- Offer Profile

-

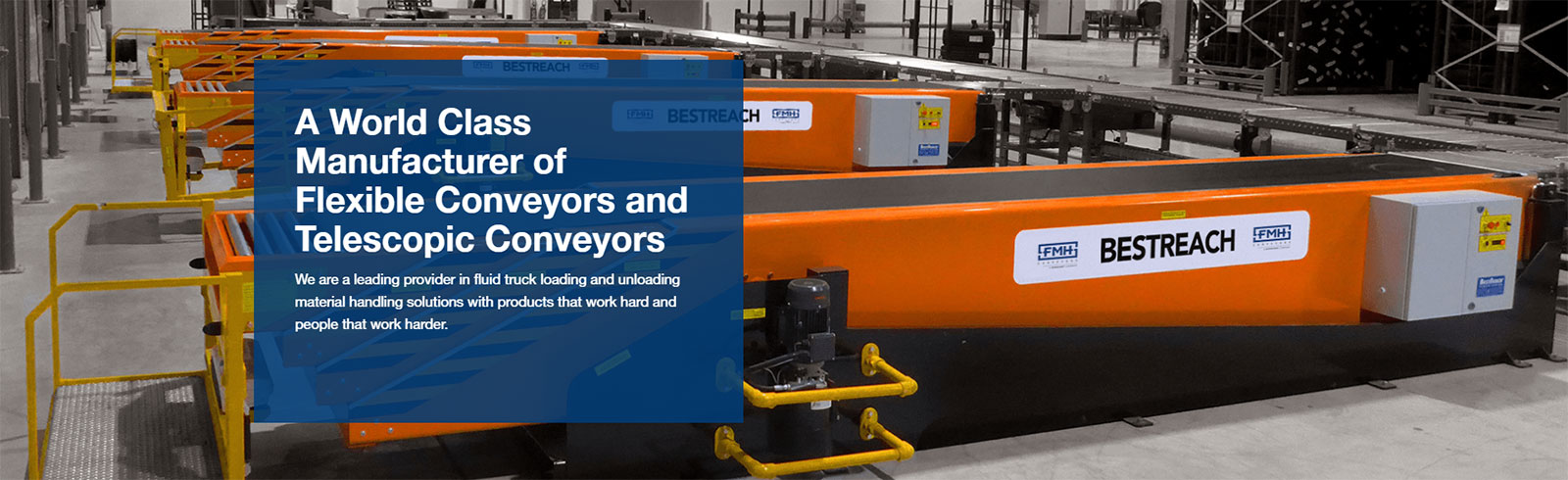

FMH Conveyors designs, manufactures and supplies products and services for truck loading and unloading applications.

FMH Conveyors is a world-class manufacturer of conveying equipment built to increase truck loading and unloading efficiency in even the toughest shipping and receiving environments. Our solutions help customers across multiple industries expedite their supply chains, integrate automation and drive greater productivity throughout their operations.

Conveyor Systems & Solutions

-

FMH Conveyors is the leader in Conveyor Systems, including fluid truck loading and unloading solutions. We manufacture, install and service a complete range of custom-engineered and designed conveyor solutions for truck loading and unloading along with other applications for manufacturing, assembly, order fulfilment, sorting, material handling and packaging operations. Whether your operation requires a belted, skate wheel or roller conveyor, we have the conveyor system you need.

Putting FMH conveyor equipment to work in your facility can:

- Cut employee absences caused by lifting, twisting and bending

- Improve safety by keeping fork trucks out of busy areas

- Prevent product spills and damage

- Reduce truck and trailer loading and unloading time

- Save on loading dock labour by reducing the amount of work involved

PowerFlex – SmartFlow

-

PowerFlex is designed to be a robust, flexible and reliable conveyor solution for almost any operation requirement. Using its integrated handles and intuitive design, the conveyor can be contorted and shaped to fit into infinite environments. Its braked castors, 240v power supply and renowned latching connections make it an incredibly user-friendly piece of equipment.

Features:

- ZLP Singulation Release

- ZLP Train Release

- Build/ Die Back

- Package Stop

- All Run

PowerFlex19

-

With its innovative design, the PowerFlex19 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity. By powering the conveyor, any package size can be moved, any distance at variable rates of speed. It is an all-power conveyor that has a capacity of 150Kg per linear metre.

Features:

- Continuous Duty Multiple Drive Motors

- Self Tracking

- Adjustable Height

- Square Tubing Legs

- 50mm Rollers

- 50mm Side Plate

- Castors with Brakes

PowerFlex15

-

Flexible powered conveyors provide maximum productivity in shipping, transportation and packaging applications where usability and adaptability are most needed. With its innovative design, the PowerFlex15 powered roller conveyor requires less storage space when fully retracted and can service multiple docking doors for maximum productivity.

