MARKATOR

Videos

Loading the player ...

- Offer Profile

- We are experts in durable and

economic marking of industrial parts to help eliminate forgery. We have been

developing and manufacturing high-quality systems for dot peen marking,

scribe marking and conventional marking for over 25 years. We can meet our

customers needs individually and precisely.

Our aim is to achieve the highest quality possible. We attach importance to solid consulting, customer-related development and user-friendly marking systems. We maintain a constant dialogue with our customers and their applications which help us maintain a continual development, optimisation and innovations within our product range.

Our benefits are completed with a committed and professional service manned by our highly-qualified employees. Since August 2004 MARKATOR® is ISO certified.

Product Portfolio

Hand-held marking systems

Electro-magnetically driven hand-held marking systems

- Our electro-magnetically hand-held marking systems are 100% mobile and with this portable. Thanks to the use of powerful Lithium-Ion-Batteries, no cables.

FlyMarker® mini 65/30

- The already fourth generation of the mobile dot peen

marker can be described as a new milestone in the history of the battery

operated hand-held marking units.

The new FlyMarker® mini builds on the strengths of the proven previous models and convinces with its light weight and its compact design as well as also due its unique introduction price.- Weights only 2.4 kg

- Marking area of 65 x 30 can be used completely

- Break-resistant housing out of glass fibre reinforced plastic

- Software is self-explanatory and intuitively to operate

- High-resolution LC-display

- Self-sufficient work due to a powerful Lithium-Ion-

- Batteries (2 are in standard scope of supply)

- Numeric keys are integrated directly in the keyboard

- Dirt-resistant and easy to operate keypad

- Second handle allows an ergonomic two-hand operation and can be dismounted easily if there is less space

- Practical carrying case for the complete standard scope of supply

- Marking force can be adjusted individually to the material to be marked and to the needed marking depth

- Characters, numbers, test symbols, logos and

- Data Matrix Codes can be marked

- Several hundreds of marking files, fonts and logos can be stored in the internal memory

- Integrated USB-interfaces enable a fast data transfer and can also be used for the operation of optional accessoires

FlyMarker® mini 120/45

- The mobile dot peen marker FlyMarker® mini 120/45 is

already the fifth generation from the product group FlyMarker®.

The long-term experience in manufacturing battery operated hand-held marking systems and the comprehensive knowledge about the customer and market requirements have been consistently integrated in the development of this product.- Marking area: 120 x 45 mm

- Weight only 3,2 kg

- Extra strong magnet for deep markings (optional)

- 18V Lithium-Ion-Battery

- High quality guidance system for highest stability

- Attractive price-performance ratio

- Integrated control system (All-In-One)

- Integrated, user friendly keyboard. Numeric keys are integrated in the keyboard.

- Illuminated marking area

- Nearly all materials can be marked – from plastics to hardened steel (63HRC)

- Latest processor technologies allow fast navigation

- Break resistant housing made of glass fibre reinforced plastic.

- The additional handle can be dismounted easily when there is less space between work pieces

- Numerous language versions available by default

- Optionally individual company logos, test symbols or Data Matrix Codes can be marked

- Integrated barcode scanner (optional)

- Column frame (optional)

Electro-pneumatically driven hand-held marking systems

- Our electro-pneumatically and with this wired hand-held marking systems are particularly suitable when extremely deep markings are required.

MV5 M50/M80/M120

- Ideal partner for self independent markings of heavy, bulky and stationary work pieces on site

- Very space-saving and handy by compact construction and ergonomic design

- High speed marking due to latest control technologies

- Low moving masses due to compact design

- Solid mechanics with high quality, double guided linear guides in x- and y-direction

- Perfect power transmission into the material to be marked

- High repeat accuracy

- Extremely precise and warp-free marking result

- 2D-marking (option)

- Can be used in any position

- Good price performance ratio

- Available marking areas:

Marking area (x/y) 50 x 25 mm (MV5 M50/25)

Marking area (x/y) 50 x 45 mm (MV5 M50/45)

Marking area (x/y) 80 x 25 mm (MV5 M80/25)

Marking area (x/y) 80 x 45 mm (MV5 M80/45)

