vargus

Videos

Loading the player ...

- Offer Profile

-

VARGUS Ltd. is a world-leading developer, manufacturer and supplier of high-quality precision threading, grooving, turning and hand deburring tools for the metalworking and plastics industries.

Established in 1960 in Nahariya, Israel, VARGUS is the tooling division of the NEUMO Ehrenberg Group, one of Europe's largest privately owned manufacturers and distributors of stainless steel products and metal cutting tools.

Product Portfolio

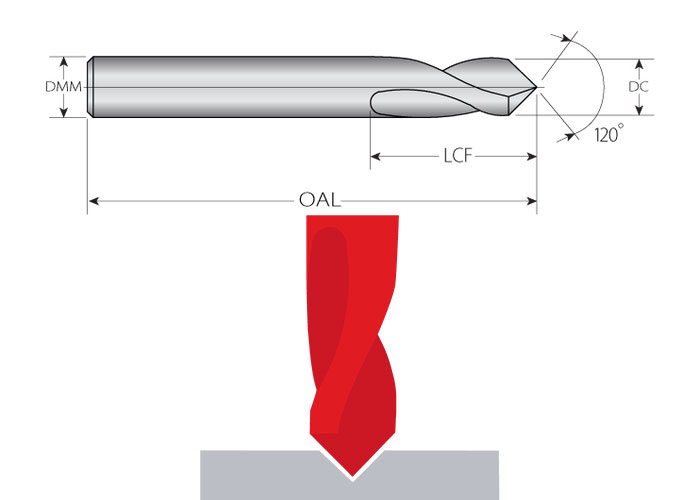