Features:

- Continuous Duty Multiple Drive Motors

- Self Tracking

- Adjustable Height

- Square Tubing Legs

- 40mm Rollers

- 40mm Side Plate

- Castors with Brakes

BestFlex200

-

Designed to expand, contract and move easily, the BestFlex200 is a self-tracking, gravity skate wheel conveyor that has a per linear foot capacity of 300 Kilograms. This unit is engineered to handle multi-sized cartons in low to medium volume applications. The all-steel construction provides unmatched structural integrity, whether the conveyor is extended, compacted or configured in simple or compound curves. Adjustable inner legs vary the height to achieve gravity flow.

The BestFlex200 is the choice for use in retail store-level applications, packaging areas, assembly lines and in low volume shipping and receiving departments.

Features:

- Self Tracking

- Adjustable Height

- Square Tubing Legs

- 32mm Side Plate

- Castors with Brakes

- Structural Steel Support

BestFlex Roller

-

The BestFlex Roller is excellent for handling odd-shaped boxes, bags and low-grade cartons in low to medium volume applications. Designed to expand, contract and move easily, the BestFlex Roller is a self-tracking, gravity roller conveyor that has a per linear foot capacity of 220Kg per linear metre. The all-steel frame construction provides unmatched structural integrity, whether the conveyor is extended, contracted or configured in simple or compound curves.

It is the best choice for moving items without a flat, solid surface.

Features:

- Self Tracking

- Adjustable Height

- Square Tubing Legs

- 40mm Side Plate

- Castors with Brakes

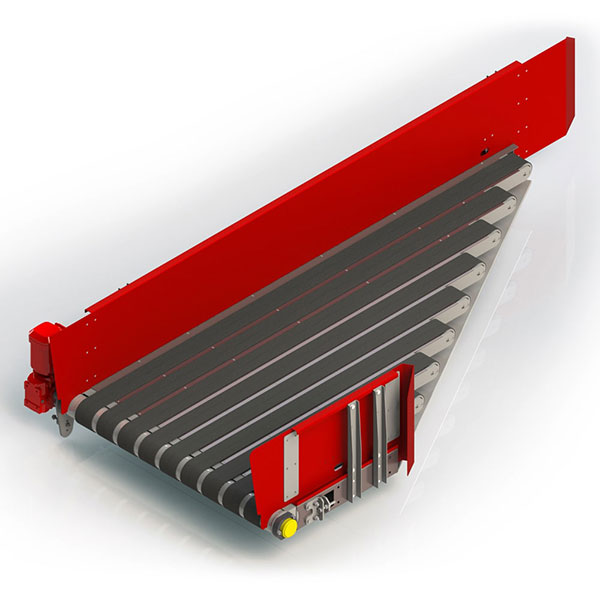

Telescopic Belt Conveyors

- When loading and unloading trucks, an extendable conveyor makes a world of difference. This solution extends all the way from the permanent conveyor to the nose of the truck trailer, making the process of getting cargo in and out faster, easier and safer. Based on our expertise and extensive customization options, FMH Conveyors is the best company to call for improved speed, efficiency, safety and ergonomics at the loading dock.

Best Reach

-

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions test.

Features:

- Construction

- Boom End Lights

- Extension Stop Bar

- Brush Strips

- Shrouded Emergency Stop Buttons

- Sprocket Guards

- Soft Start/Stop Extension

MaxxReach

-

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions.

Features:

- Construction

- Boom End Lights

- Extension Stop Bar

- Brush Strips

- Shrouded Emergency Stop Buttons

- Sprocket Guards

- Soft Start/Stop Extension

BestReach Gravity

-

BestReach Gravity Telescopic Boom Conveyors will load most items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load times significantly whilst improving operator working conditions.

These units are typically used in conjunction with sortation systems or feeding conveyors.

