Wohlhaupter

- Offer Profile

- We are known all over the

world as a manufacturer of innovative, modular tool systems for machining

centers and millturns, facing and boring heads, grooving heads, clamping

tools and customized solutions for boring operations.

- With one innovation after another, we have continually reinforced our reputation as the world leader in digital boring tools.

- Wohlhaupter has 135 employees, 1 students and 7 trainees.

- Head office: Frickenhausen (Germany)

- Subsidiaries:

- Wohlhaupter India in Delhi (India)

- Family business in the 3rd generation

- The company was first founded by Emil Wohlhaupter as a small mechanical workshop in 1929, which initially started as a repair shop for cutting and stamping tools and devices.

Product Portfolio

New Products

NOVITECH

-

Efficient machining results thanks to new vibration-dampened intermediate modules

With the NOVITECH series, Wohlhaupter is now introducing intermediate modules for high-precision and economical boring operations up to 10xD. NOVITECH was developed to increase productivity, surface quality and process reliability of boring operations, as well as extending the life expectancy of the tool and spindle of the machining center.- Machining-Ø 50 – 205 mm

- Patent pending

Our Highlights - Your Benefits- Intermediate modules for machining up to 10xD

- Efficient machining results through the viscoelastically mounted damper module

- Modular construction with MVS connection

- Existing Wohlhaupter components can be used

- Increased productivity, surface quality and process reliability

- Extended range of the cutting data

- Increased tool and spindle life

GEN3SYS® XT Pro and XT

-

The next generation of drilling

The GEN3SYS® XT Pro replaceable insert high penetration drilling system has been designed to provide high speed production machining beyond the capabilities of the T-A® drilling system. The product offering consists of various grades, geometries and coatings available to suit the most demanding applications.

Conceived from the outset as the ultimate high performance drilling solution, the GEN3SYS® drill range is incredibly versatile. Incorporating both straight and helical fluted tool holder options across the range, as well as through coolant for maximum material removal, GEN3SYS® not only gives outstanding performance from day one, but it can also be reground for extended life and economy.

More informations: www.alliedmachine.com

3ETech

-

The new external digital display

External is new: 3ETech is a technology for the micron-accurate adjustment

in connection with an external digital readout module for the easy correction of the diameter.

Features of the 3E Technology:- Direct measuring system in the tool

- Interface for data transfer

- Universal external digital readout module

- Multiple use of any 3ETech digital readout module on different tools even on specials

The 3ETech technology opens the possibility to equip all fine boring tools even with small body diameters or special tools.

Modular MultiBore Boring System

-

The system

The term MultiBore used by Wohlhaupter stands for a system of modular components which is compatible with every machine spindle. The boring tools have been developed and manufactured to the very highest standards of engineering practice and are also suitable for high-speed machining. Naturally, we will supply fully balanced complete tools on request.

The connection

The MVS (MultiBore)-connection has proved its worth in a million applications since its introduction in 1973.

Wohlhaupter was the world's first maker of modular boring tools and developed the connection into today's perfect system solution. It offers the following benefits:- Easy and practical handling

- Freely accessible threaded taper pins for precise cutter positioning

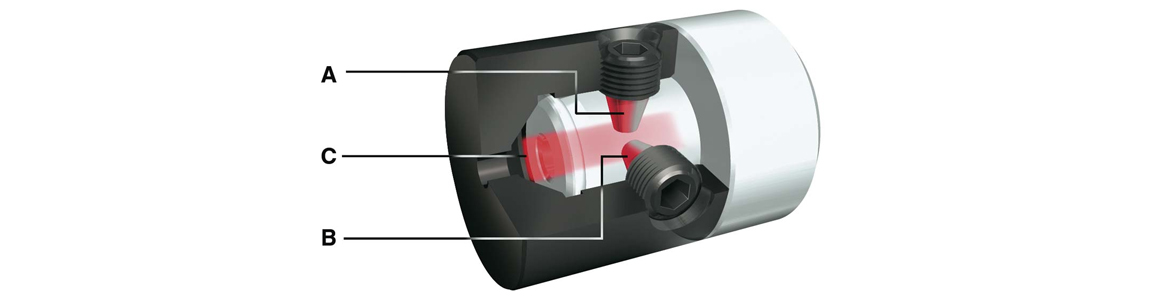

- Triple point clamping (A, B, C) ensuring high axial clamping forces on mating faces

