- Offer Profile

Motion, speed and precision: This is the world of EWS.

We call it "Precision meets Motion" because we are aware of the importance of precision for the future of our customers and target markets.

The highest quality standards and the greatest commitment to the optimal execution of our products in form and function are at the heart of everything we do.

To this end, we make targeted investments in state-of-the-art production lines and develop quality assurance methods in cooperation with external institutes.

Our top performance in development and production is also guaranteed by the high level of training of our employees.

Premium class tool systems – Made in Germany

Driven tool systems

- Large program of tool holders with VDI or BMT interface

- Over 50 machine interfaces in the program

- Licensed partner of all common alignment systems

Static tool systems

- Large selection of standard tools

- Many tools available from stock

- Special tools possible

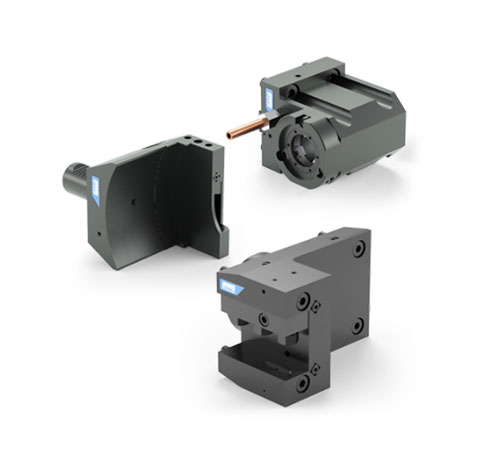

EWS.Varia VX - The innovative quick-change system

- Tool change in only 20 seconds

- Maximum flexibility

- Wide selection of Varia inserts

Driven Tool Holders

EWS.Varia VXT

-

EWS.Varia VXT is the latest addition to our successful Varia series. Specially developed for static turning applications, this system combines maximum precision, stability and flexibility. Based on the proven EWS.Varia VX system, the new VXT line enables extremely compact tool clamping. Every millimetre of the clamping length counts, especially when machining in the direction of the turret box.

For our loyal customers and users of the EWS.Varia VX system, we offer a special EWS.Varia VXT interchangeable insert, which enables a cost-efficient conversion of existing tool holders to the EWS.Varia VXT system and offers a seamless introduction to the newly developed technology.

Advantages:

Maximum cost efficiency and uncomplicated changeover: Effortlessly convert your existing VX tool holders to the VXT system and save time and money in the process.

EWS.Varia VX

- The innovative quick-change system

With the patented EWS.Varia VX quick-change system, you perform tool changes faster than your competitors.

In addition, your driven tool will adapt to your requirements in the future.

The modular interface allows you to select the ideal tool clamping for every machining process.

Two sizes - same technology

EWS.Varia VX3 is the most filigree version and is mainly used on VDI25/30 and BMT45/55 turrets.

EWS.Varia VX4 is optimized in terms of size for machines with VDI40 or BMT60/75 turrets. The maximum transmittable torque is an impressive 200 Nm.