Features:

- Construction

- Boom End Lights

- Extension Stop Bar

- Brush Strips

- Shrouded Emergency Stop Buttons

- Sprocket Guards

- Soft Start/Stop Extension

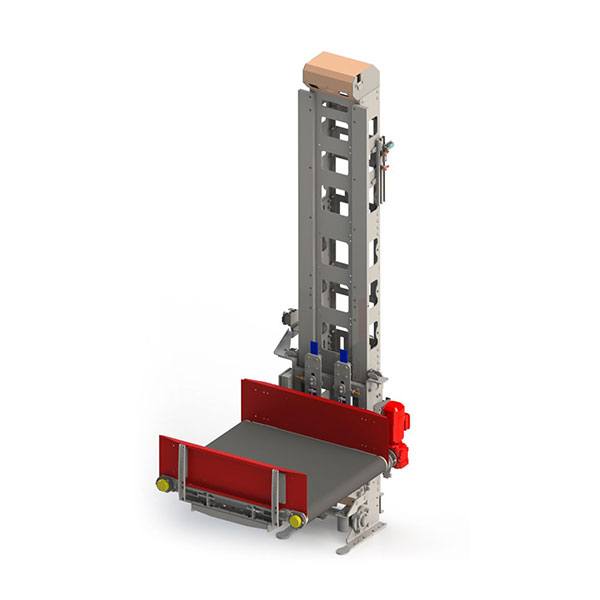

Loaders

Mobile Loaders

-

The Mobile Loader is designed specifically for use in premises without a raised loading dock, which makes it ideal for loading vans and other smaller vehicles. Using this unit makes your vehicle loading/unloading operation faster, safer and more efficient, and helps you comply with manual handling regulations.

Features:

- Construction

- Shrouded Buttons

- Fully Guarded

- Brush Strips

- Mobile

- Power

SV Loader

-

SV Loader units are designed to load small vehicles from either level access or dock levellers.

Ideally suited for the parcel, postal and 3PL markets, this unit is easy to use and can be combined with our BestFlex, PowerFlex or BestConnect to create a total loading solution.

Features:

- Construction

- Adjustable

- Fully Guarded

- Safety

- Mobile

- Power

Mobile Reconfigurable Conveyors

BestConnect

-

The BestConnect system is designed to provide rapid assembly of conveyor solutions for changing workplaces. Systems can be easily configured and re-configured as required to suit your immediate requirements. With a simple 240v power supply and latching connections, the engineering requirement is minimal.

Features:

- Continuous Duty Multiple Drive Motors

- Adjustable Height

- Fully Guarded

- Square Tubing Legs

- 50mm Roller

- Robust fabricated side-plates

- Castors with Brakes

BestConnect Balltables

-

An innovative new design to allow you to easily sort packages and parcels during your manual sortation process. The unit can also be supplied with an integrated weight scale unit with a digital display.

Features:

- Adjustable Height

- Square Tubing Legs

- Castors with Brakes

Belt Conveyors

Motion06 – Vertical Sorting Unit Belt Conveyor

-

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steel-reinforced tooth belts.

This maintenance-free lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose.

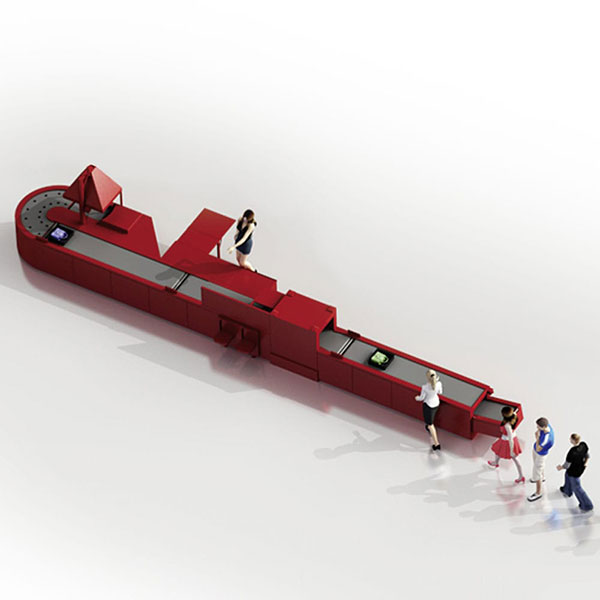

Motion06 – Check-In Easy/Premium

-

Compact, flexible, fix-mounted or extendible, and perfectly maintainable. The Motion06 Check-In, with the Check-In Premium, is the highest standard of design and functionality. The Check-In Easy, based loosely on the motto, “less is more”, completes the Check-In department at the airport base. The whole family of Check-In is characterised by optimal operability by the operator and optimal accessibility for the passenger.

The Check-In is the passenger’s point of contact with the entire flight baggage system. Whether it be the fix-mounted or the extendible version, simple and fast accessibility for maintenance and cleaning work is guaranteed with both. Depending on the feed rate, you can choose from one-belt, two-belt and three-belt systems. The position of the weighing machine also depends on the customer‘s requirements.

