- Offer Profile

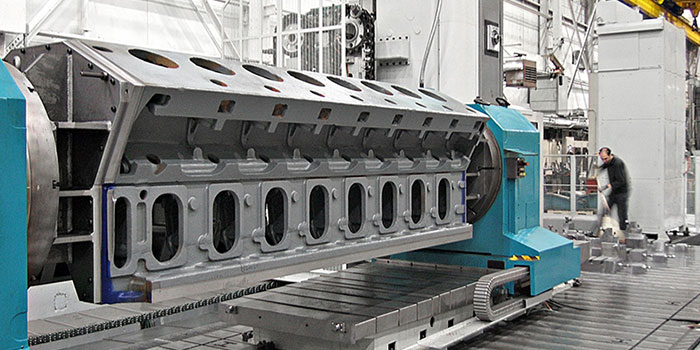

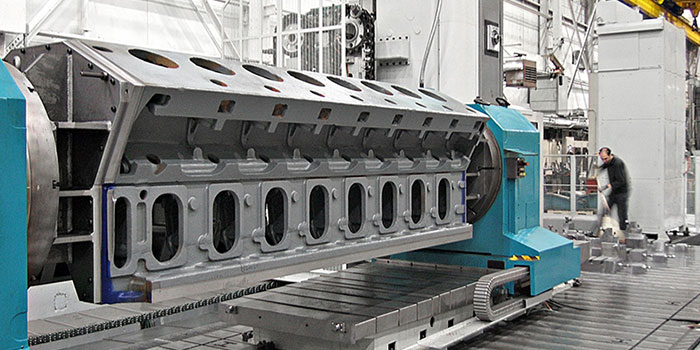

- At PAMA, we have developed an

integrated company, currently structured on two production plants in

Rovereto and Brescia since 1926.

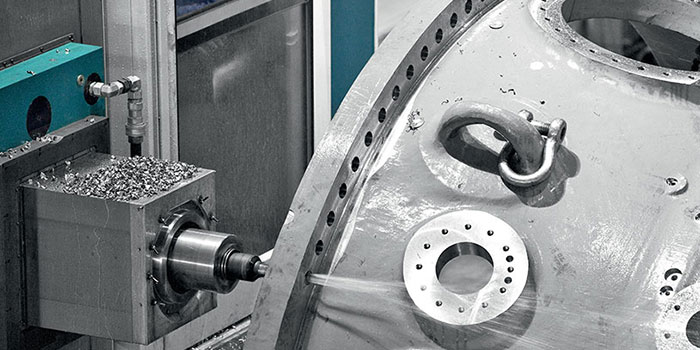

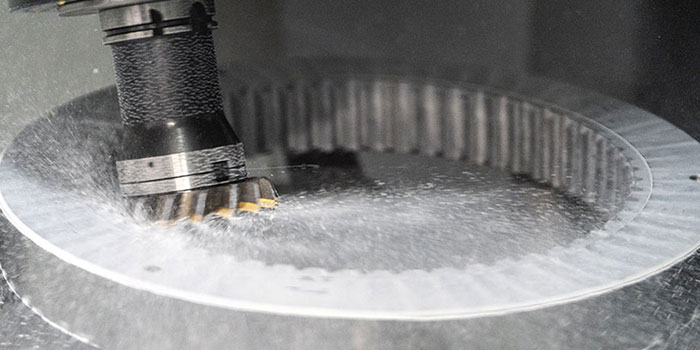

Our Technical Departments are made up of highly qualified teams with many years of collective experience; and it is in our Technical Departments where all of our products and their components are developed. All main structures are machined in-house, using PAMA boring-milling machines and machining centers. PAMA quality system is certified ISO 9001-Vision 2008. All PAMA industrial processes are defined, planned and continuously optimized within the framework of a project of constant process and quality improvement.

Our production activities are set up in specialized areas dedicated to building functionally complete modules; following a series of painstaking tests, they are then sent to the final assembly areas.

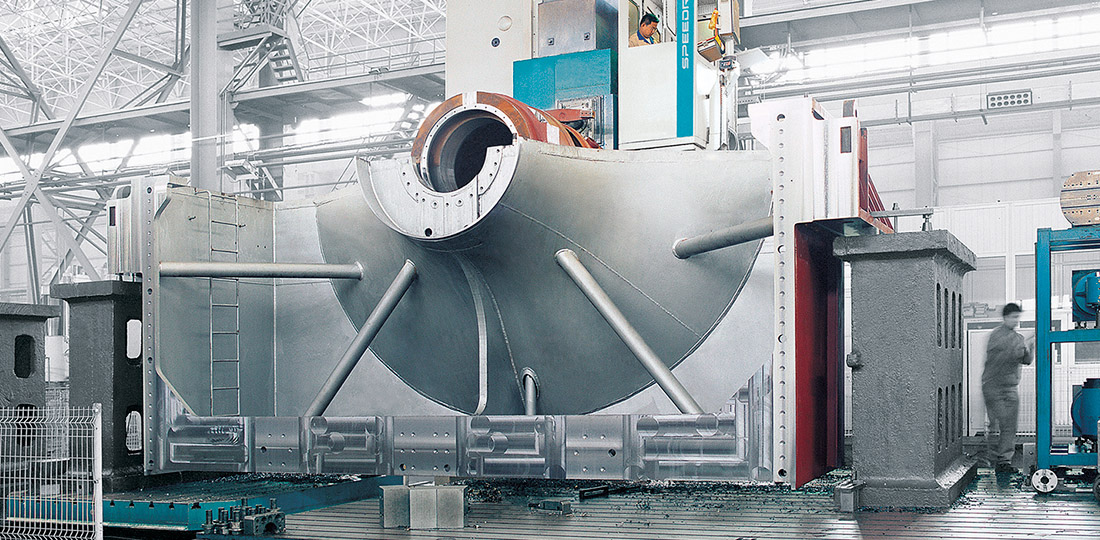

PAMA is an established supplier for the major sectors of the energy, heavy machinery and manufacturing, earthmoving, machine tools, railway, aerospace, shipyard and large diesel engine industries.

