- Offer Profile

- The umbrella brand Starrag unites the product ranges Berthiez, Bumotec, Dörries, Droop+Rein, Ecospeed, Heckert, Scharmann, SIP, Starrag andTTL. Headquartered in Rorschach/Switzerland, the Starrag Group operates manufacturing plants in Switzerland, Germany, France, the UK and India and has established a network of sales and services subsidiaries in the most important customer countries.

Starrag Magazin

Starrag Magazines

- We believe that we should provide our customers with a benefit not just in terms of performance, but also in terms of communication. With the “Star” we provide our customers sufficiently good reasons why there can be only one partner for them: Starrag. Have fun discovering our solutions for your machining task.

Horizontal machining centers

Heckert Compact

-

Universal machining centers with pallet sizes ranging from 19.7 inch (500 mm) to 39.4 inch (1000 mm).

Select the right axis concept for your requirements without compromise and expand your basic machine with optional technologies and features.

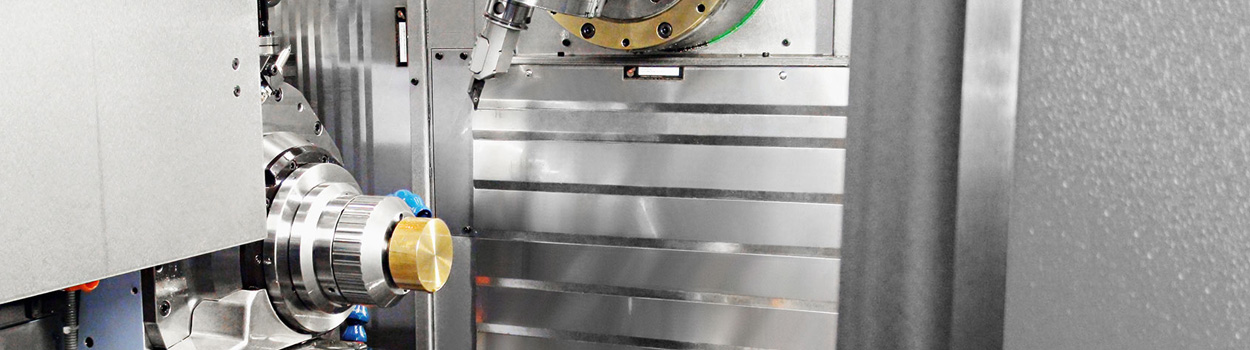

Strong and fast – spindle characteristics are the key factor in production processes.

That is why we offer a wide range of spindles from which you can choose the right one for your application.You benefit from our more than 100 years of experience in spindle construction.

Heckert Large Machines

-

Large 4- and 5-axis universal machining centres from 1000 to 1800 mm pallet size.

The complete and multi-side machining in one clamping position cuts production and processing times, increases the quality of processing, and reduces the logistics effort.

The model series has four sizes, a wide range of workspindle variants, process-optimized solutions for tool and workpiece handling, and innovative process controls and monitors.

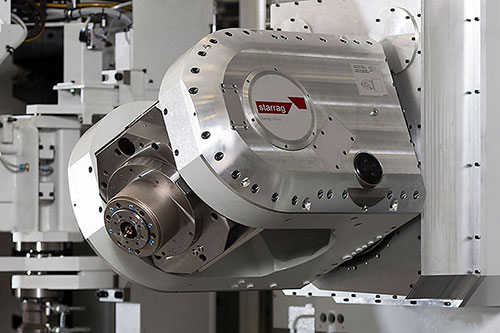

5 Axis solution - Key features

- 5-side machining in one clamping

- Maximum dynamics in positioning mode and simultanious operation

- High rotational accuracy through 4-fold precision bearing

- Optimal machining with max. 67 kW and up to 8,000 rpm

- Serrated ring couplings guarantee highly precise swivel position

- Automatic compensation of axial spindle extension under heat and sag compensation

SIP 7000/7 4A

-

The horizontal SIP machining centers are living proof that ultra-precision is by no means a myth. Gearbox housings, spindle heads and two-axis turntables can be machined with significantly higher levels of precision than with conventional machining centers, making them the obvious choice for customers.

