- Offer Profile

-

We are a global leader in the design, manufacture and distribution of precise, advanced metal-cutting machine tool solutions. We work tirelessly to help make today’s manufacturers and job shops more productive and more profitable. As manufacturing demands increase, so do we. Bringing innovation, precision and accuracy to the most demanding applications.

TURNING

- For over 130 years, Hardinge and Weisser lathes have been and will continue to be a standard for quality, longevity, and capability. Whether your needs call for high volume production or holding tight tolerances, Hardinge offers a complete range of SUPER-PRECISION and General Performance CNC turning centers with a maximum machining length of up to 47″ and a maximum machining diameter of up to 15″.

T-Series SUPER-PRECISION®

- The Hardinge SUPER-PRECISION® T-Series turning centers set the standard in high-precision and high-performance turning that will take your part quality and manufacturing capabilities to new heights. T-Series machines are designed to exceed your expectations and are ideal for two axis high-precision machining or complex multi-tasking operations that require a high level of precision, delicate part handling and for parts made complete in a single setup. Machine packages are pre-configured with our most popular features allowing you to select the proper machine tool configuration to produce your parts in the most effective and profitable manner.

QUEST Series SUPER-PRECISION

-

QUEST Series: Setting the industry standard for part roundness, surface finish, and accuracy.

Hardinge QUEST Series turning centers are designed for the quick changeovers you need to dramatically reduce setup and cycle times. QUEST Series machines include our patented, interchangeable top plates that you can pre-tool for a particular job or range of jobs and a world-renowned, quick-change collet-ready spindle.

MULTIFUNCTIONAL

- Our Multifunctional Turning/Milling Machining Centers are sold under the WEISSER brand and provide high-performance solutions for turning operations or turn-mill complete machining in one or two setups.

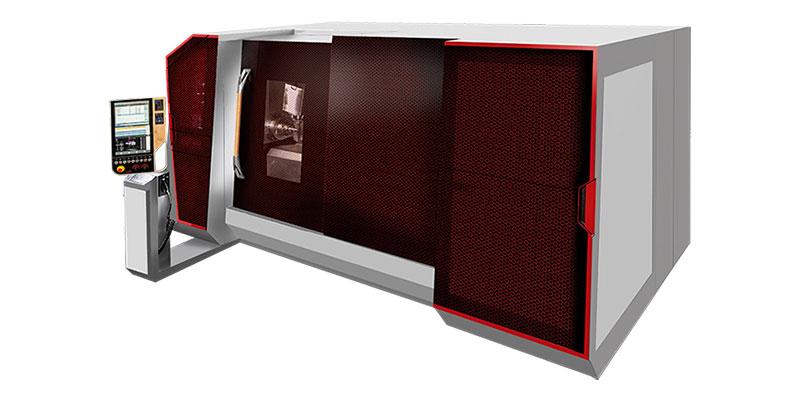

MULTICENTER

- Versatile machining possibilities for precision and flexibility

The MultiCenter presents itself as multifunctional machining center with different options. Beside the option as pure turning machine it can also be configured as turning-milling center. Due to its remarkable flexibility the MultiCenter is used in different industrial sectors. Amongst others in precision technology, aerospace, mechanical engineering, medical engineering and many other industrial sectors.

The basic machine of the MultiCenter impresses with a horizontal spindle arrangement and a compact design. The machine column made of high-quality grey cast iron, strongly ribbed and with extraordinary stiffness, offers optimum damping characteristics. The design of the working area walls guarantees an efficient removal of chips. The spacious working area door enables a simple scaffolding and resetting, as well as quick changes of chucks and tools.