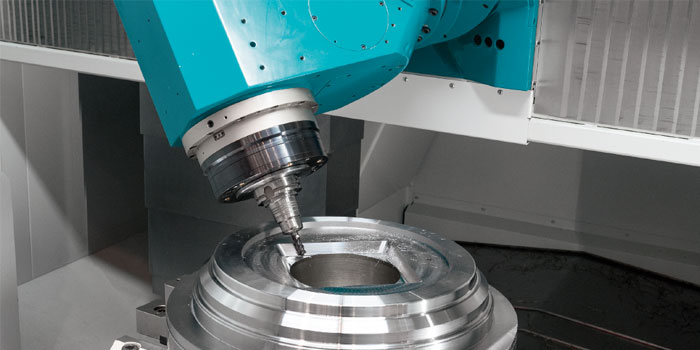

Machining Centers

SPEEDMAT VM

-

Vertical Machining Centres

PAMA Speedmat VM machining centres are able to combine high dynamics and rigidity and the highest workpiece precision to satisfy the most difficult applications when machining small and medium sized components.

PAMA Speedmat VM machining centres are distinguished by a fixed portal structure with a moveable crossrail and traveling table and is available both in the milling version (PAMA Speedmat VM) as well as the milling/turning multitasking version (PAMA Speedmat VMT).

The structures of the PAMA Speedmat VM machine were studied using modern finite element analysis techniques with the purpose of optimising the masses and guarantee high static and dynamic rigidity, as well as greater thermal symmetry.

To best satisfy customer needs, PAMA Speedmat VM can be configured with the following solutions:

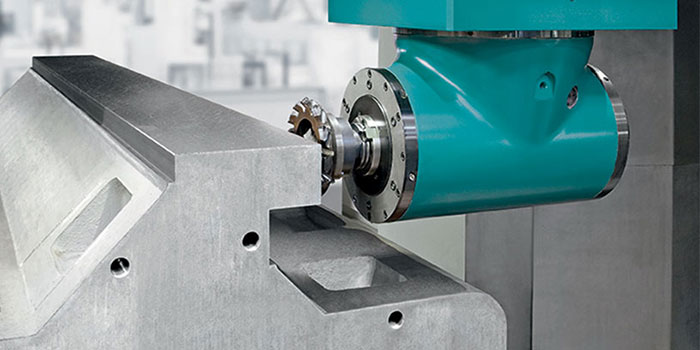

- HVA head with continuous axis inclined 45°

- A head with continuous tilting axis

Both heads are available with an electronic spindle in a high-speed version and in the high torque version.

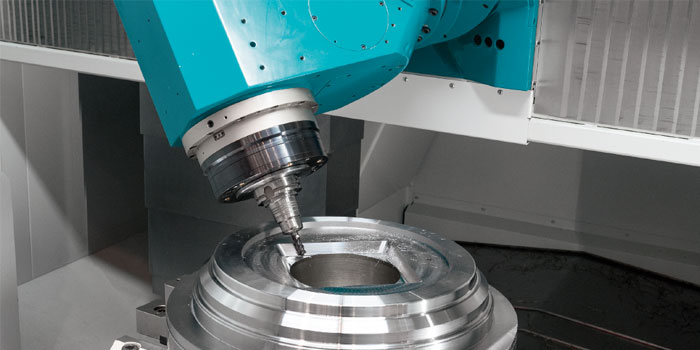

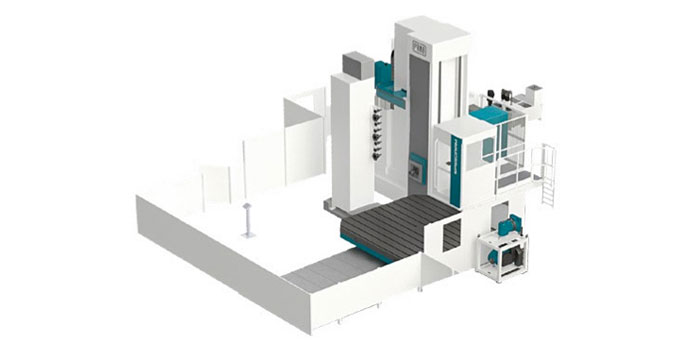

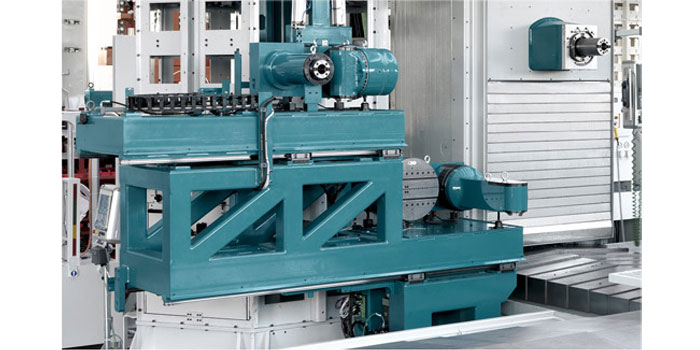

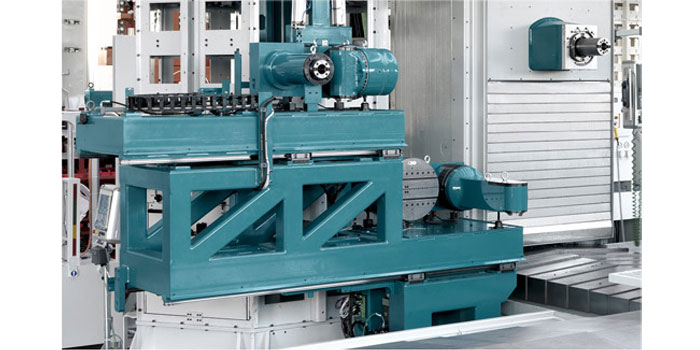

SPEEDMAT HP

-

Machining centers

PAMA Speedmat HP machining centers are able to combine high dynamics and rigidity and optimum precision to satisfy also the most difficult applications when machining small/and medium-sized components. PAMA Speedmat HP machining centers are distinguished by a T-type structure with a movable column and a travelling table. The column is thermal symmetric with a central headstock for maximum precision.

