Fezer

Videos

Loading the player ...

- Offer Profile

FEZER - simply move more.

A third generation family business FEZER belongs to the leading companies for vacuum handling with a worldwide outstanding reputation.

We keep in close contact with our customers to simplify and increase the safety of their production processes with innovative and economical solutions.

To ensure this we have a team of highly motivated, competent and totally reliable employees.

Our high grade of customer support is guaranteed with Quality Management as per DIN ISO 9001. Thus we can permanently analyse business processes and perfectly adjust them to the ever increasing requirements.

Product Portfolio

Tube Lifters

VacuPowerlift for univ. Loads up to 200 kg

- Tube Lifter

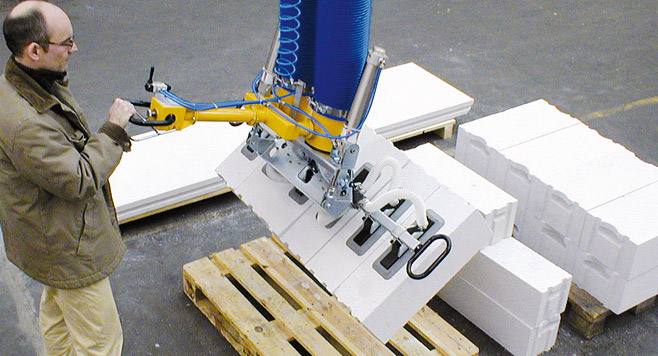

VacuPowerlift – tireless and powerful

The Tube Lifter VacuPowerlift captivates by its simple and easy operation.

With just one hand heavy loads up to 200 kg can be moved and handled effortlessly. Supported by the powerful pumps and blowers lifting speeds of up to 50 m/min can be achieved.

This guarantees a high output when stacking or commissioning different transport goods. The Tube Lifter VacuPowerlift not only excels by its very simple operation and high functionality, but proves as well to be the ideal working partner.

It relieves the operator the whole day and thus guarantees a more humane and safer workplace where work is really fun.

The application areas for the VacuPowerlifts are almost limitless. It is being used in many industries, simplifies production processes and increases the operation efficiency enormously.- Packing and logistics of cardboard boxes

- Chemical and pharma industry for drums and barrels

- Window and solar industry for glass panes and finished parts

- Wood, plastic and metal industry for plate material

- Construction industry for stones and concrete parts

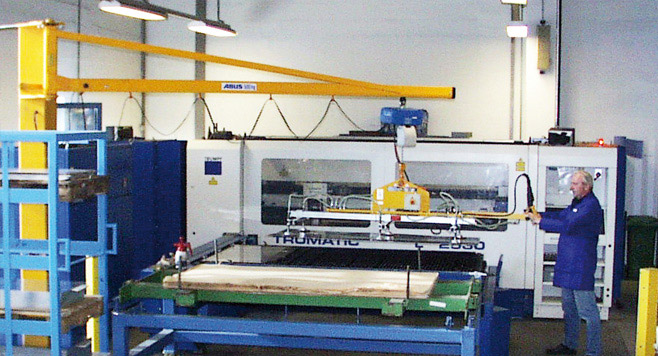

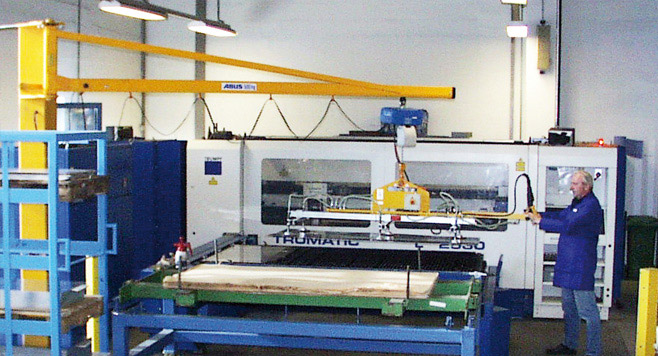

- Feeding of all kinds of CNC machines

- Handling of finished machines and machine parts

- Electronics industry for electrical appliances

- and many more

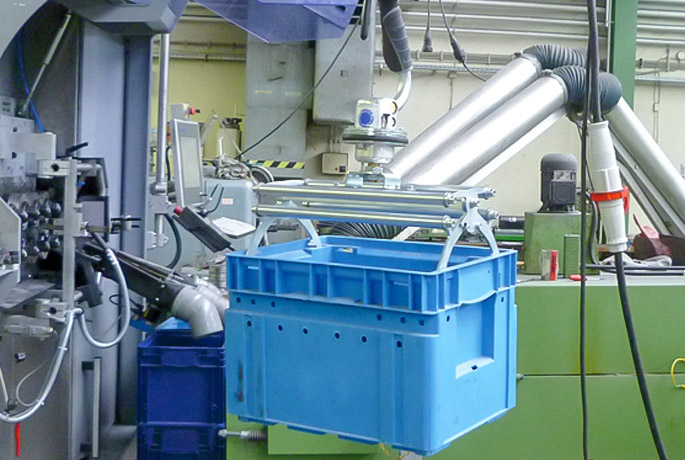

VacuQuicklift for univ. Loads up to 35 kg

- The new Vacuum Tube lifter VacuQuicklift combines many

advantages. With just one operating handle all the functions engagement,

lifting, lowering, and release can be controlled.