Unique handling advantages- Safe, fast one-hand operation

- No risk of injury

- Defined tightening torque of 6 Nm

- Mechanically actuated lift-off function

- Oriented locking of the turret unnecessary

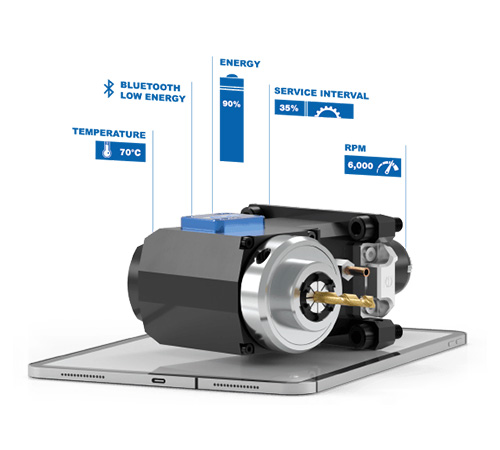

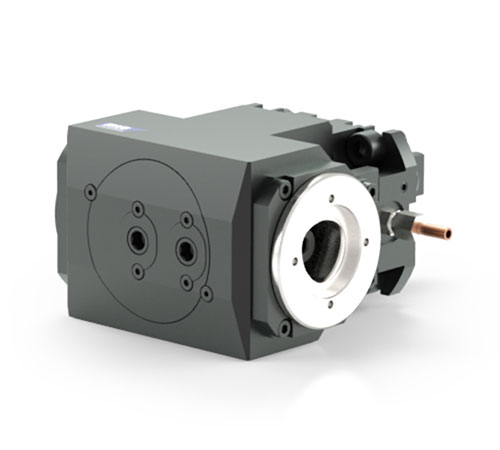

EWS.CyberCon4

- Sensor technology for driven tools

CyberCon4 from EWS provides the user with a digital insight into the kinematic processes of his tool. A tool holder equipped with CyberCon4 collects comprehensive data for checking and controlling the tool in use. This data collection facilitates both the prevention of damage to the machine and the collection of data for store floor management.

The digital view for capturing kinematic processes

EWS develops its own sensor technology as part of the Industry 4.0 concept. With EWS.CyberCon4, EWS is entering the age of digital transformation. The digital concept is also open to cooperation partners in order to offer users as much standard as possible. The data can be read on a tablet or smartphone via an app. However, this is only part of the possibilities. In the overall picture, EWS.CyberCon4 is a building block of the entire IoT concept from EWS. In addition to the sensor technology, new technology features, such as the new "HPC-Line" sealing concept, are used. Initially, the sensor technology is only available in Germany and Austria; retrofitting of existing molds is possible on request.

The advantages- Avoidance of costly machine downtime thanks to intelligent tooling system

- Dynamic determination of load-dependent maintenance cycles

- Sensors are open for communication with external interfaces

- Data management, internal and external

- Sensor is based on BLE 4.1 technology (Bluetooth Low Energy)

EWS.Slot

- Groove Punching, Internal and External Toothing

Groove jointing, internal and external splines manufactured completely and position-oriented

The EWS-Slot grooving unit is driven by the machine's tool turret, converting the rotary motion introduced into translation with a superimposed lift-off function. This makes programming extremely simple. The grooving unit is positioned in the prepared hole in such a way that the extended ram is at the end position in the Z axis. The groove depth is realized by a constant X feed, which varies between 0.04-0.15mm/stroke depending on the version.

The spindle speed ranges between 400 rpm - 1,200 rpm, with one revolution corresponding to one complete stroke. Thus, for example, a keyway with a width of 6mm and a depth of 5mm is produced within 7.5 sec. (800 rpm and 0.05mm feed/rotation) It is important in this operation that the chip can break at the end of the slot, i.e. that there is a recess or hole. But not only grooves, internal and external splines are also possible. This is particularly interesting for workpieces with partial splines.

Function- The newly developed EWS-Slot grooving unit converts the rotary motion of the turret drive into a translatory motion with integrated lift-off function during the return stroke.

- The economical production of internal and external profiles, such as keyways or splines, takes on a new dimension.

- Grooving units can be operated at up to 1500 1/min.

EWS.Multiform - polygonal drilling

- Create any desired shape centrically or eccentrically

4-, 6- or 8-edge, polygon or free-form shapes with EWS.Multiform on CNC turning/milling centers

Free forms that used to be impossible can now be made with EWS Multiform on turning/milling or machining centres. For a six-edge outside the centre or a four-edge in the centre, additional processing steps such as reaming or eroding were necessary up until now. If a position change was also needed, complicated devices were needed for processing. This is now all possible with one chuck.

What is behind this?

EWS Multiform uses a custom internal cam disc unit to produce the required form. For conventional geometry like squares or hexagons, there are standard cam discs available. The cam forces the cutting tool to follow a path in order to get the desired geometric shape. Of course you can’t defy the laws of physics which means that there will be a small radius on the edges.