- Unparalleled levels of long-term precision

- A mechanical design that has proved itself for over a century

- Genuine expertise regarding thermal factors and how to handle them

Vertical machining centers

SIP 5000/6

- Ultra precise vertical machining center

Ever since it was founded in 1862, the Geneva-based Société d’Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models.

SIP 5000/6 / 5000/7

The SIP vertical range is a must for all producers of parts with high levels of value creations. It enables ultraprecision positioning and the closest of dimensional tolerances for drilling and milled surfaces.

SIP 5000/7

- Unparalleled levels of long-term precision

Ever since it was founded in 1862, the Geneva-based Société d’Instruments de Précision (SIP) has been a benchmark for precision machine tool engineering. The basic design of SIP machines can still be found today in all traditional machining centers, both for vertical and horizontal models.

SIP 5000/6 / 5000/7

The SIP vertical range is a must for all producers of parts with high levels of value creations. It enables ultraprecision positioning and the closest of dimensional tolerances for drilling and milled surfaces.

5/6 Axis machining centers

Starrag STC Series

- High performance simultaneous 5 and 6 axis machining center

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multi-blades and casings with long cycle times, and provide the customer with a whole host of practical options.

These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

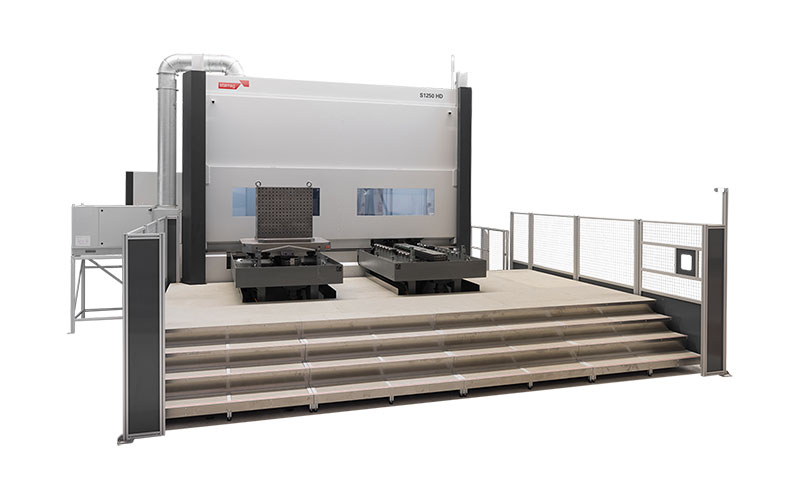

Starrag S1250 HD

- Hydrostatic bearings bring about a leap in performance in titanium machining

The S1250 HD is predestined for simultaneous 5-axis heavy machining of titanium and Inconel parts due to its excellent static and dynamic properties.

The user derives the greatest advantages from the use of hydrostatic guides in roughing operations. Due to the significantly higher rigidity and damping compared to roller guides, the cutting depths can be increased threefold. The roughing times are reduced accordingly.

The new S1250 HD also benefits from the hydrostatic bearing during finishing. The increased rigidity reduces pitching of the column, which limits jerking and acceleration. The higher dynamics are noticeable in higher starting speeds, accelerations and faster five-axis movements. This ultimately also reduces the finishing times.

Turn-mill machining centers

Bumotec s191V

-

- Cycle time reduction: Complete complex parts in one set-up from a blank or a short bar

- Wider market opportunities: Machining of hard material such as tough ceramic

- A small footprint multi-tasks machining center: A wide range of processes and multiple machine configurations (fixed machining table, Axis rotation with multiple clamping systems,…)

Bumotec s181

-

- Cycle time reduction: From Bar to finished part, in one single production cycle

- 2nd machining station working simultaneously: Optimization of production cycle and cost per part reduced

- Increased productivity: Up to +40%

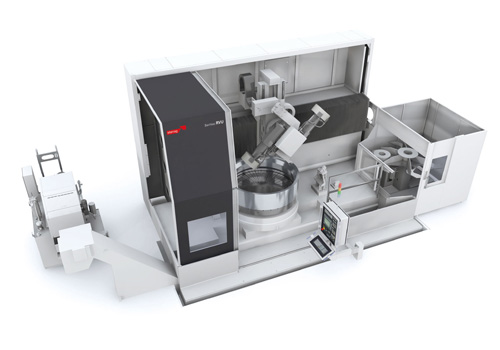

Bumotec 191neo Series

-

Extremely stable during production with a minimum of operator intervention, the 191neo offers a formidable level of productivity.