They are available in the milling version (PAMA Speedmat HP) and in the milling and turning multitasking version (PAMA Speedmat HPT).

The machine structures were studied using modern finite element analysis techniques with the purpose of optimising the masses and guarantee high static and dynamic rigidity, as well as greater thermal symmetry.

To better satisfy customer requirements, the machine can be configured with one of the following heads:

- HVA head with continuous axis inclined 45°

- AHD head with continuous tilting axis

- H horizontal head

- W headstock equipped with a boring bar, with mechanical transmission

- WD headstock equipped with a boring bar, with Direct Drive transmission

SPEEDMAT

-

T-type boring and milling center

PAMA Speedmat boring and milling centers are able to combine maximum rigidity and high precision to satisfy the most difficult applications when machining small- and medium-sized components.

PAMA Speedmat boring and milling centers are distinguished by a T-type structure with a movable column and a travelling table. The column is thermal symmetric with a central headstock for maximum precision.

The structures of the PAMA Speedmat machine were studied using modern finite element state analysis techniques with the purpose of optimising the masses and guarantee high static and dynamic rigidity, as well as greater thermal symmetry.

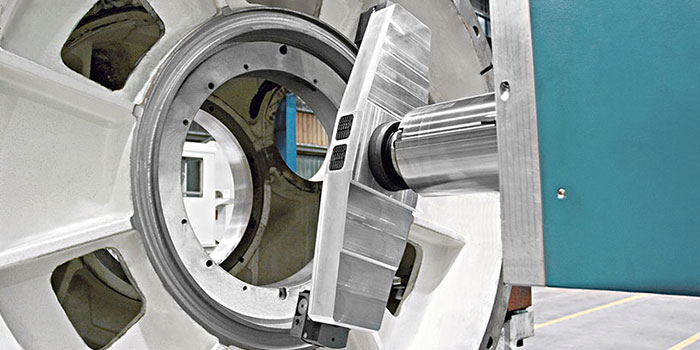

The headstock includes a mechanical transmission boring bar, with a real time feedback system; PAMA patent.

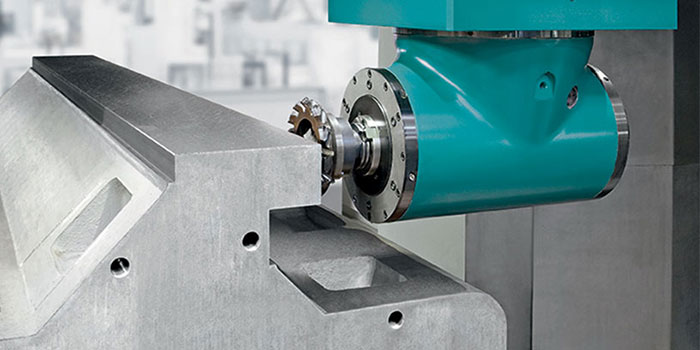

HORIZONTAL MILLING MACHINES

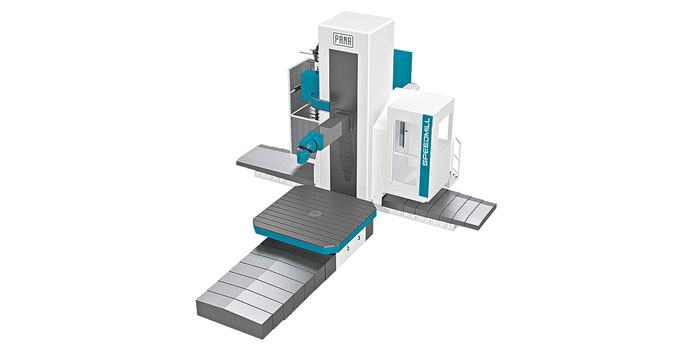

SPEEDMILL

-

Horizontal floor type milling machines

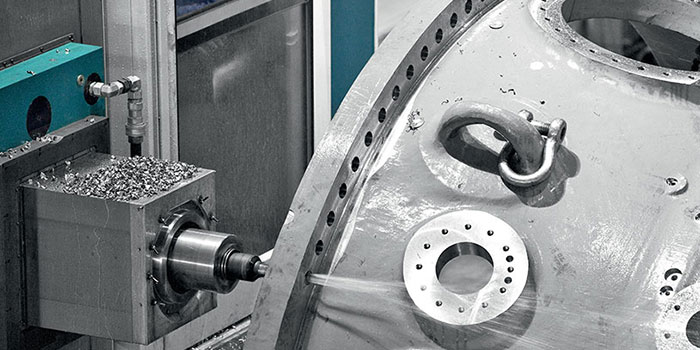

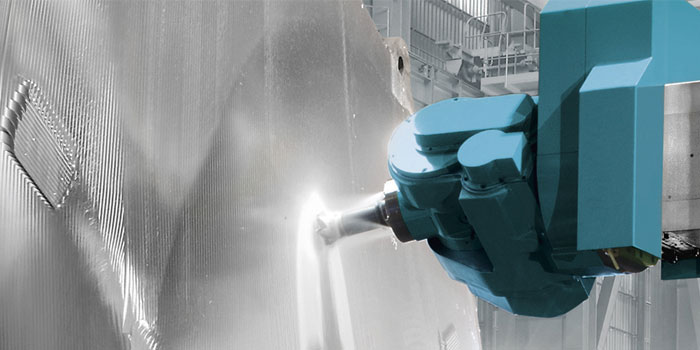

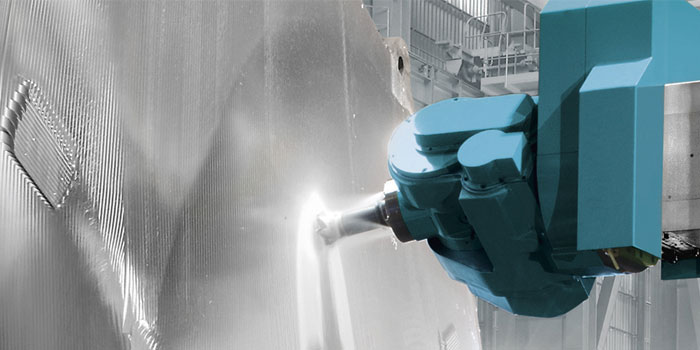

To satisfy more difficult applications when machining medium and large-sized components, where horizontal machining is optimal, the PAMA Speedmill milling machines are able to combine damping, high dynamics, high spindle speed and workpiece precision.