Marking area (x/y) 120 x 25 mm (MV5 M120/25)

Marking area (x/y) 120 x 45 mm (MV5 M120/45)

MV5 M0/M1/M2

- Mobile, hand operated marking system

- Works in all positions

- Prism Stop for applications involving round parts

- Individual supporting feet for applications involving flat parts

- Shock-resistant body

- Maintenance free mechanics and tools

Ideal for applications in swirl environments - Optimum marking depth

- Available marking areas:

Marking area (x/y) 100 x 100 mm (MV5 M0)

Marking area (x/y) 200 x 100 mm (MV5 M1)

Marking area (x/y) 30 x 65 mm (MV5 M2)

Table marking systems

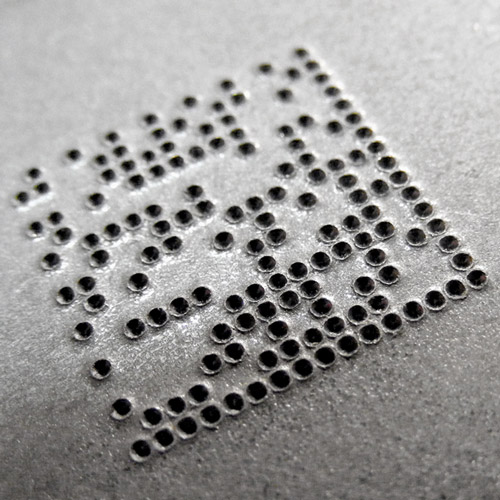

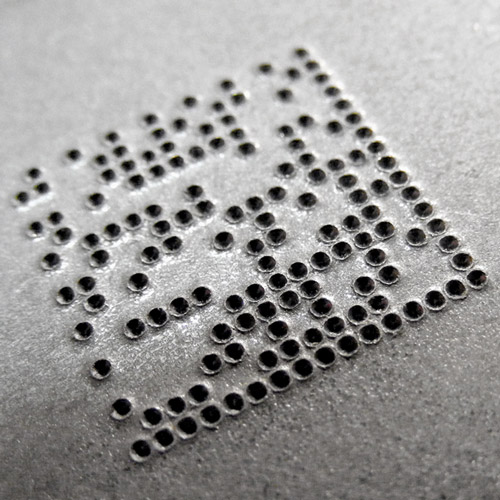

Dot peen markers

- A durable dot peen marking is generated by a pneumatically driven, oscillating carbide marking pin. The marking pin is moved during the marking process by two carriages into the x and y direction and strikes the material by an up and down movement. Almost all materials can be marked.

MV5 T0

- Highest stability of the column frame by massive tracks

- Fast adjustment of the height by a hand wheel. Four times faster than conventional column frames

- Integrated digital height index

- Highest marking quality at maximum speed by precise mechanics

- Easy operation

- Maintenance free mechanics and tools

- Highest flexibility by system expansion with additional components

- Available marking areas:

Marking area (x/y) 100 x 100 mm (MV5 T0)

Marking area (x/y) 200 x 100 mm (MV5 T1)

FlyMarker® NetMarker

- Innovative, network-compatible CNC table marking system

- Marking area (x/y) 100 x 100 mm

- Attractive price-performance ratio

- The system program is 100% operator prompted. It has a clearly arranged

design

and is easy to use - After software installation immediately ready for operation

- Operation in a company network by Ethernet connection

- Marking preview, changings of position and marking text possible

- Exact positioning of the marking pin in x and y direction by a helpful viewing window

- Extension with a lot of accessories

Maintenance-free

MV5 MT0

- Combination of table and hand-held marking system

- Stationary and mobile application

- Works in all positions

- Prism Stop for applications involving round parts

- Individual supporting feet for applications involving flat parts

- Shock-resistant body

- Maintenance free mechanics and tools

- Ideal for applications in swirl environments

- Optimum marking depth

- Available marking areas:

- Marking area (x/y) 100 x 100 mm (MV5 MT0)