Its responsive tool change, the high torque of the Starrag milling spindle, and its thermal signature inherited from the original s191 model, ensure it maintains the programmed production rate and obtains a high finish quality, regardless of the material and complexity of the part to be machined.

Equipped with "à la carte" peripherals, such as temperature-controlled high pressure, chip conveyor and bar loader, the modularity of the 191neo ensures all production requirements can be met. Coupled with the Bumotec palletiser or with a robotic, modular or custom- made automation cell, this gives you access to "24/7" type production, which is only interrupted by preventive maintenance when required.

Blade and Blisk machining centers

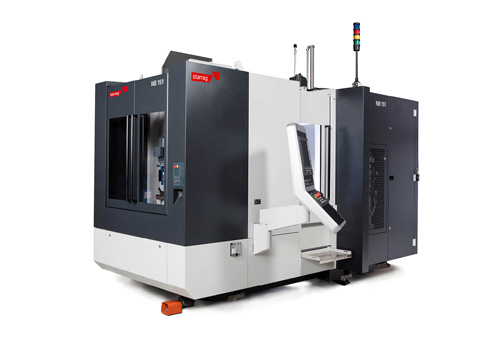

NB 151

-

Shortest cycle times and zero scrap rate production are what the Starrag NB 151 stands for. The NB 151 is based on the very successful Starrag LX series.

- Lower costs per part: Dedicated kinematic concept for efficient Blisk roughing or finishing.

- Reliable production: Expansion of the spindle through thermal drift or centrifugal forces can constantly be measured and compensated for by direct measurement.

- Efficient machining strategies: The NB 151 offers a superior accessibility for all kinds of multi-blade parts, be it blisks, impellers, diffusors or nozzle guide vanes.

LX Series

- Turbine blade machining center

Starrag LX machines are designed for the optimum machining of turbine blades. All technical parameters, such as axis strokes, forces, torques and acceleration, are set according to the application requirements.

LX machine development is never completed; the goal is to continuously increase the customer benefits, i.e. increase productivity, increase quality or expand the application options.

Ecospeed F -Series

Ecospeed F -Series

- World of aluminium structures

Down the years, Starrag has established itself as a proven partner for the aerospace industry. In 1998 the challenge was the development of a machine tool concept to achieve the lowest cost per part. This resulted in the innovative and highly efficient Ecospeed machine series.

This technology partnership includes everything from customer specific engineering to application development including CAM programming, tool and fixture design and automation.

Since market introduction in 1999, the parallel kinematic Sprint Z3 machining head technology has been successfully adapted to a modular range of machines covering component sizes from less than 1 m up to 8 m in length. Many of the world's leading aerospace manufacturers have selected Ecospeed series machining centres for the production of a wide variety of different components.