PAMA Speedmill milling machines have a thermal symmetric column with a centrally mounted headstock for maximum precision and have roller guideways on the X and Y axes to make full use of the advantages of axes dynamics.

The focal point of the PAMA Speedmill machine is the ram, guided inside the headstock by hydrostatic pads, which has a real-time feedback system to compensate for any elongation caused by temperature variations.

This solution guarantees maximum precision and rigidity together with high damping of the vibrations, at the location where they are generated.

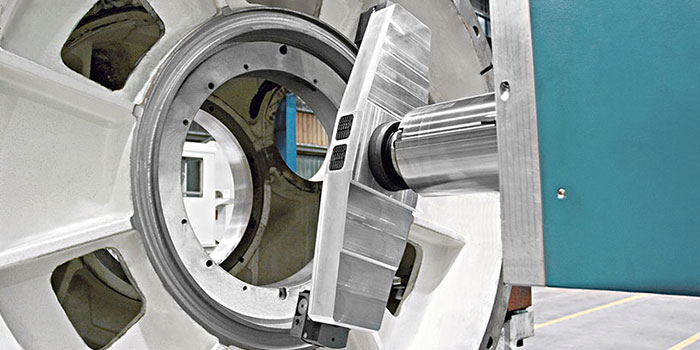

HORIZONTAL BORING Â MILLING MACHINES

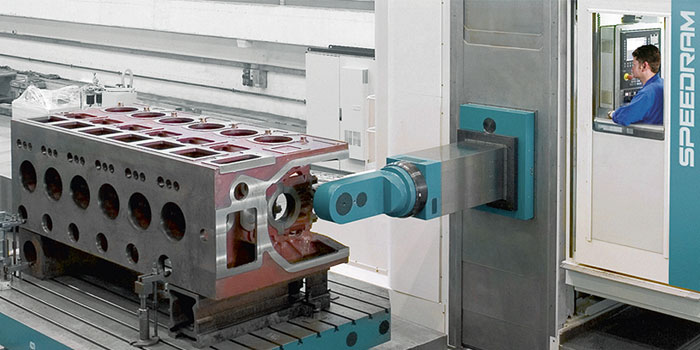

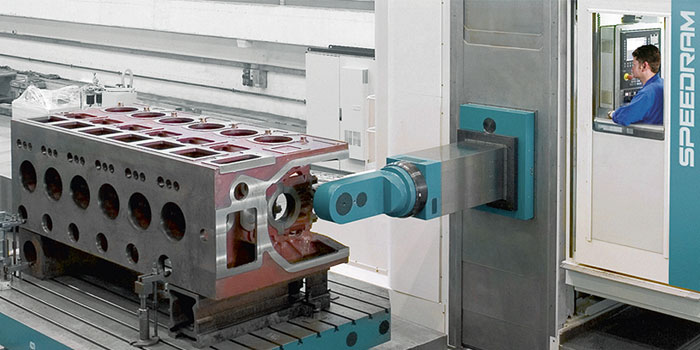

SPEEDRAM

-

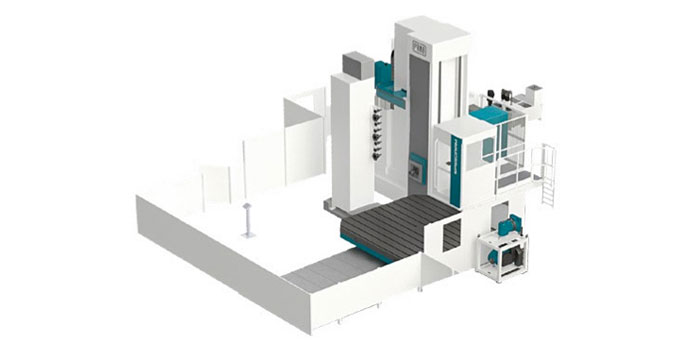

Floor type horizontal boring and milling machine

The Speedram boring and milling machines adopt preloaded hydrostatic guides on the X and Y axes to make full use of the advantages of rigidity and damping of the vibrations.

The focal point of the PAMA Speedram machine is the ram, guided inside the headstock by hydrostatic pads, and equipped with a boring bar exclusively with mechanical transmission. Both the ram as well as the boring bar have a feedback system to compensate for any elongations caused by temperature variations.

This solution guarantees maximum precision and rigidity together with high damping of the vibrations, very close to where they are generated.

The structures of the PAMA Speedram boring and milling machines were studied using modern finite element analysis techniques with the purpose of optimising the masses and guarantee high static and dynamic rigidity, as well as optimum thermal symmetry.

Depending on workpiece requirements, the PAMA Speedram machine can be customised and configured by selecting from

- a vast assortment of standard or customised CNC attachment heads

- a wide assortment of milling or turning tables

- a wide assortment of tool magazines and tool and CNC attachment head magazines

SPEEDRAM HP

-

Floor type horizontal boring and milling machine

PAMA Speedram HP boring and milling machines combine maximum damping, maximum rigidity, high spindle speed with optimal working precision to satisfy more difficult applications when machining medium and large-sized components, where horizontal machining is preferable.

PAMA Speedram HP boring and milling machines adopt preloaded hydrostatic guides on the X and Y axes to make full use of the advantages of rigidity and damping of the vibrations.

The focal point of the PAMA Speedram HP boring and milling machines is the ram, guided inside the headstock by hydrostatic pads, and equipped with a boring bar exclusively with Direct Drive transmission.

Both the ram as well as the boring bar have a feedback system to compensate for any elongations caused by temperature variations. This solution guarantees maximum precision and rigidity together with high damping of the vibrations, very close to where they are generated.