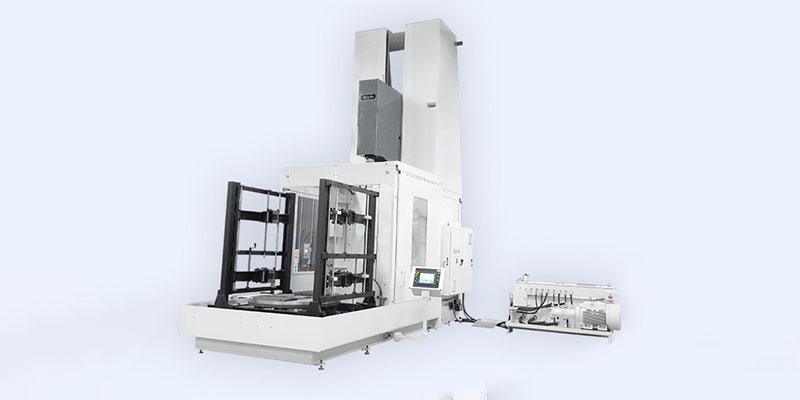

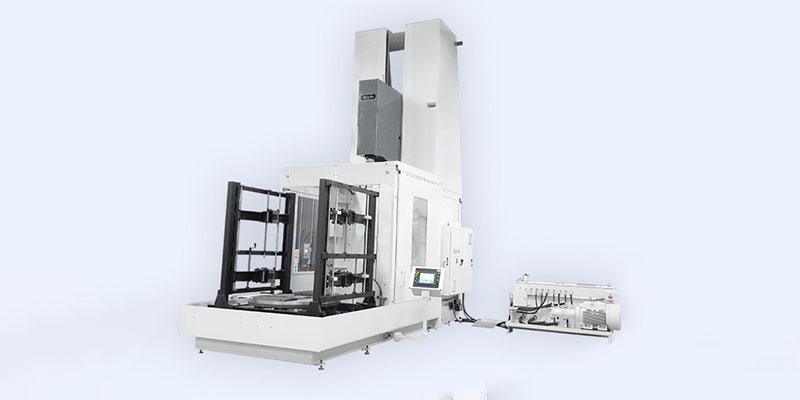

ARTERY

- MULTIFUNCTIONAL HIGH-PERFORMANCE PRECISION CENTER FOR TURNING OR TURN-MILL COMPLETE MACHINING

Available as a highly efficient 5-axis precision turning machine as well as a mill-turn center for autonomous, very precise and cost-effective 6-sided complete machining. The high flexibility of the ARTERY enables its use in many industrial sectors, e.g. precision technology, aerospace, mechanical engineering, medical technology, and many others. The high-quality ARTERY manufactures first-class surfaces as well as maximum precision and process reliability and features high vibration damping and flexibility.

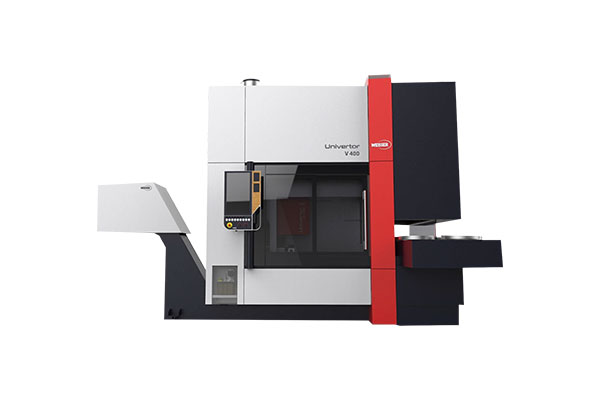

VERTOR C/M

- VERTOR C & VERTOR M

The machines of the Vertor C and M series are ideally suited for wet and dry machining of all common rotation-symmetrical workpieces with the highest precision, availability and continuous accuracy. The machines have very good accessibility with minimum space requirements and also offer the option for two or four axes. Technology integration of innovative processes such as out-of-round turning, hard turning, grinding, drilling or milling result in a significant reduction of in-house logistics processes and create high-precision machining results. The multifunctional vertical turning machines are among the world’s best machine tools in their class in terms of operating speed, availability, stability and reliability.

GRINDING

- Hardinge has become a leader in grinding solutions with a product line encompassing Kellenberger, Voumard, Hauser, USACH, and more. With offerings across the capability spectrum, standard distance between centers of up to 63″, and special distance between centers of up to 200″, Hardinge is your partner for every grinding need.