Portal and Gantry machining centers

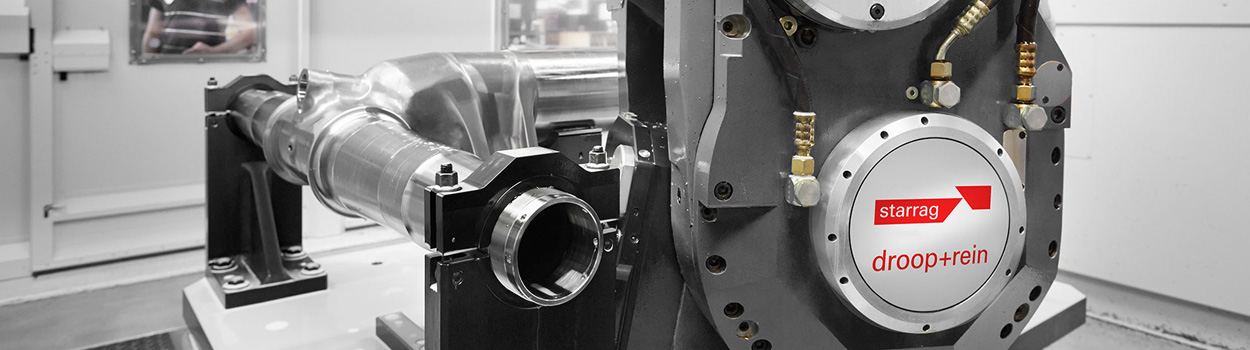

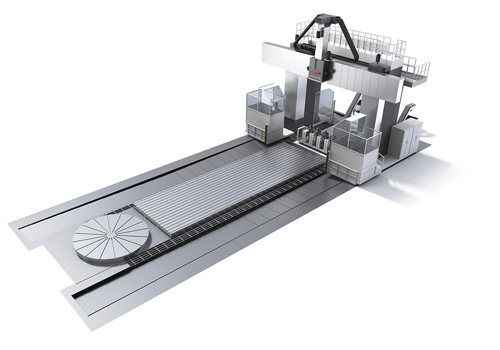

Droop+Rein TFS NEO

-

The versatile table moving machines designed and built by Droop+Rein have one thing in common:

Unmatched rigidity in its power class combined with highest flexibility in size and configuration.

Highlights- Optimised machine structure

- Large dimensioned compact linear guideways

- Preloaded double pinion to rack drive system

- Excellent dynamic behaviour

- Ram with integrated C-axis

- C- and B-axis continuously controlled or clamped in position

- Continuous 5-axis capability using fork-type heads

- Automatic cartridge change for wide range of motor milling spindles

- Large selection of automatically exchangeable milling heads

- Various table designs incl. turning table options

- Comprehensive peripheral devices

- Advanced Starrag diagnostics system

- High level of energy efficiency

- Industrie 4.0 proven by Starrag IPS

Droop+Rein T/TF

- 6-axis machining center

With the T/TF series, Droop+Rein offers gantry machining centres for heavy-duty machining in many sectors: Applications range from tool and mould making, aircraft component manufacturing and engine manufacturing to general mechanical engineering. Based on the robust, highly accurate and powerful basic machines, the T/TF series offers an extensive system of innovative automation and expansion stages that enable the machines to be adapted flexibly to each machining task.

The optional automatically changing fork-type milling head makes complex and demanding machining possible. Through extensive application know-how, a variety of different milling heads are available -including vertical milling heads, angle milling heads, and fork-type milling heads for positional or simultaneously controlled applications.

Table dimensions

Length mm 3,000 - 10,000 mm + 1,000 mm steps

Width mm 2,000 - 4,500 mm + 500 mm steps

Droop+Rein G & GF Series

- G and GF - Gantry design

For machining of largest and heaviest workpieces Droop+Rein offers a floor guided gantry machine line. Best accessibility and utilisation of floor space for largest workpieces combined with highest flexibility in size and configuration.

How can large, heavy-duty and bulky workpieces be processed without adversely affecting the weight and size of the machining result? The Droop+Rein G series has been specifically developed to tackle this difficult task. The gantry machines reliably prevent dynamic losses through the table and workpiece. The G series has many technical highlights to meet the requirements of complex machining tasks, such as the hydrostatic guide in all linear axes or the thermo-symmetrical design of the spool milling unit with an integrated C-axis. Milling heads can be changed automatically via a head change interface.

Droop+Rein FOGS Series

-

FOGS NEO and HD - Overhead gantry design

Whatever it takes - roller guided dynamic (NEO) or hydrostatic precision (HD) . The Original – invented in 1993 the Droop+Rein FOGS is the benchmark in the market of overhead gantry machines. The FOGS offers unmatched performance from high speed to heavy duty operations.

Vertical turning lathes

Dörries VT Series

- The new benchmark for vertical turning

The Dörries VT embodies the robust and durable features of the Dörries VCE series, but it has been innovated from the ground up and delivers the latest state-of-the-art technology.

It is designed for multifunctional, high-precision and flexible pre- and finish-machining.