The multiple new possibilities however will allow engineers to come up with new processes for manufacturing. ID and OD slots, offset squares and straight polygons are examples of an endless list of opportunities. To see what shapes are possible all that needs to be done is verify with EWS application engineering.

Function:- The profile to be machined is generated via appropriately designed cams. Standard and special designs are possible.

- The drive is provided by the turret station for driven tools.

- Caution: Restriction for turrets whose driven tools run permanently, since the speed is limited to 1000/min.

EWS.millLine – Angle heads for machining centers

- The new EWS.millLine program brings proven technology with new features to machining centers.

EWS goes milling

With the new angular head program, EWS brings proven technology with new features to machining centers. The system series was presented to the public for the first time at EMO 2015. Elegant design encloses high-performance technology, or simply Precision meets Motion.

Advantages- The smart solution to compensate for a missing machining axis

- Machining of difficult to access workpieces

- Machining of internal bores

- Stepless angular adjustment around the horizontal axis, with tangential double cone clamping MR > 250 Nm

Prerequisite

The basic condition is a "stop block" on the machine, which prevents the entire unit from rotating and at the same time defines the twisting position.

Variants- Basic

- Duplex

- Offset

EWS.ProLine for Trifix® turrets

- Trifix® is the new alignment system for Gildemeister turning/milling centers. The alignment bars, which are mounted on both sides, each engage in high-precision recesses in the turret surface via a bevel.

The best of both worlds!

Lack of stability, the VDI system has been increasingly associated with this fact in recent years, resulting in block tools being favored more and more, although VDI tools still offer greater variety and flexibility.

So the next step seemed obvious, to combine the best of both systems, and in cooperation with DMG, the EWS.ProLine system was developed to take full advantage of the potential of new turning machines.

EWS.ProLine has a conventional VDI shank, but can optionally be fixed to the turret via four screws, allowing the flexibility of the VDI system to be used for light machining, and the stable block-tool properties for heavy machining. The angular position of the radial tools is ensured via the Trifix® alignment system.

Cutting values like on HSK63 machining centers?

On a Gildemeister CTX Beta 1250 4A, two surfaces were milled in parallel with two cutter heads Ø 80 in 16MnCr5 steel. The infeed was 3 mm/head, at a 180 cutting speed. Without chattering or whistling, a surface was produced that was previously only known from HSK63 machining centers. The two axial tools from the EWS.ProLine were equipped with 4:1 planetary gears and had the VDI40 shank mount.

EWS.swivel head

- More compact and more stable: This is how the new swivel head from EWS presents itself.

Adjustable up to +/- 115° with collet holder and support

The latest swivel head generation from EWS is equipped with a Cylkro gearbox, which brings great advantages in terms of stability and size. Thus, it is possible to reduce the overall length of the swivel heads by up to 17 mm compared to the standard mountings. This offers significantly more flexibility in the cutting tool length, especially in the swivel range of +/-45°, and also enables use on machines with very compact swivel spaces.

The swivel unit covers an angle of +/- 92°. During the swiveling process, the coolant supply is directly carried along. The distance from the contact surface to the swivel axis can be offered from 48 mm. Even a high-pressure internal cooling system up to 70 bar can be integrated into the module without changing the external dimensions.

The limiting speed is 6,000 rpm, the maximum transmittable torque is 16 Nm, the max. cutting tool diameter is limited to max. 10 mm.

The swivel head is mainly suitable for drilling or light milling applications. For higher demands on torque and power, EWS offers its TKW series. These are fixed-angle tools that are specially made for each angle range. The standard angles from 15° to 75° - stepped in 15° increments - are part of the Uhingen-based company's standard and are usually available from stock.

EWS.module cutter – gear hobbing

- Module milling on CNC lathes without B axis

Years ago, EWS was the first tool manufacturer to offer module cutter heads in its standard program and has continuously developed the holders for the gear cutting technology. With this technology, it became possible for the first time to produce external gears on machines that do not have a Y- B-axis. In contrast to a standard disc cutter holder, the tool head of the EWS module cutter can be swiveled around the shank axis.

