- Offer Profile

-

High-tech from heimatec precision tools and systems for productive turning and milling operations

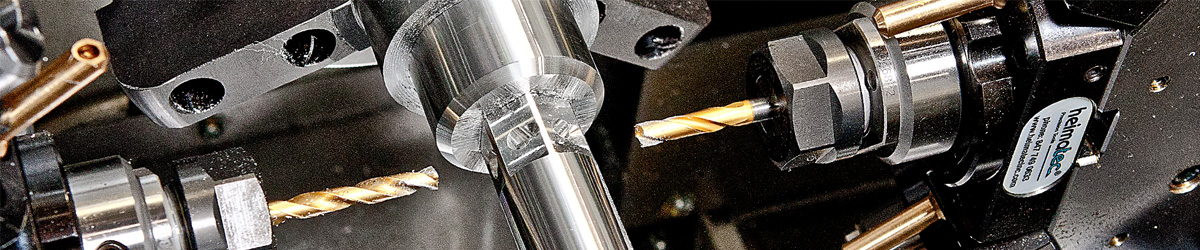

heimatec belongs to the international technology and quality leaders for precision tools and specializes in the development and production of high-precision static and driven tools for all CNC lathes, CNC turn-/mill machines and CNC machining centers. The range of products spans from static BMT and VDI tool holders, driven tools up to highly complex customer-specific individual solutions.

Tools for turning centers

Complete program for static and driven tools for turning machines and turning centers

For turning centers and turning machines of all well-known manufacturers, heimatec offers the specialist a broad range of driven tools and secure holders. In addition to axial and radial construction forms, heimatec has available multi-spindle machines, high- speed tools, universal heads and broaching units. We are furthermore in the position to design and manufacture tools to meet any customer-specific requirement. In addition, heimatec offers a comprehensive accessory range.

Accessory tools for turning centers

A range is only complete, if the necessary accessories are also available. heimatec offers for turning centers and machining centers a comprehensive accessory range, such as:- Bar pullers

- Reducing sleeves

- Collet chucks

- Collets

- Sealing disks

- Shrink collets

- Tapping collets

- Clamping nuts

- Milling arbor spacers

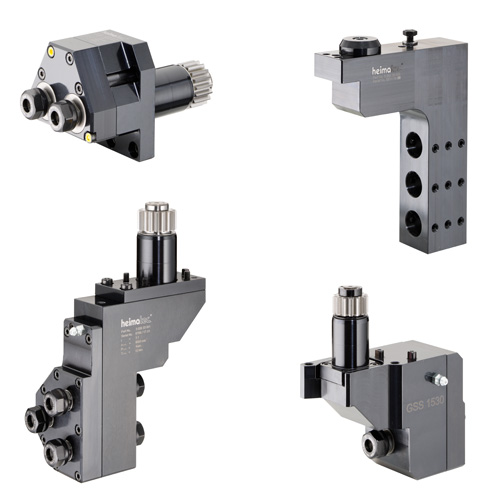

Driven tools for turning centers

Maximum productivity and performance with driven tools for turning centers from heimatec

heimatec has more than 30 years of comprehensive experience in the development and manufacture of driven tools. In this respect, we offer the widest range in the sector. Equipped with superior bearing technology, heimatecs power tools distinguish themselves to the maximum degree in terms of performance, as well as maximum longevity.

Standard program with multiple kinds of tooling units

Our tools may be applied in CNC machining centers as well as turn-mill centers of all well-known manufacturers. In the context of our standard program, we have a wide-ranging offer of axial and angled tooling units and swivel units, which are available in different versions. For special applications, heimatec offers customer-specific individual solutions.

heimatecs driven tools may be used with all current tool holders. heimatecs tools are equipped with different drives and particular to the relevant machine, such as bevel gear, splined shaft profile according to DIN 5480, DIN 5482, TOEM, flat-drive/or two flat DIN 1809, special couplings and further drive types.