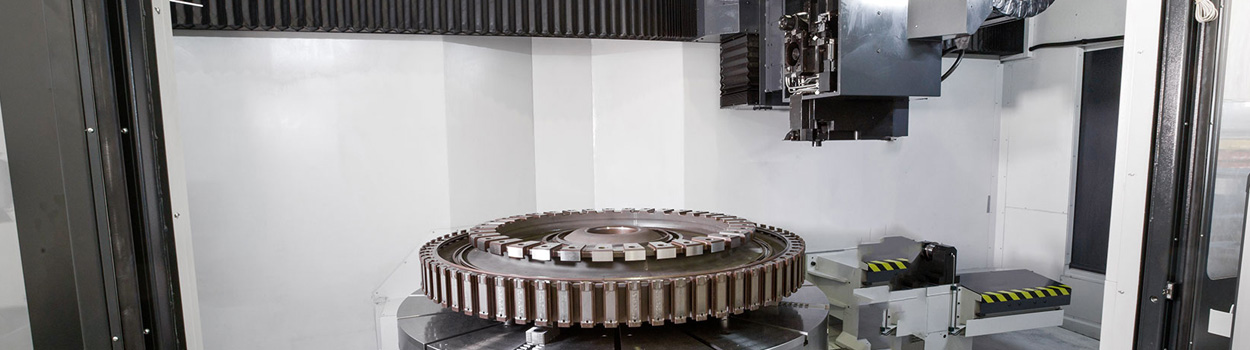

Berthiez TVU Series

- Berthiez TVU - Turning, boring, milling, grinding

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, high-precision static and dynamic positioning as well as long-lasting reliability.

Advantages of the TVU vertical turning lathes are: completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Y-axis table traverse will permit the turning, milling and grinding of complex components in a single clamping.

Berthiez VT Series

- The new benchmark for vertical turning

The Berthiez VT embodies the robust and durable features of the Dörries VCE series, but it has been innovated from the ground up and delivers the latest state-of-the-art technology.

It is designed for multifunctional, high-precision and flexible pre- and finish-machining.

Dörries VC Series

- Powerful and flexible

Double column vertical turning lathes Dörries VC are build in portal design. The portal design ensures high inherent stiffness while the cast iron construction provides good damping and thermal stability with excellent life time precision – even on heavy workpieces with up to 350 tons.

Dörries VC-V Series

- A flexible heavyweight

The VC range of products includes the double column vertical turning lathe Dörries VC-V, offering the advantages of a moving table for complete processing. This type of machine features a fixed portal frame, an adjustable cross rail and a hydrostatically guided Y-axis table base.