The advantage for the user is that a B-axis can be substituted with a comparatively small investment. In the meantime, even module 3 is common practice on VDI40/BMT65/BMT75 machines. The tool heads have become more stable and at the same time more user-friendly. The alignment system via sinus ruler has become established and saves enormous alignment and setup time.

EWS.Swiss Tools – High precision machining on sliding headstock lathes

-

In the design of EWS.Swiss Tools, the main focus was on the bearing arrangement and spindle runout. The requirements profile was developed together with an American medical technology company that uses very small drills and needs extreme runout characteristics. The spindle bearing technology used with labyrinth sealing sets new standards in this area, combined with a long service life.

Service is also already taken care of. The service centers in Germany, China, Korea and the USA are trained in the systems and can respond immediately. Third-party products can also be serviced there at any time.

Advantages:- High precision bearing

- Innovative sealing technology

- Spindle runout < 3μ

- Permanent running tested

- Maintenance-free

EWS.Spinjet – High-speed spindle up to 55,000 rpm

-

At least when using EWS.Spinjet, the coolant is used to drive a turbine that rotates the tools at up to 55,000 rpm, depending on the type. The tool drive of the turret is at a standstill during this machining operation!

Advantages of the GreenLine:

- Saves up to 70% of machining time (20,000 to 55,000 rpm)

- High-speed machining

- Less tool and machine wear

EWS.TAPMATIC – Highspeed tapping head

-

High-speed thread cutting with reversing kinematics: The new EWS Tapmatic thread cutting head for driven tools, with its reversing kinematics, enables thread cutting processes without reversing the direction of rotation. This saves time, energy and protects the motor, and all this at a defined thread depth. The units are available for threads from M3-M12.

Advantages:

- Reduction of processing time up to 50%

- Increase in production capacity

- Increase of the service life of the threading tool by 3 times

Static tool holders

EWS.Rigid

- EWS.Rigid is our vibration-damped boring bar holder for higher machining quality.

EWS takes a stand against vibrations in deep wells Machining deep holes with long projecting boring bars is one of the most demanding tasks in machining technologies. What influences vibrations, what amplitudes do they generate, what is the effect of their superpositions, when do you encounter uncontrollable resonances? These are all questions that are difficult to address from theory.

This insight was the basis for the new development of EWS Rigid. The aim was to create a drill holder that counteracts vibrations by means of a passive damping system. Variable vibration dampers with linear degrees of freedom act on the dampers, which are mounted floating in the interior of the cutter carrier.

The position of the absorber is adjusted by means of a radially mounted adjusting screw, which can be used to create optimum vibration conditions. The improvement of the surface finish of bores, as well as the increase of the cutting edge life are significant.

EWS presented the new boring bar system for the first time at EMO 2013, equipped with an HSK63 basic holder and an adaptation to EWS Capto C3.

EWS.CenterPoint

- Center point for the counter spindle

Would you like to use your counter spindle temporarily as a tailstock, and then once again as a normal chuck? You can with the EWS.CenterPoint. For machines with one turret and two spindles for flexible insertion into the counter spindle.

The changeable centring tip for counter spindles

Area of application- Lathes without tailstock and with a turret

- For supporting long tools

- Top changeable short taper 12

- The top kit can be integrated into simple combination holders

Prerequisite- Counter spindle with tailstock function

- Taper shank adjusted to the GSP

EWS.tcJet – Cut-off toolholder with internal cooling

- EWS.tcJet brings the cooling directly to the cutter through the insert and ensures optimum chip removal. At the same time, cutting edge life is significantly increased. The internal cooling version of EWS is available for normal and high-pressure applications for different tool holders and cutting edge carrier manufacturers.

Optimum chip removal thanks to EWS.tcJet

The new EWS program for optimum chip removal!