Live tool unit, axial

Live tool unit, offset

Live tool unit, swiveling

Live tool unit, angled

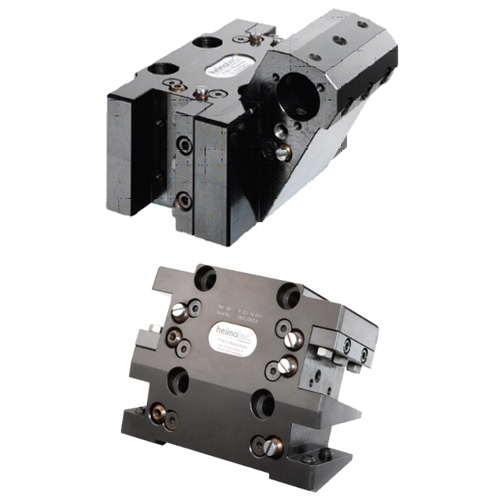

Static tools for turning centers

Static tools for cost-efficient turning

As one of the leading manufacturers of precision tools, heimatec offers a massive choice of static tooling units for turning centers.The range is available with standard VDI, as well as BMT interfaces and includes among others:

- Boring bar holders

- Turning holders

- Bar pullers

- Cut-off holders

In addition, heimatec has a wide-ranging program of machine-related solutions for practically all well-known manufacturers. Further to standard holders, heimatec holds a large range of special tools and accessory components for commercial turning.

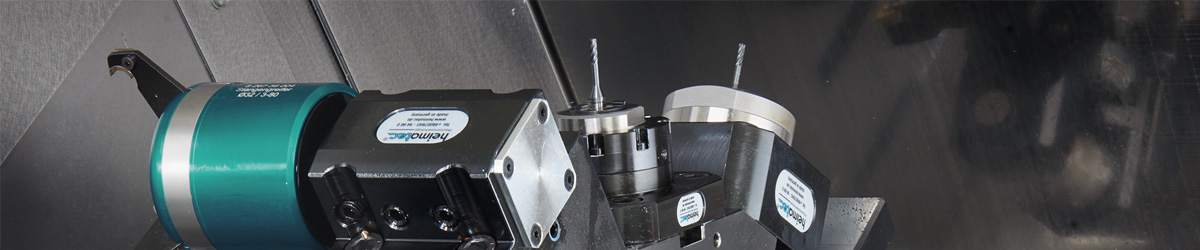

Multi-spindle heads and high-speed tools

For high performance and large runs - Multi-spindle machines and high speed tools

For highly productive processing on turning centers, multi-spindle tools are today indispensable, as with them processing with multiple tools on one machine is equally as viable as multiple processing on one workpiece. heimatec offers a wide selection of multi-spindle tools, which come in standard, as well as customer-specific configurations, in addition to internal and external coolant supply versions.

High-Speed tools from heimatec

Program of special tools

High-speed tools come into play, if the main spindle speed of machines are too low to reach guaranteed optimum cutting speed. The High-Speed tools from heimatec permit a ratio of up to 1:4 at 24,000 rpm. Speed reduction for torque increase are also available from heimatec.

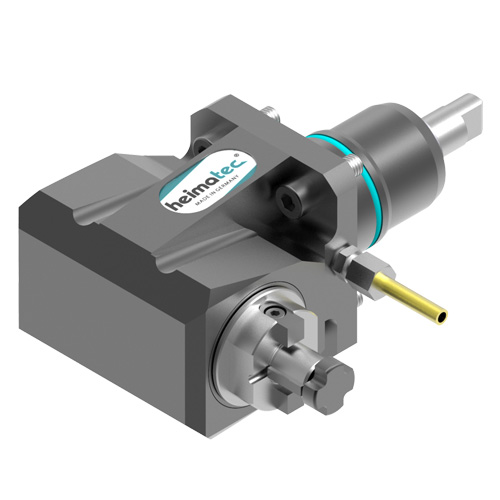

The program of individual special tools from heimatec is even more comprehensive and also includes:- Tools with minimum lubrication

- Tools able to be connected to the central lubrication of the machine

- Tools that have an air purge seal

- Tooling units for grinding

Tools for swiss type lathes

heimatec.SwissTooling - the complete tooling program for swiss type lathes

Specially for swiss type lathes, the new heimatec.Swiss Tooling has a complete tooling program available. Optimally coordinated with the necessary mechanical parameters, users of swiss type lathes may use the tooling standard system from the specialist, heimatec.

