- Offer Profile

- KITO Armaturen GmbH – Your specialist for Explosion prevention & protection

Today, with about 70 employees, KITO® manufactures flame arresters, valves and special devices for a diverse array of customer requirements. Just like top-ranking athletes, we are never satisfied with average performance levels. Our aim is to produce innovative and efficient solutions for explosion prevention & protection, with a consistent focus on quality, protection and safety.

Virtuel Company Presentation

Visit our virtual world and get to know KITO Armaturen GmbH.

End of line armatures

- KITO® end of line devices (with and without a KITO® flame arrester)

The high-quality range of KITO® end of line devices offers a large number of potential applications. Based on the processes of our customers, we develop environment-related solutions that are intended to enable tanks to breathe out flammable gases and to provide protection against flashback from an external source.

Many applications for KITO® products serve to protect storage tanks and pipeline systems. An important constituent element is the protection of the openings on storage tanks that inhale or exhale into the atmosphere. These end of line devices prevent flashbacks from the atmosphere to the interior of a tank when storing flammable fluids. These products are also used on venting lines that discharge to atmosphere.

Our KITO® end of line devices (with or without an integrated KITO® arrester flame arrester) are divided into:- Ventilation hoods (catalogue chapter B)

- Pressure relief valves (catalogue chapter C)

- Vacuum relief valves (catalogue chapter D)

- Pressure and vacuum relief valves (catalogue chapter

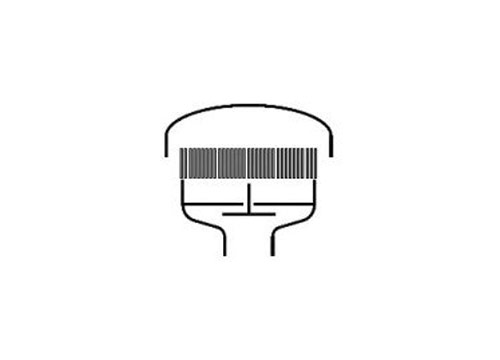

Ventilation Hood

-

Venting lines on tanks, vessels and pipelines that enables an on-going gas exchange (flammable or combustible air-gas mixture) must be protected using explosion-proof devices. Explosion-proof KITO® ventilation hoods are designed as deflagration proof or as devices that protect against endurance burning.

Flammable vapours can flow out of tanks and/or ambient air can flow in without restriction. The ingress of rain, dirt and foreign bodies is prevented by a protective cover. Here, the integrated KITO® flame arrester protects against flame transmission into the tank. For cases where a vapour/air mixture might burn for a very long time on the flame arrester element surface, KITO® provides, so called, endurance burning proof flame arresters. Meeting the highest level of safety for burning scenarios.

Our KITO® ventilation hoods help to protect your production and storage facilities. We can devise a made-to-measure solution for your particular application.

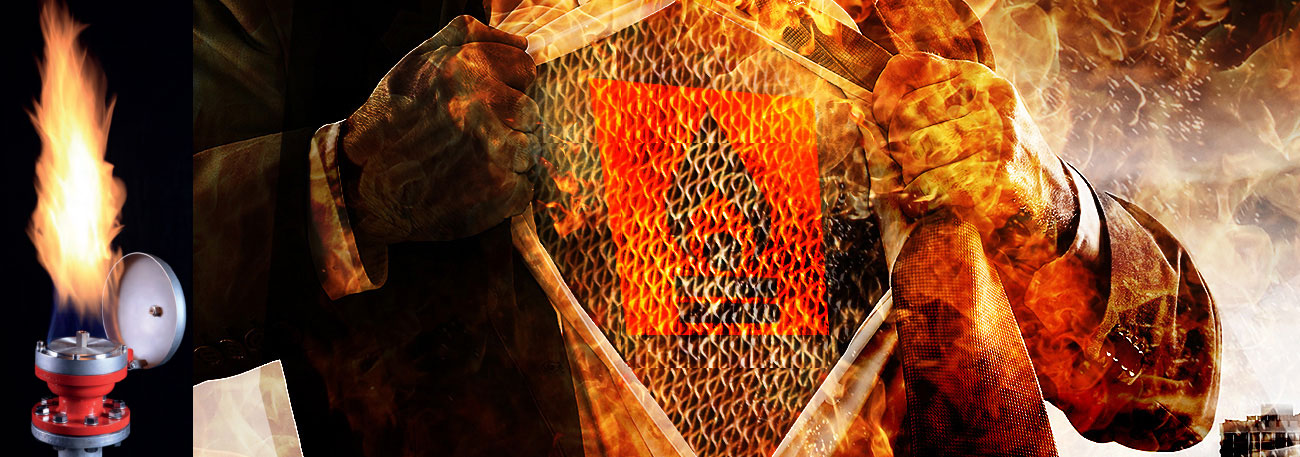

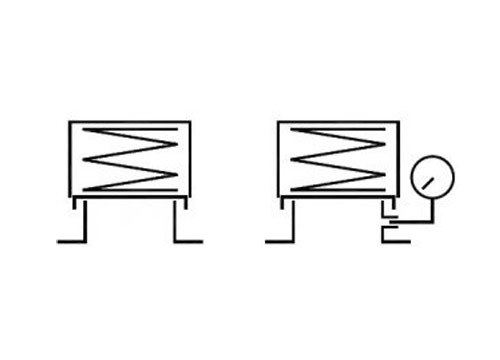

Pressure Relief Valves

- KITO® pressure relief valves are used to prevent or minimize the loss of gas/vapours allowing econimical savings and reducing environmental pollution. KITO® pressure relief valves are used wherever pressure needs to be relieved in closed systems storing gases or vapours.

Pressure rises inseide liquid storage tanks and eventually must be relieved by a pressure relief valve to avoid tank collapse during operational filling or due to thermal effects caused by a hot sunny day, for instance. Also, possible malfunctions of inert gas valves can cause pressure in the storage tank to rise suddenly.

Applications for KITO® pressure relief valves cover a range of operating pressures that are less than or equal to 0.5 bar. In cases where protection against excessive levels of negative pressure is also required, please check out the product group of KITO® pressure and vacuum relief valves. KITO® pressure relief valves can also be used for flammable air-vapours mixtures with an integrated KITO® flame arrester element. In this case, the integrated KITO® flame arrester element provides the same protection against flashback into the storage tank as it does with ventilation hoods. Where there is a risk of a continuous release of a flammable air-vapours mixture through the KITO® pressure relief valves, the requirements for endurance burning proof must be satisfied.

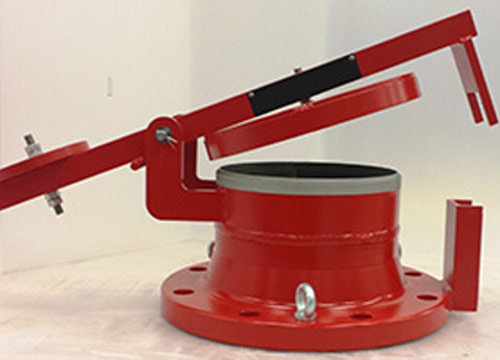

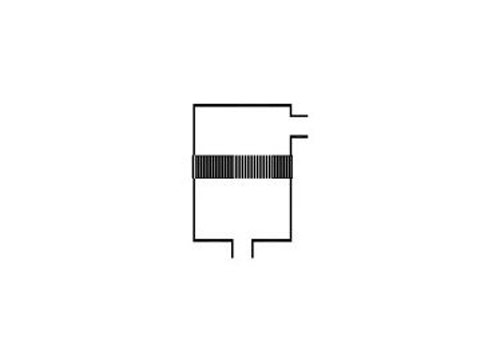

Vacuum Relief Valves

-

KITO® vacuum relief valves are used where closed systems are being emptied or cooled by their local environment, preventing, for example, negative pressure to damage storage tanks.

KITO® vacuum relief valves can also be equipped with a KITO® flame arrester that prevents flashback from atmosphere to storage tank. These KITO® vacuum relief valves can be used for atmospheric deflagration scenarios. There is not usually any risk of an endurance burning in typical applications involving a vacuum.

Valve pallets for KITO® vacuum relief valves are designed either weight-loaded or spring-loaded, depending on the pressure settings required.

All KITO® valves use a range of different valve sealings to suit the prevailing process conditions to assure low rates of leakage between valve seat and valve pallet.

Pressure and Vacuum Relief Valves

- Typically, KITO® pressure and vacuum relief valves are used to prevent unacceptable levels of positive and negative pressure in closed systems. They constitute an important factor in preventing inadmissible pressure and vacuum and to minimize product losses.

The most frequent type of application involves storage tanks containing liquids. These valves are used to relieve the positive and/or negative pressures that can build up in tanks. Positive and negative pressures can build up as a result of the filling or emptying process in the storage tank, and by the thermal influence of changes in prevailing weather conditions. Here is the aim of the KITO® range of combined pressure and vacuum relief valves: To minimise product losses and emissions.

By using combined KITO® valves, substantial cost savings can be achieved in a short period of time through the reduction of product losses as a function of process conditions. For more detailed information, please contact our experienced KITO® sales team. Depending on the pressure settings required, the valve pallets for KITO® pressure and vacuum relief valves are designed either weight-loaded or spring-loaded. Depending on valve type, combined KITO® pressure and vacuum relief valves can be configured with different valve sealings. The aim is to assure a low rate of leakage between valve seat and valve pallet across the various ranges of pressure setting.

Mobile Applications

M 3 N Pressure relief valve

-

KITO® DS/o cont. 32

- Pressure relief valve for portable tanks, especially for rail tank cars and road tank cars for the transport of sodium Hypochlorite dilution (GGVSE class 8).

M 2 N Pressure relief valve

-

KITO® DS/o cont. 25

- Pressure relief valve for portable tanks for the transport of non-inflammable liquids.

- To prevent inadmissible tank pressure by warming or filling.

- Not explosion proof.

M 02 N Applications of KITO® valves for tank containers

- M 02 N Applications of KITO® valves for tank containers

M 1 N Deflagration and endurance burning proof pressure relief valve

-

KITO® DS/cont. 25

- Endurance burning proof pressure relief valve for portable tanks (GGVSE/ADR, GGVSE/RID) for the transport of flammable liquids and gases with the exception of carbon disulphide.

- To prevent inadmissible tank pressure by warming or filling.

- Approved for all substances of explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm.

- An operating temperature of 60°C must not be exceeded.

M 01 N Applications of KITO® valves for rail tank cars

- M 01 N Applications of KITO® valves for rail tank cars

M 11 N Deflagration proof pressure and vacuum relief valve

-

KITO® K/DVE-IIB3-80

- Explosion proof combined pressure/vacuum relief valve to prevent excessive pressure and vacuum.

- Approved for flammable liquids and gases of explosion group IIB3 with a maximum experimental safe gap (MESG) > 0.65 mm.

- An operating temperature of 60 °C must not be exceeded.

- Low height of construction, for portable tanks, preferably for rail tank cars and tank containers.

- Upon request without KITO® flame arrester element available.

M 10 N Deflagration proof vacuum relief valve

-

KITO® K/VG

- Explosion proof end-of-line vacuum relief valve to prevent inadmissible vacuum.

- Approved for flammable liquids and gases of explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 mm.

- An operating temperature of 60 °C must not be exceeded.

- Low height of construction, for portable tanks, preferably for rail tank cars and tank containers.

- Equipped with a function control equipment for the valve pallet.

- Upon request available without KITO® flame arrester element.

M 9 N Vacuum relief valve

-

KITO® VS/o cont. …

- As end-of-line device for venting of tank installations for ventilation and to prevent inadmissible vacuum.

- Usually installed on top of a tank, if applicable in conjunction with a pressure relief valve on a common connecting pipe.

- Valve is not explosion-proof, thus cannot be used for flammable media.

M 8 N Deflagration proof vacuum relief valve

-

KITO® VS/cont. …

- Explosion proof end-of-line vacuum relief valve for storage tanks, vessels and pipes to prevent inadmissible vacuum.

- Approved for flammable liquids of explosion group IIB3 (MESG) ≥ 0.65 mm. An maximum operating temperature of 60 °C must not be exceeded.

Suitable also for portable tanks for the transport of flammable liquids.

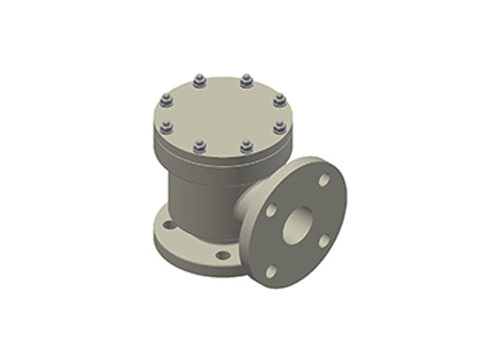

M 12 N Pressure relief valve

-

KITO® K/DO-…

- Pressure relief valve against excessive pressure in rail tank cars (RTC) for the transport of dangerous goods of cl. 3, 5.1, 5.2, 6.1 and 8 with special regulations (RID/GGVSE, dangerous goods V sea).

- If used in combination with a rupture disc broken disc will be indicated by a pressure gauge which is fitted to the ½” threaded connection between rupture disc and valve pallet.

M 5 N Uni-directional in-line detonation flame arrester

-

KITO® Rd/C-Det4-IIA-…-1.2

- Detonation flame arrester for installation into pipes to protect containers and components against stable detonation of flammable liquids and gases.

- Tested and approved as detonation flame arrester type 4.

- Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm.

- An operating pressure of 1.2 bar abs. and an operating temperature of 60 °C must not be exceeded.

- Positioning should be as close as possible to the protected object; it is only allowed to connect pipes with the same or a smaller diameter than the diameter (G) of the device.

- The installation of the detonation flame arrester into horizontal and vertical pipes is permissible.

M 6 N Deflagration and endurance burning proof pressure relief device

-

KITO® DE/cont. 20

- Endurance burning proof pressure relief device for portable tanks (GGVSE/ADR and GGVSE/RID) for the transport of flammable liquids and gases of explosion group IIB3 (MESG ≥ 0.65 mm) with exception of carbon disulphide.

- An operating temperature of 60 °C must not be exceeded. For safe tank pressure relief to the atmosphere before opening of the tank caps or connected lines.

- A pipe connection instead of the cap is not allowed.

Inline armatures

- KITO® Inline devices (with and without a flame arrester)

The high-quality products in the KITO® range of Inline devices with and without flame arrester are offered in variety of potential applications. In the light of the processes operated by our customers, we develop environmentally relevant solutions that aim to reduce emission levels as well as to provide protection against flame propagation, protecting people and equipment.

KITO® products are used primarily to protect tank systems and pipeline systems, and also constitute an important role in protecting parts of a system that are interconnected by pipeline systems. KITO® inline devices with a pressure holding function reduces excessive overpressure in the system. Flame arresters are used for storing or transporting of flammable liquids. They permit the flow of liquids and/or gases but prevent any flashback to the plant to be protected.

Our KITO® inlin devices (with or without integrated KITO® flame arrester element) are divided into:- inline pressure and vacuum relief valve (catalogue chapter F)

- inline and end of line detonation flame arresters (catalogue chapter G)

- inline deflagration flame arrester (catalogue chapter H)

Inline Pressure and Vaccum Relief Valves

- Typically, KITO® inline pressure and vacuum relief valves are used to prevent excessive levels of positive and negative pressure in closed systems. They also constitute an important factor in the reduction of product evaporation losses and impermissible emissions.

KITO® inline pressure & vacuum relief valves are mainly installed in piping systems and in technical process equipment. The goal is to safety relieve the increased positive/negative pressures.

The purpose of combined KITO® inline pressure & vacuum relief valves is to minimise product losses and emissions. Using combined KITO® valves, substantial cost-savings can be achieved in a short period of time by reducing the evaporation losses in dependece of the process conditions. For more detailed information, please contact our experienced KITO® sales team.

Depending on the requested set pressure, the valve pallets for the combined KITO® inline pressure and/or vacuum relief valve can be carried out as weight or spring-loaded. Depending on valve type, different valve sealings are used on the combined KITO® inline pressure & vacuum relief valves in pipelines. That makes it possible depending on the different pressure settings to ensure a low leakage rate between valve seat and pallet. KITO® uses proportional valve pallets in its inline pressure & vacuum relief valves. These pallets enable opening and closing operations to be stable through the dynamic build-up of backpressure in a piping system.

Inline Deflagration Flame Arresters

-

If potentially explosive gas-air mixtures ignite in a section of pipeline, the explosion starts out as a deflagration propagating at relatively low pressures and flame speed below speed of sound.

KITO® inline deflagration flame arresters are used to prevent a chain reaction from propagating into connected sections of equipment.

In contrast to inline detonation flame arresters, their usage is restricted to short sections of pipelines between a potential ignition source and the device. This distance, known by the L/D relation (ratio of pipe length over pipe diameter) is specified for each explosion group in the standard ISO 16852.

By stating the maximum operating parameters such as pressure, temperature and explosion group, the appropriate deflagration flame arrester can be selected for a given application.

Under particular application conditions such as installation in flare lines or thermal incineration plants, the installation of one or more thermocouples on the KITO® flame arrester is specified to enable detection of a fire.

Inline Detonation Flame Arresters

-

If potentially explosive gas-air mixtures ignite in a section of pipeline, a deflagration can turn into a detonation under certain instances.

The impact of such detonation is considerable with greatly increased pressure and flame speed; our KITO® detonation detonation flame arresters and end of line detonation flame arresters (also known as detonation-proof foot valve) are designed for such scenarios. The installed KITO® flame arrester remains functional and arrests the flame front following the shock wave. The selection of an appropriate detonation flame arrester is based upon a classification of the working medium in explosion groups and the maximum operating parameters for pressure and temperature.

Our product range includes KITO® detonation flame arresters for all explosion groups in different applications. The installation position and the direction of flow is arbitrary since almost all KITO® detonation flame arresters are bi-directional which means they can offer protection in both directions. KITO® flame arresters are optimised for low pressure losses combined with an inexpensive modular design. Liquid detonation flame arresters are used predominantly in pipelines used to transport liquids. Detonation-proof foot valves are used exclusively in suction lines that transport liquids.

Special armatures

-

KITO® –Special devices – plastic valves

KITO® Armaturen GmbH has more than 90 years of experience on this market, time that it has used to develop a multi-faceted, high-quality range of valve technology products.

Plastic valves are used primarily for aggressive, corrosive and environmentally hazardous liquids, gases and vapours. Whereas products made of metal can rust when in contact with water and air unless protected in an appropriate manner, corrosion is not a problem at all for KITO® plastic valves.

KITO® plastic valves can be used as pressure or vacuum relief valves as well combined pressure & vacuum relief valves in the low-pressure range. The choice of material for KITO® plastic valves includes PP, PE and PVDF.

KITO® plastic valves are also characterised by great seal integrity and this has a decisive impact on potential product losses and their environmental impact. Our plastic valves can also satisfy your individual needs and can contend reliably with very stringent requirements.

K 10 N Pressure and vacuum relief valve

-

KITO® VD/oSR-…

- Not explosion-proof valve combination for venting and breathing of containers, in which non-combustible but aggressive media e. g. acids are stored.

- The pressure side is intended for connection to a pipe, in which the vapors are transported to a waste disposal installation.

- In case of use in explosive atmospheres of gas/vapour-air mixtures ignition hazards need to be considered.

- Plastic material tends to electrostatic charging.

- The use should be completed respectively decided by a risk analysis considering countryspecific rules and regulations.

K 8 N In-line pressure or vacuum relief valve

-

KITO® VD/ScS-…

- Not explosion-proof intermediate armature, with venting or breathing function for containers. For installation in pipe.

- The armature either serves as vacuum valve or as pressure valve, this depending on the fact which flange is connected to the tank side.

- Also used as nonreturn valve or overflow valve.

- In case of use in explosive atmospheres of gas/vapour-air mixtures ignition hazards need to be considered.

- Plastic material tends to electrostatic charging.

- The use should be completed respectively decided by a risk analysis considering countryspecific rules and regulations.

K 5 N Vaccum relief valve

-

KITO® VS/ScS-…

- Not explosion-proof valve to prevent dangerous vacuums in tank installations.

- For installation on tank roofs, if desired by the customer, in connection with a pressure valve.

- In case of use in explosive atmospheres of gas/vapour-air mixtures ignition hazards need to be considered.

- Plastic material tends to electrostatic charging.

- The use should be completed respectively decided by a risk analysis considering countryspecific rules and regulations.

K 3 N Pressure relief valve

-

KITO® DS/ScS-…

- Not explosion-proof valve to prevent dangerous pressures in tank installations.

- Valve is mounted on the tank roof, if desired by the customer, in connection with a vacuum valve.

- In case of use in explosive atmospheres of gas/vapour-air mixtures ignition hazards need to be considered.

- Plastic material tends to electrostatic charging.

- The use should be completed respectively decided by a risk analysis considering countryspecific rules and regulations.

K 30 N Halar® (E-CTFE) – Coating of KITO®-Armatures

-

(with and without KITO®-flame arrester element)

Used for gases or vapors, against which cast iron, steel including Cro-Ni-Mo alloys are not resistant.

K 11 N Pressure and vacuum relief valve

-

KITO® VD/oSA-…

- Not explosion-proof valve combination for venting and breathing of containers, in which non-combustible but aggressive media e. g.

acids are stored.

In case of use in explosive atmospheres of gas/vapour-air mixtures ignition hazards need to be considered. - Plastic material tends to electrostatic charging.

- The use should be completed respectively decided by a risk analysis considering countryspecific rules and regulations.

- Not explosion-proof valve combination for venting and breathing of containers, in which non-combustible but aggressive media e. g.

Equipment for armatures

L 30 N Condensate drain flame arrester

-

End-of-line deflagration flame arrester endurance burning proof

KITO® SK/K-IIA-…- Fittings for screwing in armature housings, of endurance-burn proof pressure valves and combined PV valves for all inflammable liquids and vapors of explosion group IIA with MESG > 0.9 mm.

- The condensate drain device enables draining of the condensate inside the housing to the outside and prevents flames from entering the valves

L 10 N Proximity switches for valves

-

(End-of-line and inline armatures with and without KITO® flame arrester)

Application

If an indication is desired or required (e. g. VdTÜV-guideline 967, §9.2.2.2), if the valve disk is in the position „closed“ or if a signal should be given if the valve opens.

L 4 N Electrical heating sleeve for KITO®-Armatures

-

(with and without KITO® flame arrester)

Application

HORST®-Heating sleeves can be used on valve housings and serve as frost protection heating or for temperature maintenance for ambient temperatures of -40 °C to +85 °C.

L 3 N Electrical heating for KITO®-Armatures

-

Application

- Frost protection or heating for constant temperature in the valve casings for ambient temperatures down to -20 °C.

- Heater cables of temperature classes T4 and T6 are used depending on the product to be heated.

- A constant heating is only permitted up to ambient temperatures ≤ +20 °C.

- An electrical fuse of at least 10 amps is required as a safety measurement.

- The use of a residual current circuit breaker (30 mA) is recommended.

L 1 N Heating jackets for KITO®-Pipe armatures

-

Application

Warm-water / steam heating, as frost protection or to maintain temperatures in the armature housings. Maximum temperature of the heating medium:KITO®-flame arresters :

Max. 25 K above the permissible operating temperature, but no more than 80% the ignition temperatureother KITO®-armatures :

• For flammable products max. 80% of the auto-ignition temperature

• For non-flammable products established in accordance with design and materials

Specification according to CEN-TR 16793, §6.7Note :

Heating jackets are usually subject to the Pressure Equipment Directive (PED) and they need CE-marking.

L 2 N Heating jackets for KITO®-End-of-line armatures

-

(with and without KITO® flame arrester)

Application

Warm-water / steam heating, as frost protection or to maintain temperatures in the armature housings. Maximum temperature of the heating medium:KITO®-flame arresters :

Max. 25 K above the permissible operating temperature, but no more than 80% the ignition temperatureother KITO®-armatures :

• For flammable products max. 80% of the auto-ignition temperature

• For non-flammable products established in accordance with design and materials

Specification according to CEN-TR 16793, §6.7Note :

Heating jackets are usually subject to the Pressure Equipment Directive (PED) and they need CE-marking.

L 31 N Condensate drain flame arrester

-

End-of-line deflagration flame arrester endurance burning proof

KITO® SK/K-IIB1-…- Fittings for screwing in armature housings, of endurance-burn proof pressure valves and combined PV valves for all inflammable liquids and vapors of explosion group IIB1 with MESG ≥ 0.85 mm.

- The condensate drain device enables draining of the condensate inside the housing to the outside and prevents flames from entering the valves.

L 32 N Condensate drain flame arrester

-

Deflagration flame arrester proof

KITO® KA-IIB3-1/2”- Fittings for screwing in armature housings, of deflagration-proof pressure relief valves and combined PV valves for all inflammable

liquids and vapors of explosion group IIB3 with NSW >= 0.65 mm. - The condensate drain device enables draining of the condensate inside the housing to the outside and prevents flames from entering the Valves.

- Fittings for screwing in armature housings, of deflagration-proof pressure relief valves and combined PV valves for all inflammable

L 20 N Temperature sensor

-

(Resistance thermometer)

- For monitoring the temperature on the flame arrester element on the unprotected side (side of ignition source), mainly where a flow of flammable mixture is present for longer time.

- This could be e.g. in pipes to flares, ovens, fans, recuperation or thermal recovery units.

- In case of a temperature rise a stabilized burn situation could be present.

- Then the thermometer has to give a signal which must be used to start emergency safety reactions (e.g. inerting, stoppage of flow etc.).

- The tripping temperature as low as possible, according to PTB recommendation ≤ 80 ° C or 20 K above max. operating temperature.

- Additional protective measurements as per VdTÜV-guide line 967, §10.2.5 shall be installed.

L 33 N Condensate drain flame arrester

-

End-of-line deflagration flame arrester endurance burning proof

KITO® KA-DB-IIB-1/2”- Fittings for screwing in armature housings, of endurance-burn proof pressure valves and combined PV valves for all inflammable liquids

and vapors of explosion group IIB with NSW >= 0.5 mm. - The condensate drain device enables draining of the condensate inside the housing to the outside and prevents flames from entering the valves.

- Fittings for screwing in armature housings, of endurance-burn proof pressure valves and combined PV valves for all inflammable liquids

L 41 N Sampling device

-

End-of-line deflagration flame arrester endurance burning proof

KITO® ZP/R-IIB-1/2″

-design with flange connection-- End-of-line deflagration flame arrester endurance burning proof, as sampling device for filling of smallest quantities from containers and pipelines in which flammable media are stored or transported.

- Can also be used for aeration and ventilation.

- Approved for deflagrations of explosive vapour-air or gas-air mixtures of explosion group IIB with a maximum experimental safe gap (MESG) ≥ 0.50 mm.

- Tested and certified for a maximum operational temperature of 60°C.

L 40 N Sampling device

-

End-of-line deflagration flame arrester endurance burning proof

KITO® ZP/R-IIB-1/2″- End-of-line deflagration flame arrester endurance burning proof, as sampling device for filling of smallest quantities from containers and pipelines in which flammable media are stored or transported.

- Can also be used for aeration and ventilation.

- Approved for deflagrations of explosive vapour-air or gas-air mixtures of explosion group IIB with a maximum experimental safe gap (MESG) ≥ 0.50 mm.

- Tested and certified for a maximum operational temperature of 60°C.

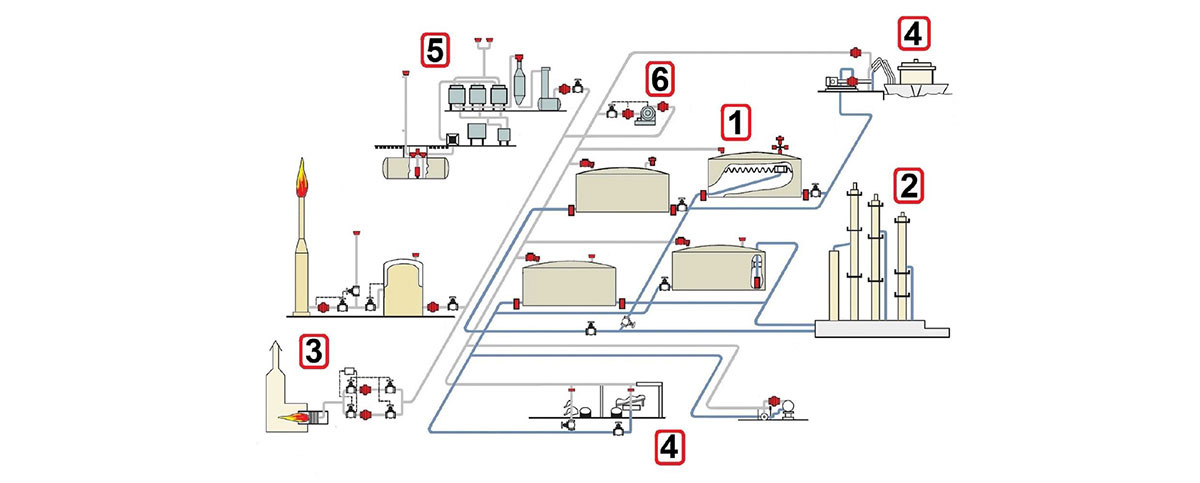

Fitting examples

-

1. Tank farms (see page A 01.1 N – A 01.5 N)

2. Process plants

3. Thermal treatment plants (see page A 03.1 N)

4. Loading and unloading process as part of logistics (see page A 04.1 N – A 04.3 N)

5. Vapor recovery units (VRU’s)

6. Components as safety part of devices

7. Protection of other plants – not illustrated- (see page A 07.1 N – A 07.2 N)

A 01.1 N – Tank farms

- Exemplary protection of tanks above ground – endurance burning proof performance

A 01.2 N – Tank farms

- 1.2 A – Exemplary protection of tanks above ground – explosion-proof, not endurance burning proof 1.2 B – Exemplary protection of tanks above ground – non-flammable liquids

A 01.3 N – Tank farms

- Exemplary protection of tanks above ground – KITO® flame arrester armatures

A 01.4 N- Tank farms

- Exemplary protection of underground tanks

A 01.5 N – Tank farms

- Exemplary protection of floating roof tanks

A 03.1 N – Termal treatment plants

- Combustion chamber

A 04.1 N – Loading and unloading process as part of logistics KITO

- Rail tank cars and road tanker

A 04.2 N – Loading and unloading process as part of logistics

- Rail tank cars and road tanker

A 04.3 N – Loading and unloading process as part of logistics

- Ship loading

A 07.1 N – Protection of other plants

- Exemplary protection of a biogas plant

A 07.2 N – Protection of other plants

- Exemplary protection of a municipal waste water plant