Redefining Precision in Milling and Drilling Solutions

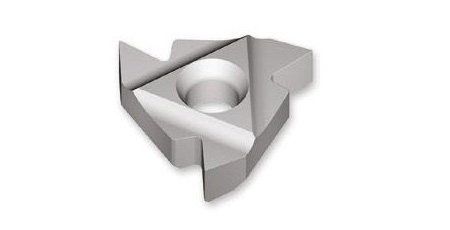

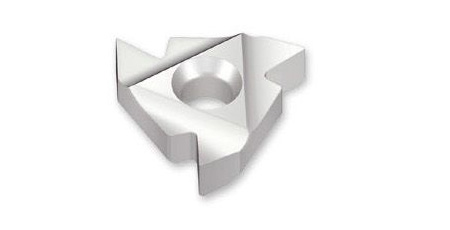

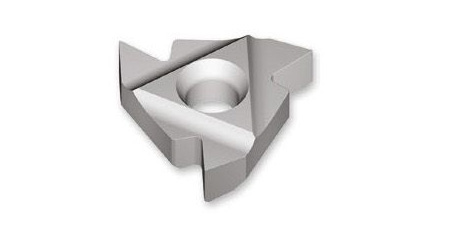

Threading

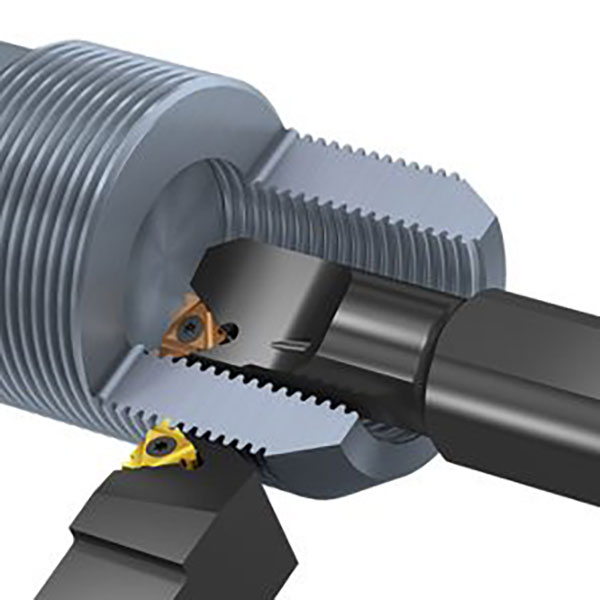

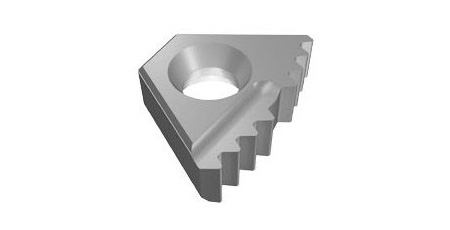

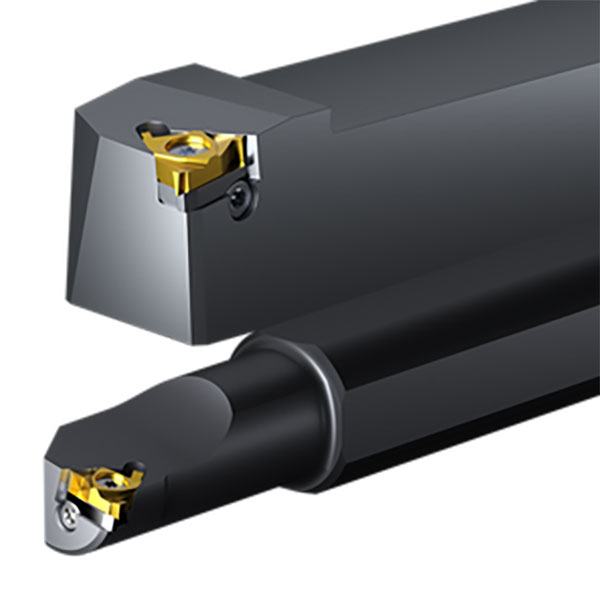

Thread Turning External

-

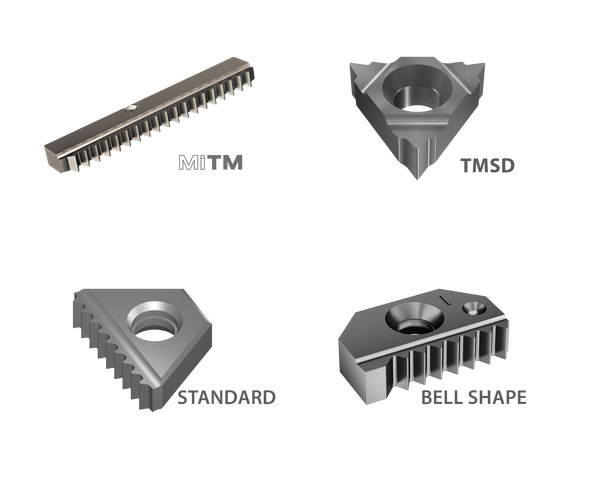

- Inserts and Toolholders

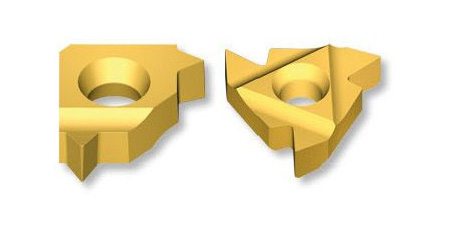

Thread Milling External

-

