra-hard materials aimed at increasing production efficiency and improving grinding performance. Based on that experience, we will present new solutions and contribute to increasing the process efficiency of users.

IT/Electronics

- The field of tablets, mobile phones, and electronic components undergoes rapid material transformations and demands precision machining for a variety of tough and composite materials. For a considerable period, we have been engaged in the manufacturing and development of diamond materials, including diamond powders and sintered diamonds, along with carbide materials for rotary tools.

Particularly, our sintered diamond materials encompass a wide range of particle sizes, from ultra-fine to coarse, enabling us to offer various types of materials suitable for diverse customer machining concepts and requirements.

Construction / Mining

- To enable more effective and durable machining without incidents in diverse construction and mining sites, we supply high-spec ultra-hard materials like diamond powders in various sizes worldwide. We possess various hard coating technologies to withstand harsh conditions, including high temperatures and humidity within the strata. Additionally, we have established an efficient supply system with local stock and inventory management to enable swift delivery.

Woodworking

- The materials used in the woodworking industry are becoming increasingly composite and reinforced. Efforts are ongoing to enhance machining efficiency and productivity.

Moreover, the woodworking market is experiencing intensified tool price reductions, emphasizing the importance of cost competitiveness.

We also have sintered diamonds at more accessible prices, and we are working with our customers to find solutions to difficult processing issues.

Oil and gas

- Drilling in the oil and gas industry requires a variety of impact resistance and wear resistance characteristics depending on the various environments within the formation. To drill more effectively towards specific directional targets, we collaborate with our customers to develop various materials tailored to their usage conditions. Ultimately, our aim is to enhance the efficiency of the drilling industry and contribute to cost savings.