heimatec.SwissTooling for the manufacture of precise and affordable turned parts

Originally developed for the manufacture of precision parts for the watch industry in Switzerland, swiss type lathes are being applied everywhere, where large batches of high precision and efficiency are being manufactured. On such machines automotive components are being made, for example, or screws and pins for medical technology, as well as precision parts for electrical engineering. For this worldwide machine maintenance, heimatec offers a comprehensive range of static and driven tools. During the development of heimatec.SwissTooling, there occurred an optimal alignment of machine requirements, as well as a precise configuration of the specific mechanical parameters.Tools for swiss type lathes

-

Considerable longevity and great workmanship from heimatec.SwissTooling

The SwissTooling tooling program from heimatec distinguishes itself with considerable longevity, as well as the highest workmanship. In this, heimatec insists on the best possible spindle bearing technology and ground gear components. Additionally, housings and spindles have the maximum possible rigidity. Among all the advantages of the heimatec.SwissTooling product group, user-friendliness was given the highest priority. Completing the standard program for heimatec.SwissToolings tools, special tools and specialist solutions have also been developed and the experiences of users integrated into them.Advantages of the heimatec.SwissTooling tool program

Users of swiss type lathes can gain a range of advantages from heimatec.SwissTooling, such as:- Comprehensive standard program of driven precision tools

- Optimal coordination with machines parameters

- Special and specialist solutions according to customers wishes

- Diverse range of accessories

Tool change systems

Efficient and complete processing using flexible tool change systems

Today, workpieces generally need to be machined using multiple tools, which in turn means that tool changes are required during the machining process. To keep the machines retooling and setup times as short as possible, the application of quick-change systems has been introduced. heimatec offers a wide spectrum of tool holders and tool changing systems.heimatec.u-tec® Universal Changing System

Flexible system for collet chuck holders according to DIN 6499

Efficient manufacture is made significantly easier in two ways. If machine downtimes can be reduced, the productive time thereby increases automatically. By using flexible universal tools, the tool inventory can also be reduced, and costs saved as a result. heimatec developed the flexible heimatec.u-tec® tool change system for this purpose, which is established in the market for many years, and allows machining companies to utilize different adapters for a wide variety of machining tasks.

The driven heimatec.u-tec® tools are designed with a collect chuck according to DIN 6499, which allows the user to use the driven tools without additional tool adapters.

As an option, different changer inserts with standard tool change inserts such as Weldon, Kombidorn, collect chuck (including extended) or customer-specific tool change inserts can be used in the heimatec.u-tec® tools. With the heimatec.u-tec® system, a cylindrical polygon is positioned in the tool spindles behind the collect chuck cone.

This design enables huge force transfer during the machining process. The goal of the engineers was to find a sweet spot, where on one hand load steps are avoided, but on the other hand high force transmission is possible.

The tools fitted with u-tec® are supplied with a conventional clamping nut. This must be removed before inserting the tool change inserts. The u-tec® tool change inserts also have a cylindrical polygon after the collet chuck cone and are supplied as a unit with an integrated clamping nut. The tool change inserts can therefore be inserted directly into the standard u-tec® tool.

u-tec® Tool changing system

- Operating principle of the u-tec® Changing System

When doing so, slight turning of the polygon of the tool change insert allows it to locate the tool spindle polygon. There is no chance of incorrect operation, because the clamping nut of the tool change inserts can only be screwed in after the polygons are located correctly. Finally, the clamping nut is tightened in the tool spindle with the appropriate torque for the size.

The special feature of the heimatec u-tec® change system is the significant improvement to torque transmission while at the same time the strength and stiffness of the complete tool system is increased. The short mounting length is another special feature of u-tec®.

The associated short design length ensures exceptionally stable clamping of the cutting tool with low cantilever forces, leading to excellent machining results and a long service life of the cutters.