- Inserts, Toolholders and Solid Carbide

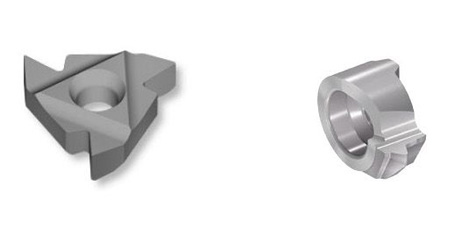

Whirling External

-

- Whirling Inserts and Whirling Holders

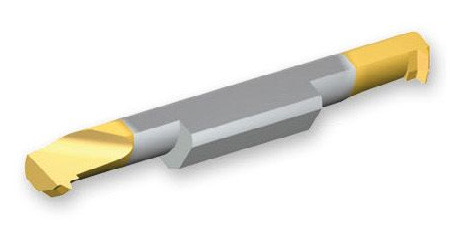

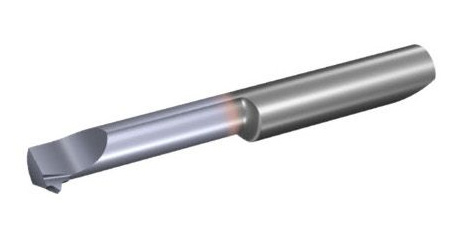

Threading Turning Internal

-

- Inserts and Toolholders

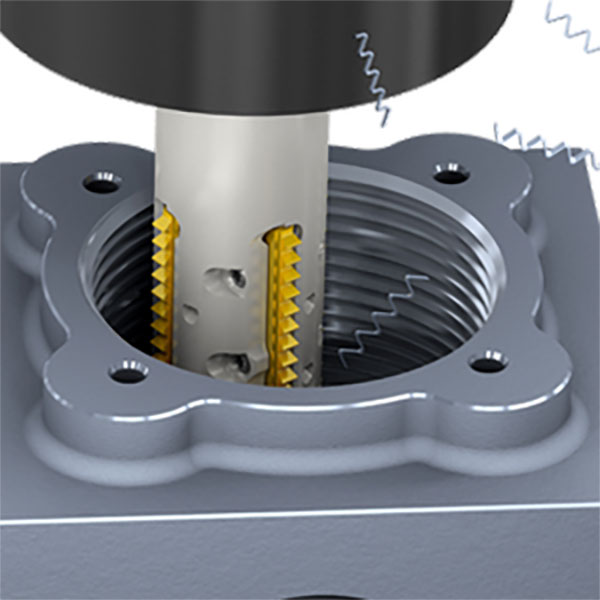

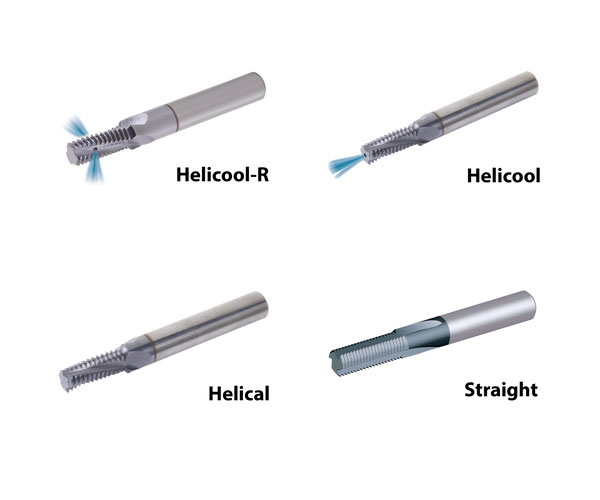

Thread Milling Internal

-

- Inserts, Toolholders and Solid Carbide

Tapping

-

- Cold Forming, Straight Flute, spiral Flute and Straight flute with Spiral Point