Vertical grinding machines

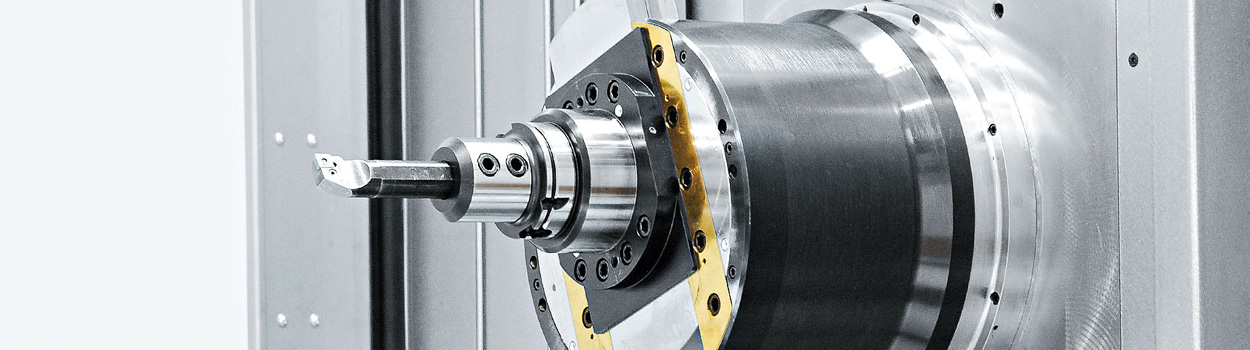

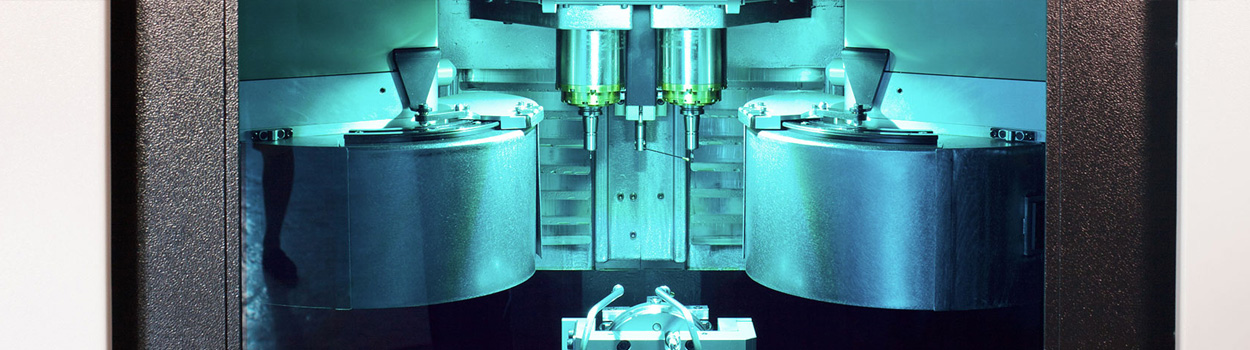

Berthiez RVU Series

- Berthiez RVU - Precise grinding

The RVU grinding machines set new standards in high-precision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four water-cooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected)

The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Transfer machines

Bumotec s1000C

-

- Effiecient technology: Efficient machining with up to 32 tools - Maximum bar diameter 28 mm (optional 42 mm) - 9 Position automatic bar feed system (3,000 mm max.) - High speed spindles (10,000 rpm) - Optional high-frequency spindles - Optional high-pressure coolant

- Optimized productivity: More than 6 time faster in production in comparison to a mono station machining center

Bumotec s100multi

-

- Innovative concept: Four machining centers - High rate of acceleration (maximum 3 g: 27.24 m/s²) - Fully developed linear motors - Fast feed rate in all axes (50 m/min) - Fast rotating spindles (maximum 60,000 rpm) - Extensive tool magazines (for up to 144 tools) - Very fast tool changing times (< 500 ms)

- Optimized productivity: +85% of productivity obtained with 4 machining stations working simultaneously

Faceting machines

Bumotec s220 / s230 Series

- Faceting and diamond finishing center for dials index

s230 is an automatic solution for faceting and diamond finishing dials index. s230 production center allows the production of a wide variety on index in various metals. Contrasts of different visual effects are performed by the use of diamond tools or solid carbide tools. The complete solution for small and medium series for finishing index combines multiple operations on a single machine.

Features

- Optical recognition and origin definition of blanks

- Diamond with the revolver toolholder

- Machining of LuniNova pockets and micromilling

- Simple programming interface on Windows

- A variety of automation systems are available to ensure a high level of autonomy in production

Automation

-

Everything from simply part storage to most complex flexible manufacturing systems – even of the largest machines. The Starrag Group makes Industry 4.0 a reality.

Automation solutions

The Starrag Group has comprehensive expertise in the systems business and has been processing complete turnkey technology solutions for many years. The range of services covers every aspect of the project, from the engineering, deliveryand assembly of all system modules including tools and jigs, to providing ultra-modern manufacturing technologies, user training sessions, production assistance and service.

A big plus is the possibility of interlinking various different machine designs. Complex production processes can thus be put into reality.Key benefits:

Reduction in unit costs thanks to flexible fully-automated complete machining

Customized solutions for lot sizes from one-offs to large quantities

Production based on demand with low levels of material inventory

Guaranteed highly effective just-in-time production

Unmanned machining in a multiple shift operation

Reduction in production and through-put times whilst maintaining the same high levels of processing quality

Turnkey project solutions

Optimum conditions for system extension and the integration of additional machines

Interlinking of a variety of machine designs as well as auxiliary like CMM’s engraving or deburring stations.

High level of in-house expertise in the handling of major projects

Consistent high quality output requiring less manpower Technology Services

-

More and more, the unique nature of our services can be seen beyond the individual machine systems. A comprehensive technology services package which can be tailored every time to meet the needs of the specific customer are of great help in ensuring that manufacturing is always geared towards the highest levels of productivity and, where necessary, adapted to take on new tasks.

The most important engineering services include:- the products by the leading company TTL, «Adaptive Machining» technology automates the machining of complex blades, blisks, impellers, etc., previously requiring extensive hand-work

- the CAM software package for the efficient machining of flow parts and the simulation programme, which enables complex blade machining processes to be set out, checked and refined on-screen

- the Center of Production Excellence in Rorschach, where demanding machining processes for the customer can be tested and optimised technology services which enable machining strategies and technologies to be designed and further developed.