The preference for BMT tools with the u-tec® System are the driven tools with a so-called combined bearing, fitted with tapered roller and spindle bearings. Tapered bearings are able to transmit extremely high radial and axial forces. This bearing combination reduces the total heat generation compared with tools only fitted with tapered bearings. The service life is also substantially improved compared with tools which only have spindle bearings.

Quick-change of tools thanks to easy-quick HT

Tool changes faster by seconds with easy-quick HT from heimatec

heimatec developed the easy-quick HT series easy-quick especially for fast changes in the area of driven and static tools more than 20 years ago. This means different tool change inserts with market-standard tool adapters can be preset outside the machine and when required, can be simply, safely and quickly installed by the machine operator with just one hand. The machine downtimes are reduced significantly with the help of the easy-quick HT. The basic tools remain in the machine, so that little effort is required to install the preset tool change inserts.easy-quick HT quick-change system

- easy quick-change HT was the worlds first quick-change for driven tools from heimatec

Every easy-quick HT fast tool change insert is fitted with a locating pin, which prevents incorrect handling of the tool changing inserts. The design of the system provides high rigidity with the largest possible force transfer and highest precision. In addition, the overall tooling costs are reduced thanks to the multiple and flexible use of the easy-quick inserts. Custom tool adapters can also be implemented cost-effectively.

heimatec.Capto™ for tools with CAPTO holders

Greater efficiency during retooling and setup times with quick-change system, heimatec.Capto

With heimatec.Capto, a further modular quick-change system is available to its product range, which considerably improves efficiency during retooling and setup. heimatec.Capto is extremely flexible and offers wide modularity, as well as high availability of interchangeable inserts for turning machines and machining centers.

Advantages of the heimatec.Capto quick-change tooling system

For users of tools with Capto adapters, the heimatec.Capto quick-change tooling system offers a variety of advantages, such as:- Simplest handling and faster tool change

- Highest possible accuracy and stability

- High flexibility from wide modularity

- Minimization of retooling costs

- Pinpoint cooling from internal coolant supply

heimatec.Capto quick-change system

-

Wide range of heimatec.Capto standard and specialist tools

Coromant Capto® is an internationally distributed, modular fast change tool system, which can be used in all machine types. The special advantage is the substantial reduction of the retooling and setup times, whilst retaining high tool flexibility. With heimatec.Capto, heimatec is extending its range of modular, quick-change tool systems. As well as a wide range of standard tools with Capto® adapters, the heimatec.Capto program also offers a multitude of specific tool adapters with machine-optimized designs.The modular heimatec.Capto quick-change system has a compact design with short projection lengths, which allows high cutting speeds to be achieved with the greatest possible tool flexibility. The heimatec.Capto fast change tool system is available for Capto sizes C3, C4, C5, C6 and C8. heimatec only uses original Capto® components from the Sandvik company.

Quick-change system with heimatec.u-tec CKB

New adapter program for precision boring heads from the specialists at heimatec

Users of precision boring heads can employ the comprehensive adaptation solutions from heimatec. Adapters from heimatec are available for all common tool sizes, which can be applied in connection with the Universal Changing System heimatec.u-tec® for highly accurate processing on machining centers.

Comprehensive spare part offer from heimatec.u-tec® CKB

heimatecs product offering holds a wide range of spare parts available for the heimatec.u-tec® CKB Changing System, such as:- Clamping nuts

- Snap rings

- Wrenches

- Allen wrenches

- Clamping screws

heimatec.u-tec® CKB quick-change system

- heimatec.u-tec® changing system for time-saving retooling

In order to enable time-saving retooling during turning, drill and milling, the heimatec.u-tec® changing system was developed. heimatec.u-tec® inserts consist of a tool holder in response to customers wishes and cone, corresponding to a collet chuck in accordance with DIN 6499. With the heimatec changing system, a cone was provided with a polygon at the end, which enables, that during machining operations, an enormously high force transfer can take place.

The heimatec.u-tec® changing system distinguishes itself further from a very short mounting length. The associated short design length ensures exceptionally stable clamping of the cutting tool with low cantilever forces, leading to excellent machining results as well as long tool life and thus enabling a rational, efficient and flexible machining. Manufacturing businesses, which implement precision boring heads, can now use them with the proven heimatec.u-tec® changing system. A wide range of adapters for boring tools in sizes CKB1 to CKB5 is now available from heimatec.