Features- EWS.tcJet brings the cooling directly to the cutting edge through the insert and ensures optimum chip removal

- Longer tool life and higher productivity due to optimum cooling

- For normal and high pressure applications for different tool holders and cutting tool manufacturers

Technologies

EWS.HPC-Line

-

The time when you had to decide between using high speed in conjunction with low coolant pressure or high pressure at low speed is over. The newly developed EWS.HPC-Line sealing technology now represents a further quantum leap. The seal set, which is based on technical ceramics, is capable of covering 70 bar at up to 12,000 1/min. Added to this is unrestricted dry-running capability.The running-in process in particular meant the technical knockout for many sealing systems after only a short time, because the previous seals burned out after only seconds or they hardened, which then led to failure within a very short time. The technical ceramic used in the HPC-Line has excellent dry-running properties, which was a key criterion in the developers' specifications.

High pressure: up to 70 bar

Nmax: up to 12,000 1/min

Dry running: Unrestricted

EWS.Polygon Joint

-

For centuries, the keyway or spline connection was considered a set for the transmission of torque. The new possibilities in the field of manufacturing technologies, open up new dimensions for the developers of transmission units.

Advantages:

EWS relies on the polygonal shaft-hub connection in its new series and thus exploits significant technological advantages:

- The balanced geometry reduces the imbalance of the driveline towards zero, a positive effect on the vibration of the work spindle and thus on the surface of the component. Added to this is the improved service life of the cutting edge and the increase in the service life of the entire tool system.

- Due to the homogeneous force distribution over the entire circumference, up to 30 percent more power can be transmitted with the same dimensions, and the resistance of the connection to impact and breakage increases many times over.

EWS.Butterfly Seal

-

Advantages:

- The triad of front labyrinth, special sealing elastomer and preload ring forms the heart of this technology

- The labyrinth technology protects against direct contact with cooling emulsion and dirt particles

- The speed-related lift-off function of the sealing element reduces mold heating by up to 50 percent

- Due to the contraction effect of the sealing elastomer, the sealing lip closes the path to the mold interior and ensures maximum safety against the suction of emulsion during the cooling phase (∆t compensation)

- No friction-induced running-in at the mold spindle (50 percent of all service cases).

- In case of service: Inexpensive seal replacement instead of expensive spindle replacement

EWS.Highspeed

-

EWS.Highspeed – these are special high-precision spindle bearings from EWS that enable particularly high speeds and are used in high-speed applications. The Highspeed tool series from EWS has lower heat generation, resulting in longer tool life. Not suitable for rough machining!

EWS.Coolant Management

-

The efficient coolant management from EWS

Advantages:

- Opening and closing of the external cooling via 360° rotation

- Universally applicable

- Axial and radial design

- Coolant flow adjustable

- Time saving due to easy handling

- Standard for Varia VX3 / VX

- Upgradeable for many toolholders

- Different lengths

Exchange systems

EWS.Varia VX - The innovative quick-change system

- With the patented EWS.Varia VX quick-change system, you perform tool changes faster than your competitors.

In addition, your driven tool will adapt to your requirements in the future.

The modular interface allows you to select the ideal tool clamping for every machining process.

Optimize setup times and maximize contribution margin

Lot sizes are going down, machine kinematics are moving at the physical limit.

Nevertheless, our customers achieve even better performance on the machines!

We are proud to be able to design the tooling for such experts.

With EWS Varia VX, we have succeeded in developing a system that enables optimum concentricity thanks to axial, shear force-free three-point clamping, and that isahead of the game in terms of work safety.

Two sizes - same technology

EWS.Varia VX3 is the most filigree version and is mainly used on VDI25/30 and BMT45/55 turrets.

EWS.Varia VX4 is optimized in terms of size for machines with VDI40 or BMT60/75 turrets. The maximum transmittable torque is an impressive 200 Nm.

Kennametal KM™

- Kennametal and the EWS Group have raised their partnership to a global cooperation, offering a wide KM system range for turning and milling operations, both static and live.

The tool systems offer extremely high cutting performance and enable guaranteed high productivity, ensuring optimized machine utilization through higher repeatability and shorter setup times. The range includes tool systems with KM interface for various machine models from leading machine tool manufacturers such as DOOSAN™, HAAS™, HWACHEON™, HYUNDIA WIA, Mazak™, DMG Mori, and OKUMA™.