- Maximum rigidity due to triple-point clamping

- Accurate to less than 3 μm when tool is changed

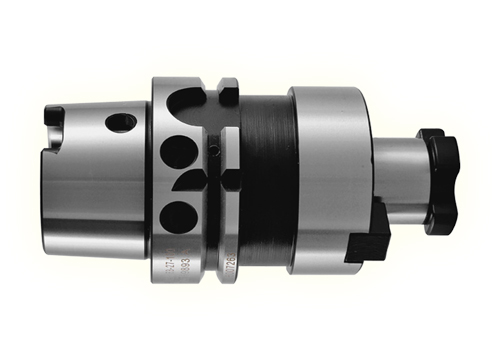

Master shanks

-

For every job Wohlhaupter has just the right connecting component. Master shank connections between the machine tool and the MultiBore modular components are supplied for all machines. The MultiBore boring tools fit straight into the master shanks or can be fitted with intermediate modules to make up a complete tool suitable for the component being machined. Wohlhaupter master shanks equipped with the following MVS connecting components are available to meet the different machine requirements:

- MVS 50-28 preferably for SK 40/HSK-A50 machines up to a boring diameter range of 83 mm

- MVS 63-36 for machines bigger than SK 40/HSK-A50

- MVS 80-36 up to 205 mm boring range

- MVS 100-56 preferably from 200 mm boring range upwards

Connection D40 / D60: For short overhangs and high torque transfers above 200 mm boring range. Each master shank with the MVS connection is supplied with the corresponding threaded taper pins. Shanks for a D 60 flange connection similar to DIN 6357 are supplied with T-bolts fitted and no M 16 pull studs.

HSK master shanks for the Wohlhaupter MultiBore range offer you many benefits which include:- High level of accuracy when repeating or making a replacement

- Quick replacement times

- High static and dynamic rigidity

- Safe machining at high speed

- With standard balancing

- Position of the tool edge

- Field of application: machine tools

German standard DIN 69893 (tapered hollow shanks Part 1, Form A and Form C) defines the position of the tool edge in single-edged cutting tools as right-hand versions.

Based on this specification relating to the driving slots, every deviating edge position is expressed at Wohlhaupter in clockwise angular dimensions.

In principle, the cutting edge position should be checked before any tool application, and with orders for special tools and special clamping devices must be approved in writing by the user.

Intermediate modules

-

The wide selection of intermediate modules on offer means the tool can be modified to suit the exact requirements of any machining task.

The right choice of intermediate modules ensures a high degree of tool stability.

For the best possible results when working with a diameter-to-length ratio over 1:5, we recommend intermediate modules made either of heavy metal or solid carbide which have special vibration damping properties.

Wohlhaupter intermediate modules with precision balancing

Tools and tool spindles are being designed for ever higher speeds resulting in higher requirements for balancing quality. The residual imbalance relating to the complete tool for various balance quality stages Q in relation to the operating speed is easily achievable with the balancing set screws screwed from outside into Wohlhaupter extension pieces, reducers, adapters and tool bodies. As a result, the additional fitting of balancing pieces is frequently unnecessary.