By its unique „Quick-Release-System“ the Tube lifter VacuQuicklift lifts automatically when release and does not have to be tilted. This makes the Tube lifter incredibly quick and guarantees shortest cycle times.

Ideal, if boxes, containers, or crates have to be commissioned or re-stacked.

The Tube lifter VacuQuicklift is available in two basic designs. The first one is for strictly horizontal applications, the second one with a swivel feature that allows to manually tip over workpieces. In both cases the VacuQuicklift is only controlled with one control handle, which makes the operation very simple and ergonomical.

With the free hand the loads can be brought into the target position. Thus the VacuQuicklift not only makes the daily work easier, it also increases the safety and ergonomy at the workplace.- Commissioning, stacking of boxes

- Handling of canisters, containers and small drums

- Handling of baggage

- Handling of sacks

Vacuum Lifters

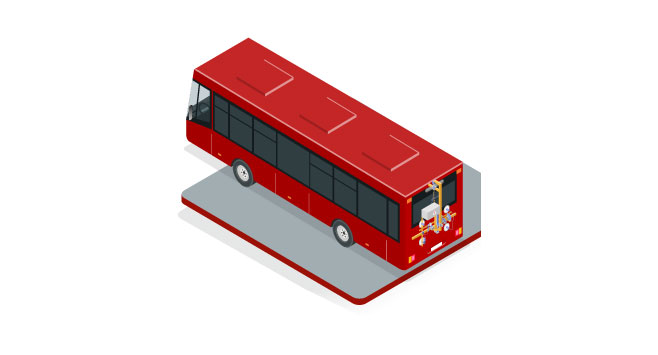

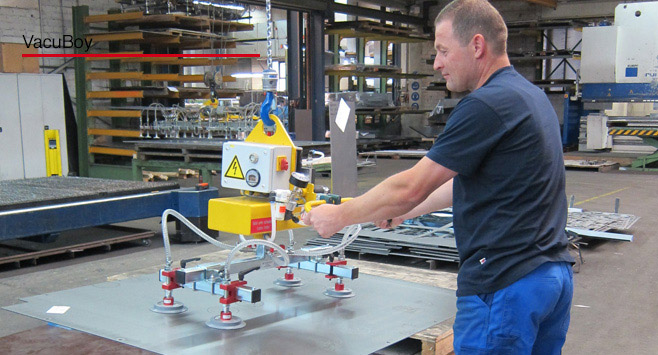

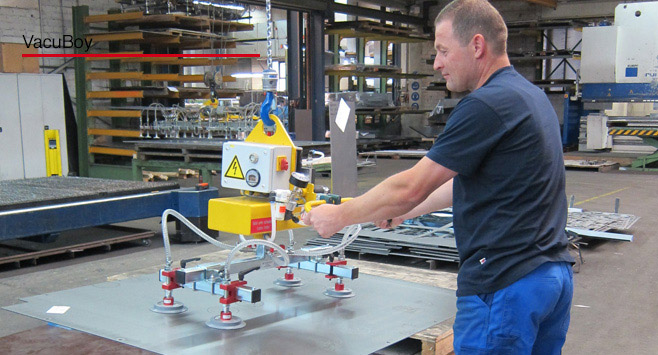

VacuBoy for dense plates up to 2000 kg

- VacuBoy - universally suitable Vacuum Lifters

These FEZER lifters are suitable for horizontal transport, swivelling or turning over plate materials of all kinds.

The vacuum lifters stand for absolutely gentle handling, efficient and ergonomical working processes with highest operational safety. For that reason all manually operated lifters are equipped with the unique "main switch supervision", which sets new standards when it comes to the safety of vacuum lifters.

VacuGiant for heavy sheets up to 40 t

- VacuGiant - move heavy Loads easily

The VacuGiants are Fezer's heavy-duty lifters.

They stand for highest capacities, hardest working conditions and the most stable design. Their sturdiness in connection with their simple control ensure efficient and economic working processes with highest operational safety.

All manually controlled vacuum lifters are equipped with the unique "main switch supervision". Fezer sets new standards when it comes to safety on vacuum lifters