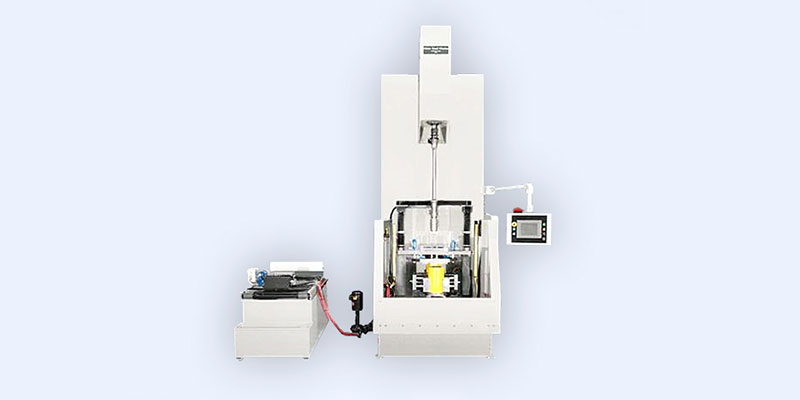

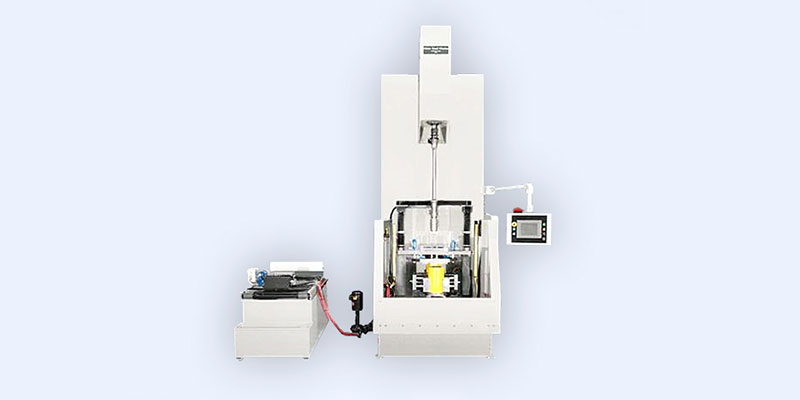

BOULEPRO 200

-

- X-Axis Travel 19.68” (500 mm)

- Z-Axis Travel 23.62” (600 mm)

The future of semiconductor manufacturing has arrived.

Currently the only machine of its kind, the BoulePro 200 allows for a much faster and cost-effective boule-to-puck conversion to meet the high demand for Silicon Carbide (SiC), a crucial semiconductor material. With its patent-pending Single-Step Dual-plane Compensation (SSDC), the BoulePro 200 takes what has traditionally been a multistage process performed on several machines and converts the process into a single-machine operation to dramatically improve efficiency and costs at every step.

KELLENBERGER® 10

-

- Distance between centers 1,000 mm (39.37in)

- Center height 200 mm (7.87in)

Efficient, modular, and precise

As a standardized machine, the KELLENBERGER® 10 is able to deliver a price-performance ratio yet to be matched. Combining proven components now updated according to the latest technology, with an intuitive programming surface, it creates a very capable base easily customizable by a range of optional equipment to the needs of the customer.

KELLENBERGER 100

-

- Distance between centers: 600mm / 1,000mm (23.62in / 39.37in)

- Center height: 200mm (7.87in)

A CNC Universal grinding machine with a choice of 10 wheel head versions

The KELLENBERGER® 100 universal CNC OD/ID grinding machine is a new, high-performance, and economical grinder for use across medium- to large-scale universal grinding applications. The Swiss-Made KELLENBERGER 100 grinding machine is highly configurable and offers a plethora of industry-leading options to accommodate the widest range of universal grinding operations across the semiconductors, aerospace, automotive, high-end tool and die industries, and beyond.

KELLENBERGER® 1000

-

- Distance between centers: 1000 / 1600mm (40 / 60in)

- Center height: 200 / 250 / 300mm (7.87 / 9.84 / 11.81in)

The ultimate expression of the Swiss ethos.

The KELLENBERGER 1000 universal CNC OD/ID grinding machine represents the ultimate expression of the Swiss ethos: a technical tour-de-force encompassing every facet that has come to define KELLENBERGER, a premium Hardinge brand, as the world leader in grinding design, precision, and quality. KELLENBERGER 1000’s clean, sleek, and modern design confidently relays its ability to handle the most demanding universal grinding tasks required for today’s rigorous manufacturing requirements.

VOUMARD® 30

-

- Max workpiece length: 300mm / 11.81in

- Swing diameter: <300mm / 11.81in

New grinding machine concept

The VOUMARD 30 internal grinding machine complements the internal grinding expertise of the Voumard brand with a machine for all industries whose main focus is on simple internal grinding operations in small and medium batch production. The VOUMARD 30 is designed for workpiece lengths up to 150 mm and diameters up to 150 mm.