- close collaboration with leading technical universities and research institutes means that new findings from the world of science can be made available to customers

- ultra-modern equipment and clamping technologies whose priority is to ensure high levels of availability and productivity for the equipment

- a comprehensive range of ultra-modern tools which are constantly being further developed in combination with our machines and adapted to new challenges

- planning and installation of turnkey production equipment. One of the group's main strengths is the inter-linking of a variety of machine concepts which provides low unit costs and a high level of flexibility when companies wish to go in new directions

Center of Production Excellence (CPE)

-

In its state-of-the-art Center of Production Excellence (CPE), Starrag gives customers the opportunity to test and optimise new and demanding machining processes or to produce pilot lots or small batches. The 2,000 m2 CPE is equipped with the latest 4 and 5-axis machine centers and can machine all types of different flow faces, rotating parts and complex work pieces, including those which cannot be machined at right angles. The extensive services range from the heavy-duty machining of high-strength titanium alloys to the high-speed cutting of light metal alloys.

Key benefits:- State-of-the-art technology to increase productivity

- The possibility of producing pilot lots and small batches cost-effectively

- The ability to accommodate seasonal peaks without investment in new machinery

- Simultaneous and concurrent consultancy services

- Reduced ramp-up time for machine investments

Engineering

-

Starrag Group companies combine their leading technology with sophisticated process services, drawing on over 30 years of experience in tailoring manufacturing solutions for companies which are leaders in their fields, in cooperation with manufacturers of clamping tools. Our comprehensive offer includes the development of complete machining strategies and clamping concepts, innovative milling cutters and the optimisation of cutting performance.

We also work in close cooperation with leading research institutes, making new discoveries all the time and ensuring that solutions created for customers always include the very latest manufacturing technology.

Key benefits:- Professional consultancy and optimum solutions for the most demanding manufacturing needs

- Increased productivity thanks to tailor-made advice

- Machines and services all from one sources

- An unbeatable package of machinery, tools, software and expertise

- Expert support for on-site implementation

Fixture and Clamping Technologies

-

The Starrag Group offers tailor-made solutions with ultra-modern fixture and clamping technology. The basis of this intelligent process technology is the experience and expertise, acquired over decades, of our highly-qualified technicians who can design concepts which exploit the full potential of mechanics, automation, hydraulics and vacuum and magnetic technology.

The result of this process is that customers can benefit from optimum availability and productivity for their equipment.

Customers gain a leading edge with innovative fixture and clamping technologies, including:

- Clamping fixtures for high-precision work pieces

- Cost-efficient and flexible multiplecomponent clamping fixtures

FMS Flexible Manufacturing Systems

-

The Starrag Group companies have comprehensive expertise in the systems business and have been processing complete turnkey technology solutions for a number of years now. The range of services covers every aspect of the project, from the engineering, delivery and assembly of all system modules including tools and jigs, to the providing of ultra-modern manufacturing technologies, user training sessions, production assistance and service.

A big plus is the possibility of interlinking various different machine designs. Complex production processes can thus be taken into account thanks to the variability of the machine designs.

Key benefits:- Reduction in unit costs thanks to flexible fully-automated complete machining of lot sizes from one-offs to large quantities

- Low levels of changes to cater to individual customer wishes and alterations in ranges

- Production based on demand with low levels of material inventory

- Guaranteed highly effective just-in-time production

- Unmanned machining in a multiple shift operation

- Reduction in production and throughput times whilst maintaining the same high levels of processing quality

- Turn-key project solutions

- Optimum conditions for system extension and the integration of additional machines

- Interlinking of a variety of machine designs

- High level of in-house expertise in the handling of major projects

Tools

-

Modern machine tools and ever more complex parts, made from materials that are difficult to machine, require tools with specific contours, angles and radii with good rotation characteristics and high surface qualities. To enable customers to machine at high levels of efficiency, our solid carbide milling machines are adapted to handle highspeed machining. These tools are subjected to intensive tests in our modern machine park and are constantly being further developed. We exclusively use top-quality solid carbide, and you have the possibility to select tools from our standard range or have them produced individually according to your specifications, either coated or uncoated.