Marking area (x/y) 200 x 100 mm (MV5 MT1

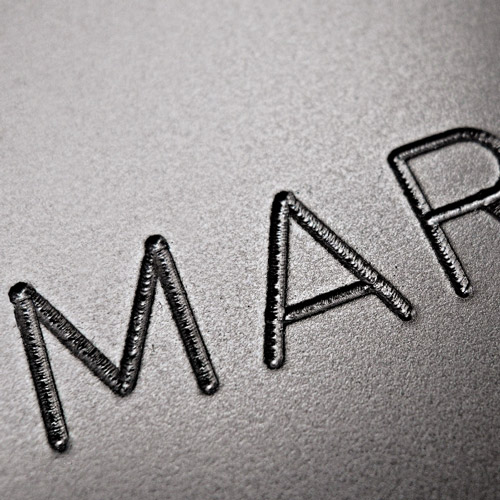

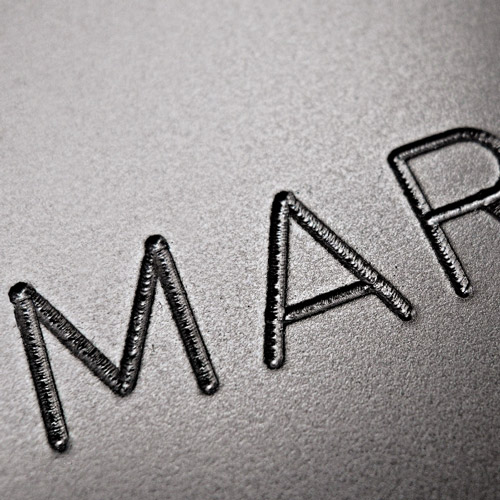

Scribe markers

- Compared to dot peen marking the scribe marking pin does not strike into the material with an up and down movement but is pressed into the material. In this position the carbide or diamond scribe marking pin is moved by two carriages in x and y direction. Almost all materials can be marked.

MV5 VT0

- Marking area (x/y) 100 x 100 mm

Very low acoustic emissions at marking - Highest marking repeat accuracy by high value linear guidance in connection with ball bearing screws

- Maintenance free mechanics and tools

- Infinitely adjustment of the different marking strengths

- Highest marking quality at maximum speed by precise mechanics

- Marking area (x/y) 100 x 100 mm

Integration units

Dot peen markers

- A durable dot peen marking is generated by a pneumatically or electropneumatically driven, oscillating carbide marking pin. The marking pin is moved during the marking process by two carriages into the x and y direction and strikes the material by an up and down movement. Almost all materials can be marked.

MV5 U65/30 INTEGRAL

- Compact dot peen marker with integrated control

unit -

no external central control unit is necessary - Electromagnetic driven marking pin - therefore no compressed air supply is necessary

- Compact design and low weight of only approx. 3.2 kg

- Big marking area of 65 x 30 mm in a low volume

Communication with SPS optional via function block - Fast function check via 6 status LEDs on the marking head

- Perfect for the integration in test facilities

- Solid mechanics with high quality, double guided linear guides in x- and y-direction

- Data-Matrix-Code marking (optional)

- High repeat accuracy when marking nearly any metals and plastics

- Can be used in any position

- Extremely precise and warp-free marking result

- Very good price-performance ratio

- Marking area of the dot peen marker:

65 x 30 mm (x/y)