VOUMARD® 1000

-

- Max workpiece length: 300mm / 11.81in

- Swing diameter: <300mm / 11.81in

The new standard in ID grinding

Introducing the VOUMARD® 1000 internal grinding machine, the new standard in ID Grinding. The innovative system improves the precision and productivity for the most demanding machining applications. A rigid base, hydrostatic guideways on all axis, and new user interface on our controls will deliver on your most challenging requirements. With its almost infinite configuration options for the widest range of grinding operations, the Voumard 1000 delivers an excellent price/performance ratio.

HAUSER™ 2000

-

- Range of adjustment X, Y, W: 550 x 300 x 450mm

- Clearance between table top and U-axis reception face grinding motors: 745mm max

Combining grinding and hard milling on a single jig grinder

The Hauser 2000 not only meets the demand of the market for combined grinding and hard milling on a single jig grinder, but also enables further improvements in machining precision to meet future requirements. The main technical feature is the dual-frame design, which significantly increases the rigidity of the grinder and therefore ensures even higher precision.

HAUSER™ H55

-

- Range of adjustment X , Y: 700×500mm (H45) / 1,300×800 (H55)

- Vertical adjustment of grinding head (W): 500mm (H45) / 635mm (H55)

Hauser 55: Technology to measure

Hauser 55: An expandable jig grinding machine, from simple bore and form grinding machine to fully automatic high-tech grinding cell

TSCHUDIN T35

-

- Distance between centers / Height of centers: Up to 400mm / 175mm

- Weight of workpieces: 150kg

The modular production cylindrical grinder

The Tschudin™ T35 is the modular cylindrical grinding machine for production, satisfying the most varied applications needs in the production of medium and large series. Hydrostatic guides and a large application range, from small integrated handling to complex systems with autonomous cells. The production machine offers synchronous processing, prism and rod grinding, and integration of additional operations.

USACH 75

-

The economical and flexible CNC ID / OD Grinder

The USACH 75 CNC cylindrical grinder delivers accuracy and power in a compact design for all production and/or universal small precision parts manufacturing where IDs, ODs and faces need grinding. This model is extremely flexible in handling a wide variety of workpieces for both job shops and high-production applications, especially where high-precision is required. The machine features an 8.5” swing diameter and handles parts up to 5” in length. The USACH 75 can be configured with up to three grinding spindles for maximum production capabilities and added flexibility.

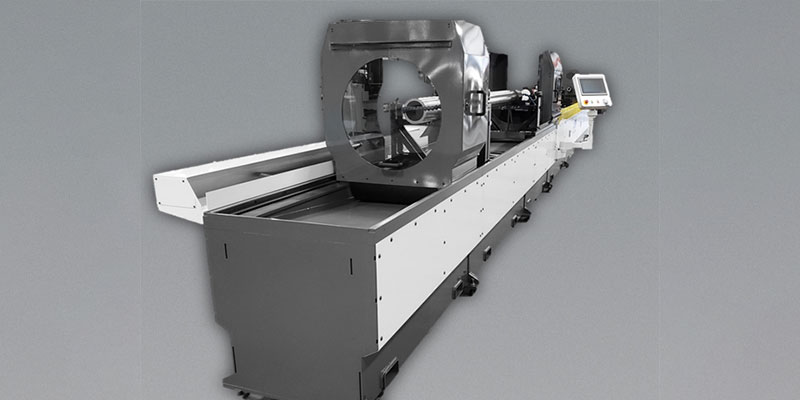

USACH OD GRINDERS

- OD machines can be configured for flexible or dedicated applications with single or multiple spindles.

100 OD for part lengths up to 20″ (500 mm).

150 OD for part lengths up to 47″ (1200 mm).

200 OD for part lengths up to 80″ (2000 mm).

300 OD for part lengths up to 138″ (3500 mm).

500 OD for part lengths up to 200″ (5000 mm).

OD machines can be configured for flexible or dedicated applications with single or multiple spindles.