Advantages- Large standard product portfolio of static and driven tools

- Machine optimized tool systems

- Sizes: KM32, KM40, KM50 and KM63 Special solutions with KM shank

- Driven tool systems with up to 12,000 rpm; transmission ratio 1:1

- Fit into different interfaces of machine tool dependent turret designs

- VDI units for easy handling

- Bolted units (BMT) for increased rigidity

- Available with internal and external coolant supply

EWS.PSC - The quick-change system according to ISO 26623

-

EWS.PSC offers flexibility and rigidity, combined with short set-up and changeover times for a wide range of interchangeable inserts. This is the right choice for anyone who values a standardized changing system. EWS.PSC is compatible with products from market competitors.

The EWS.PSC program includes a wide range of standard tools with PSC shank for milling spindles as well as tool systems with PSC spindle for lathes. Furthermore, tool holders with plate seat are available.

The interface allows you to reduce the time spent measuring, setting up and changing tools.

In addition, improved machine utilization can be achieved.

Allignment systems

EWS.Trifix® Alignment System

- The EWS Trifix® System

EWS Trifix® is the alignment system for Gildemeister turning-milling centers. the alignment bars, which are mounted on both sides, each engage via a bevel in high-precision manufactured recesses in the turret surface. the bars are preset with preload. the spring effect of the alignment system eliminates static overdetermination. this ensures the twisted position of the tool holder without additional adjustment effort and thus significantly reduces machine set-up times. due to the high precision requirement, application for double-toothed tools is not possible. the tools are delivered pre-aligned and can be used directly.

EWS is a system partner of DMG MORI for this tool generation.

EWS Trifix® advantages- Repeatability on one station below 6 µm with 200 mm throat depth

- high positioning accuracy from one station to another (0.01mm)

- completely aligned driven tools and static holders

- static holders can be used with additional mounting hole pattern

- heavy duty spindle heads with additional mounting hole pattern can be used

- tool disc / functional surfaces easy to clean

Accessories

EWS.Zero-Zero - Chuck

- Zero runout with a completely normal collet!

Achieve 0 runout within one minute with a simple collet – that's Zero-Zero!

The specially developed clamping nut with 6 symmetrically arranged screws on the circumference make this possible. The clamping nut is split in two, so that the inner ring can be moved minimally. Thus, tolerance additions can be eliminated via this simple technical finesse.

It is only necessary to replace the previous clamping nut and the user is already moving in a new concentricity dimension and that from 90.- €. Zero-Zero is available for collet chucks according to DIN 6499 from ER 16-ER40.

EWS Tool carrier Systems

- EWS T-Shuttle: The tool trolley to accommodate individual tool holders

Depending on the requirements, the pallets can be designed with the same or different tool holders. Ideal for multi-tasking machines, turning/milling centers or modular systems. The TS 400 tool shuttle can be offered with three or four pallets. The range also includes tool carriers with different holders as table superstructures.

EWS Universal Mounting Block UMB 100

- Mounting tools safely and in the correct position while still being flexible - that's what the UMB100 mounting unit is all about.

Accessories

The mold clamping units can be changed quickly, making the system an ideal mounting aid even on multi-tasking machines. It only takes a few seconds to change from one adaptation to another. The unit can be swiveled 4 x 90° at the touch of a button, so that straight or angled fixtures can always be mounted in the ideal position.

COMMAND PRODIGY P1

- New wind for workpiece or fixture cleaning: chip and emulsion removal or drying processes via the tool spindle

Features- The clamping shank can be clamped in a Weldon or collet chuck diameter 20

- Programming is identical to that of a milling operation

- By varying the speed, the air flow volume can be dosed

Advantages- Internal coolant supply for pre-cleaning of the workpiece.

- Clean workpieces, e.g. before a process-integrated measuring operation

- Reduction of emulsion consumption by blowing off in the machine room

- Stable design

- Rotor blades easily replaceable