SPEEDMILL B

-

Floor type horizontal boring and milling machine

PAMA Speedmill B boring and milling machines combine high levels of damping, dynamics and spindle speed with optimal working precision to satisfy the most complex applications when machining medium and large-sized components, where horizontal machining is preferable.

PAMA Speedmill B boring and milling machines have a thermal symmetric column with a centrally mounted head for maximum precision and have roller guideways on the X and Y axes to take full advantage of dynamics on the axes.

The focal point of the PAMA Speedmill B machine is the ram, guided inside the headstock by hydrostatic pads, which has a real-time feedback system to compensate for any elongations caused by temperature variations.

This solution guarantees maximum precision and rigidity together with high damping of the vibrations, very close to where they are generated.

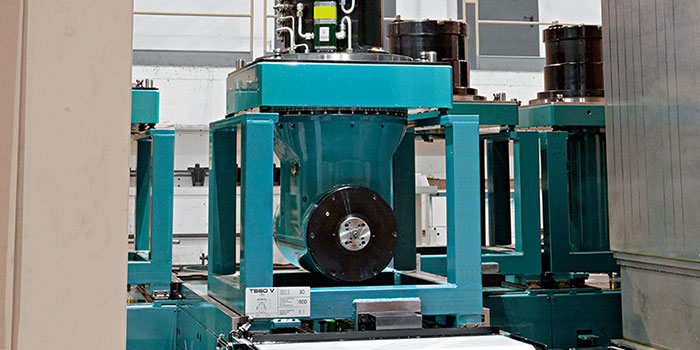

Gantry Machining Centers

VERTIRAM TT

-

Vertical machining centers, traveling table

The medium-small sized PAMA Vertiram TT vertical machining centers combine dynamics and high spindle speed, whereas the medium-large size combines maximum damping, maximum rigidity and high spindle torque. Both guarantee optimal workpiece precision.

The wide range of the PAMA Vertiram TT is able to satisfy the most difficult machining applications for the majority of small, medium and large-sized components for which vertical machining is preferred.

The PAMA Vertiram TT machines can be equipped with a mobile crossrail to increase versatility and better adapt the spindle height to the workpiece being machined.

The medium-large sized PAMA Vertiram TT machines have roller guideways on the linear axes to optimize the axes dynamics, whereas the medium-large sized machines have preloaded hydrostatic guideways to optimize the advantages of rigidity and vibration damping.

The focal point of the PAMA Vertiram TT machine is the ram, guided inside the headstock by hydrostatic pads, which has a real-time feedback system to compensate for any elongation caused by temperature variations. This solution guarantees maximum precision and rigidity together with high damping of the vibrations, very close to where they are generated.

VERTIRAM GT

-

Vertical machining centers, traveling gantry

The medium-small sized PAMA Vertiram GT vertical machining centers combine dynamics and high spindle speed, whereas the medium-large size combines maximum damping, maximum rigidity and high spindle torque. Both guarantee optimal work precision.

The wide range, PAMA Vertiram GT is able to satisfy the most difficult machining applications for the majority of small, medium and large-sized components for which vertical machining is preferred.

PAMA Vertiram GT machines can be equipped with mobile crossrail to increase versatility and better adapt the spindle height to the workpiece being machined.

The medium-large sized PAMA Vertiram GT machines have roller guideways on the linear axes to make full use of the dynamics on the axes, whereas the medium-large sized machine has preloaded hydrostatic guideways to make full use of all the advantages of rigidity and vibration damping.

The focal point of the PAMA Vertiram GT machine is the ram, guided inside the headstock by hydrostatic pads, which has a real-time feedback system to compensate for any elongation caused by temperature variations. This solution guarantees maximum precision and rigidity together with high damping of the vibrations, very close to where they are generated.