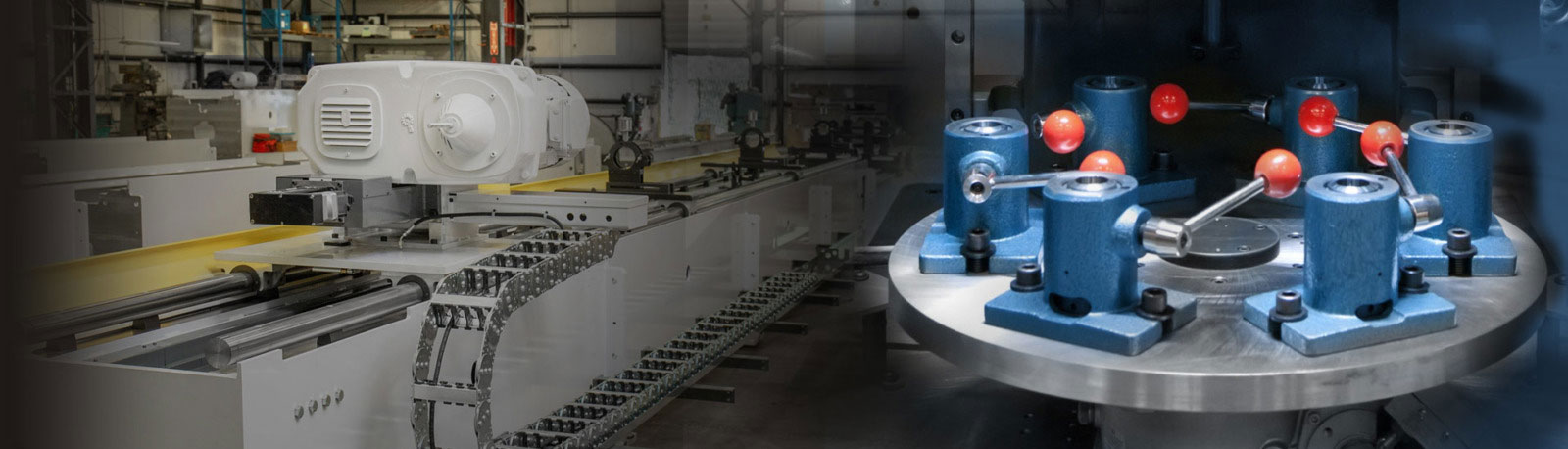

CUSTOM USACH OD AND ID/OD GRINDERS

Single-spindle for flexible or dedicated production applications

Usach Custom Solutions are a leader for advanced material manufacturing, including materials like ceramics, silicon, quartz and more. Usach has developed successful processes and applications to support the semiconductor industry and other related advanced material industries.

HONING

- Our vertical and horizontal honing machines and abrasives by Ohio Tool Works (OTW) are distinguished by industry expertise acquired over many years that has positioned us as a leader in the honing industry.

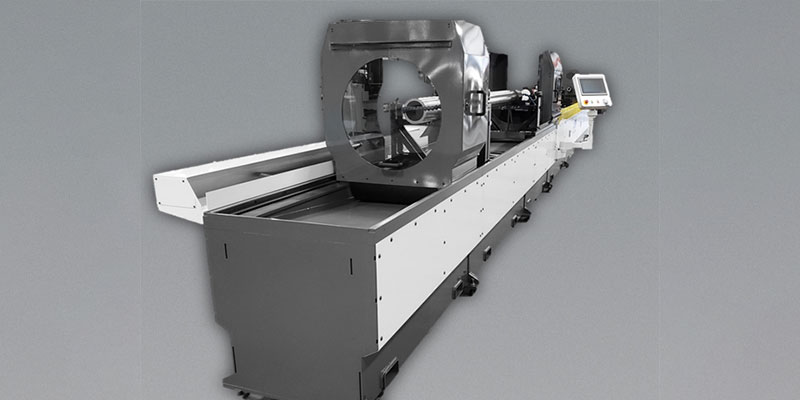

OTW HORIZONTAL HONING MACHINES

-

- ID Capacity Max* (UltraHone XL): 24.0”

610mm - OD Capacity* (UltraHone XL): 26.0”

660mm

Maximum flexibility, value and ease of use for companies seeking to produce a broad range of parts

OTW doesn’t sell machines, it sells solutions. With advanced honing application knowledge and engineering expertise, OTW has updated its lineup of horizontal tube honing machines to deliver technology that simplifies your production process, improves system monitoring and provides more power, precision, repeatability and feedback.