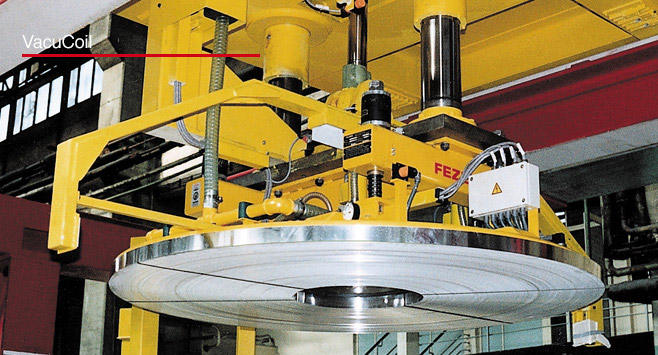

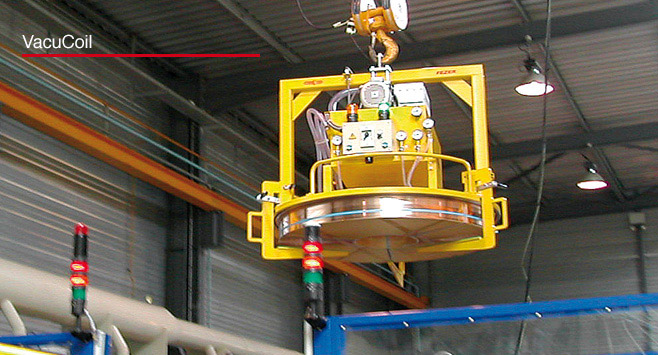

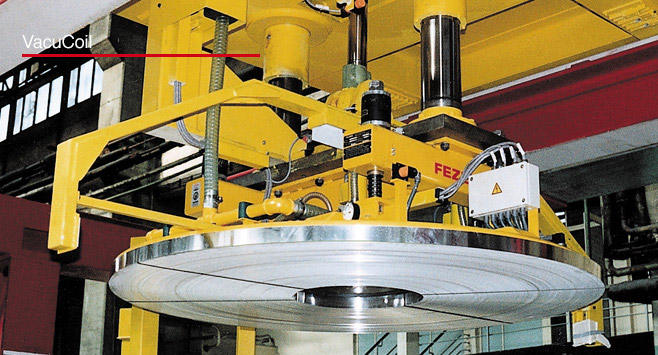

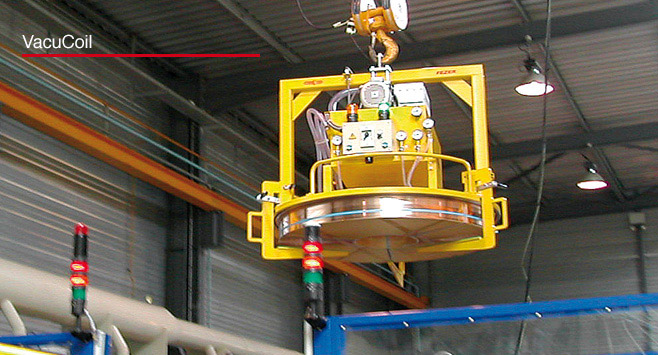

VacuCoil for split strips and coils up to 10 t

- VacuCoil for handling coils, split strips and paper

rolls

With the device series VacuCoil FEZER offers vacuum lifters for handling coils, split strips and paper rolls.

Depending on the requirements the lifters can be equipped with a steel, aluminum, or plastic suction plate. Depending on the density of the material powerful vacuum generators are being used to build up a safe operational vacuum. Additionally, the lifters can be equipped with features like single chamber supervision, automatic control of the required chambers or undergrippers for long transport ways. Fezer also offers system solutions to flange coil suction plates onto robots or linear axes. A data exchange of important signals guarantees a high operational and process safety.- Commissioning of coils and split strips

- Restacking, putting in or taking out of storage

- Use in automatic storage of paper rolls

- System solutions for robots and linear axes

VacuWood for planks and boards up to 1000 kg

- VacuWood - horizontal Transport of Planks and Gluelam Beams

With the VacuWood series Fezer offers special vacuum lifters for handling planks, boards and gluelam beams.

They are able to transport parts with a length of over 24 m in a safe and gentle way. For raw planks special suction pads are available that guarantee a 100% sealing. Additionally the lifters can be equipped with water separator, swivelling manipulating handle für long boards and electrical vacuum control. This guarantees you a high operational safety and quick, rational processes.- Engagement of planks after sawing

- Putting into and taking out of storage

- Commissioning of boards

VacuPoro for porous plates up to 2000 kg

- VacuPoro VP, VP-90E - horizontal and swivelling design

With the VacuPoro series FEZER offers a special vacuum lifter for handling porous materials.

Powerful vacuum blowers guarantee an absolutely safe operational vacuum. For different applications the lifters are available in horizontal or swivel design.

Both designs convince by their sturdy construction and the simple electrical vacuum control. Fezer also offers special designs in flat construction or for loads of several tons.- Handling of raw chipboards, MDF-, or OSB boards