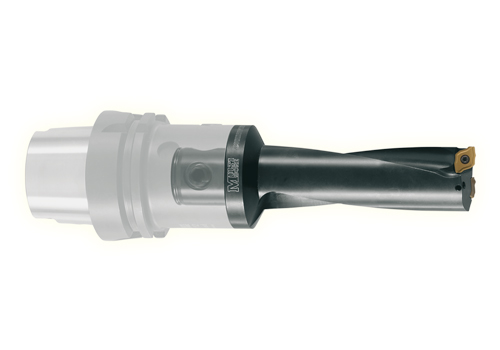

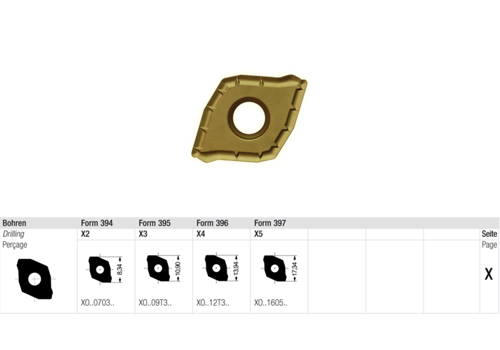

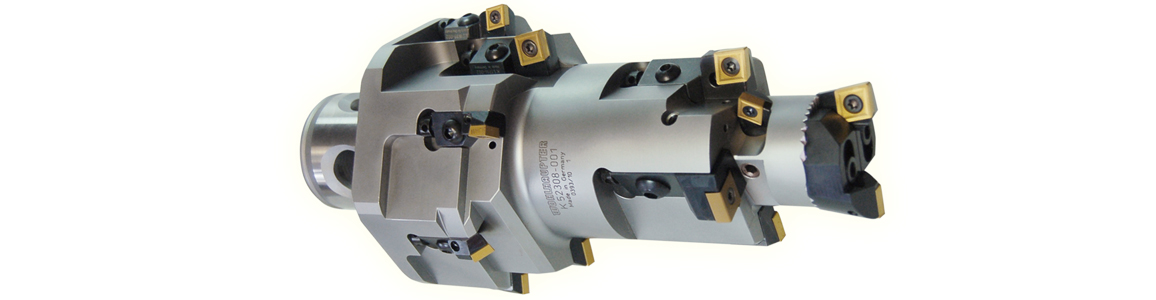

Insert drills with replaceable inserts

-

Wohlhaupter offers you a trailblazing indexable insert drill series - developed to the latest state of the art. In modular application with the MVS connection 50 - 28 and 63 - 36 respectively and thus fitting the internationally proven MultiBore program with its unsurpassed variety.

Drilling + core drilling + precision boring = Wohlhaupter.

Properties - Tool:- Designed for maximum system rigidity.

- Optimum coolant holes guarantee stable drilling performance.

- Improved chip removal due to optimized chip gullets.

- Can also be used for simple turning operations.

Properties - Inserts:- inserts XOMT in: 3 geometries

- 4 carbide grades to cover all applications

- 2 x 2 = 4 effective cutting edges for high cost efficiency.

- Perfect separation of inner and outer cutting edges for full use of all four cutting edges.

- Four cutting edges can be used in any sequence.

Boring tools for rough machining

-

Rough machining, chamfering, reverse machining, circular milling, axial grooving - MultiBore serrated bodies, combined with various insert holders, provide the greatest variability in machining. Wohlhaupter offers the widest range for premachining bores.

Characteristics:- Boring range Ø 19.5 - 3255 mm

- Serrated tool body with ground serrated body

- A wide variety of different insert holders for rough machining, chamfering, axial grooving and reverse machining guarantees a wide diversity of applications

- Insert holders for level or height-staggered machining

- Use of manufacturer-independent ISO replaceable inserts is possible

- Boring range 200 - 3255 mm with slides in aluminum lightweight construction

Boring tools for rough and finish machining

-

Rough and finish machining in one operation - with a feed-in accuracy of 0.002 mm in diameter - level or height-staggered machining - from Ø 24.5 to 3255 mm. Wohlhaupter Combi-Line: doubled productivity, coupled with the flexibility of the MultiBore range - the production manager's dream.

