- Offer Profile

- Occupational Health and

Safety

With our innovative sensor technology, we make industrial trucks and forklift trucks fit for effective and safe use / material flow. The additional intelligence prevents accidents and operational disruptions and increases driving comfort. We upgrade your forklift trucks so that you can maintain your delivery and production plans.

Safety Technology at the Highest Level

-

For around 30 years we have been an innovative and leading company for

safety-related equipment and solutions in logistics and property protection

With our products and services, we contribute to the optimization of the operating procedures and thereby to the optimization of productivity and earnings. DriverAssistanceSystems increase driving comfort

- The tbm driver assistance systems make the materialflow in intralogistics effective, quick and safe. Our systemsassist the driver during his journey with the industrial truck and help him, just like a co-pilot in rally sport, to recognize and warn him of hazards in good time. In hazardous situations, the systems intervene in the vehicle control in advance. This takes place automatically and self-acting, either by a reduction in the speed or the stopping of the vehicle. In doing so, the autonomy of the driveris not affected.

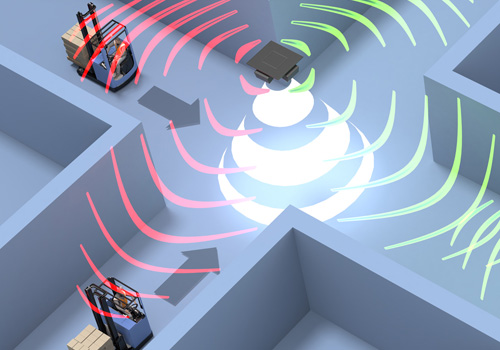

NoColl Collision Protection

-

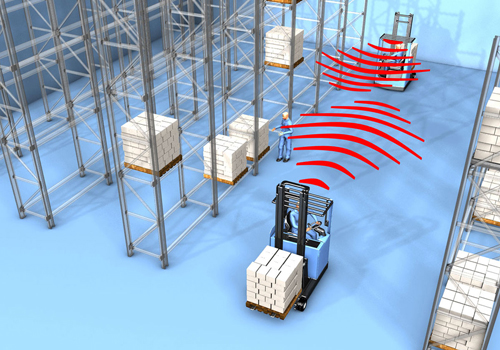

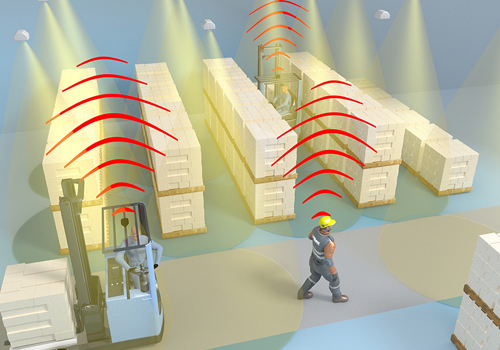

NoColl is a patented, versatilely deployable protection devicefrom tbm for use in the logistics industry. For this purpose, the hazard areas are fitted with small, high-performance NoColl sensors. These in turn communicate with the NoColl sensors on the vehicle. Bidirectionallyand at the speed of light.

The NoColl Collision Protection System is the interactive protection system for numerous hazard points and hazardous situations

Reverse Travel – Reliable Hazard Recognition – Technology Supported

-

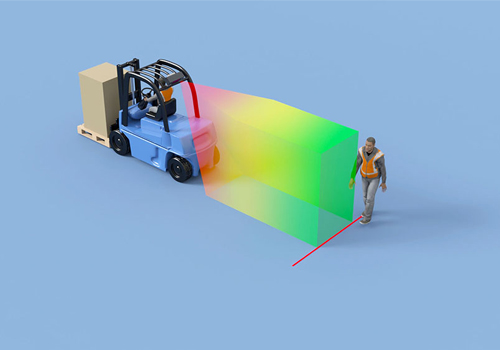

A rear area warning device – as with a convenient passenger car – ensures safe and collisionfree reverse travel. It relieves the driverandalso covers the area which the driver cannot (so easily) see into. Thedamage rate is considerably reduced and pedestrians are protected.

New 3D sensortechnology provides the highest levels of convenience and safety,

and no more constantly irritating "beeping".

The Forklift Truck Aura is the perfect all round Personnel Protection

-

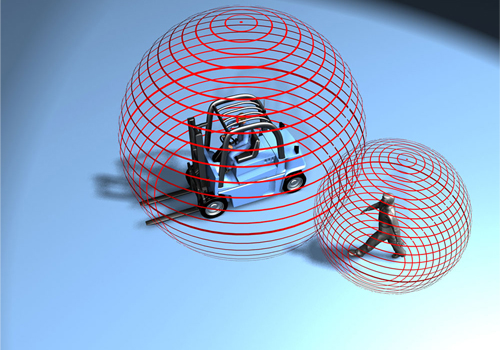

The forklift truck RFID-Aura, with a special RFID tag in the pocket or on a keyring, is an RFID system for the recognition of personnel, tried and tested over many years. The encryption technology used ensures safety and convenience. We use this technology for the protection of pedestrians in forklift truck traffic

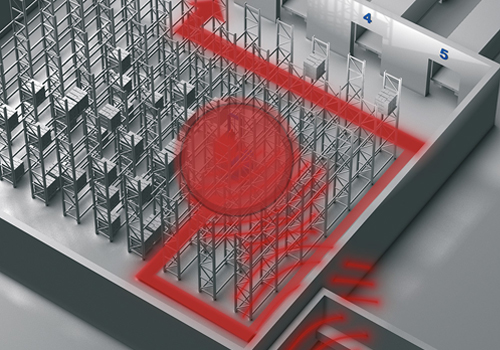

RFID-Aura 207

The RFID-Aura 207 forms an almost spherically shaped protection area all around the forklift truck. The area which the driver cannot see into when manoeuvring or storing or removing. The RFID-Aura 207

Warns the driver of the presence of people

Thereby protecting the people in the vicinity of the vehicle

Therange is individually adjustable between 1 – 8m and can, therefore be adapted to special requirements. By means of anintegrable "booster" the range can be extended up to 15m.

IOG InDoor/OutDoorSpeed Regulator

- In order to prevent accidents, a very effective and efficient measure is to reduce speed inside buildings. The tbm InDoor/ OutDoor speed regulators release the speed restriction when travelling outside the building. Automatically, and without the need for any additional equipment on the door through-paths.Thus the full performance of the vehicle can be utilized outside the building.

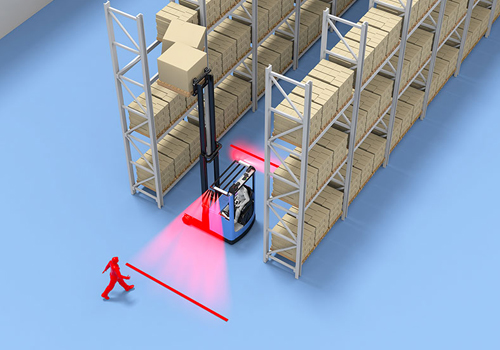

GBA Hazard Area Indicator

-

Falling loads are a great danger for pedestrians who are order picking in close proximity to the vehicle when goods are being stored or removed with a reach truck. Here there is a real threat to life! With the hazardous area indicator we simply and effectively reduce this risk.

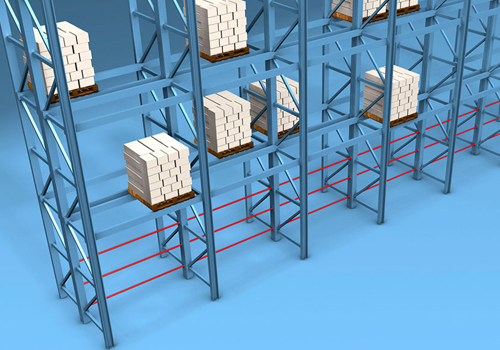

Hazardous Area Indicator GBA 100

With the hazardous area indicator, GBA 100,the hazardous areas to the left and right of a reach truck are indicated by means of high output power LEDs and a clearly visible laser line on the floor. There by pedestrians are clearly warned: "Stop! Serious Risk! Do not enter the marked area!"

So that no sensor overload occurs, the hazardous area indicator, GBA-100, is only activated in the event of serious risk, that is, when the load has been lifted above a specified height.

Hazardous Situation Indicator GSA-107

-

The hazardous situation indicator GSA-107 is a sensor-controlled, stationary warning device for intersections, pedestrian crossings or curvesand, situationdependent, distinctively and conspicuously illuminates the hazardous area with a Power-Blue- Spot.

The hazardous situation indicator GSA-107 acts preventively directly at the hazard point and attracts a very high level of attention. The hazard point becomes "live" and responds by itself to potential or imminent danger. Powerful  effectiveand efficient.

Sensor-controlled, the hazardous situation indicator GSA-107 differentiates between vehicles and pedestrians and recognizes the direction of travel of the vehicle and the direction of walking of the pedestrian.

The hazardous situation indicator GSA-107 permanently monitors every movement at the intersection.