- Feeding of lying or upright wood handling machines

- Commissioning of wooden boards

Cranes / Manipulators

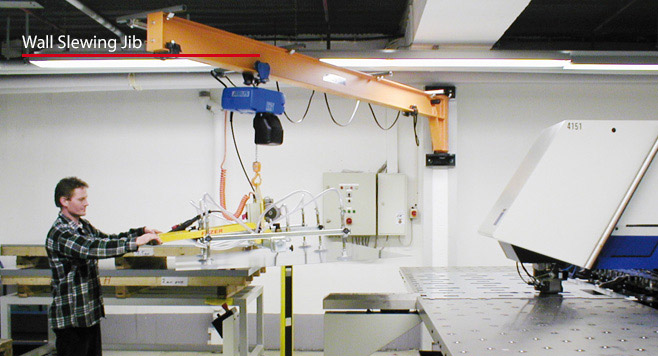

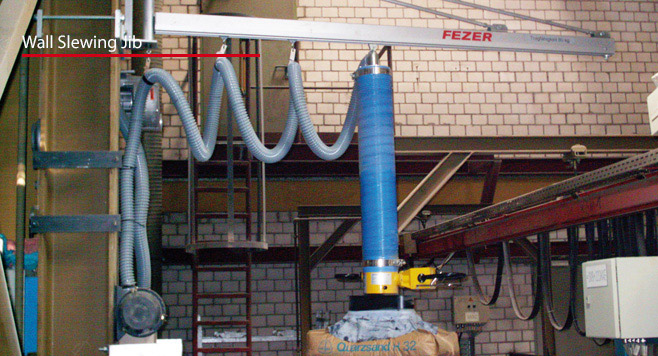

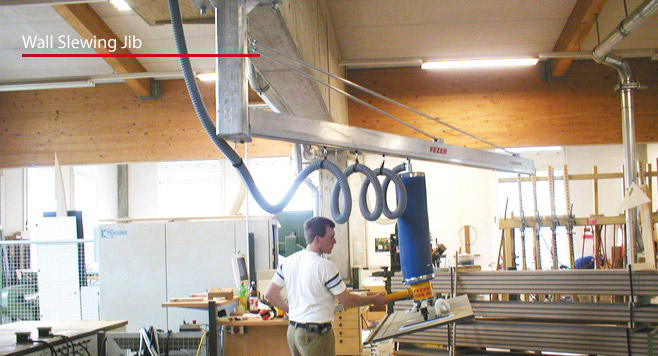

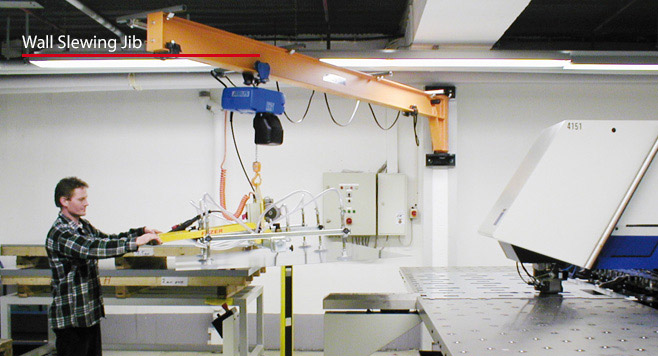

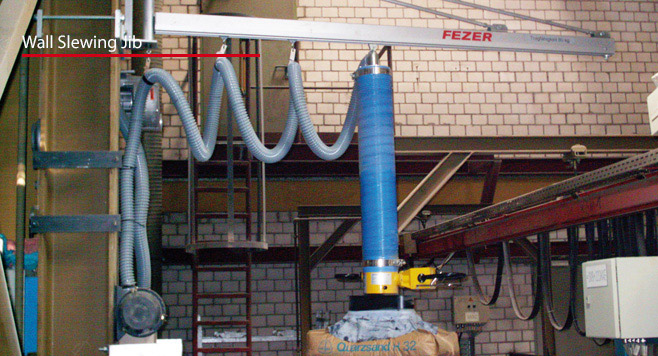

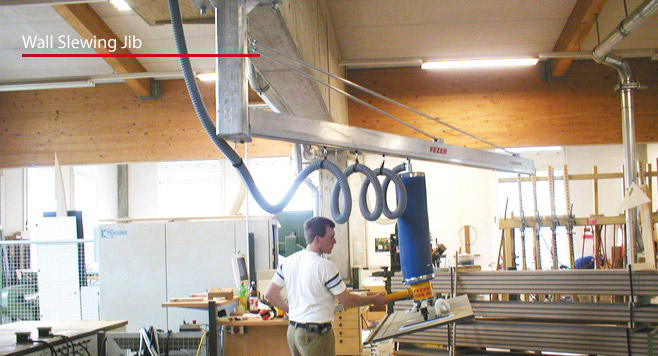

Wall-mounted jib cranes

- Wall-mounted jib cranes - for Loads up to 1.000 kg and jib lengths up to

6 m

The FEZER Wall-mounted jib cranes distinguish themselves by their sturdy design and their smoothness.

This is achieved by special console constructions with bush bearings and trolleys with large castors. For loads up to 500 kg FEZER offers their own aluminum track system which additionally supports the free movement. For higher capacities stable steel constructions are being used that guarantee a high degree of strain on slightest bending. In addition to the Wall-mounted jib cranes FEZER offers as well suitable chain hoists with two speeds and crane pendant.- smooth aluminum profile up to 500 kg

- highest operational safety by perfectly harmonized components

- stable and sturdy consoles with bush and ball bearings

- for higher capacities electrical drives

Column-mounted jib cranes

- Column-mounted jib cranes - for Loads up to 1000 kg

and jib lengths up to 6 m

The FEZER Column-mounted jib cranes distinguish themselves by their sturdy design and their smoothness.

This is achieved by special console constructions with bush bearings and trolleys with large castors. For loads up to 500 kg FEZER offers their own aluminum track system which additionally supports the free movement. For higher capacities stable steel constructions are being used that guarantee a high degree of strain on slightest bending. In addition to the Column-mounted jib cranes FEZER offers as well suitable chain hoists with two speeds and crane pendant- smooth aluminum profile up to 500 kg

- highest operational safety by perfectly harmonized components

- stable and sturdy consoles

- for higher capacities with electrical drives

- direct connection on the floor without intermediate plate

- mobile base plate (on aluminum design) for free installation and positioning with a forklift truck

- design with telescopic and arresting column

Overhead crane systems

- Overhead crane systems - for areas of up to 50 x 12 m

No matter if single track, single bridge or double bridge design. The perfectly attuned components allow to adjust the crane system to your individual requirement.