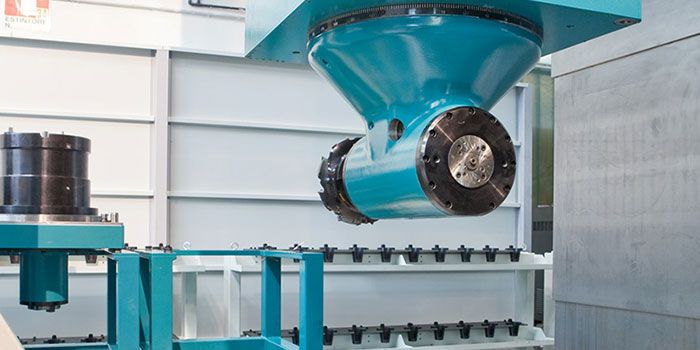

Accessories

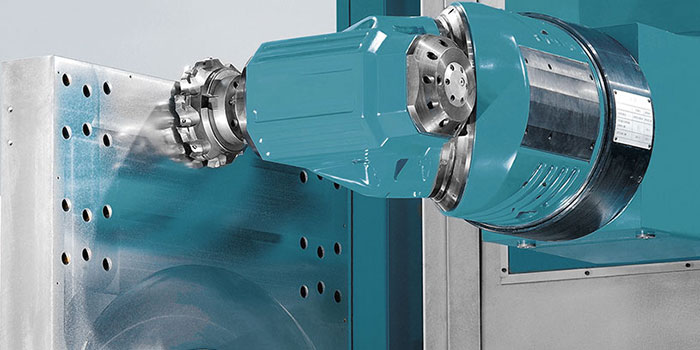

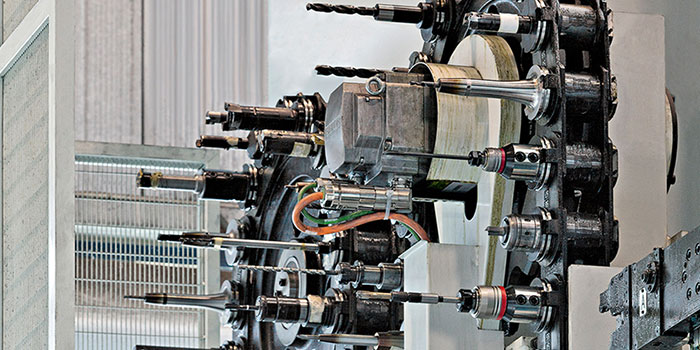

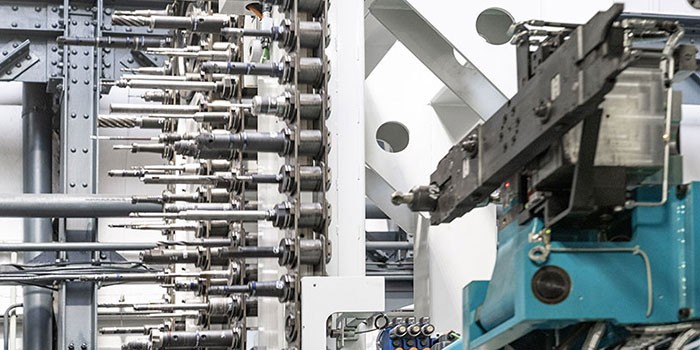

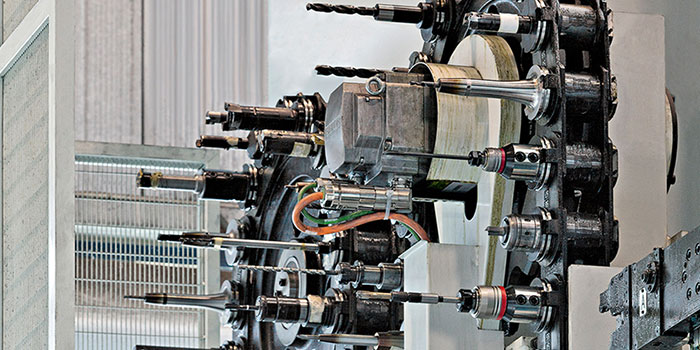

HEAD ATTACHMENTS

-

HEAD ATTACHMENTS

PAMA has a wide range of Attachment head magazines that were designed and developed to interface with horizontal or vertical machines- RT Radial turning heads for horizontal and vertical machines

- AT Axial turning heads for horizontal and vertical machines

- RT/AT Radial/axial turning heads for horizontal and vertical machines

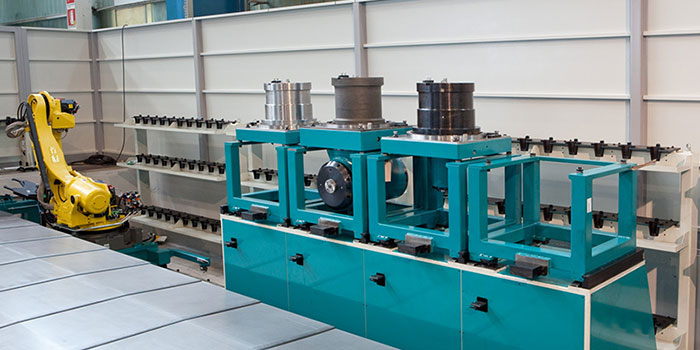

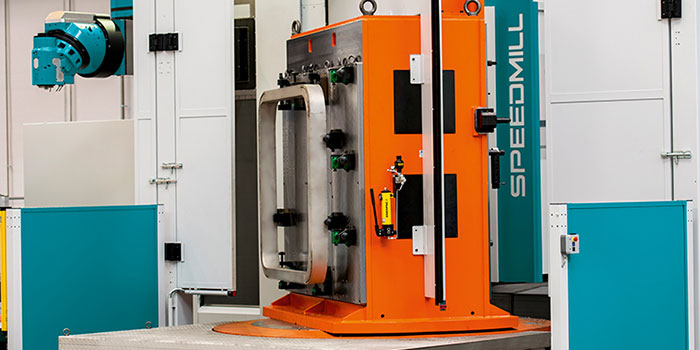

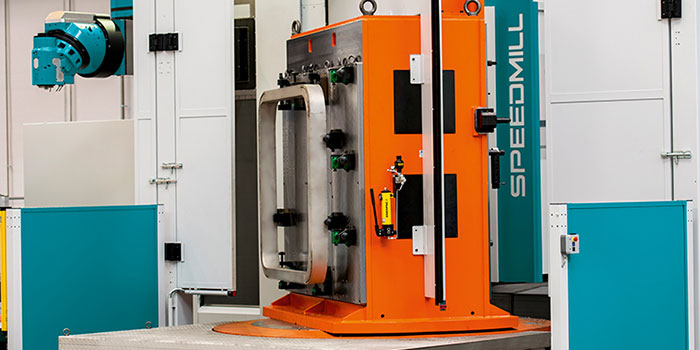

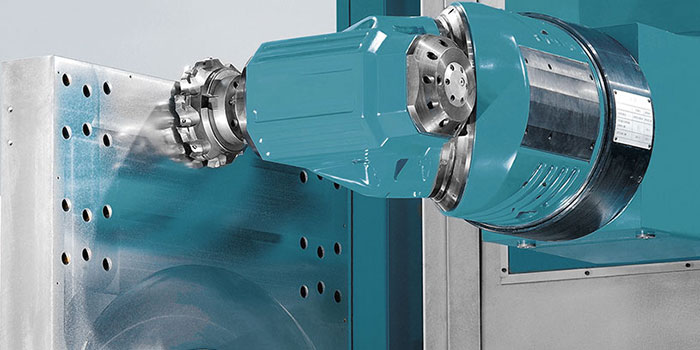

ATTACHMENT HEAD MAGAZINES

-

PAMA has a wide range of Attachment head magazines that were designed and developed to interface with horizontal or vertical machines.PAMA attachment heads magazines for vertical machines

The PAMA Attachment head magazine (pick-up) is a structure able to receive and protect the attachment heads from any contamination generated by machining or the workshop environment when they are not in use.

Depending on the selected configuration, the PAMA attachment head magazine can be:

- installed in a fixed position

- equipped with a translating slide to minimise attachment change times

- installed on the machine to minimise the attachment change times and the occupied space

The attachment head change operations are completely automated.

- Fixed PAMA attachment head magazines for vertical machines

- Carousel PAMA attachment head magazines for vertical machines

- Shuttle PAMA attachment head magazines for vertical machines

DIVIDER - STEADY RESTSS

-

PAMA machines can interface with part rotation systems with hydrostatic and tailstock steady rests, part rotation systems, hydrostatic steady rests and trunnion systems.