- ID Capacity Max* (UltraHone XL): 24.0”

OTW VERTICAL HONING MACHINES

-

- ID Capacity Max* (UltraHone Vertical XL): 24.0”

610mm - OD Capacity* (UltraHone Vertical XL): 26.0”

660mm

- ID Capacity Max* (UltraHone Vertical XL): 24.0”

OTW HONING OIL

-

Keep your honing machine running like-new for years to come with OTW honing oil.

OTW honing oils are specially formulated and tested to cool, flush, and optimize various honing operations. This oil contains elevated additive levels and higher viscosity to provide the ultimate boost to material removal rates, stone life, and bore finish.

HONING ABRASIVES

-

VITRIFIED ABRASIVES

Ohio Tool Works manufactures the honing industry’s highest quality line of standard, custom, and replacement vitrified honing abrasives designed to meet the needs of customers from any industry in the world. Whatever your application or production volume, we offer a complete line of conventional abrasive types, grades, sizes, and mounting configurations.

Workholding & Accessories

-

Pioneers of Workholding

Team up with Workholding brands Hardinge®, Forkardt™, and Buck Chuck™ to add value to your material-cutting processes and assembly operations.

Hardinge® Workholding & Accessories

-

Hardinge® Workholding is the leader in quality standard and custom collets. Over the years, we have expanded our collet and workholding options to satisfy a variety of applications and machine types.

Work with dedicated sales, design, and application engineers to solve difficult process problems, or choose your standard collet or step chuck knowing that quality and reliability comes with the Hardinge name. Experience value in longer lasting products, value in machine uptime, value in work-piece accuracy and value in your customer’s satisfaction.

Individual care goes to every workholding device at each manufacturing process, from handling the initial bar stock to polishing and laser etching. Generations of skilled-machine operators have taken part in the many critical processes of producing a hardened, precision-machined collet. Hardinge has been manufacturing workholding and industrial products for all brands of lathes, mills and grinding machines for over a century. Their process expertise, precision and accuracy provides a workholding product that is world-renowned.

C SERIES COLLETS - 1C, 3C, 4C, 5C, 16C, 20C & 25C

- Choose from a large inventory of 5C, 16C, 20C, 25C and 3J collets, FlexC vulcanized collet systems, emergency collets and step chucks, as well as B42 and B65 stationary collets. Let Hardinge solve your workholding problems such as hard-to-grip shapes and surfaces, part length control, thin-wall turning, etc. Hardinge supplies D-style, WW and 3C collets and step chucks for instrument lathes, turret lathes and micro-drilling machines for the medical, dental, electronic, watchmaking, model engineering and related industries.

FLEXC® COLLET SYSTEMS

- Replace your standard collet or 3-jaw chuck to ramp up productivity. When compared to a jaw chuck, the precision-engineered Hardinge® FlexC Collet Systems allow you to increase the spindle rpm without concern for centrifugal forces for faster setup, changeover, higher accuracy, and a wide gripping range for stock variation. Advanced cutting tools, along with higher feed rates and spindle speeds with our FlexC Collet Systems. Systems available for A2-5, A2-6, A2-8 and some flat-back CNC lathe spindles.

SWISS STYLE COLLETS AND GUIDE BUSHINGS

- Hardinge® Swiss-type Collets are ground to precise size and TIR to meet precision machining requirements with a standard accuracy that rivals the industry! Every collet and guide bushing is inspected on a Hardinge Super-Precision (.000015″ TIR) headstock before reaching the stockroom. Hardinge manufactures to Swiss quality, in the USA, for all brands of Swiss-style machines and cam-operated lathes. Hardinge round Swiss Guide Bushings are carbide-lined to keep the stock clean and unmarked. Hardinge manufactures bar feed collets for FMB, IMECA, LNS and Robobar bar feeders. Collets available for other brands on request. Hardinge offers a complete line of tool holders, tap holders, toolholder collets, tap collets and bushings that can be used on Swiss-type lathes. You’ll find reliable and economical solutions for back-end, sub-spindle and end-working slides.

SURE-GRIP® EXPANDING COLLETS

- Hardinge® Sure-Grip® Expanding Collet Systems offer solutions to difficult machining problems for turning, milling, grinding, assembly and automation applications. Hardinge is the expert when it comes to exact part length control, patenting the first Dead-Length 5C and 16C collets used for high-production manufacturing. Our Sure-Grip Expanding Collet Systems have true part length control built into its double-angle design, assuring exact workpiece lengths by locating the part against the face of the arbor or against a machineable work stop. The collet draws the workpiece firmly against the stop, producing an extremely stable part. The results are heavier cuts, better surface finishes, and closer tolerances. Long parts can be easily machined due to this added stability. Sure-Grip Collets can be custom manufactured for special applications for spindles, sub-spindles and mill tables. Pick-off collets are frequently engineered for Swiss and multi-spindle machines. Splined or serrated surfaces can be made for special grips and shapes, while recessed draw-plug styles might solve your short gripping problem.

HCAC COLLET ADAPTATION CHUCKS

- Hardinge® HCAC Collet Chucks offer collet capability for higher precision and accuracy when you need it. Increase productivity, capability and control when compared to 3-Jaw chucks. HCAC Collect Chucks offer faster job changeover at higher spindle speeds for reduced cycle times. Achieve higher precision and improved concentricity for optimum part roundness. Available in 42, 65 and 90mm sizes for A2-5, A2-6 and A2-8 spindle noses.

COLLET BLOCKS

- Hardinge® provides an extensive line of collet blocks that can be used for milling, drilling, grinding, crimping, inspection, testing and assembly applications. Collet blocks can be used vertically or horizontally on mill tables, flat or angled fixture plates, tombstones or rotary trunnions. Sizes are available from the 1C micro medical manufacturing needs up to the 35J mid-range for applications in the automotive and aerospace industries. Purchase individual components to build our own pneumatic or hydraulic system, or let Hardinge configure a complete turnkey package for you.

STYLE S MASTERS AND PADS

- The Style “S” master collets and pads overcome all the problems associated with master collets. When loading bars, the rugged shoulder of the pad locates against the front of the groove in the master collet. There are no set screws or clamps to be damaged or loosened. When a part is machined, the working forces are against the rear shoulder of the pad which is located against the rear shoulder of the groove in the master collet. Again, there are no screws or clamps to wear or break. The clamp which holds the pads captivated in the collet literally floats longitudinally, assuring that there is never any pressure on the clamp. There are no holes in the OD of the master collet, or on the ID of the pads, resulting in maximum bearing on the workpiece and the spindle collet seat. When Style “S” collets are used, there will never be high spots on the spindle collet seat caused by the master collet and pad design. When selecting master collets from this catalog, remember the Style “S” design has been in existence for over 50 years and is the preferred system.

STYLE B MASTERS AND PADS

-

Style “B” master feed finger pads are uniquely designed and proven by over fifty years of use in the machine tool industry. The straight-forward design allows for full bearing of the pad ID on the workpiece. There are no screws or tabs to wear, or to remove bearing area from the pads ID. The master feed fingers are spring tempered to the proper gripping tension for maximum longevity. Custom master feed fingers can be easily and quickly manufactured at Hardinge to give extremely light grip, or heavier grip for nonstandard applications. The use of Style “B” master feed fingers will assure you of minimum downtime on your production floor.

Hardinge Style “B” feed fingers and pads are the most practical feed fingers for high production bar machining. Designed and manufactured to be the most reliable on the market today, they offer many advantages over other styles.

TOOLHOLDER COLLETS AND BUSHINGS

- When it comes to tool holding, value is all about precision and reliability. Hardinge® Toolholder collets, bushings and toolholders are designed and engineered for quality and durability. Hardinge’s standard of performance level is high to help you achieve the level of accuracy required for automotive, medical, aerospace and the electronic industries. Hardinge is committed to being your SINGLE SOURCE for all of your workholding and industrial products. Well known for high accuracy and precision, Hardinge can provide any gripping solution needed.

HQC QUICK CHANGE SYSTEMS FOR LATHES AND AUTOMATICS

- Hardinge® HQC Quick-Change collets can be changed from one size to another in less than 20 seconds. The HQC System requires less draw bar force to adequately grip the bar, greatly reducing the breakage of closing fingers and pins common when the bar varies beyond the range of a standard solid collet or master collet with pads. Eliminating the need to change collets due to normal variations in bar stock, greatly reduces the downtime normally required. Since solid collets and master collets are of a one-piece construction, considerable force is required to flex the leaves of a solid collet and bring the gripping surface in contact with the workpiece OD. Because there are no leaves in the HQC system, additional gripping pressure is directly applied to the workpiece. Higher feed rates and higher spindle speeds are possible. Because of the extra gripping force, tool life increases and parts come off the machine quicker.