Ceiling, I-beam or gluelam beam suspensions - for all needs the correct connections are available and guarantee a safe suspension. For loads up to 500 kg FEZER offers the self-developed aluminum rail system that allows to move loads effortlessly and which can cover 100 m or more. For higher capacities steel rails are being used which can even realize long suspension distances and bridge constructions.- Smooth and sturdy aluminum profiles with lengths of up to 12 m and loads up to 500 kg

- Vast accessory range for limits, trolleys, connections and suspensions

- Drives for electrical movements as option

- Special solutions for special applications

Rigid Lifting System LiftFix

- LiftFix LF - Rigid Guiding System up to 500 kg

In combination with the smooth aluminum rails FEZER offer a rigidly guided system that allows to precisely place and pick up loads.

The telescopic aluminum profiles with their sturdy and exact guides not only allow large strokes with low heights, but also to pick up off-center loads which makes it possible to feed over-built machines. The stroke can be controlled sensitively with two speeds.

There are a multitude of options so that almost any application can be realized.- Telescopic lifting system with sliding guides

- Lifting drive by chain hoist with two speeds and adjustable limit switches

- Friction wheel drives for electrical motions in x- and y-direction

- Flange-on grippers with vacuum or mechanical clamping elements

- Ergonomical manipulating handles with all required control buttons

Working Stands

Manual Working Stand VacuStand VSI+II

- VacuStand VSI+II Working Stands with rotation and

swivel features

The Working Stands distinguish themselves by their light and very sturdy design. The workpieces are automatically engaged and safely held when being set down.

On the VS-I sucked on workpieces can be swivelled manually by 90° and endlessly rotated. On the VS-II the workpieces can be swivelled by 90° in both directions. The pre-adusted positions can be clamped manually or by foot control. They are released by simple activation of the foot control, so that the workpiece can always be held onto. Additionally, the Working Stands can be equipped with different suction pads, pneumatic drives and different vacuum generators. The areas of application are almost limitless:

For both designs various suction pads and attachments and a multitud of accessories are available.- Allround handling of workpieces of all kinds

- Assembly aids for working on glass panes

- Fasten brackes in the furniture industry

- Assembly aids for automated production processes

Turning Table VacuStand VS 180E

- Stationary turning stations

For the integration in running work processes where workpieces need to be turned over the stationary turning stations by FEZER offer a multitude of advantages.

By vacuum technology workpieces can be safely engaged within seconds and turned over in a gentle way. And this, if required, within 20 seconds. Individual requirements allow to adjust the turning tables to adjust to different production processes. Stipulated safety functions and exchange signals can be simply integrated and controlled by SPS. There are almost no application limits for the turning stations:- Turning over of workpieces on CNC machines

- Assembly aids for automotive industry

- Turning over workpieces to control surfaces

Mobile Working Stand Mobilift ML

- MobiLift ML - Mobile Working Stand with lifting drive

up to 200 kg

The mobile working stands MobiLift ML are suitable aids to lift loads and move them from one place to the other.

The large dimensioned castors can even push effortlessly loads up to 200 kg. The stroke is carried out by a tilting lever which is controlled by an electrical drive. The power is supplied by integrated batteries which are charged by a charging cable. FEZER offers both the simple lifting aids and devices with integrated vacuum technology and additionally electrically driven axes. Therefore the MobiLift can be used for a variety of applications:- Lifting aid for all kinds of loads

- Commissioning of workpieces

- Simple assembly aids

- Mounting aids for CNC machinery

- Handling of coils and split strips

Branches

Automotive

- Vacuum Lifters for Automotive Industry

Handle simple and safe formed, chassis, assembly parts or whole front, side and roof elements.

With FEZER vacuum lifters you not only rationalize your production processes, but at the same time you increase the operational safety and ergonomy of your work places. The individual workpieces can not only be transported horizontally, but also be rotated, swivelled or turned over.

The vacuum lifters guarantee a safe and above all gentle handling of the automotive parts. For handling processes that are carried out with a crane the VacuBoy series is being used. This series features a robust design and a clever modular system which allows to adjust it to individual requirements.

For exact positioning FEZER offers you the Liftfix system. With our own aluminium suspension crane system with rigid guiding system we offer you a complete system to transport and install individual parts. Additionally FEZER also offers complete suction spiders to flange onto robot systems or linear axes. These can be integrated in existing controls and automates handling tasks with shortest cycle times and highest process safety.

Metal sheets up to 2000 kg

- Safely lift Sheets and Plates up to 2000 kg

For handling plates up to 2000 kg FEZER offers you the universally suitable series VacuBoy.

No matter if the workpieces have to be transported horizontally, swivelled or turned over by 180° the lifter VacuBoy is the ideal help to feed sheet working machines, commission dense, plate-like materials or bring them into or take them out of storage. Fpr special applications the VacuBoy can be adjusted to different requirements. The clever modular system knows almost no limit and allows a nearly unrestricted adjustment to different requirements. The sheet lifters stand out because of their robust design, simple operation and high safety features. All manually controlled sheet lifters are equipped with the unique "main switch supervision". FEZER sets standards when it comes to the safety of your personnel.