Characteristics:- Two tools in one

- Rough and finish machining in one operation for tolerance groups up to IT6

- Boring range Ø 24.5 - 201 mm in steel version with feed-in via vernier

- As of boring range Ø 100 - 3255 mm with modular slide range, feed-in via digital display

- Feed-in accuracy 0.002 mm in diameter

Boring tools for finish machining

- With its MultiBore boring tools for finish machining with decades of success worldwide, Wohlhaupter offers the widest production range for internal machining of bores in the well-known quality. A high degree of flexibility in application, selection of cutting materials as well as simple handling guarantee optimum tool solutions for the greatest machining diversity. Wohlhaupter - for highest precision.

Boring tools Ø 200 - 3255 mm

-

For the past ten years, Wohlhaupter has continued to raise the bar in the internal machining of large bores with the Alu-Line series. Wohlhaupter has used existing product and system expertise to redesign the standard tools of the series Flex of Ø 500 - 3255 mm and seamlessly integrated it by adding it on to the Alu-Line tools of the series Eco of Ø 200 - 500 mm. Wohlhaupter therefore offers not only one of the largest, but also one of the most powerful and flexible tool ranges in the world for these bore sizes.

This allows even the smallest slide with a boring range of Ø 500 - 780 mm to be used. Four base slides and four serrated slides alone cover the entire boring range of Ø 500 - 3255 mm. The serrated slides fit each of the four base slides, which make optimum combinations possible for whatever the current requirements demand.

The Wohlhaupter MultiBore system also includes a wide selection of insert holders and precision boring tools 337 or 537 digital: rough and finish machining or the combined rough and finish machining Combi-Line - all this included with just one investment.

With the tools of the series Basic D40 Wohlhaupter is adding lean, high-performance slides to its product range. This Basic D 40 slide range allows turning to be performed up to Ø 840 mm on lower-power machines: simple and flexible in use.

Clamping tools with MVS connection

-

Wohlhaupter supplies a complete range of clamping tools, matching the MVS connection proven successful a million times over. MultiBore tools provide the basis for the modular and service-orientated design of cutting tools.

Here also, continuing change constantly puts a query over existing concepts or encourages innovations and additions. Perception is also a decisive factor here and as a result the adapter sleeves and arbours have also been supplemented with a coolant supply.

The additional downward supplementary modular connection with smaller interfaces, in part above the size MVS 32-18, provides additional flexibility and allows the generation of added manufacturing value from this change. An interesting and fast alternative, instead of inflexible special solutions with delivery times!