Thread Gauges

-

- Thread Gaguges External/Internal

Spare Parts

-

- Spare Parts for Thread Milling/Turning

Groove-Turn

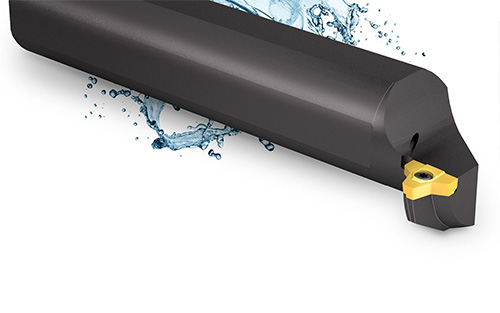

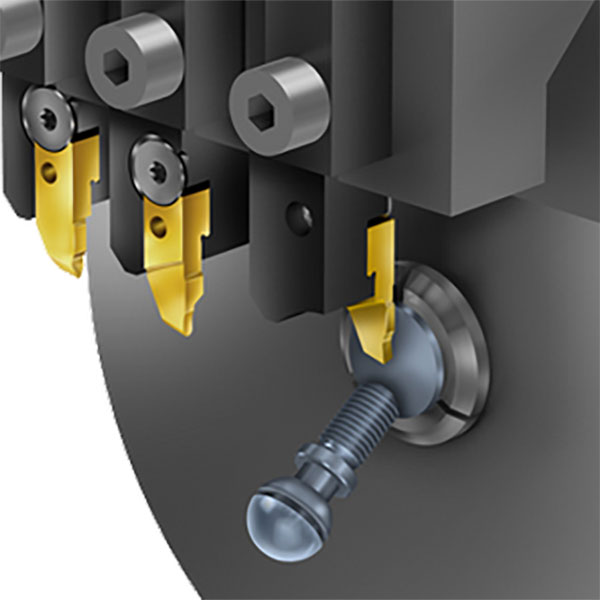

Groove Turning External

-

- Inserts and Holders

Grooving External

-

- Inserts and Holders

Parting Off External

-

- Inserts and Holders

Profiling External

-

- Inserts and Holders

Threading External

-

- Inserts and Holders

Undercat External

-

- Inserts and Holders

Internal

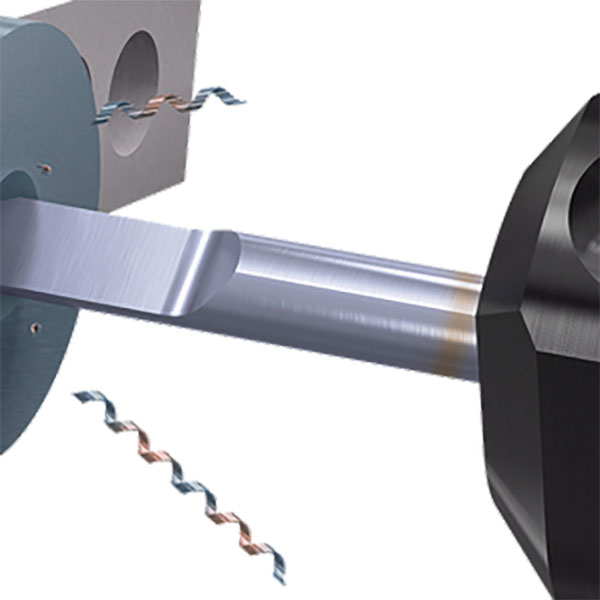

Boring

-

- Inserts and Holders

Grooving

-

- Inserts and Holders

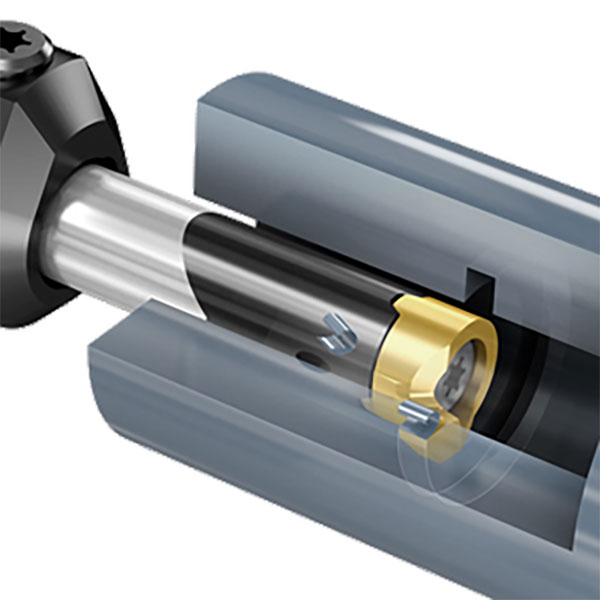

Profiling

-

- Inserts and Holders

Pre-Part Off

-

- Inserts and Holders

Chamfering

-

- Inserts and Holders

Threading

-

- Inserts and Holders

Face Grooving External

-

- Inserts and Holders

Face Grooving Internal

-

- Inserts and Holders

Broaching

-

- Inserts and Holders