For automated working processes FEZER offers you these sheet lifters with mounting elements to flange onto hoist axes, linear systems or robots. In both cases you can rely on the dependability and safety of the systems. Large dimensioned vacuum tanks and intelligent control and supervision systems make this sheet lifter a universally suitable all-rounder.

Metal sheets over 2000 kg

- The VacuGiant series can transport sheets of more than

30m of length, 4m of width and weights of above 40 tonnes in a safe, quick

and absolutely gentle way.

The lifters are mainly used in steel and aluminum roller mills and for feeding giant CNC machines or else as assembly aids for lorry superstructures or others applications. Loads can not only be moved horizontally, but also be swivelled or turned over. The robust steel profile design and the special suction plates guarantee that these heavy duty lifters transport large plates absolutely safe and gentle. Additionally all manually controlled lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the saftey of your personnel.

Even for automated work processes FEZER offers these heavy duty lifters with connection elements to flange them onto hoist axes and linear systems. In both applications you can rely on the dependability and safety of the systems. Large dimensioned safety tanks and intelligent control and supervision systems puts these giant lifters into a class of their own.

Coils, Split strips

- Whether in automated processes or for manual handling

technology. To transport and swivel coils and split strips you can rely on

the qualities of the VacuCoil series.

To feed mandrils, separate cut strips or for automated commissioning and storage - the VacuCoils convince by their robust design and intelligent safety concept. Loads of up to 10 tonnes can be transported and swivelled effortlessly. FEZER relies on the proven safety features. Large dimensioned safety tanks and intelligent control and supervision systems guarantee an absolutely safe handling of coils and split strips. Additionally all manually controlled vacuum lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the safety of your personnel.

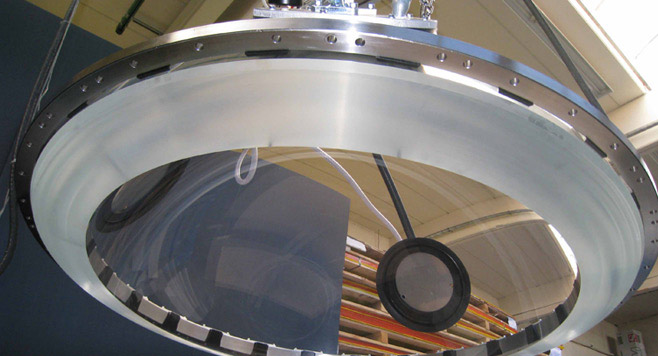

For special handling tasks FEZER offers special solutions. Suction plates are available in "flattened" design allow to centrally lift standing split strips with different outer diameters. With the "transparent" suction plate the operator has always a clear vision and always finds the center. Addtionally the coil lifters can be equipped with centering pins or mechanical undergrippers if long transport ways through large halls have to be covered.

Drums, Barrels, Containers

- For lifting drums, canisters and containers FEZER

offers you several solutions.

These loads can be handled very quickly with the Vacuum Tube Lifters VacuPowerlift and VacuQuicklift. They not only use the vacuum for engagement, but also for the lifting motion. Therefore no additional lifting unit like chain hoist or balancer is required. FEZER also offers solutions where the loads are strictly manually engaged by means of clamps or undergrippers. This is recommended for canisters and containers that have no suction area to speak of.

The VacuBoy series can move drums, canisters and containes with the aid of crane systems and chain hoists. The VacuBoy captivates by its robust design and safety features. Special adaption of the suction pads allow the VacuBoy to handle several drums, canisters or containers at the same time which reduces cycle and processing times. Additionally all manually controlled vacuum lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the safety of your personnel.

Glass

- Safey Handling of Glass and Window Elements

Glass- and window elements are absolutely vacuum-dense and therefore ideally suited for handling them with vacuum technology.

FEZER offers a variety of application for automated and manual transport of these materials. No matter, if glass elements need to be transported horizontally, rotated or swivelled. FEZER offers you with the VacuBoy series the ideal handling device for glass elements. The series is that variable that almost any application can be covered.

Even for the use on construction sites FEZER can offer redundant designs with two-circuit systems as per DIN EN 13155. Additionally all manually controlled vacuum lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the safety of your personnel.

For automated production processes individually manufactured suction spiders are available that can be flanged onto robot systems and linear axes. Depending on the requirements the suction spiders are designed with simple control or via solenoid valve up to Bus control by valve islands.

All handling tasks contain the high FEUER safety standards. Large dimensioned safety tanks and intelligent supervision of the vacuum circuits guarantee a safe and rational transport with highest operational safety.

Wood

- For handling dense or porous wooden elements FEZER offers

various device series which can lift these workpieces in a safe and reliably

way.

The VacuWood can handle planks, boards and gluelam beams up to a length of 24 m. The vacuum is generated by oilless vacuum pumps which prevent oily residues on the wooden parts. This series is especially suitable for the safe restacking and commissioning of planks, boards and gluelam beams. Additionally all manually controlled vacuum lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the safety of your personnel.

For the transport of chipboards, MDF and OSB plates please choose the VacuPoro series.geeignet. The powerful blower guarantees that porous materials are safely engaged and transported. The series is also available with swivel feature; the plates can be picked up lying flat and transported to upright machines or vice versa.

Additionally chipboards, MDF and OSB plates can also be handled with the Tube Lifter VacuPowerlift. The tube lifter excels above all by its quick speed. Because the vacuum is not only used for engagement, but also for lifting the plates the lifter does not require additional lifting aids like chain hoists or balancers.