- Compact dot peen marker with integrated control

unit -

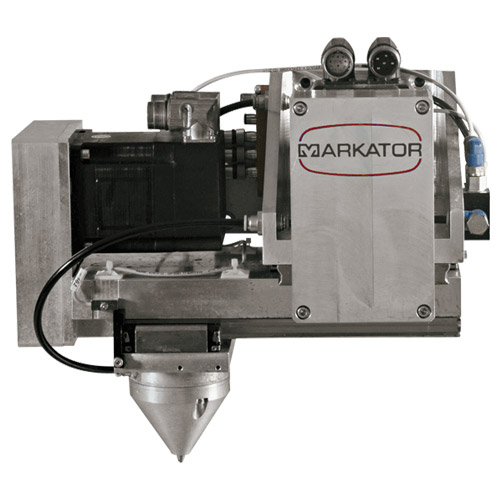

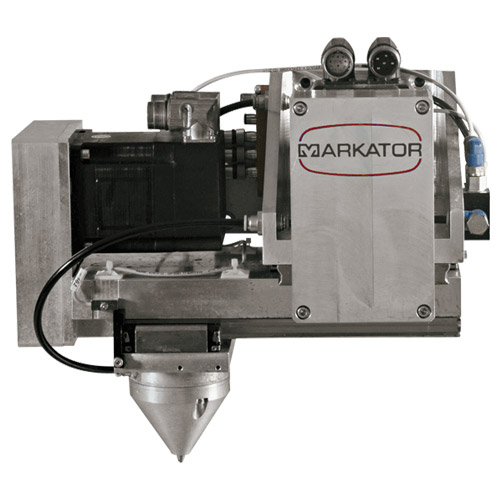

MV5 U50/U80/U120

- Easy Integration in production and assembling lines

- Rapid marking speed for shortest cycle times

- Low moving masses due to compact design

- Solid mechanics with high quality, double guided linear guides in x- and y-direction

- Perfect power transmission into the material to be marked

- High repeat accuracy

- Extremely precise and warp-free marking result

2D-marking (option) - Can be used in any position

- Good price performance ratio

- Available marking areas:

Marking area (x/y) 50 x 25 mm (MV5 U50/25)

Marking area (x/y) 50 x 45 mm (MV5 U50/45)

Marking area (x/y) 80 x 25 mm (MV5 U80/25)

Marking area (x/y) 80 x 45 mm (MV5 U80/45)

Marking area (x/y) 120 x 25 mm (MV5 U120/25)

Marking area (x/y) 120 x 45 mm (MV5 U120/45)

MV5 U30/U100/U200

- Fully prepared and ready to be integrated marking system

- Works in all positions

- Easy Integration in production and assembling lines

- Highest marking quality and speed by precise mechanics

- Maintenance free mechanics and tools

- Marking areas:

Marking area (x/y) 30 x 65 mm (MV5 U30)

Marking area (x/y) 100 x 100 mm (MV5 U100)

Marking area (x/y) 200 x 100 mm (MV5 U200)

Scribe markers

- Compared to dot peen marking the scribe marking pin does not strike into the material with an up and down movement but is pressed into the material. In this position the carbide or diamond scribe marking pin is moved by two carriages in x and y direction. Almost all materials can be marked.

MV5 VU2

- Marking area (x/y) 80 x 50 mm

New scribe marking head developed due to years of experience - Tailor-made markinghead for the integration in automatic production lines

- Compact and weight-optimized construction of the scribe marker enables a space-saving installation in a production line and the installation on small industrial robots

- Very stiff and long-lasting due to double guided linear guides and the use of precise ball screws

- Precise marking of twodimensional Data Matrix Codes

- Highly reliable marking system

- Installation in any position

- Stepless adjustment of the marking force of the scribe marker through to a pressure regulator

- Maintenance free mechanics and tools

- Protection cover against dirt

- Marking area (x/y) 80 x 50 mm

MV5 VU2 SPRINT plus

- This marking head has the same characteristics than the above mentioned scribe marking head MV5 VU2. Using the optional available version SPRINT plus it is possible to achieve very high marking speeds. A marking of 10 characters in 3mm character height can be done in 3 seconds.

Marking area (x/y) 80 x 50 mm.

MV5 VU4

- Marking area (x/y) 80 x 50 mm

Fully prepared and ready to be integrated marking system - Easy integration in production and assembly lines

- Infinitely adjustment of the different marking strengths

- Works in all positions

- Highest marking repeat accuracy by high value linear guidance in connection with ball bearing screws

- Particular suitable for data matrix marking

- Maintenance free mechanics and tools

- Protective covering against smut

- Further marking areas:

Marking area (x/y) 160 x 50 mm (MV5 VU5)

Marking area (x/y) 80 x 100 mm (MV5 VU6)

Marking area (x/y) 160 x 100 mm (MV5 VU7)

- Marking area (x/y) 80 x 50 mm

MV5 VU4 ECO SPRINT

- This marking head has the same characteristics than the above mentioned marking head MV5 VU4. Due to other motor performances shortest marking times can be achieved; approx. 3 - 4 seconds for 10 characters in 3 - 4 mm character heights.