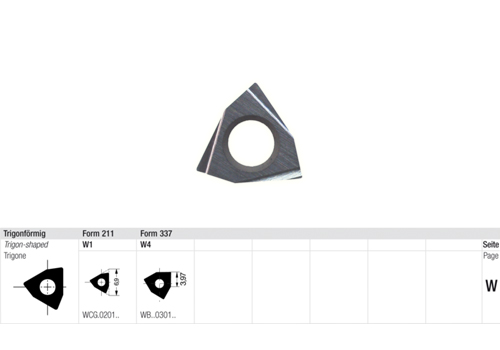

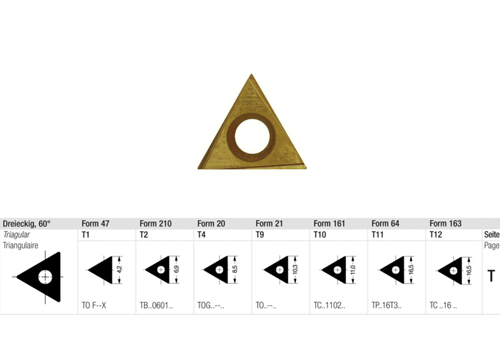

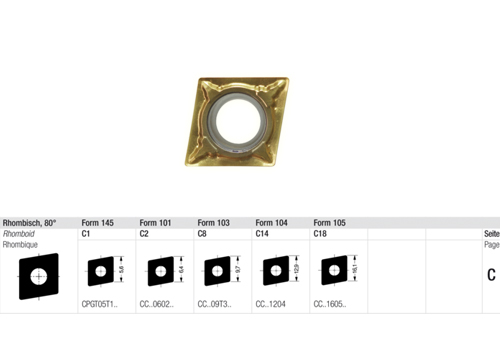

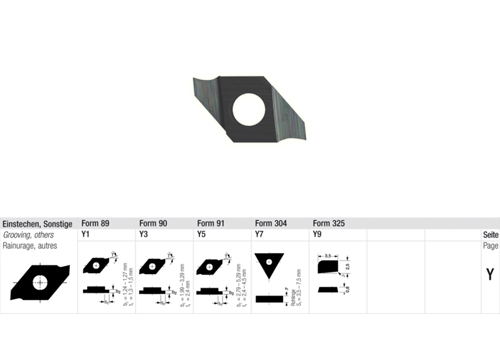

Replaceable Inserts

-

The Wohlhaupter replaceable inserts range: extensive and always up to date

Wohlhaupter is an independent supplier of indexable carbide, maintaining an extensive and technically strong replaceable insert program for its modular tool systems which are known throughout the world. In contrast to manufacturers of cutting materials who operate globally, Wohlhaupter can react rapidly to new trends in machining and offer a totally flexible program that is always up to date.

This program is made up of replaceable inserts to Wohlhaupter specifications which are specially matched to precision holemaking and of the best established replaceable inserts on the market.

The last-mentioned replaceable inserts were designed by the individual manufacturers principally for turning, which involves totally different machining conditions than precision holemaking. So only those replaceable inserts were selected which promised and could demonstrate in extensive tests special suitability for all aspects of boring with respect to their geometric characteristics in the area of the nose radius, the form of the edge preparation and their suitability for the particular cutting material.

As the result of close technological cooperation with the suppliers and constant machining tests internally and externally, the existing range is constantly updated, amended and revised. This ensures that up to date cutting materials and geometries are always available.

Form W

Form T

Form C

Form S

Form Y

Form X

Form Z

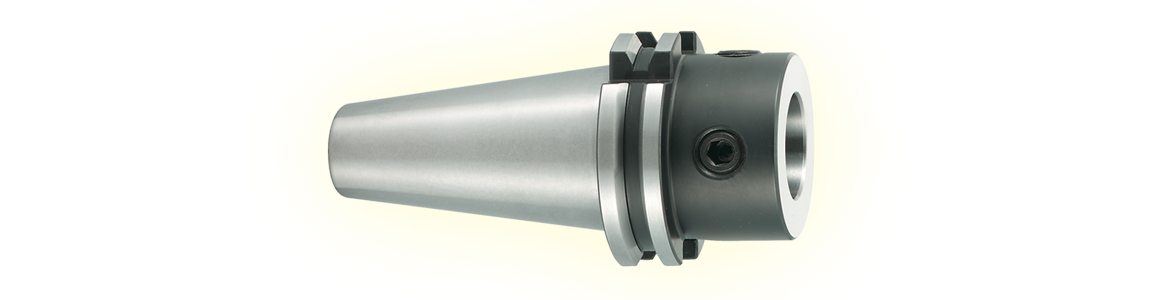

Clamping Tools

-

Secure connections for precise machining

Our standard clamping tools excel through uncompromising Wohlhaupter precision. We offer an extensive range of all common clamping tools in HSK or angle taper design.

As an innovation driver, we have been using the HSK connection for years. Its superior tool change and repeat accuracy and maximum static and dynamic rigidity allow it to be used on the latest machining centers.

Our angle taper clamping tool range is designed for use on all standard CNC machines, as per DIN 69871 -A/AD / B and MAS-BT.

All-round proven Wohlhaupter quality.

DIN 69 893 HSK

-

The HSK clamping tools program

The clamping tools to DIN 69893 Form A out of this catalogue fit straight into the machine spindle and can also be used for manual tool change.

The most important advantages of the DIN standardized interface are:- High level of accuracy when repeating or making a replacement

- High static and dynamic rigidity

- Quick replacement times

- Safe machining at high speed

The HSK master shanks for the MultiBore-range of tools are included in the catalogue 90 100.