Turning

Back Turning

-

- Inserts and Holders

Front Turning

-

- Inserts and Holders

Groove and Turn

-

- Inserts and Holders

Parting off

-

- Inserts and Holders

Square Grooving

-

- Inserts and Holders

Round Grooving

-

- Inserts and Holders

Milling - Solid Carbide End Mills

Slot Milling

-

- Inserts and Holders

Shoulder Milling

-

- Inserts and Holders

Profiling Millling

-

- Inserts and Holders

Trochoidal Milling

-

- Inserts and Holders

Helical Interpolation

-

- Inserts and Holders

Ramping

-

- Inserts and Holders

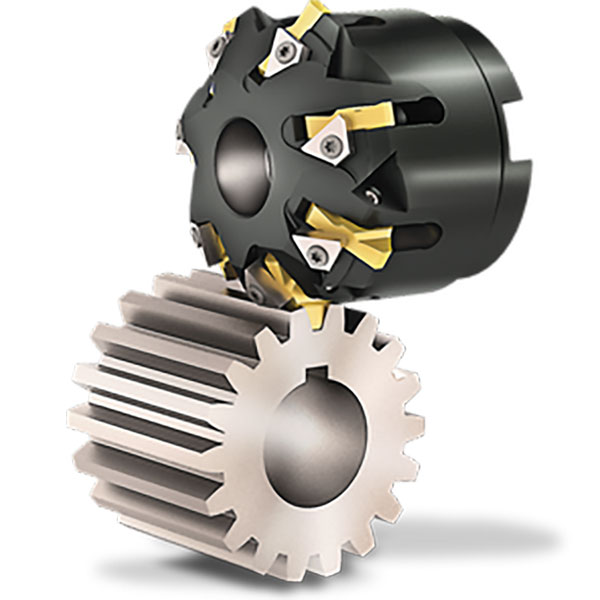

Gear Milling

Groove Milling

Holemaking

Shaviv: Industrial Deburring Solutions

- SHAVIV is a world leader in hand-deburring solutions for a wide range of metal, plastic and wood materials.

SHAVIV - Sets and kits

-

SHAVIV blades, holders and handles are available as individual components or in combination of sets and kits.