NC dividers

- divider plate from 1,250 mm up to 1,600 mm

- radial capacity from 100 t to 120 t

Steady rests

- Hydrostatic steady rests with capacities up to 120 t

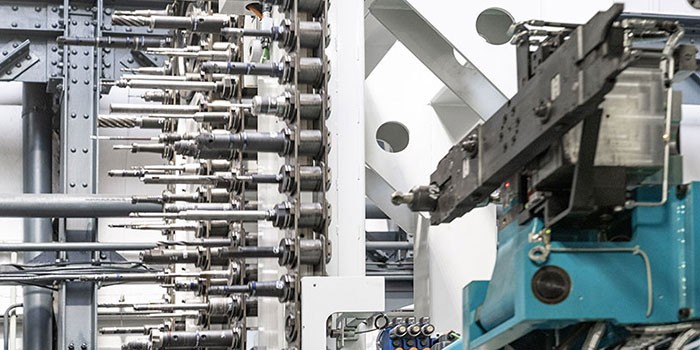

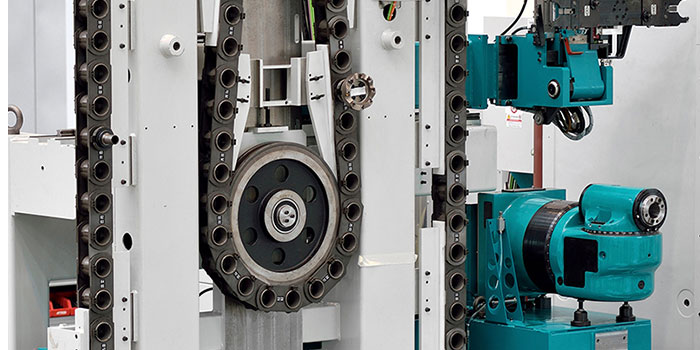

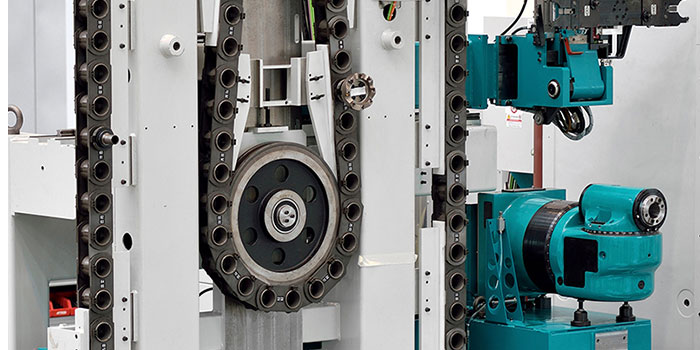

TOOL MAGAZINES

-

PAMA has a wide range of Tool magazines that were designed and developed to interface with horizontal or vertical machines.

PAMA chain tool magazines

The PAMA chain tool magazines are comprised of an electro-welded steel structure and a rotating chain to support the tools in a horizontal position.

Depending on the selected configuration, the PAMA tool magazines can be installed on the floor or on the machine.

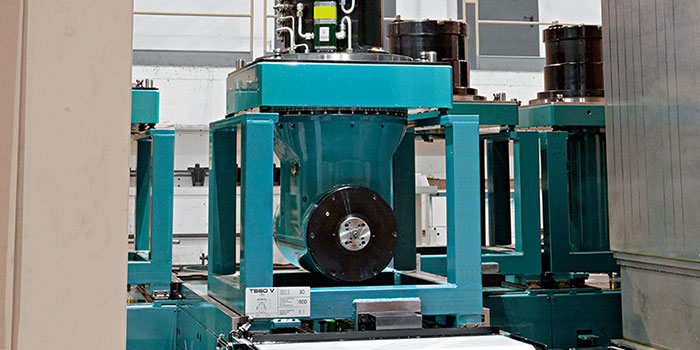

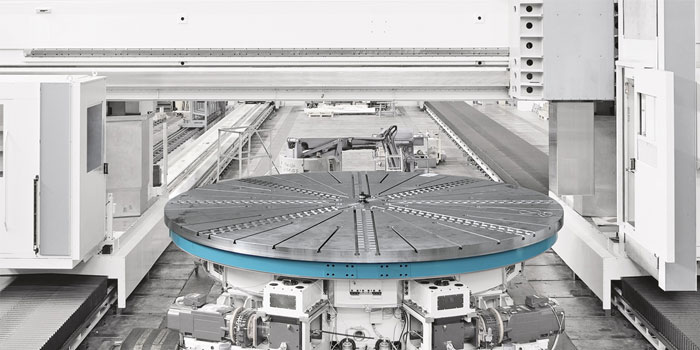

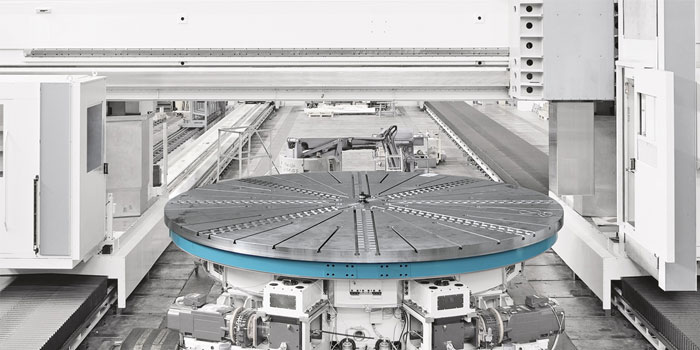

Tables

-

PAMA has a wide range of tables that have been studied and developed for performing milling, boring and turning work, which were fully designed developed at its site in Rovereto.

PAMA has recently developed in-house a range of tilting tables for the wind energy sector as well as others.