All tools are usually supplied with a central coolant feed facility, except the tools which are marked.

The high centrifugal forces which result from increasing spindle speeds are potentially dangerous and there are limits to the parameters which can be set and applied economically in practical application.

Tooling systems can be balanced in our BALANCE-Center.

Why not have a word with one of our product specialists!

Further executions on request.

Please order coolant transfer sets separately.

DIN 69 871 -A/AD / B

-

The steep taper clamping tools program

is especially designed to accept boring, reaming and counterboring tools with straight or tapered shank, milling cutters and tapping tools.

WOHLHAUPTER clamping tools are made of case-hardened steel and precision ground at the points of connection with the machine and the tool.

Steel: case-hardened of at least 950 N/mm² core tensile strength

Hardness: HRC 58 ± 2

Taper tolerance AT 3 to DIN 7178 / 2080

MAS BT JIS B 6339

-

The steep taper clamping tools program

is especially designed to accept boring, reaming and counterboring tools with straight or tapered shank, milling cutters and tapping tools.

WOHLHAUPTER clamping tools are made of case-hardened steel and precision ground at the points of connection with the machine and the tool.

Steel: case-hardened of at least 950 N/mm² core tensile strength

Hardness: HRC 58 ± 2

Taper tolerance AT 3 to DIN 7178 / 2080

Customized Solutions

-

Precisely tailor-made for maximum efficiency and process reliability

Where the most stringent machining requirements have to be satisfied, our individual, customized solutions are the first choice. All over the world. Wohlhaupter special boring bars stand out from the crowd with exceptional stability, precision and modularity - and the power advantages of our MultiBore tools.

Every new solution is based on our decades of experience in boring operations. Innovative tool technology with maximum precision, which sets new performance benchmarks in many industries and areas of application. The use of standard replaceable inserts delivers the utmost flexibility.

The tools have been specially developed by our design engineers, are mostly modular in construction and are always perfectly adapted to the manufacturing process and the workpiece. For example, our PKD tools with polycrystalline diamond achieve a longer tool life, shorter machining times and high process reliability, even with highly machining-resistant materials. Grooving Head

-

The innovation: Grooving head

Cuts machining time by up to 80%

Pure innovation - a trailblazer for cost efficiency: the Wohlhaupter grooving head for internal and external grooving in batch production. It combines linear single-cutting feed with multi-cutting circular milling.

It´s all in your head: creating competitive advantages- Improvement in quality

- Reduction in machining times by up to 80 %

- Machining safeguarded by electronic tool monitoring

- Simple to operate

- Problem-free integration into the machine control system

- Designed for all machining centers

- Comprehensive service package

- Single or double grooving in one machining operation

- The economic process in the mass production

Facing and Boring Heads

-

Efficient machining with productive heads

When you need to perform highly efficient and precise facing and boring, taper turning or tapping, the legendary Wohlhaupter head maximizes your productivity. First-class technology for over 70 years - in use all over the world in single-part and batch production.

The universal facing and boring head is available in sizes UPA 3, UPA 4 and UPA 5-S6. Industries

Agricultural Technology

-

Long-lasting tools that bring you savings

Wohlhaupter tools: a true investment for major productivity gains.

With Wohlhaupter tools, the manufacture of agricultural appliances, machines and systems is highly productive. With savings in machining time from 10 to 15%, they offer high efficiency combined with a long life. Wohlhaupter special boring bars are the customized solution for individual machining requirements. Thanks to decades of experience in bore machining, our innovative tool technology satisfies the most stringent requirements for precision, robustness and service life. It ensures great flexibility through the use of standard replaceable inserts. Our modular tool concepts, developed specially for the manufacturing process and the workpiece, reflect the industry-specific expertise of the design engineer, and provide the optimum tool solution.

Automotive

-

Get ahead of the competition

Trailblazing innovations, such as the Wohlhaupter grooving head, Smartbore or ActiveEdge from Rigibore, offer competent solutions for high-volume production.