Safety Technology at the Highest Level

-

With the mobile on-board safety devices, the requirements of the Machinery Directive, DIN ISO 13 849 and DIN 15 185-2 are satisfied.

Mobile personnel protection on industrial trucks has been standard practice for many years. The on-board safety deviceson industrial trucks enable the convenience and flexibility of a modern logistics operation.

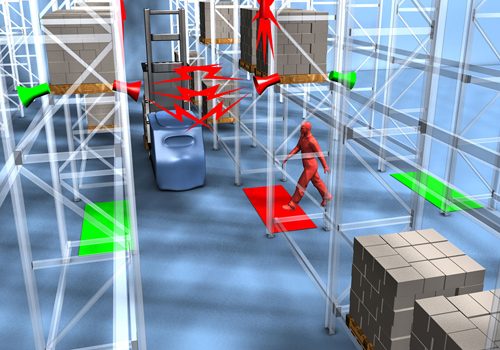

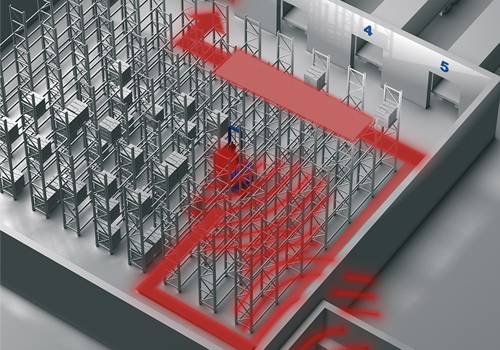

Mobile Personnel Protection GM-107cpu/V3

-

The standard for controlled warehouse operation

The personnel protection system, GM-107cpu/V3, is the most commonly used personnel protection system. With a laser scanner in each of the load and drive directions, the entire width of the narrow aisle is fully and driving direction-dependantly monitored.

The central microprocessor-controlled evaluation electronics manage the two laser scanners and the other components of the personnel protection system. It is the intelligent and secure logic for the integration of the protection functions in to the vehicle control. On the detection of a person or an object the vehicle is brought to a standstill.

Extensive optional functions turn the personnel protection system into a multi-functional safety packet.

Aisle end protection

Collision protection outside the narrow aisle

Comfort travel to the end of the aisle

Fullstop at the end of a cul-de-sac

Position stop within the narrow aisle

Speed-dependant protection field adaptation

Mobile Personnel Protection GM-107cpu/TK

-

The standard for deep-freeze warehouses

For use in deep freeze areas (down to -30°C),thepersonnel protection systemis specially prepared and special components are used

Special heated laser scanners

Special driving direction encoders (where necessary)

Special rack equipment

The special components, however, do not change the structural shape, so no special preparations on the vehicle are necessary for a pre-prepared ex works vehicle.

Mobile Personnel ProtectionGM-107cpu/Ex

-

The standard for ex-protection areas

The personnel protection system, GM-107cpu/V3, is designed for use in ex-protection areas in accordance with the ATEX requirements for

The equipment group II

The category 3G for use in potentially explosive atmospheres of

Zone 2,

Explosion group IIB and

Temperature class T4

for those of the ex-protection Zone 2.

We will take care of the individual special case approvals for you, the specific tests (temperature tests; gas tests,etc.). You don't have to worry about anything else.

Mobile Personnel Protection GM-107cpu/AC

-

The standard for collision protection within narrow aisles

With the use of the personnel protection system, GM-107cpu/AC, the simultaneous use of two or more vehicles within a narrow aisle is allowed in accordance with the regulations.

In this special design, the range of the collision protection up to 15m necessary for this is safety-related guaranteed. At the same time, the safe personnel protection of up to 7m is complied with.

Prescribed Warehouse Equipment

- With effective equipment we ensure the necessary protection at specific hazard points throughout the entire warehouse area. According to regulations and safely.

Cross-aisle Safety

-

In accordance with the Regulation BGV D 27 (Employers' Liability Association Regulation) and DIN 15 185-2, cross-aisles within a storage rack must be especially protected.

TheCross-aisle Safety System, QGS-107, is the Solution for this

The cross-aisle safety system, QGS-107, monitors the entire area of a storage rack through-path. A person who enters a cross-aisle triggers an optical / acoustic alarm on both sides of the rack – or stops the approaching vehicle for so long as the person is in the cross-aisle.