CAPSULE COLLETS

- Hardinge, a global designer and manufacturer of machine tools and advanced workholding products, has been producing capsule collets for the world’s leading capsule manufacturers for the past 50 years. These partnerships have resulted in state-of-the-art collets for the production of capsule bodies and caps in sizes of #00, 0, 1, 2, 3, 4 and 5. Hardinge precision, hardened and ground collets assure reliability and long life for the medical and pharmaceutical industries. A polished radius nose on the collet reduces friction and eliminates marketing, while allowing you to take full advantage of your production capabilities with reduced downtime. Collets are 4-split or 3-split, depending on size. Hardinge also designs and manufactures custom gripping devices for turning, milling, grinding, process and assembly applications.

SCREW MACHINE COLLETS AND TOOLING

- Choose from a large inventory of 5C, 16C, 20C, 25C and 3J collets, FlexC vulcanized collet systems, emergency collets and step chucks, as well as B42 and B65 stationary collets. Let Hardinge solve your workholding problems such as hard-to-grip shapes and surfaces, part length control, thin-wall turning, etc. Hardinge supplies D-style, WW and 3C collets and step chucks for instrument lathes, turret lathes and micro-drilling machines for the medical, dental, electronic, watchmaking, model engineering and related industries.

HYDROMAT

- Hardinge offers collets for the following Hydromat Rotary Transfer Machines: HW/25-12, HB/32-16, HB32/45-16, HB/45-12 and Pro20. Round fractional, metric, hexagon and square collets are available in standard sizes up to the maximum capacity of the collet and machine tool. The cross-corner dimension of the hexagon and square hole cannot exceed the maximum bore diameter for the specific collet. Stepped hole collets are available to machine capacity.

R8 COLLETS

-

Hardinge R8 collets are the result of over 100 years of experience in serving the needs of the machining industry. The Hardinge R8 collet is manufactured to exacting standards from special alloy steel. All Hardinge R8 collets are a solid one piece design, hardened and spring tempered to assure accuracy and durability.

Precision R8 Collets for manual and CNC milling machines are carburized and case hardened for maximum wearability and strength. They are harder than any other R8 collet on the market. A custom process is used to eliminate the use of bushings for the internal draw threads.

Buck Chuck™

- Buck Chuck™ provides the benchmark in manual chucks as well as power precision chucks. Chucks come in a variety of sizes and styles and are ideal for replacement of OEM manual and power chucks. Buck Chuck also offers hard and soft jaws, replacement seal kits and wear parts.

SCROLL CHUCKS

-

Scroll Chucks offer dead true precision and guarantee .0005” repeatability on duplicate parts. This precision comes from a built-in .020” clearance between the chuck body cavity and the mounting plate hub. This allows opposing screws ample movement to adjust work accurately.

This adjustment takes less than a minute, and no further adjustment is needed to get precision within .0005” TIR on duplicate parts.

INDEPENDENT CHUCK

-

The Buck Chuck model independent chucks provide rugged versatility and a quick change jaw system. The independent jaws can be adjusted individually, making the PSA ideal for both cylindrical and irregular shaped workpieces. The spindle housing and jaws are made from hardened steel, guaranteeing a long service life and high precision.

The jaws are made according to American Standard Tongue and Groove and are equipped with a quickchange jaw system. The base jaws are divided with a thread for the adjustable spindle and stepped reversible top jaws. To turn the top jaw on the base jaw, simply release the jaw mounting bolt.

POWER CHUCKS

-

The Buck Chuck power chucks provide a high precision, universal application chuck that is suited for practically all turning applications. The lightweight design allows for faster speeds, which combined with the optional quick change jaw system makes an excellent choice for decreasing machine cycle times while saving energy and spindle wear.

They feature a higher clamping force and higher precision especially suited for heavy duty machining of disk and bar components as well as high precision finish machining of easily deformed workpieces. The jaw selections available are compatible with the industry standards in the US, Europe and Asia, making top tooling purchases simple and economical.