- Sets

- Professional Kits

- Premium Kits

- GloBurrization

Blades

Holders

Handles

Kits

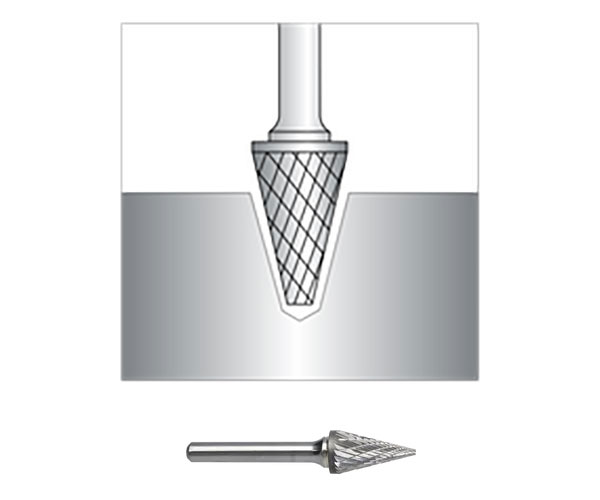

SV-Burr - Carbide Burrs by Shaviv

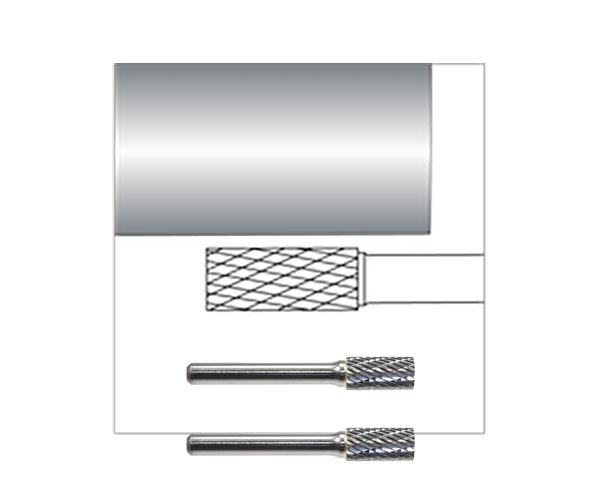

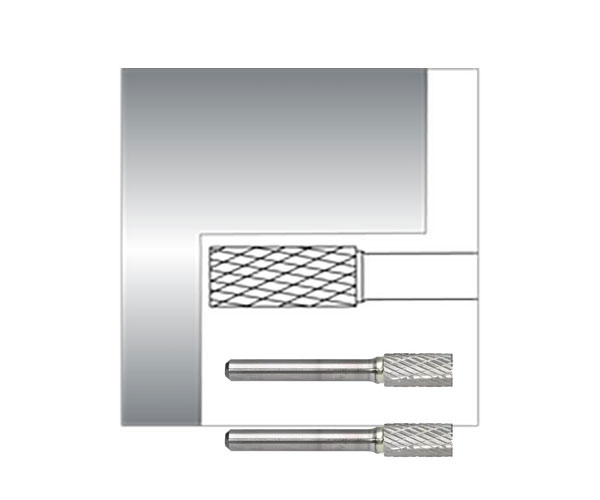

SA - Cylindrical Shape Burrs without End Cut

SB - Cylindrical Shape with End Cut Burrs

SC - Radius Cylindrical Shape Burrs

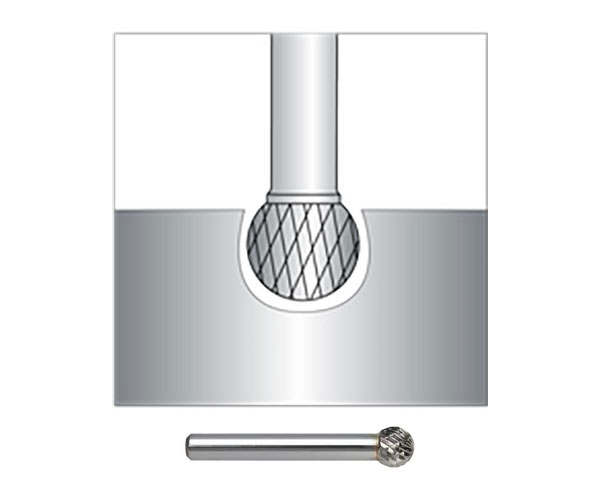

SD - Ball Shape Burrs