Tools for machining centers

Top performance during milling, boring, reaming and tapping on machining centers

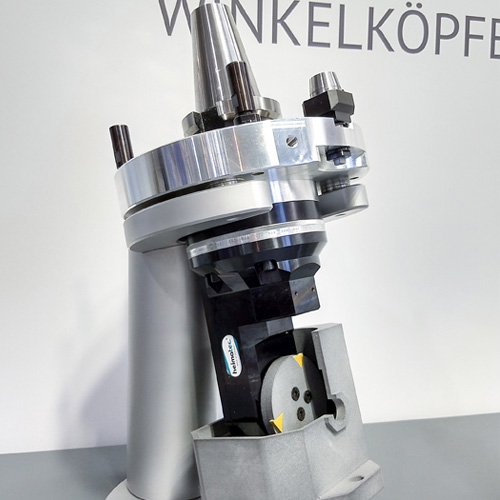

Designed for the most difficult manufacturing tasks, heimatec offers a comprehensive program for machining centers of standard and customer-specific precision tools. heimatec angle heads are available in standard 90° version, recessed and slim design as well as in dual-spindle and +/-90° adjustable versions. With heimatecs angle head tool program, full processing on machining centers is made possible.

The angled head tool program for full processing on machining centers

- All of our angled heads are mainly equipped with the heimatec u-tec® tool changing system, rotatable through 360° and compatible with industry standard machining centers.

Especially matched, the tools are also suitable for automatic tool changers.

High-performance slim design range from heimatec

- In addition to a comprehensive program of standard angled heads, heimatec offers a compact, high-performance slim design range, which has been specially developed for difficult contours and is ideal for small immersion diameters and large immersion depths:

- Smallest immersion diameter Ø 12.0mm

- Available with or without splash splash guard

- Comprehensive standard program in longer and shorter versions, as well as customer-specific component solutions

- High-performance high-speed tools with a rotational speed of 20,000 rpm

- BAZ Slim

Inside operation on housing parts of machining centers

- Inside working on housing parts, such as the bearing seats for hydraulic pumps or hydraulic engines, sets high demands on tool units. The new heimatec.Cradle tool is a revolutionary tool system, which has been developed for high-precision inside operation on machining centers. Using the foundation of proven heimatec angled heads, the housing of the cradle tool unit is individually adapted to the geometry of the pump housing. In this way, the maximum rigidity of the tool system can be assured and as a direct result, precision processing may be achieved.

As in these special processing situations, the implementation of quick-change systems is generally not worthwhile, heimatec has implemented a specific interface for milling tools, in order to achieve the best processing results. So a powerful transmission ensures optimal torque transfer with maximum smooth running, as well as a support adapted for the machinery for the best possible transfer of processing power. Via both of these design attributes, high-performance processing may be assured with minimum vibration behavior. For efficient and reliable dissipation of heat caused by processing and shavings, the Cradle tool unit from heimatec offers either an external or an internal coolant supply.

Furthermore, heimatecs engineers have also given thought to the efficiency of the entire manufacturing process. As via individual adjustments, automatic tool changes for the machinery can also be used in most cases. Should this option not exist, with the heimatec Pickup-Station a custom solution is available, assuring storage place inside the machinery and thereby maximum process automation.