Cardboard boxes

- For handling cardboard boxes the most suitable are the

FEZER Tube Lifters.

No matter if you have to put into or take boxes out of storage, commission them or make them ready for packing reasons. The tube lifters VacuQuicklift and VacuPowerlift guarantee an absolutely safe handling at maximum speed.

With the powerful vacuum generators speeds of up to 1 m/s can be realized. To control these speeds safely both tube lifters are equipped with intelligent and very sensitive control units that allow the operator to handle them very easily. Additionally FEZER offers a variety of accessories and options for both tube lifters to adapt them to individual requirements and to guarantee a high grade of efficiency and ergonomy for your production processes.

Different suction pads are available for both tube lifters to ensure an optimum adjustment to the boxes. Also available are rotation features, extensions, and many more.

Plastic

- For handling plastic plates and formed parts the VacuBoy

and the FEZER Tube Lifters are suitable.

No matter whether you have to transport horizontally, swivel or turn over the VacuBoy is the right partner. This type guarantees an absolutely safe, reliable and gentle handling of your plastic plates. The lifters are just suspended from a crane, supplied with electricity and are instantly ready for operation. Additionally all manually controlled vacuum lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the safety of your personnel.

The FEZER Tube Lifters are universal devices that can not only engage formed parts but also grip or clamp them mechanically. Thus formed parts with complex outer dimensions can be safely engaged and moved. The tube lifters not only work particularly fast, but also absolutely safely and gently.

Their sensitive control unit make them easy to handle and increase the ergonomy and efficiency of your workstations.

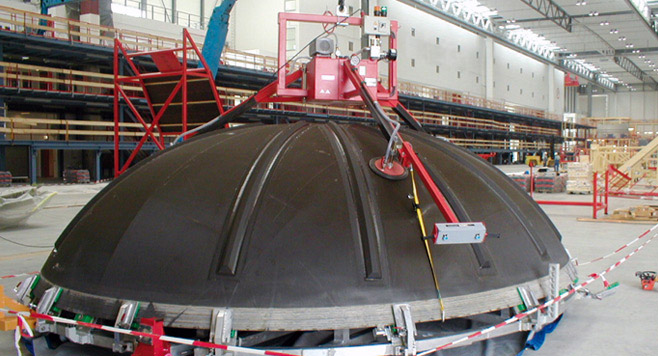

Aeronautics

- Payload covers, pressure bulkheads, chambered wing parts

or 40 m long aluminum plates - for Aeronautics FEZER offers special vacuum

lifters that meet the high requirements of this industry.

As here, after the safety of the operators, particular attention is paid to the safety of the parts. Parts for Aeronautics have an enormous high value and the smallest damage or deformation can lead to them being rejected.

Therefore FEZER lifters are equipped with special features like specially suspended suction pads with clamps, redundant two-circuit systems or interruption-free power supply so that the parts can be fixed absolutely without stress and even kept in place for hours after a power failure.

Paper

- For handling paper rolls in automatic storage FEZER

offers robust, efficient and above all highly intelligent paper lifters.

These are distinguished by high economy and operational safety. Telescopic centring pins can adjust themselves to different core diameters and guarantee an exactly centered engagement. Light sensors integrated the crane control make sure that they are exactly positioned. Additionally the correct setting-down is controlled by sensors and a deviation is reported back to the crane control. The vacuum supervision is done by special vacuum sensors that realize a possible decrease of the vacuum instantly and report back. On a possible power failure an integrated, interruption-free power supply guarantees that the engaged paper rolls are kept in place for a sufficient time period.

For fully-automatic production processes for sheet and circuit board handling with paper layers FEZER offers complete suction spiders that alternately separate sheets and paper layers. Thus production processes can be done efficiently and economically in combination with highest operational safety.

Pipes, tubes

- The handling of Pipes, Rods and Profiles requires a large

know how and lots of experience.

FEZER offers special suction pads that can engage a large diameter range. This saves high preproduction costs. No matter if you have to handle pipes, rods and profiles manually or in an automated operation. Additionally, FEZER offer many option to adjust the pipe and rod lifters to your individual production processes.

For variable tube lengths different suction circuits can be built in which are automatically switched on or off. This is done by flow valves that switch off the suction pads if they are not engaged or else by intelligent system solutions with vacuum supervision and valve islands.

On manually led pipe and rod lifters the required suction pads can be manually switched on and off. Furthermore, FEZER offers exchangeable attachments should the diameter range become too large to be picked up with one suction pad design.

Sacks

- For handling sacks particularly suitable are the FEZER

Tube Lifters.

Putting into or taking sacks out of storage, commissioning or prepare them for packing. The tube lifters VacuQuicklift and VacuPowerlift guarantee an absolutely safe handling of sacks at maximum speed. With powerful vacuum generators a lifting speed of up to 1 m/s can be reached.

To control these speeds safely both tube lifters are equipped with intelligent and very sensitive control units that allow the operator to handle them very easily. Additionally FEZER offers a variety of accessories and options for both tube lifters to adjust them to the individual requirements and thus achieve a high grade of efficiency and ergonomy.

Various sack suction feet are available, to adapt them in the best way to different sacks. Also available are rotation features, extentions and many more.