Climb-through Protection System DSS-107

-

In accordance with the Regulation BGV D 27 and DIN 15 185-2, storage racks whose bottom level bay is higher than 1.2m must be especially protected against simple climbing through

The Climb-through Protection System, DSS-107,is the solution for this

The climb-through protection system, DSS-107, consists of three ropes lying one above the other stretched between a double rack. Spring mounted so that no damage can occur during the loading or removal of goods. Thus the simple climbing through of a storage rack is effectively prevented.

Traffic Signs VZ-107

-

In accordance with the Regulation, BGV D 27,and DIN 15 185-2, traffic routes must be equipped with the prescribed traffic signs. This also applies to the narrow aisles which count as traffic routes

The Traffic Signs, VZ-107, are the solution for this

The DIN A3-sized traffic signs, VZ-107, with the necessary additional text attract the necessary attention of the pedestrians.

Collision Protection AFS-107

-

Beams or doors / through-paths are a particular source of risks when the mast of an industrial truck has been raised too high.

The Collision Protection System, AFS-107, is the solution for this.

The through-path and / or the beam are equipped with a high-performance light barrier and a radio transmitter. If the light barrier is broken by the mast, the vehicle is stopped via a radio signal sent to its radio receiver.

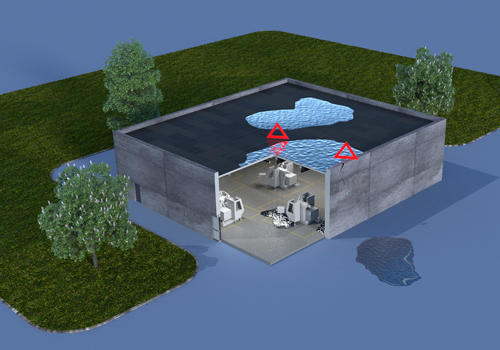

Safety at Work + Logistics Management = IntraSafety

-

IntraSafety –the reliable logistics management system, combines safety at work and logistics management

IntraSafety is the result of a successful research project funded by the BMBF (German Federal Ministry for Education and Research). Top-class partners and consortium participants, such as Chemion Logistik GmbH, BIBA, Bremer Institut für Produktion und Logistik GmbH were involved under the leadership of tbm. The objective of increasing the safety and efficiency of industrial trucks in intralogistics through the use of intelligent ICT was achieved with the IntraSafety system and was presented with the great appreciation of the BMBF.

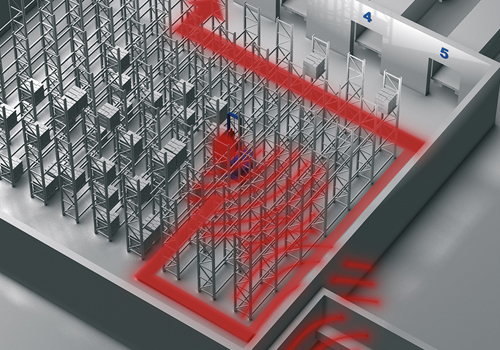

Vehicle Tracking Systems ensure Transparency

-

You know where which vehicle is located in real time. You can effectively access the system, issue appropriate travel instructions and improve the material flow.

With the overview of the logistics, new opportunities are opened up for you for the organizationof the logistics.

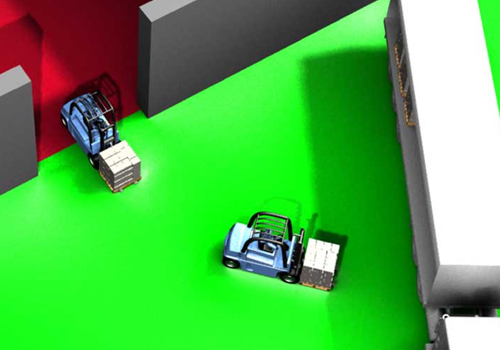

Area-related Speeds Create Safety

- Speed limits on individual traffic routes in specific areas or at especially hazardous locations increase safety and reduce damage and injuries.

Route Optimization Increases Efficiency

- With the tools of the IntraSafety webservice you can recognize highly frequented zones, traffic routes and hazard points. Thereby you can quite quickly and simply identify optimum traffic routes and speed up the material flow in doing so. The tools of the IntraSafety webservice are a real bonus for your logistics optimization.

IntraSafety also Recognizes Pedestrians

- when they are wearing a special IntraSafety vest. This has special sensorsand devices with which a person can be recognized and be warned of danger via a vibrating alarm.