Features:

- Stainless Steel

- Access

- Easy Accessibility

- Simple and Safe

- Quick Installation

- Efficient

Motion06 – Inclined Transport Unit

-

Unique and light as a dragonfly – this is how the Motion06 Inclined Transport Unit works – quickly and safely overcoming any height difference. The inclined conveyor transports flight baggage directly to the passenger boarding bridge, meaning it can be used in direct proximity to the aircraft.

Baggage or similar general cargo is either safely lifted onto the aircraft or lowered onto the apron. Staff must no longer carry the baggage up and down the sometimes wet or icy stairs in any weather.

Features:

- No Maintenance

- Quick Installation

- EEfficient

- Ultra-Simple Adjustment

Motion06 – Manual Sorting Belt Conveyor

-

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed.

The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wear-resistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Features:

- No Maintenance

- Quick Installation

- X-Ray Machines

- Efficient

- Ultra-Simple Adjustment

Motion06 – Vertical Transporting Belt Conveyor Unit

-

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steel-reinforced tooth belts.

This maintenance-free lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter.

VTU – 420/660

Motion06 – Strip Belt Merge

-

From 0 to 3.0 metres per second. The Motion06 Strip Belt Merge puts baggage on the right track like no other. It is exactly this construction – the design as an adjoining merge point – that can provide the fundamental advantage of operational safety. In the case of one strip being damaged, the system continues to work flawlessly. In connection with a belt deflector, the merge can also be used to transfer baggage from different angles.

Motion06 – High Speed Diverter

-

A real high-performance device – ingenious, innovative and extraordinary. Its job is to sort out pieces of baggage or general cargo from a conveyer line with the highest possible sorting output. Its capacity is up to 1,500 pieces of baggage per hour. The Motion06 High Speed Diverter is output to the power of two.

The currently common and expensive two-band diverters can now be replaced economically. Thanks to the latest drive concepts (Class IE4), the High Speed Diverter is extremely energy efficient and the flexible construction concept makes changing the swivel direction on site simple. Maintenance free components with the lowest possible operating costs are included.

Due to the stand-alone principle, the machine is easy to integrate without mechanical connection to the feed system (to the lower conveyor belt of the line).

Motion06 – Full Belt Merge

-

From 0 to 2.5 meters per second. The Motion06 Full Belted Merge brings the packages or parcelled cargos onto the track like no other. Thanks to our sophisticated design using a belt, safe and fast transportation of the parcelled cargo are ensured. In connection with the Motion06 High-Speed Diverter, the merge can also be used to transfer packages outwardly at different angles. FBM 112/157

Features:

- Operational Safety

- Smooth Transfer

- Belt Tracking Integrated

- Short Lengths Available

- Low Height Possible

- Various Operations

- Quick Installation

- Efficient

Motion06 – Flat Slat Conveyor

-

From 0 to 3.0 metres per second. The Motion06 Strip Belt Merge puts baggage on the right track like no other. It is exactly this construction – the design as an adjoining merge point – that can provide the fundamental advantage of operational safety. In the case of one strip being damaged, the system continues to work flawlessly. In connection with a belt deflector, the merge can also be used to transfer baggage from different angles.

Motion06 – Hand Baggage Control Unit

-

The Motion06 Hand Baggage Control Unit conforms to the latest standard of technology and requires minimal staff involvement for handling. The defined field of use is automated hand baggage transportation into containers with automatic container return. This keeps the manual handling of the containers to a minimum. The security personnel can focus entirely on checking passengers and baggage.

Motion06 – Curved Belt Conveyor

-

With a conveying speed of up to 3.0 m/s, flexibility and hardiness are also demanded of the curves. The area of application for the Motion06 Curved Belt Conveyor is in the continuous or clocked transportation of pieces of luggage and packages with changes in direction. When developing the Curved Belt Conveyor, the highest priority was given to the ‘small space requirements’ and a wide range of standard measurements or customer-specific measurements for integration into new or existing systems.

The entire product range is a modular design and is designed based on state-of-the-art technology. A consistent appearance for the operation of a wide variety of weight classes and product sizes is available worldwide. CBC – 080/100/120.

Motion06 – Straight Belt Conveyor

-

Whether straight, inclining or declining – the Motion06 Belt Conveyor transports luggage, packages and general cargo across any distance. As a modular system, the conveyor belt is suitable for a wide variety of requirements. The basic model includes the head drive or central drive, reversing station, normal round, pass round and support or suspension modules.

The transitions between the individual conveyors are fitted with individual transition sheets. The tensioning station at the head drives and reversing stations is tensioned from both sides on the basic model. The tensioning station on the centre drives is tensioned on one side. SBC – 080/112/157.