Stone, concrete

- No matter if for manual or automatic processes. FEZER

offers a variety of solutions to transport these parts efficiently and

economically.

For manual handling tube lifters and other vacuum lifters are available that allow to swivel or turn over stones and concrete parts. Up to a weight of several tonnes. The lifters are distinguished by a high operational safety, even on extremely rough surfaces. Special suction pads and sealing profiles keep the stones and concrete parts engaged for a sufficient time period even after a power failure. Additionally all manually controlled vacuum lifters are equipped with the unique main switch supervision. FEZER sets new standards regarding the safety of your personnel.

For automatic processes to transport, swivel and turn over stones and concrete parts FEZER offers highly effective and intelligent vacuum components. Powerful vacuum generators build up the required vacuum. Robust and precise vacuum switches supervise the vacuum and report in case of failures. Thus process and operational safety can be increased and high availability can be maintained.

Wind power

- Transportation of steel plates and cross segments with

several tonnes of weight.

FEZER offers special solutions for this. They can not only transport the rough sheets but also the finished welded tube segments. The combo lifters are equipped with suction pads on special suspensions and meachnical grippers to move the finished segments. The mechanical grippers can be moved to the required position via electric motors without having the operator having to lend a hand. This saves complex set-up costs and increases the efficiency and economy of the lifters.- Transport of heavy steel sheets

- Putting into and taking plates out of storage

- Handling of tubes and cross segments

- Special lifters for outdoors use

Vacuum Components

Suction Pads

- FEZER offers you a large range of suction pads in

different forms, sizes and materials. From universally suitable flat and

bellows cups to special suction pads for structured surfaces or tube and rod

materials. Here you can find the suitable suction pad for your application.

- Flat Suction Cup, round

- Flat Suction Plate, oval

- Bellows Suction Cup, round

- Bellows Suction Plate, oval

- Grip Suction Cup

- Bubble Cap Suction Cup

- Soft Suction Cup

- Foil Suction Cup

- Structure Suction Plate

- Separation Suction Plate

- Bar Suction Plate

- High Temperature Suction Plate

- Rectangular Suction Plate

- Sealing Profiles

- Accessories for Suction Pads

Mounting Elements in Modular Design

- For the right installation of suction pads FEZER offers a

multitude of different mounting element. From connection nipples to

suspension bolts to aluminum profiles for designing individual suction

spiders FEZER offers a vast range. The clever modular system makes it

possible to combine the elements at will.

- Mounting Elements

- Holders for Suction Pads

- Suspension Bolt

- Holders for Suspension Bolts

- Profile Systems

- Single Components

Vacuum Generators

- For the vacuum generation FEZER offers a wide range for

any application. From oilless and oil-lubricated vacuum pumps to extremely

powerful vacuum blower to the smallest inline ejectors and controlled

compact ejectors. FEZER provides for almost any application the right vacuum

generation.

- Vacuum Pumps

- Vacuum Blowers

- Accessories for Vacuum Pumps and Blowers

- Ejectors

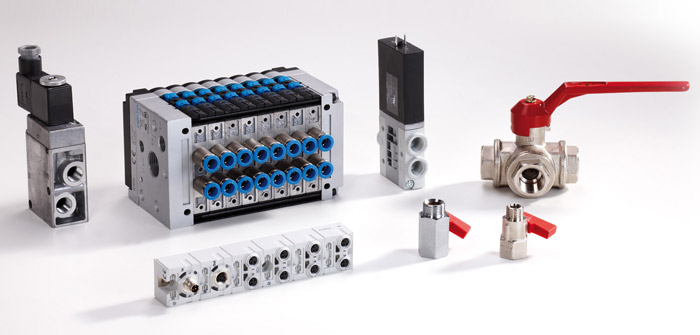

Valve Technology

- Vacuum Valves and Vacuum Islands

For controlling vacuum circuits FEZER offers a multitude of different valves. Whether manual, electrical or automatic or controlled via Bus technology - FEZER provided the suitable valve technology in robust and intelligent design.- Electro-Pneumatic Valves

- Solenoid Valves

- Manually controlled Valves

- Automatic Valves

Vacuum Supervision

- Vacuum Switches, Vacuum Gauges, and Warning Units

For automated processes FEZER provides electronical vacuum switches with digital display and several adjustable exits as well as analogous vacuum switches for the permanent supervision of the vacuum level and corresponding analysis possibilities. Visual vacuum gauges and intelligent warning units for manual handling complete the production range.- Mechanical Vacuum Switches

- Electronical Vacuum Switches

- Measuring and Warning Units

Filter Elements

- Vacuum and Ventilation Filter

To protect vacuum valves and vacuum generators from pollution and resulting operational failures FEZER offers a large range of vacuum and ventilation filters. From the smallest inline filters to cup filters to large dimensioned filters with sheet metal housings. All filters are equipped with exchangeable filter cartridges, that can be cleaned or exchanged if necessary.

Connection Elements

- Plug-in Connections, Hoses, and Cables

The complete program for safe vacuum and electrical connections. Threaded unions and plug-in connections, hose nipples, hoses in different designs and materials and retaining elements. For cabling vacuum valves and vacuum switches a multitude of connection and junction cables in different materials and lengths are available.- Vacuum Hoses

- Connections

- Distribution Elements

- Electrical Connections