SE - Oval Shape Burrs

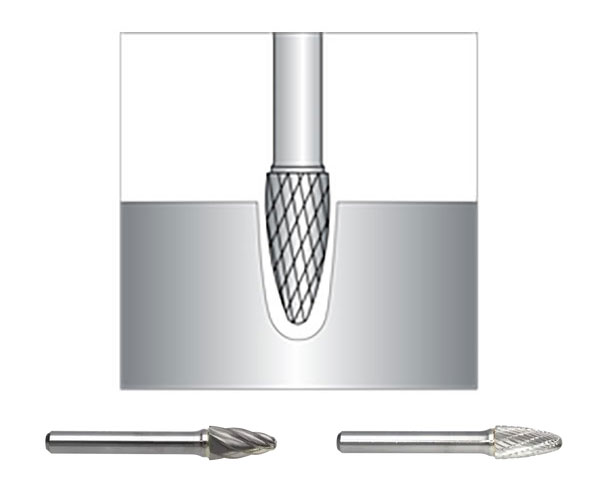

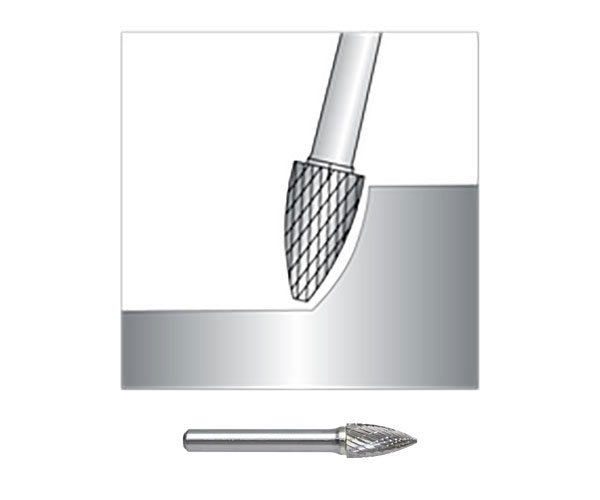

SF - Radius Tree Shape Burrs

SG - Pointed Tree Shape Burrs

SH - Flame Shape Burrs

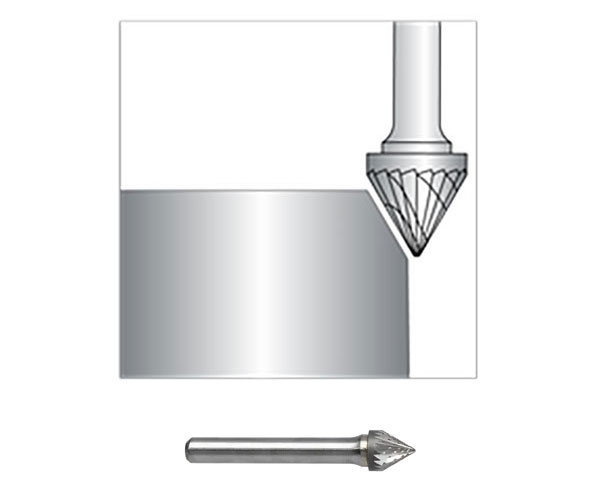

SJ - 60° Cone Shape Burrs

SK - 90° Cone Shape Burrs

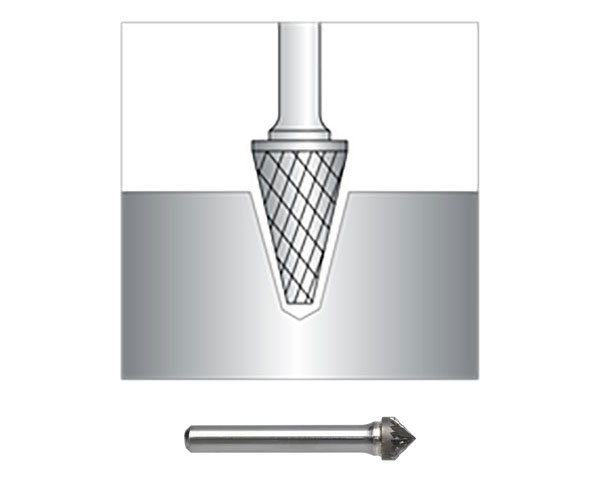

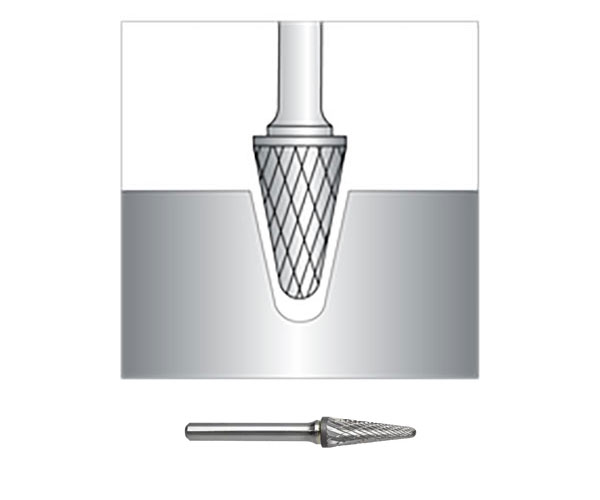

SL - Radius Cone Shape Burrs

SM - Pointed Cone Shape Burrs