- Available marking areas:

Marking area (x/y) 80 x 50 mm (MV5 VU4 ECO SPRINT)

Marking area (x/y) 160 x 50 mm (MV5 VU5 ECO SPRINT)

Marking area (x/y) 80 x 100 mm (MV5 VU6 ECO SPRINT)

Marking area (x/y) 160 x 100 mm (MV5 VU7 ECO SPRINT)

- Available marking areas:

MV5 VU4 SPRINT

- This marking head has the same characteristics than the above mentioned marking head MV5 VU4. Due to other motor performances shortest marking times can be achieved; approx. 2 - 3 seconds for 10 characters in 3 - 4 mm character heights.

- Available marking areas:

Marking area (x/y) 80 x 50 mm (MV5 VU4 SPRINT)

Marking area (x/y) 160 x 50 mm (MV5 VU5 SPRINT)

Marking area (x/y) 80 x 100 mm (MV5 VU6 SPRINT)

Marking area (x/y) 160 x 100 mm (MV5 VU7 SPRINT)

- Available marking areas:

MV5 VT0

- Marking area (x/y) 100 x 100 mm

- Fully prepared and ready to be integrated marking system

- Works in all positions

- Very low acoustic emissions at marking

- Highest marking repeat accuracy by high value linear guidance in connection with ball bearing screws

- Maintenance free mechanics and tools

- Infinitely adjustment of the different marking strengths

- Highest marking quality at maximum speed by precise mechanics

MV54

- Fully prepared and ready to be integrated marking system, particular for chassis frame numbers and deep scribe markings

- Compact, electropneumatic marking unit

- Marking area (x/y) 160 x 60 mm

- Infinitely adjustment of the different marking strengths

- Works in all positions

- Two brushless stepping motors drive the marking axis and exhibits

optimal wear behaviour

Highest marking repeat accuracy by high value linear guidance in connection with ball bearing screws - Maintenance free scribe stylus

- Very stable diamond-equipped marking pin works pneumatically

- Optimal wear behaviour of the pneumatic valve by oil-free operation

Central control units

- Hand-held and

table marking systems

Our marking systems are part of a modular construction system. To operate our hand-held and table marking systems, following central control unit can be used.

Marking systems to integrate in automatic production lines

Our marking systems are part of a modular construction system. To operate our dot peen and scribe marking heads to integrate in automatic production lines,

following central control units can be selected.

MV5 ZE 301 XL

- Both the hand-held and table marking systems can be controlled with this central control unit

- Based on a consistent modular design system

- Space-saving housing

- Stand-alone use

- Integrated colour LC-display with a resolution of 640 x 480 pixels

- Integrated Ethernet and USB interface

100% operator prompted - Logical and self-explanatory user surface

- Marking preview

- The option PC-software XL CONTROL enables to create, modify and administer the marking files directly on the PC

- Several hundred marking files, logos and fonts can be saved directly on the controller

- The substitutes time, date, auto-numbering, shift identification and wait time are included in the standard scope of supply

- Optional program package DMC (data matrix code)

- Many other software options are available

MV5 ZE 101 XL

- Very compact design

- Integrated PC functions for independent applications

- Protection IP54

- DEVICENET-/INTERBUS-/PROFIBUS- or PROFINET-cards (also LWL) can be used

- Integrated Ethernet and USB interfac

- High resolution LC-display

- Capacitive keyboard

- Simple, intuitive and easy to operate device

- Logical, self explanatory user-interface

- Several hundred marking files, logos and fonts can be saved directly on the unit

- By using the latest processor technologies, fast navigation and fast access times can be provided

- The software is available in several languages

MV5 ZE 401 XL

- Especially designed for industrial marking jobs

- All components for daily marking tasks – such as the power units for stepping motors, microprocessors and memories – are combined on a compact control module

- Using a DEVICENET-/INTERBU S-/PROFIBU S-, or a PROFINET card (also LWL), the control unit MV5 ZE 401 XL can be linked to a production process (e.g. PLC)

- Protection IP54

- Integrated foil keyboard

- Integrated high resolution display

- Integrated Ethernet and USB inteface

- Logical and self-explanatory user surface

- The software is available in several languages

- Several hundred marking files, logos and fonts can be saved directly on the controller

Optional Accessories