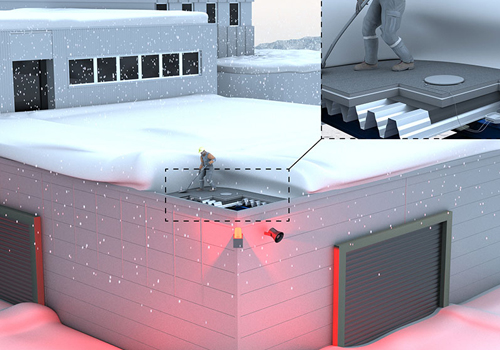

Snow- and Flood water AlarmSystem SAS-307

- The load capacity of a flat roof is limited. Due to snow or also heavy rain, this limit is frequently reached without it being noticed. Catastrophic roof collapses are the result. Innovative roof load monitoring protects against potential damage.

The Snow and Accumulated Water Alarm System, SAS-307

-

The snow and accumulated water alarm system, SAS-307, is the professional system for the continuous and all year round measurement of the actual roof load.

In winter it averts the risk of a too high a snow load and in summer it warns of unnoticed accumulated water which can collect due to heavy rain.

Depending on the roof load, two individually adjustable threshold values trigger a pre pre-alarm and eventually an evacuate alarm.

The snow and accumulated water alarm system can be quickly and simply installed on a flat roof by a roofing contractor (and possibly an electrician).

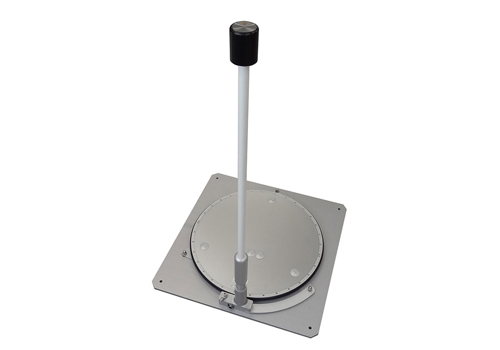

Monitoring Stations

-

Three monitoring stations are installed on the roof surface at selected and exposed positions. Through this "triple system" there is the three-fold security of also being able to recognize different roof loads.

The monitoring stations are fully equipped with electronics and sensors. They have a measurement range of 5 to 750kg/m². The measurement tolerance is 1% of the maximum load capacity. With a diameter of only 50cm and a weight of 10 kg, they are easy to handle.

Every monitoring station is equipped with a locating rod which clearly identifies its position, even with a snow-covered roof.

Control Cabinet

-

The control cabinet with integrated evaluation electronics is the actual alarm centre of the snow and accumulated water alarm system. The monitoring stations are connected to it.

Via the integrated LCD display, the monitoring stations can be set and the load values of the individual monitoring stations read off. Optical / acoustic alarm transmitters can be connected to pluggable switched outputs.

Optionally, the control cabinet can also be equipped with an analogue output in order to connect the existing building services systems. The triggering of the alarm can also be done optionally via a GSM modem over which the responsible persons are alertedvia SMS.

On request, the control cabinet can also be supplied with remote access via the internet.

Pre-assembled Control Cables

-

For the simple installation and connection of the monitoring stations to the control cabinet, pre-assembled cables in lengths of 30m, 50m or 100m with plug connectors in IP 68 are available.

With this innovative sensor technology we satisfy the highest requirements in the area of property protection.

Flat Roof Leak Location

-

For the preservation of the value of a building, comprehensive roof and building management is necessary. To this end we work hand in hand with the roofing experts of the SLD – Scandinavian Leak Detection.

Highly accurate measurement results by means of electrical impulse technology - the SLD Leak Detection measurement system locates even the slightest of sites.

Use the cost saving leak measurement methodology, too, for the accurate documentation of all the weak points of your flat roof.

Logistics Management

-

IntraSafety is the result of a successful research project, sponsored by the BMBF (Federal Ministry for Education and Research). Top level partners and consortium participants such as Chemion Logistik GmbH, BIBA Bremer Institut für Produktion und Logistik GmbH were involved under the leadership of tbm. The objective "Increase in the Safety and Efficiency of Industrial Trucks in Intralogistics through the Use of Intelligent ICT" was achieved and presented with the IntraSafety System and with great appreciation by the BMBF.

IntraSafety

IntraSafety is based on the proven NoColl technology and integrates safety at work into a perfect logistics management system.

For this purpose, networked NoColl matrix sensors locate vehicles and personnel and control the material flow and personnel safety in real time.

With it, Industry 4.0 is supplemented by an extra dimension.

IntraSafety is, therefore, the intelligent logistics management system with bidirectional communication between vehicles and a central master computer for transparent logistics. Configurable protection functions at defined positions or in specified areas and the central event logging increase the added value when compared with mere collision protection or stand-alone logistics management.