If you wish to remain competitive in the automotive industry, you have to do more than deliver good, precise parts on schedule. Time and time again, increasingly complex machining tasks, narrow tolerances and high expectations for surface quality present the user and the tool with new challenges. With Wohlhaupter, you have the right partner at your side for meeting the most exacting requirements. For we promise customer-focused, consistent and systematic project support. Our special team for customized solutions consists of experienced design engineers and sales specialists, who can deal with all the technical and commercial aspects of a project and come up with solutions. Experience in industry plus innovation: Make Wohlhaupter’s strengths work to your advantage.

Energy Production

-

Reliability on a large scale

Maximum flexibility, process reliability, "Made in Germany"! For the diverse requirements of the energy industry, you can get exactly the right high-precision tool solution from us - in large sizes, too.

Internal machining from Ø 100 to 3,255 mm – the range of slides from Wohlhaupter permits boring in larger sizes, with numerous benefits, including high quality of the bore in the shortest machining time. With Alu-Line lightweight tools, Wohlhaupter is setting new standards in weight reduction. This way, large tools can also be integrated in the production process – and with simple handling and maximum precision.

Uncompromising high-end technology: Modular, flexible, highly efficient, with first-class advice and worldwide service. We are the system supplier you need to forge ahead with your large-scale energy projects.

Aerospace Technology

-

Digital tools - global successes in a new dimension

Safety-relevant, expensive components, narrow tolerances for the finish machining of bores, right up to the final machining operation: aerospace travel presents tools with the most exacting requirements of all. Our digital tools get you reliably and economically to the precise dimension you require.

We are the world's only manufacturer to offer finish machining tools with continuous digital traverse measurement from Ø 3 - 3,255 mm. Since 2003, our customers have appreciated the rapid, precise and convenient digital adjustment of our DigiBore precision boring tool. Now with automatic balancing facility and tools in lightweight Alu-Line construction from Ø 65 mm, Wohlhaupter is consistently further developing the digital precision adjustment of the Balance series. The new precision boring tool from the 537 digital series also offers the advantage of µ-accurate digital tool adjustment from Ø 100 - 3,255 mm. Innovations that get you where you want to go, faster.

Machine and Plant Engineering

-

Use production potential to the full

In the field of machine and plant engineering, Wohlhaupter is known as a universal tool supplier with a far-reaching service. And for repeatedly redefining the limits of what is possible.

"Use quality and produce quality" - this has been Wohlhaupter's motto for many years. The challenges of modern machine and plant engineering demand a huge range of modular tool concepts that can individually adapt to suit changing tasks. As a partner with extensive experience in numerous industries, we offer highly sophisticated systems, innovative technologies, a high level of service and the flexibility of our standard range, to bring you process reliability, productivity and cost efficiency.

Medical Technology

-

Digital precision boring at high speed

Now you can improve precision, quality and efficiency when finish machining bores, with the smallest digital precision boring tool in the global market.

For the manufacturing industry, medical technology is a market of steadily growing importance. Here, precision tools are the key to success. The complex tasks and special materials of medical technology present machining tools with major challenges. As your partner with many years of expertise in industry, we offer powerful high-speed tools for machining bores from Ø 0.4 mm. With highly precise digital adjustment - for better results.

Pumps and Compressors

-

Efficiency under pressure

For pump and compressor manufacturers, high performance capabilities, precision and cost-efficient production are the keys to success, whatever the task at hand. Tools from Wohlhaupter withstand the pressure to succeed, and reduce machining times.

With our CombiLine tools, you can double productivity and achieve over 30% time savings in the machining of pumps and compressors. You can accomplish rough and finish machining in a single operation with a feeding accuracy of 0.002 mm in diameter - with level or height-staggered cutting from Ø 24.5 to 3,255 mm. And CombiLine also ensures optimum surface quality. The tool from the MultiBore range delivers maximum flexibility for your work.