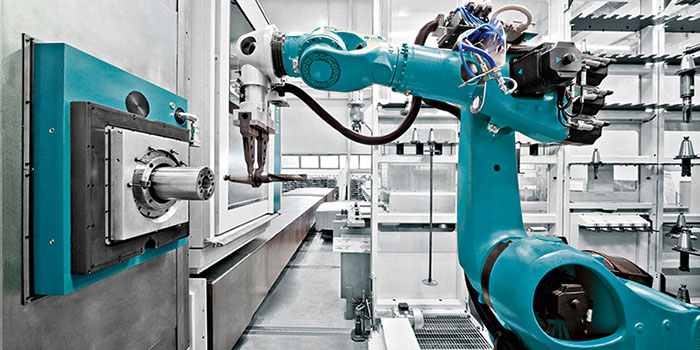

AUTOMATION

-

A single machine for multiple operations

PAMA is able to propose and supply solutions that are automated on different levels depending on customer requirements.

Automation

-

It starts from a single machine interfaced with a pallet change system, passing to a machine interfaced with a multi-pallet system and finally a production system comprised of multiple machines interfaced with each other.

The machines have highly automated tool and attachment changing systems and all systems that make it possible to work unattended.

Main advantages:

- better rescheduling of machining in the case of emergencies

- better productivity

- less machine downtime

- lower costs for tools and personnel

- unattended machining

TECHNOLOGY SERVICES

- Pama is organised with specialised technicians dedicated to the development of intelligent systems with the aim of increasing the productivity and efficiency of the machines as well as supporting and training the customer.

SOFTWARE and INDUSTRY 4.0

-

PAMA has developed intelligent software solutions able to collect, analyse and process data to offer customers not only support and management of the machine tools but also the workshop.

In modern industry, it has become of fundamental importance to have interconnected machines equipped with advanced solutions that permit increasing productive efficiency and the reduction of waste.

We offer:

- PGE is a software option developed by PAMA to reduce the machine’s energy consumption.

- P HUB is a software platform developed by PAMA that makes it possible to exchange data between the machine and the corporate IT system.

- PMP is a software developed by PAMA for managing preventive maintenance operations from the machine.

- PR2 SUITE is a multi-user software platform developed by PAMA for the support and management of the machine tool and the workshop.

PAMA TECH CENTER

-

PAMA has a PAMA technology center is dedicated to research and development, execution of tests on customer components and collaboration with suppliers.

- continuous training of PAMA personnel with theoretical and practical instruction targeted towards improving support service and technological consultancy levels

- theoretical and practical training for customers

- seminars in collaboration with our technological partners

- network of companies in innovative sectors and reinforcement of traditional sectors by increasing the level of technology and qualitative standards

- R&D activity based on actual market needs, which identifies the criteria for success to increase the competitiveness of PAMA customers

ADVANCED TECHNOLOGY & INNOVATION

-

PAMA has developed intelligent systems that make it possible to increase machine efficiency and productivity while at the same time supporting the operator to make its use easier.- Hydrostatic Sliding Spindle (PAMA S.p.A. patent)

- Hydrostatic Tilting Compensation (PAMA S.p.A. patent)

TECHNICAL AND TECHNOLOGY SERVICES

-

PAMA is organised with specialised technicians who analyse the machining requests and propose technological solutions able to optimise the customer’s production processes.

Machine startup and machining support

- support to the customer during machine startup and when machining the first parts at the customer site

Pre-sales machining tests on the customer parts

- technological study of the part

- technological study of the tools and equipment

- execution of the part

Post-sales machining tests

- machining tests at the Pama site and at the customer site

Machine study

- technological study of the part

complete study of the most suitable machine configuration

Machine and equipment study and Turn-Key

TRAINING

-

PAMA is organised with specialised technicians for the certified training of operators, programmers and maintenance staff on PAMA machines.

During training participants receive complete documentation and, depending on the requirements, training can take place at the PAMA or the customer site.

Courses can be customised with a level of detail depending on customer needs.

Operator training

- machine composition and safety devices

- machine operation

- machine operating and diagnostic modes

- special functions

Maintenance staff training

- machine composition and safety devices

- machine mechanics

- machine electrics and electronics

- machine hydraulics

Programmer training (Siemens, Heidenhain, Fanuc)

- machine composition and safety devices

- fundamental programming concepts

- advanced programming and parametrisation

- special PAMA options

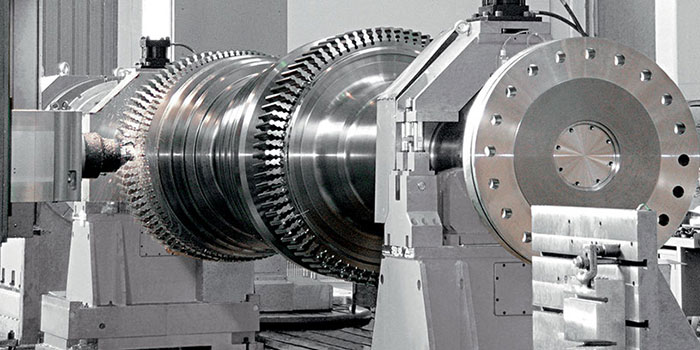

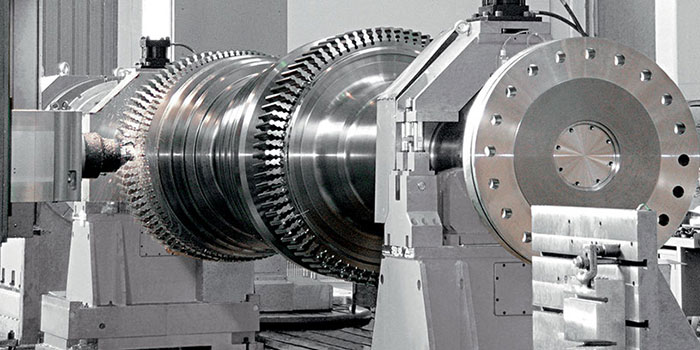

Applications

- Established in 1926, we at PAMA have made a strong name for ourselves throughout the world thanks to a combination of our tradition and the technological excellence of our products. PAMA produces in two production plants in Northern Italy. Over 80% of the production is exported, mainly to China, India, Russia, Germany and the USA: all countries are supported by sales and service organizations. PAMA, established in 1926, is one of the leading companies with over 90 years of tradition and knowhow, applied mainly to following fields of application: