- Offer Profile

-

Dalmine Logistic Solutions realizes high quality industrial warehousing systems, combining experience and technological vanguard at the service of logistics.

More and more companies are choosing the competence and reliability of Dalmine Logistic Solutions for the creation of safe and efficient logistics spaces.

Warehousing Solutions

- A complete range of solutions for storage and material handling of different load units. Logistics systems tailored to meet every need, adaptable and implementable over time.

PALLET SOLUTIONS

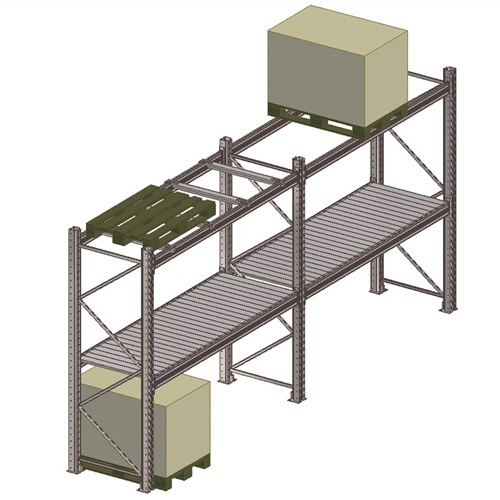

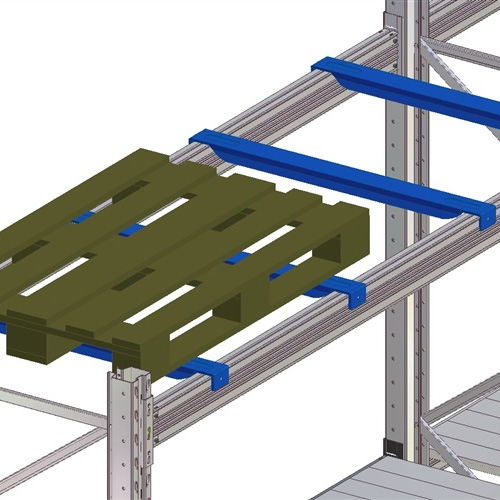

Pallet racking

-

The pallet racking until today is the system more common in the logistic field. One of the best benefits is the possibility to be used with most widespread forklifts.

Flexible configurations, for different kinds of pallet: for several weights and dimensions, short and long side handling. This system is adaptable to any space and always implementable and open to new configurations.

The pallet racking system allows the access to every pallet and very easy stock control, it is suitable for a huge reference number, with a low economic impact.

According to the forklift in use, aisles can be designed customized.

The system could be also a high-bay storage solution, with different levels of automation, till stacker cranes. Also Lgv machine could be used.

Features

- direct access to every handling unit

- different kinds of pallet

- tailor-made solutions

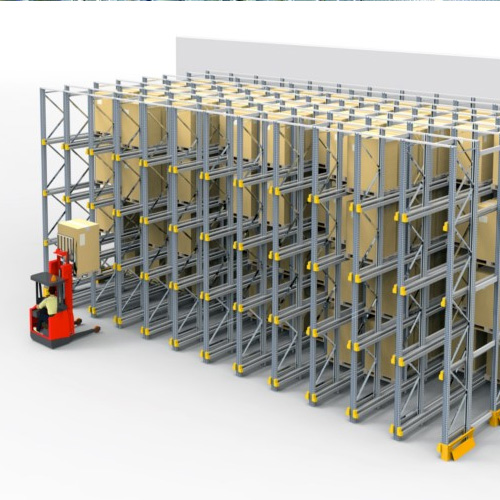

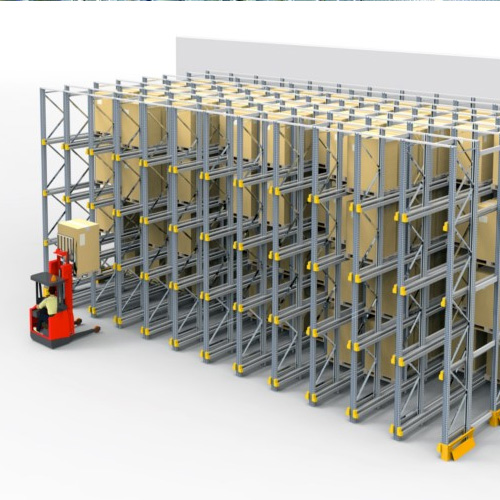

Mobile pallet racking

-

The mobile pallet racking is a high-density storage system made by racks mounted on mobile bases, that slide on floor rails.

The system allows to save space reducing the number of aisles for handling: the space could be nearly doubled. Aisles can be opened time-to-time, in order to increase handling unit a lot and their width can be adjusted according the forklift in use.

The control of the storage system is always possible by using the software control.

This is the perfect solution for cold storage.

This is the best solution where is not possible to implement the storage area and for cold environment.Features

- high densisty storage

- easy access to all the units

- storage software management

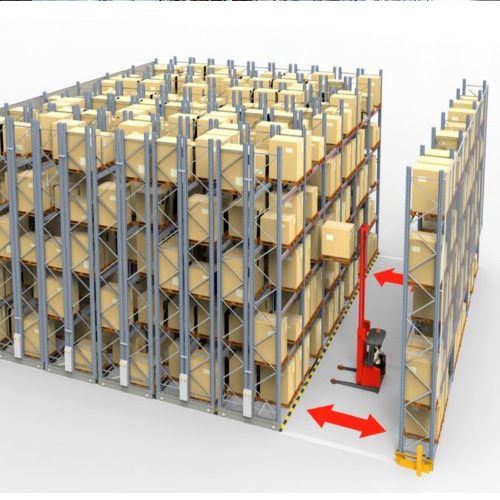

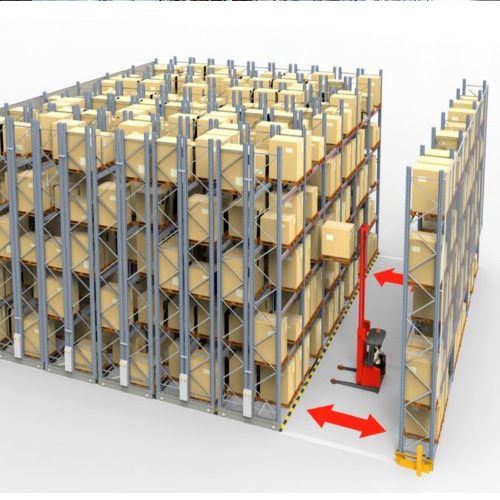

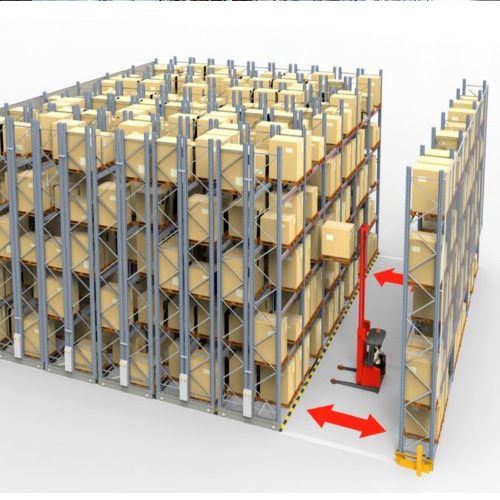

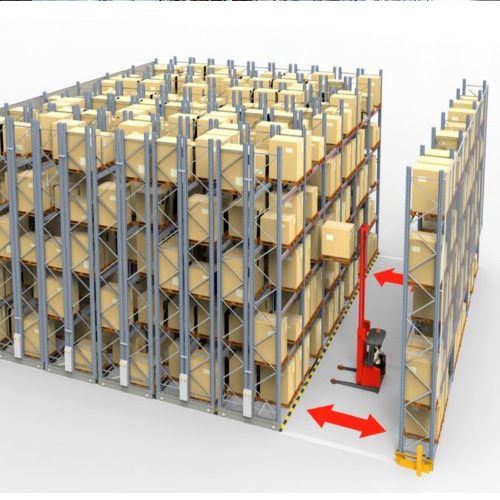

Drive-in racking

-

Drive-in racking system is the storage solution that combines huge numbers of pallets with high-density storage.

Depth pallet storage allows space increase: only few aisles are necessary. Goods are stored following the Li-Fo (Last In-First Out) mode, but also the mode Fi-Fo or drive through can be implemented. Patented guides are used to store pallets and forklifts are driven inside the structure.

One of the common use is for seasonable goods storage.

Features

- intensive storage of small items

- Li-Fo or Fi-Fo mode

- higher space saving

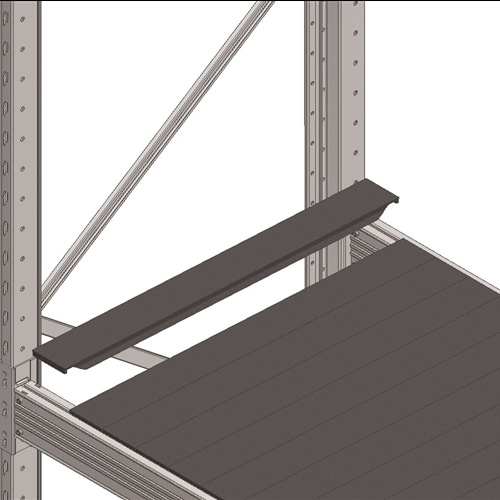

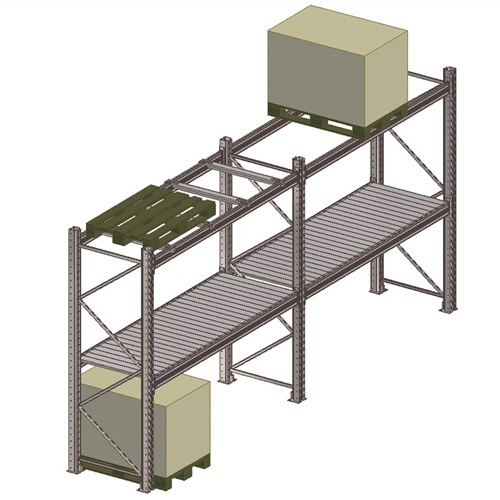

Pallet live storages

-

Pallet live storages are racking structures designed with roller conveyor lanes. Lanes have a slope that allows pallet sliding from loading aisle to picking position. Brake rollers guarantee perfect and safe pallet flow. Duly to massive storage and just two aisles, the system is considered a space-saving solutions.

Operations time is reduced because loading and picking moving are more rational and do not cross each others: productivity improves a lot. Loading time decreases a lot, items are grouped toghether and ready for picking any time.

The system is useful for storing and picking, for goods with high and medium rotation frequency, respecting Fi-Fo organization. The system could be adapted also Li-Fo (Last In-First Out) stock, in this case only one aisle is necessary.

The system could be adapted also Li-Fo (Last In-First Out) stock, in this case only one aisle is necessary.

Loading and picking are normally done by forklifts, but it is possible combine the system with stacker cranes or laser guided vehicles.

Features

- high ntensity storage

- time saving system

- Fi-Fo principle

- high ntensity storage

Shuttle system

-

The racking Shuttle System is provided with deep lane with support guides for pallet, where shuttle runs.

Pallets are moved with forklift, they are positioned at the beginning of the lane and the shuttle provides to move them to the back in store position. Shuttle is relocated from one lane to another one by forklift. When pallets are selected for picking, shuttle provides to carry them to the front of the lane.

Both Li-Fo (Last In-First Out) and Fi-Fo (First In-First Out) are applicable.

Shuttle activity is done by remote control. A special remind is sent when shuttle battery is going down.

The advantage is the mapping of stocks and the reduction of cycle times of warehouse management.

Best advantages are stock under control, time-saving for handling, staff travel routes reduce a lot compared to classic pallet racking system. This solution can be implemented also with automated handling system.Features

- intensive storage

- timing reduction

- stock control in every moment

SOLUTIONS FOR SMALL ITEMS

Manual order picking

-

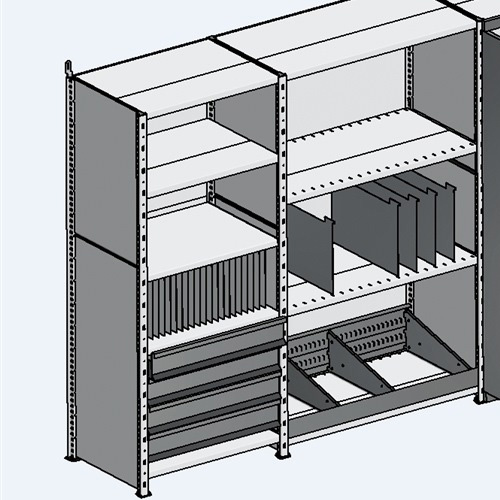

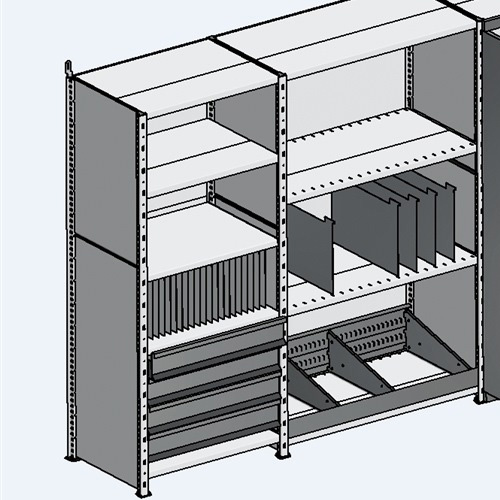

The manual order picking system is a versatile and convenient solution for small and bulk goods, cartons and bins, for storing and picking needs.

A huge number of different configurations are possible in order to be suitable for many handling units.

The system could be improved with additional levels: maximum use of floor surface and building height. Orders pickers trucks are used for reaching high levels.

Accessories complete the system and allow customizations.

Features

- shelving system for small goods

- high level order pickers

- huge variety of accessories

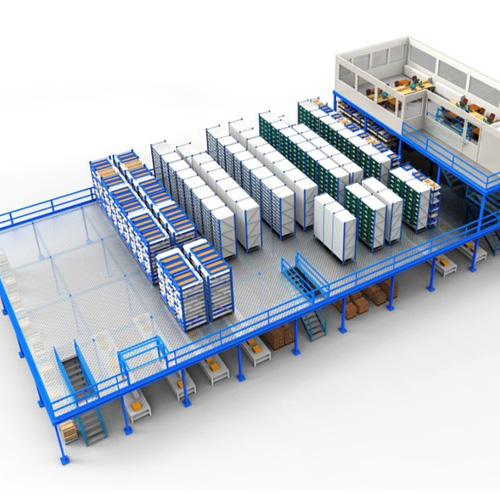

Multi-tier shelvings with walkway decking

-

Multi-tiers shelving with walkway decking is functional and convenient solution for small and bulky goods.

Staff operations are done manually, following the principle man-to-goods. The system allows floor surface to increase according to the levels.

Inner areas could be useful for different purposes: assembling, receiving goods, picking, preparing orders and much more. Stairs or lifts connect the walkways on different tiers. Different kinds of floor are available in order to answer to different needs.

This kind of solution is adaptable for many different applications.

Features

- solution for floor increasing

- useful for non-palletized goods and direct access to handling units

- protected walkways for safe environment

Carton live storage system

-

Carton live storage system could be implemented by shelves for manual picking made by plastic roller tracks. These racking are really useful for intensive storage of bins, cartons, eventually bulky goods.

This system is very useful for the massive storage of small packages. Operation follows the Fi-Fo (First In-First Out) principle and the storage solution is efficient as it allows separation between loading and retrieval aisles and stock monitoring.

Loading times and order preparation are significantly reduced thanks to the clear arrangement of materials on the shelf, which leads to rationalizing the internal routes, increasing the use of storage space.

Different purposes could be reached in the meantime: goods batch, picking, packaging returns.

Is possible also to automate picking and loading or implement functionality with pick-to-light systems, all integrated with the warehouse management software.

The carton live storage is also useful for the edge of the line, allowing the creation of ergonomic workstations, with the consequent increase in the productivity of the operators.

Features

- suitable solution for picking of supply-chain components

- stock level and expiring dates under control

- flow-shelf with buffer on the top

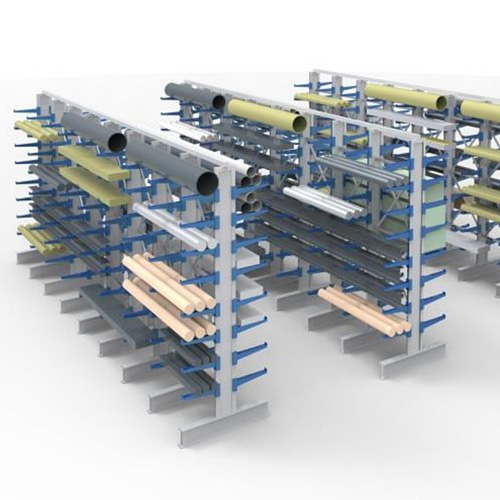

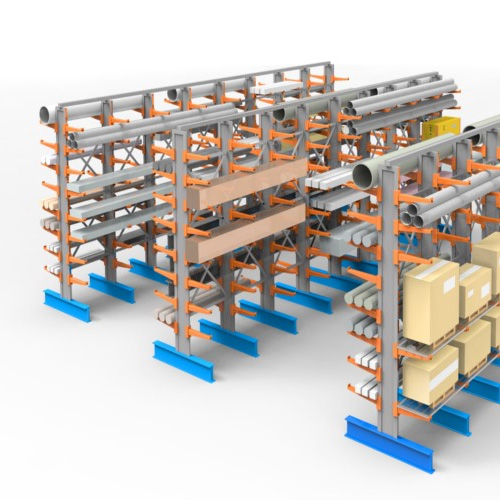

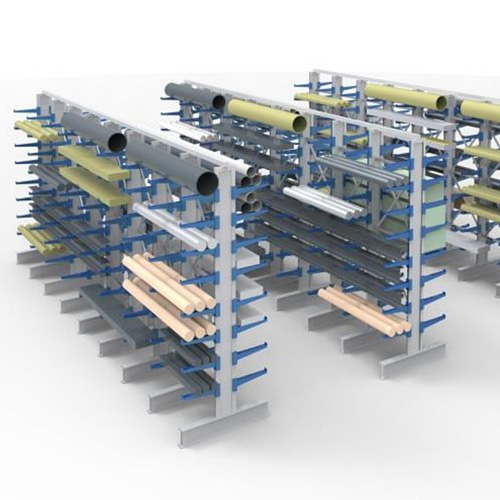

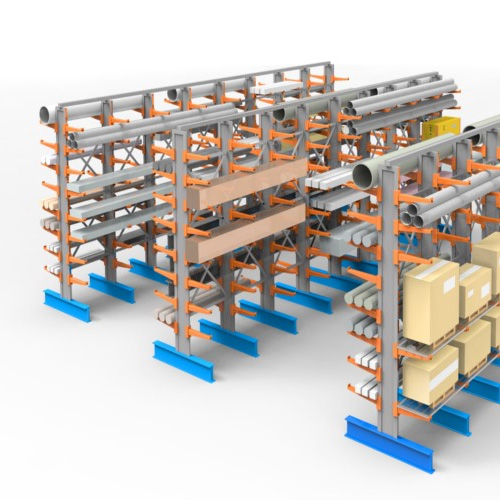

Cantilever

-

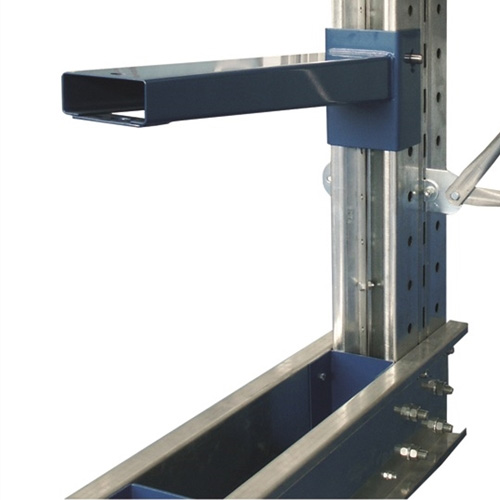

Cantilever system allows storage for bars, tubes, sheet, coils.

Racking can be single or double sided.

For light goods there is a practical solution, with 3 meters column height. Heavy solutions allow storage of goods with very hard weight.

It is possible create long shelving using drop on panels for arms, avoid uprights interruption. This solution combines the storage of long and small, non-pallettized goods.

Racking could be implemented by mobile base or automated system for an optimize use.

Features

- useful for long goods

- arms spacing adjustable

- possible to create continuos long shelving

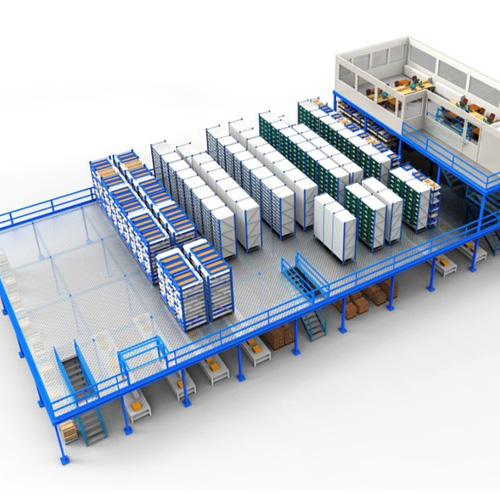

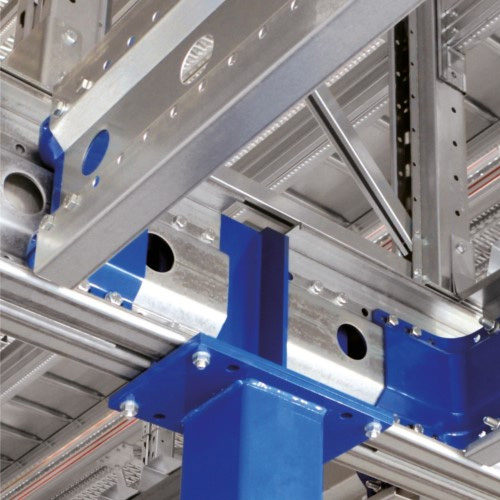

Mezzanines

-

There are trade fields needs special solutions, for example fashion world. The garments rails hangers system allow to vertical handling of garments.

These systems could have different automation levels and large reference numbers can be managed.

Features

- perfect solution for fashion warehouses

- different kinds of automation

- combined solutions for GOH (Garments On Hangers) and flat-packed garments

There are different applications for mezzanine system: the way to multiple floor space.

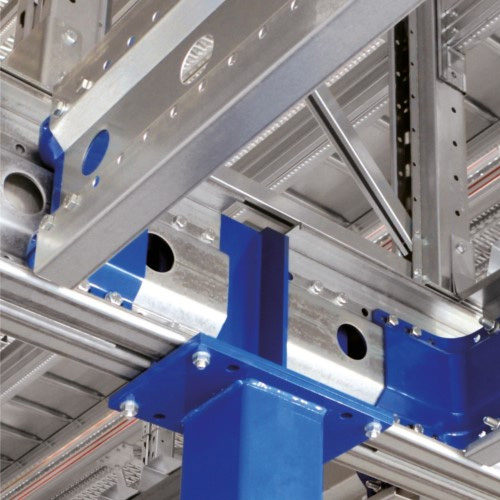

Special construction of columns and beams allows to have long-span between columns and high capacity loads. Floor and levels can be easily accessible. Structures could be designed in order to meet seismic regulations.

Floor levels are adaptable to different handling systems, like gratings, corrugated metal sheets, woods.

Stairs, ladders, handing rails and gates are developed in order to create a safe and efficient working environment for staff people.

Features

- floor surface multiplying

- also for heavy loads

- great variety of floor types

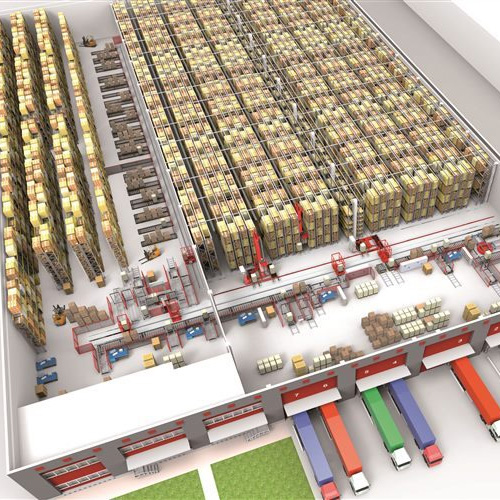

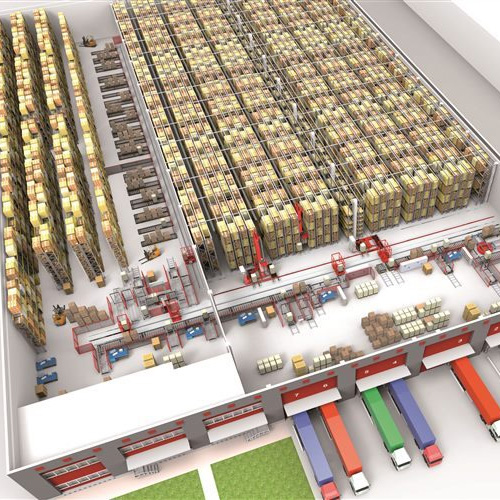

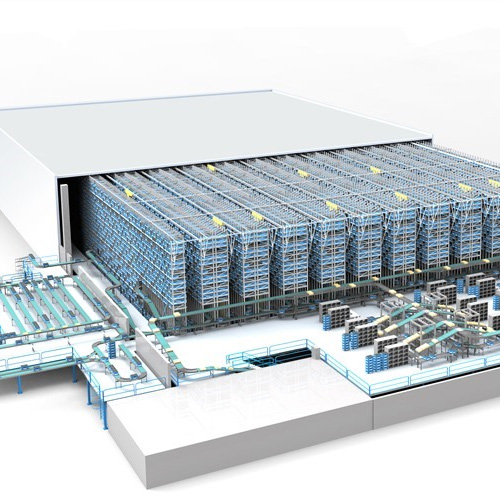

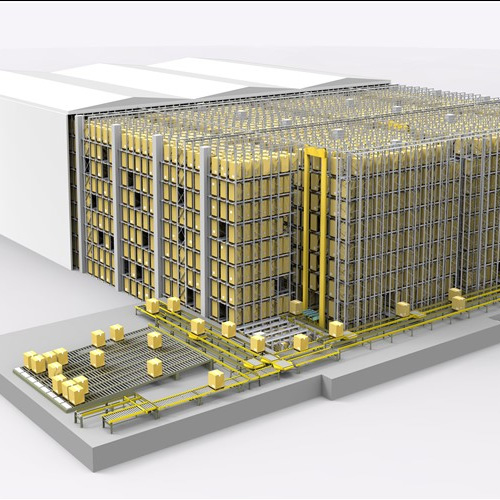

Automated Systems

- Automated and self-supporting systems are the cutting edge of the logistics sector. They guarantee the perfect flow of goods, time optimisation, low costs and zero errors.

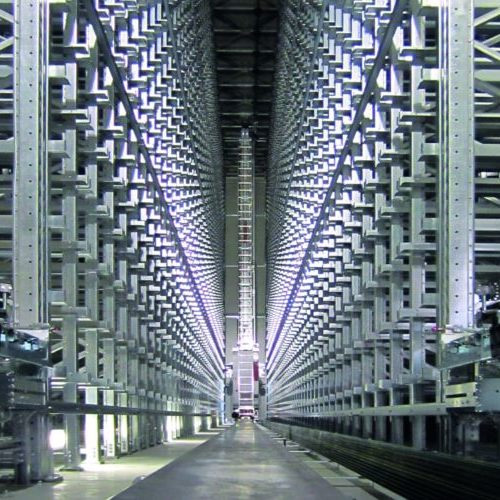

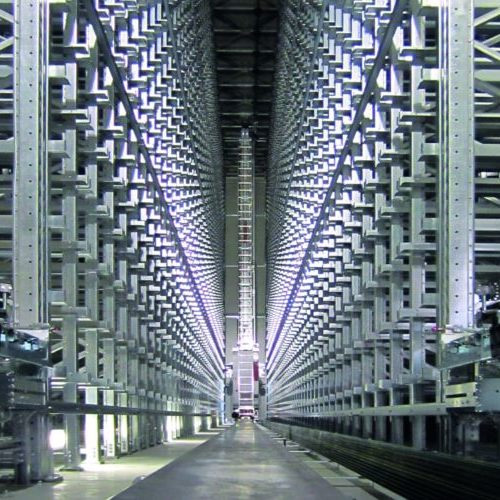

Automated system for pallet

-

Best space optimization, no mistakes on time: these are just some advantages that automated system for pallet can give.

These systems guarantee safe operations, good performance in terms of load and picking activities and they can manage pallets, no matter if wood, plastic or metal type, wire-mesh box, as well sheet metal containers of every loads.

Many different configurations are possible: single, double deep storage and multi-position system, according to customer needs. Reference numbers, pallet loads, picking activities desired are some of the relevant factors.

Single deep storage solution is recommended where there is a huge reference number, every pallet remains directly accessible. Double deep storage allows the increase of storage density, aisle number is halved. In multi-position system aisles are few compared with other solutions and operations are optimized duly to item codes and not unit loads.

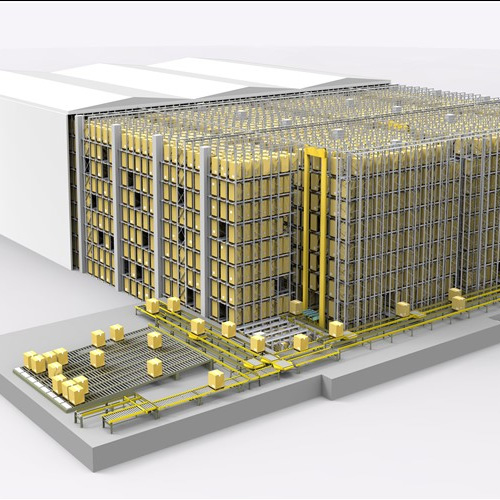

Miniload

-

Miniload systems is a perfect solution to current market needs requires high and higher picking performances: huge orders number with few codes, short timing for processing. During last years e-commerce pushed a lot in this direction and changed a lot also storage activities.

Automatic systems can work 24 hours and all items in-out are recorded. Strength points is: processing time scheduled without mistakes.

Miniload systems manage cartons, bins, trays, made of cardboard, plastic and metal. All unit loads can be divided internally. These systems are integrated by picking stations for order preparations.

According to unit load type, miniload recking can be equipped by shelf angled runners or continuous shelvings.

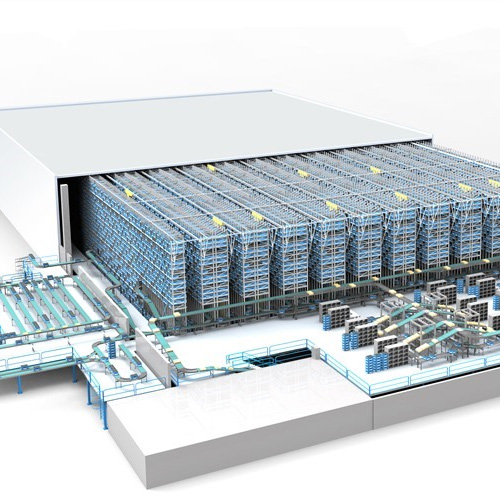

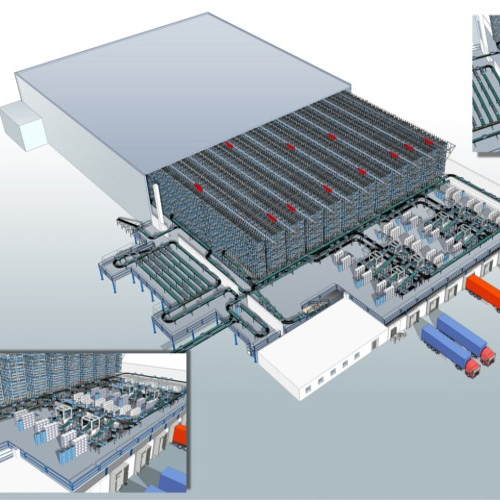

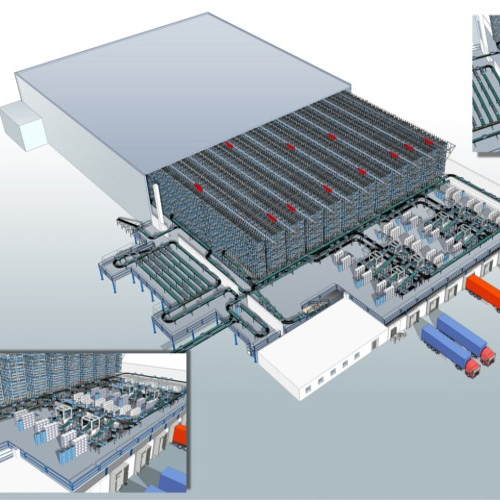

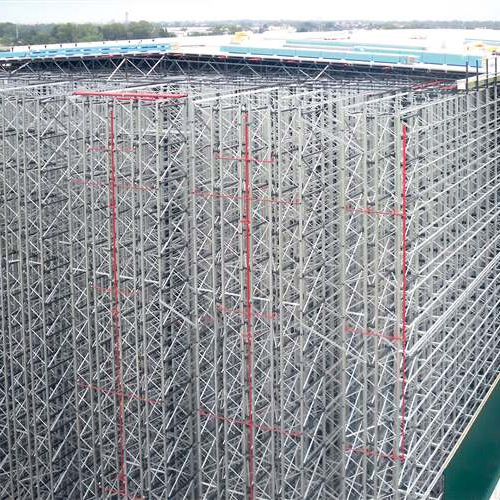

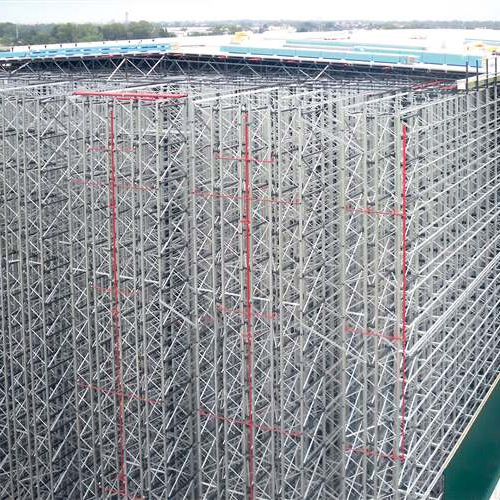

Self-supporting warehouse

-

Self-supporting structures are the most representative expression of Dalmine Logistic Solutions’ project and realization capabilities: just one partner to build-up impressive structures, nowadays protagonist in logistics.

These systems allows an excellent use of vertical space. The racking supports its own load, unit loads, weathering like wind and snow.

Self-supporting structures are designed around storage needs, despite the building’s structural constraints.

Architectural rules are different for building and self-supporting structures, these last one are considered like equipment. Also about building area itself there are different rules. With this system it is possible realize automated system for pallet or miniload.

From the environmental viewpoint, a self-supporting structure allows a better use of the soil because it develops in height. Furthermore roof and wall coverage could be implemented by photovoltaic panels, in order to feed the storage itself. Materials used can be totally recycled, once the structure would be dismissed.

All our constructions are designed following seismic regulations. Dalmine Logistic Solutions is a whole partner, from design till implementation, its references are its best credential.

Product Range

- A wide choice of industrial shelving to simplify storage and picking operations. Adaptable products designed to support different load unit and satisfy any logistical need.

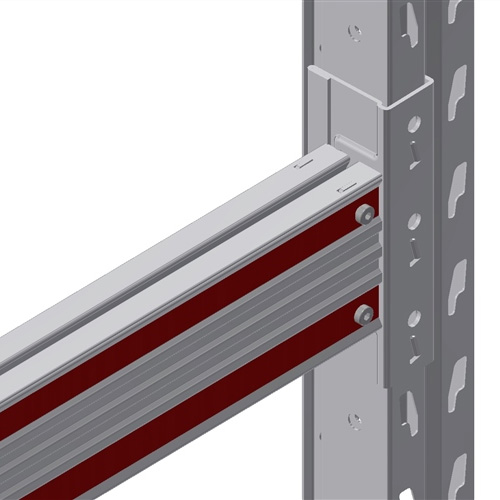

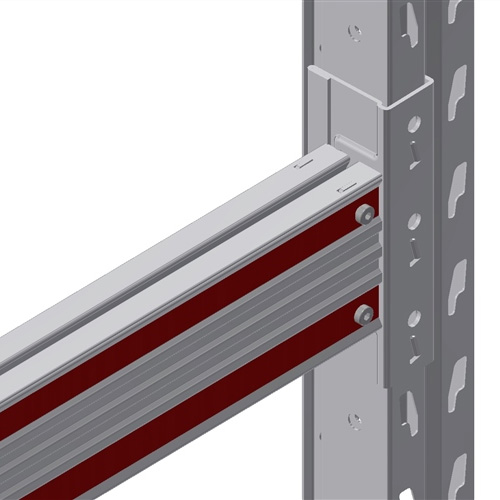

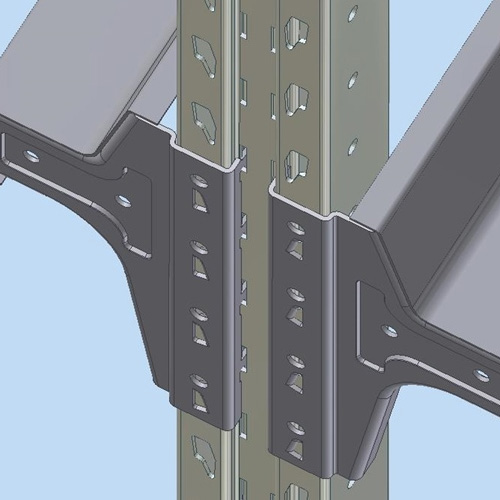

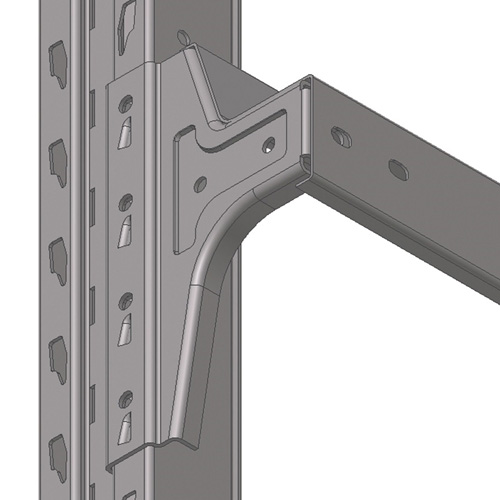

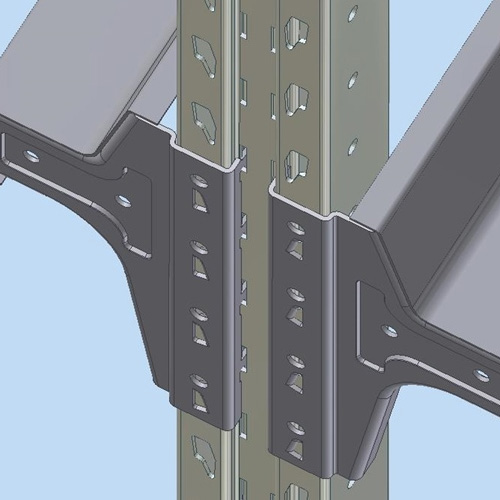

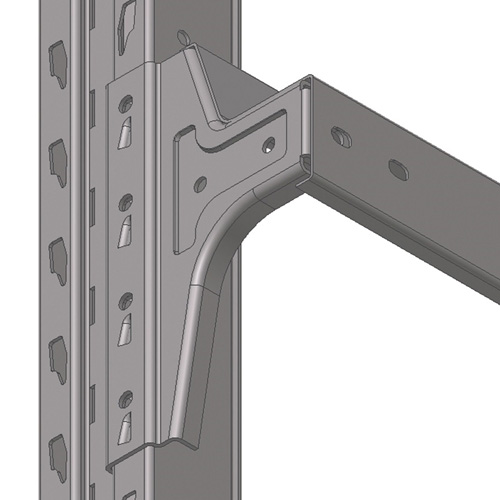

Bi-Bloc industrial racking

-

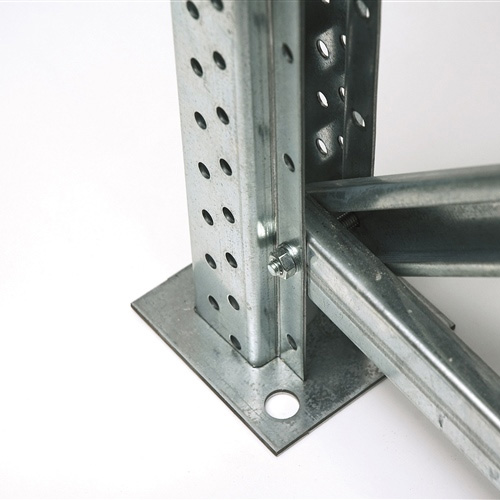

Bi-Bloc industrial metal racking suitable for earthquake-proof warehouses, pallet storage and various high capacity loading units.

Shoulders

- three types of uprights and different widths: 80, 100, 120 mm

- standard shoulders with depths from 600 to 1200 mm

- capacity per shoulder: from 9 to 29 tons

Current

- seamless, heights from 60 to 160 mm

- standard sizes: from 1300 to 3600 mm

- capacity per pair: from 900 to 5400 kg

- safety system with anti-release plug

Accessories

- tiles for picking floors

- parachute transoms for pallets

- upright and shoulder protectors in different solutions

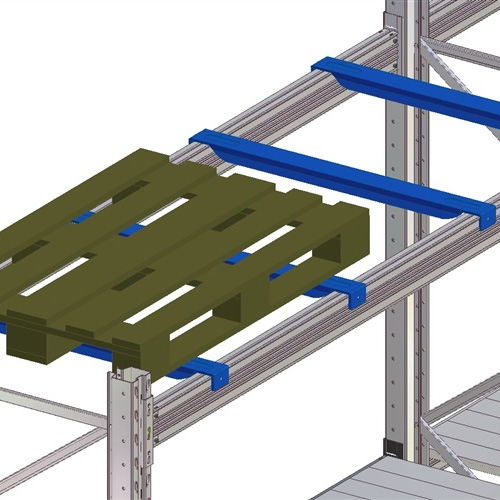

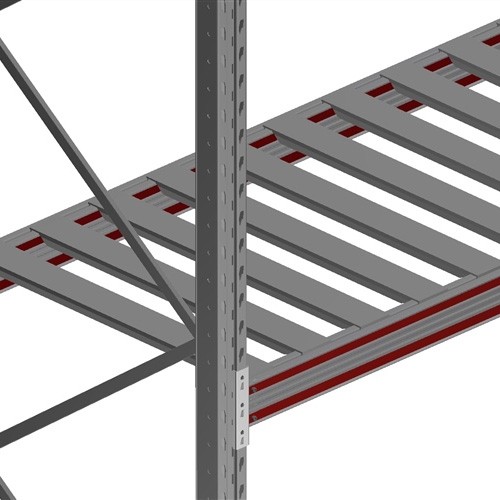

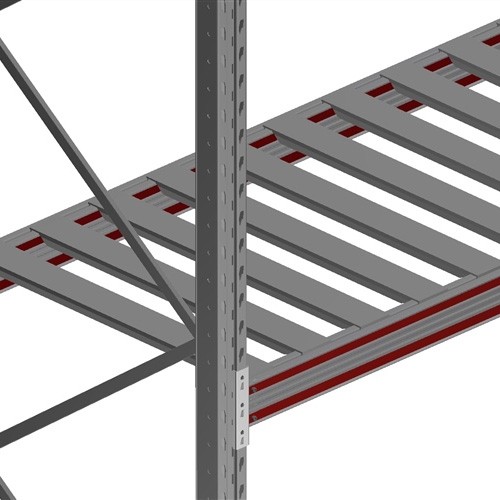

Drive-in Bi-Bloc industrial racking

-

The drive-in racking system, suitable for creating earthquake-proof warehouses, allows the storage of large quantities of pallets with high storage density.

The accumulation of the loading units in the tunnels allows a great recovery of space, minimizing the number of corridors necessary for handling.

Storage is normally carried out according to the Li-Fo logic (Last In-First Out), but it can also be carried out according to the Fi-Fo logic (First In-First Out) or drive through: the pallets are arranged on special guides and the picking means can be guided inside the shelf.

The main component of the storage system is the Bi-Bloc shelving system equipped with the appropriate support guides.Features

- Bi-Bloc shelving uprights

- height: max 12 m

- tunnel width: from 1350 to 1400 mm

- Capacity: max 2200 kg

- drive-in guides

- ground guides

- pallet back-stop

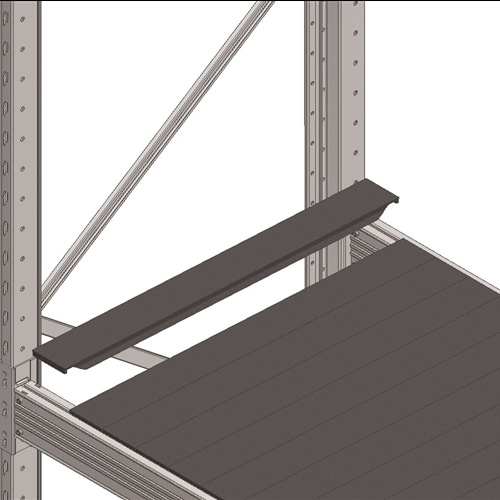

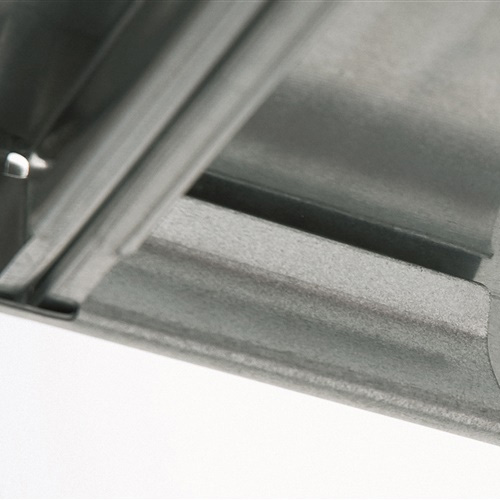

Light Bi-Bloc wide span shelving

-

Light Bi-Bloc wide span shelving with large spans for containers, cartons and bulk goods. Useful for creating multi-storey warehouse systems with walkways.

The warehouses can be built according to anti-seismic regulations.Shoulders

- uprights width: 55 mm

- Max capacity 6500 kg

- max height 8200 mm

Shelves

- beams: h 65 mm; l 1200 and 2400 mm

- Max capacity 800 kg

Accessories

- longitudinal and transverse side separators

- side and back panels

Errex Boltless Shelving

-

rrex is a registered trademark of Dalmine Logistic Solutions.

It is a unique, versatile and durable interlocking metal shelf. The shelves are composed of panels and crossbars suitably sized to reach the required load capacities.

The Errex shelf allows many configurations thanks to the richness of the range and the accessories available. Assembly is quick and easy thanks to the interlocking system that does not require the use of special tools.

Being able to support various load units, it is suitable for industrial warehouses, offices, homes and ideal for creating picking solutions.Shoulders

- upright width: 35.5 mm

- shoulder height: from 2 to 5 m

- shoulder depth: from 200 to 800 mm

- Max. load capacity: 3600 kg

Shelves

- shelves length: from 550 to 1300 mm

- panel depth: 100, 200, 300 mm

- different configurations: max depth 800 mm, max capacity 500 kg

Accessories

- side and back panels

- dividers, coat racks, drawers, hinged doors

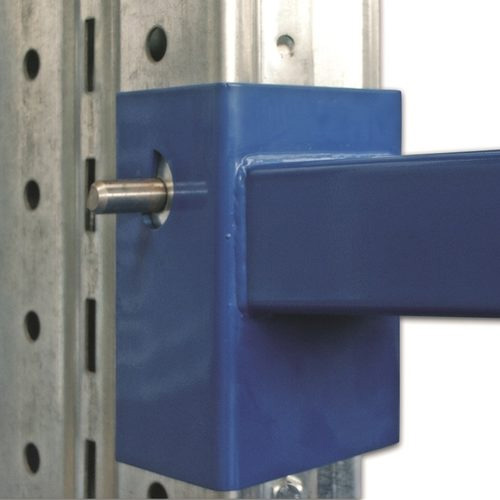

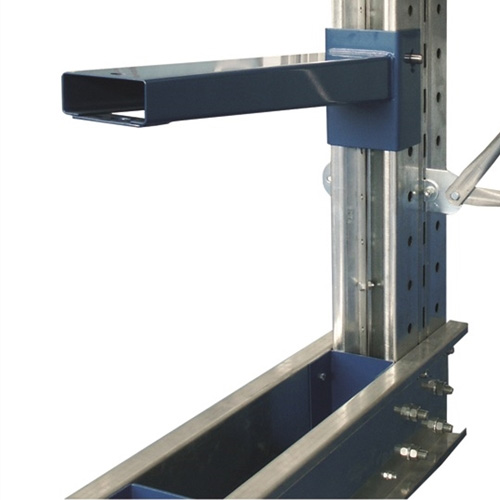

Cantilever

-

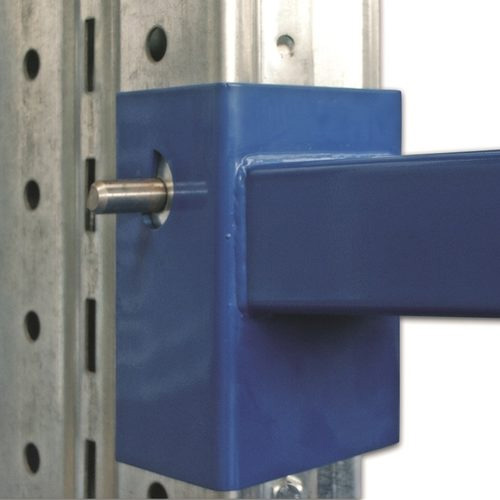

The cantilever racking system makes it easy to store long bodies such as pipes and boards, and is available in both a lightweight and a high-performance version, to meet different requirements.

By inserting the appropriate shelves on the arms, it is possible to create long continuous planes without interruptions due to the assembly.

The warehouses can be built according to the anti-seismic regulations.Features

- column height: from 2025 to 6000 mm

- depth of arms: from 400 to 1500 mm

- single and double-sided configurations

- distance between columns: from 750 to 2000 mm

- adjustable pitch height: 75 or 100 mm

- arms safety stop

Shelving Kit

-

Dalmine Logistic Solutions offers its Errex industrial interlocking shelf also for domestic use as a kit solution: a single package with everything needed for assembly.

This is the ideal shelf for those looking for a high quality product, which can also withstand large loads, in a practical format and easy to assemble.

Features

- span width: 100 cm

- height 180 cm

- shelves: 5

Kit Errex shelves are available in two versions:

- Errex Kit 1 – shelves 40 cm deep with capacity 140 kg;

- Errex Kit 2 – 30 cm deep shelves with capacity 100 kg.