Technologies

Gear production - Power Skiving

-

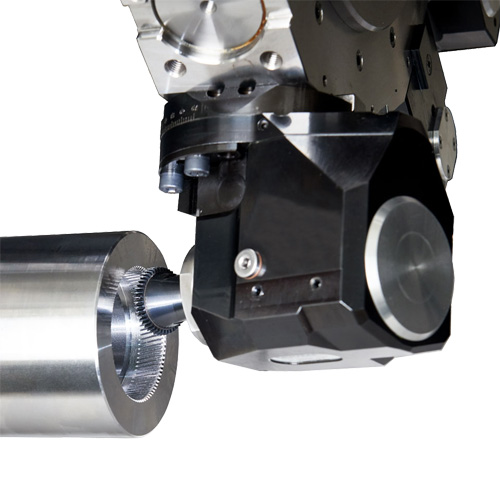

Productive gear production with heimatec.Skiving

Gear skiving, a combination of gear hobbing and gear shaping, allows teeth to be machined in the most productive and high-quality method on turning centers for volume production. heimatec.Skiving is an innovative extension to our comprehensive tool program. The particular advantage of the Power Skiving process is the high machining speed, which allows teeth to be manufactured in a highly productive way and at least three times quicker than with the typical industry standard machining processes.

New family of tools for gear production with heimatec Power Skiving Owing to the combination of the most modern machining technology with innovative tool designs, it has become possible to implement long-established Power Skiving procedures commercially for series production. With heimatec.Skiving, heimatec has developed a new family of tools for gear manufacturing on turning centers, which permit the manufacture of high-quality internal and external gears in the same way as oblique and straight toothings.

Efficient tool handling with the heimatec.Skiving tool program To allow a wide range of machining capabilities, the heimatec.Skiving series tools are equipped with an angle adjustment of ± 45°. This ensures that the required working angle is continuously variable. The heimatec.Skiving tools are available with external or internal coolant supply. Efficient and user-friendly tool handling is ensured through the many available tool adapters, for example such as versions with standard collect chuck seats, heimatec.u-tec interface, hydraulic chuck and milling arbor adapters.

User-friendly tool design from the heimatec.Skiving tool family The new tool program from the heimatec.Skiving series was designed to be user-friendly and distinguishes itself through the following features:

- Maximum rigidity and concentricity

- Different tool holders are anticipated

- Standard collet holder

- heimatec.u-tec® changing system

- Milling arbor adapters

- Cutter arbor

- Angle adjustment of ± 45°

- Internal and external coolant supply

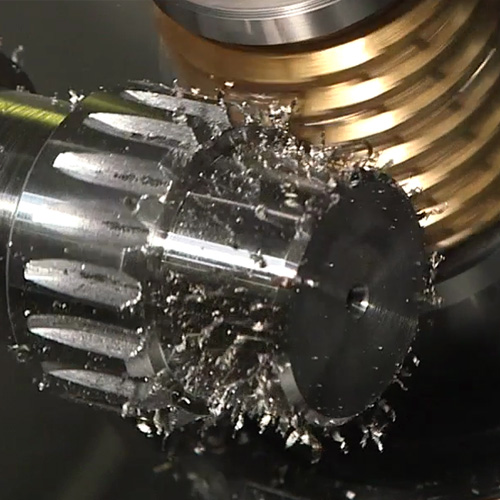

Gear production - Gear Hobbing

High precision manufacture of toothing on turning machines with heimatec.GearHobbing

The demands for the production of gears are huge. Connectors and gear wheels, for example, in businesses are safety-related parts and their manufacture demands the greatest precision. Using the steplessly adjustable, driven tooling unit from heimatec, toothing can be produced with the machining center with the greatest possible precision, maximum rigidity, retooling expenses and minimum operating costs.

Further characteristics of the gear cutters from heimatec:

Continuous manufacturing with the turning machine

With shaft-hub connections or gear teeth, industry needs and produces toothings of all kinds and in large quantities. In order to use machining centers as manufacturing systems optimally and thereby reduce the retooling and setup times, heimatec equips you with additional tools.

You can request that heimatec tooling units be provided with gear cutters, so that directly upon the tool revolver and/or the milling spindle of a turning machine, the gear cutting processing, the so-called Gear Hobbing can be carried out. An additional Gear Hobbing machine is unnecessary and the classic manufacturing process of impacting or milling may be dispensed with.

Cutting tools in the tooling unit are steplessly adjustable up to 360° - according to machine factors and gear geometry. In the designing of toothing, straight and oblique toothings, as well as worm shafts are possible. High stability and rigidity and thereby minimum vibration behavior are ensured and guarantee the highest possible precision and finish quality.- The tooling units are also available in slimline versions 2:1 or 3:1, whereby the torque is increased

- Toothing can be produced up to module 3 in the machining center

- Quality of toothing is possible from IT-6 to IT-10 - dependent on module, machine factors, materials and the cutting tool

Gear production - Fly Cutting

Fastest gear production in industrial series manufacturing from the heimatec.FlyCutting

Fly Cutting is the manufacturing process, that is particularly suited to large series, possibly in the automotive supply and electronics industry.

Fly Cutting is well-known for some time on machining centers and is successfully implemented there.

On turning centers, this manufacturing process is, however, still new and heimatec is the first manufacturer to offer tooling units for Fly Cutting on machining centers and thus enabling such highly-productive series manufacturing.

heimatec.FlyCutting processing is characterized by the best coordination of form and quality of toothing with the highest size accuracy. In connection with the quick-change system, easy-quick HT, with heimatec.FlyCutting quick tool change and thereby an efficient processing is made possible.“heimatec.FlyCutting is the fastest and so the most productive procedure for industrial series manufacture of toothing.“

Key Features of heimatec.FlyCutting:

- First series-capable tooling unit on the market for Fly Cutting on turning centers

- Extremely high dimensional accuracy and size accuracy

- In connection with the quick-change system, easy-quick HT enables highly-productive manufacture

Polygon milling

Production of polygonal surfaces with tool holders from heimatec

During polygon milling, through the implementation of polygon fly cutters, wrench flats can be created. Thereby, 2, 4, 6, or 8 sided surfaces, and also customized shapes are made possible. With the tool holders from heimatec for polygon milling, polygonal forms can be produced straight from the machining center.

High-Speed 1:4

-

For high performance and large quantities - High-speed spindles from heimatec

High-speed spindles are always used when the cutting speeds on a lathe are too low for machining. The high-speed tools from heimatec enable a gear ratio of up to 1:4 at 24,000 rpm. Reduction gears to increase torque are also available from heimatec.

- The program of individual special tools from heimatec is even more extensive and also includes:

- Tools with minimum quantity lubrication

- Tools that can be connected to the central lubrication system of the machine

- Tools that have a sealing air seal

- Tool units for grinding

Digital tool management

Process monitoring with heimatecs digital tool program

In order to achieve a higher productivity in the manufacturing process, critical tool parameters must be controlled and checked. Digitization now also enables process optimization with driven tools.

In this way, with heimatec.Sensoric, tool parameters, such as rotational speed, temperature and/or moisture level can be recorded and relayed to a monitoring station.

In the context of digital tool management, it is reviewed when the next servicing is required and which measures must be taken for it. heimatec.Sensoric is the foundation stone in a digital concept with a holistic approach. Further solutions are already in development and shall complete our digital tool management concept step by step.- Sensors are integrated into the driven tools from heimatec

- Tool data is transmitted to the monitoring station via Bluetooth

- Digital tool management concept with holistic application

Accessories

Wide range of spare and accessory parts

As much as possible from one reputable company - this is a strict requirement that we aim to satisfy with our wide range of spare and accessory parts. Users of precision tools can, because of heimatec, also obtain reducing sleeves, collets, collet chucks, sealing disks, clamping nuts and many other accessories and components.Service

Impressive service offering for comprehensive total care

Repair of original or competitors products

Precision tools are valuable working materials - therefore it has been our tenet at all times, not only to sell new products, but also to carry out repairs. Thereby tools entrusted to us are subject to a careful inspection upon receipt and then brought back into technically correct condition. We repair third party constructions as much as our own tools.Training and courses for optimal tool usage

So that our customer can use heimatecs precision tools comprehensively and over the long term, we offer training and courses at our Head Office in Renchen. Assembly of bearings and transmissions, maintenance of the internal tool cooling or the adjustment of couplings are topics of our practical training and courses.Wide range of spare and accessory parts

As much as possible from one reputable company - this is a strict requirement that we aim to satisfy with our wide range of spare and accessory parts. Users of precision tools can, because of heimatec, also obtain reducing sleeves, collets, collet chucks, sealing disks, clamping nuts and many other accessories and components.